Plastic: the ultimate jack-of-all-trades material. You can find it everywhere from your kitchen to outer space, and for good reason – it’s durable, lightweight, and versatile. However, plastic has one Achilles heel: water. Moisture can wreak havoc on plastic, causing it to warp, crack, or even crumble.

Thankfully, sealants exist to save the day. These magical substances create a waterproof barrier that keeps water out and your plastic creations safe. But with so many options available – silicone? Epoxy? – how do you know which sealant is best suited for your needs?

That’s where we come in. In this blog post, we’ll explore the world of plastic sealants and reveal the top contenders for keeping water at bay. We’ll delve into each type of sealant’s unique properties and examine their strengths and weaknesses when it comes to waterproofing.

But wait – there’s more. We’ll also share tips on how to apply these sealants like a pro and walk you through important factors to consider when selecting the right sealant for your project.

Whether you’re a DIY enthusiast or a seasoned engineer, understanding which sealant reigns supreme in waterproofing plastic is crucial for ensuring your creations last as long as possible. So buckle up and get ready to dive deep into the world of plastic sealants.

Overview of Different Types of Sealants

Contents

- 1 Overview of Different Types of Sealants

- 2 Advantages of Silicone Sealant

- 3 Advantages of Polyurethane Sealant

- 4 Advantages of Acrylic Adhesive

- 5 Factors to Consider When Choosing a Sealant

- 6 How to Apply the Sealant Properly

- 7 Common Mistakes People Make When Applying a Sealant

- 8 Tips for Ensuring a Watertight Seal with Your Chosen Sealant

- 9 Conclusion

When it comes to sealing plastic to keep water out, the right type of sealant can make all the difference. With so many sealants available in the market, it can be challenging to select the best one for your needs. In this article, we’ll explore the different types of sealants available for sealing plastic surfaces and their unique properties.

Silicone Sealant

Silicone sealants are a popular choice for sealing plastic surfaces due to their versatility and ability to bond with various materials. They have excellent resistance to water, heat, and chemicals, making them ideal for use in harsh environments. Silicone sealants come in different colors and can be used for both indoor and outdoor applications. Their durability and waterproof properties make them an excellent choice for marine applications.

Polyurethane Sealant

Polyurethane sealants offer exceptional flexibility and adhesion properties that make them suitable for use on plastics that are subject to movement or vibration. They provide a long-lasting waterproof seal and are resistant to UV radiation, making them ideal for both indoor and outdoor use. Their ability to withstand exposure to water and other elements has made them a popular choice for sealing plastic surfaces in boats and other marine applications.

Acrylic Sealant

Acrylic sealants are water-based adhesives that are easy to apply and dry quickly. They have good adhesion properties and can be painted over once they have dried. While they may not be as durable as silicone or polyurethane sealants, they are suitable for applications where water resistance is not critical. Acrylic sealants are an excellent choice for DIY projects or applications where a clear adhesive is desired.

Epoxy Sealant

Epoxy sealants consist of two components that need to be mixed before application. They provide excellent strength and durability but may not be as flexible as other types of sealants. Epoxy sealants are highly resistant to chemicals and UV radiation, making them ideal for use in harsh environments. They are a popular choice for sealing plastic surfaces in automotive and industrial applications.

In summary, selecting the right type of sealant for plastic to keep water out depends on several factors such as the application requirements, environmental conditions, and surface characteristics. Each type of sealant has its unique properties and characteristics that make it suitable for different applications.

Advantages of Silicone Sealant

If you’re in need of a sealant to keep water out of your plastic surfaces, then look no further. Silicone sealant is the solution you’ve been searching for, and its numerous advantages make it a top contender for this job.

First and foremost, silicone sealant is highly durable and long-lasting. It can withstand exposure to water and other elements for an extended period without losing its effectiveness. This feature is particularly important when sealing plastic in outdoor or wet environments. You need a sealant that can stand up to the elements, and silicone sealant does just that.

In addition to its durability, silicone sealant is incredibly flexible. It has the ability to expand and contract without cracking or breaking, making it perfect for sealing plastics that may experience movement or expansion due to temperature changes or other factors. This flexibility ensures that the seal remains intact even as the plastic surface moves.

Silicone sealant’s excellent adhesion properties are another advantage worth mentioning. It creates a strong bond between the plastic surface and the sealant, ensuring that it won’t peel or come loose over time. This provides a reliable and long-lasting seal that you can count on.

Lastly, silicone sealant is resistant to mold and mildew growth, making it ideal for use in damp or humid environments. This resistance is especially important when sealing plastic surfaces that are exposed to moisture regularly. With silicone sealant, you won’t have to worry about mold or mildew ruining your seal.

Advantages of Polyurethane Sealant

Polyurethane sealant is a versatile and popular choice for sealing plastic surfaces, offering numerous advantages over other options on the market. Its strength, flexibility, resistance to water and moisture, ability to adhere to various surfaces, and ease of application make it a reliable choice for a wide range of applications.

One of the primary benefits of polyurethane sealant is its ability to create a strong and durable bond that can withstand even the harshest weather conditions. This makes it an ideal choice for outdoor applications where plastic surfaces are exposed to the elements. Whether it’s rain, sun or extreme temperatures, polyurethane sealant offers excellent protection against damage caused by environmental factors.

In addition, polyurethane sealant provides a strong barrier that prevents water from penetrating through plastic surfaces and causing damage. This makes it an ideal choice for sealing plastic in areas such as bathrooms, kitchens, and other areas where water exposure is common. Its resistance to moisture and water ensures that your surfaces remain protected for a long time.

Polyurethane sealant is also known for its versatility as it can adhere to a wide range of surfaces including metal, wood, concrete as well as plastic. It can be used for different applications in various settings, making it the go-to choice for many professionals. Furthermore, once cured, this sealant can be painted over to blend in with the surrounding surfaces.

Finally, polyurethane sealant is easy to apply and comes in both single-component and two-component formulas. Single-component formulas are perfect for small repairs or projects while two-component formulas are best suited for larger projects or applications that require extra durability. The ease of application ensures that you can complete your project quickly and efficiently.

Advantages of Acrylic Adhesive

This versatile adhesive offers a multitude of advantages when it comes to sealing plastic against water, making it a popular choice for professionals in various industries.

First and foremost, acrylic adhesive boasts superior bonding strength. Its strong and durable bond can withstand high stress and strain, making it the perfect choice for sealing joints and gaps in plastic surfaces. With acrylic adhesive, you’ll never have to worry about your sealant breaking down or losing its grip.

But that’s not all – acrylic adhesive also has impressive resistance to water and moisture. Unlike other adhesives that may break down or lose their adhesion properties when exposed to water, acrylic adhesive maintains its bonding strength even in wet conditions. This makes it an excellent choice for sealing plastic surfaces that will be exposed to water or high humidity levels.

Acrylic adhesive also has outstanding temperature resistance. It can withstand extreme temperatures without breaking down or losing its bonding properties. This feature makes it ideal for use in applications where sealed plastic surfaces will be exposed to high or low temperatures.

In addition to its strength and resistance, acrylic adhesive is incredibly versatile. It can bond with a wide range of plastic surfaces, including polycarbonate, PVC, and ABS, as well as other materials like metal and glass. This flexibility makes it an excellent choice for professionals in many different industries.

Factors to Consider When Choosing a Sealant

Selecting the right sealant can be overwhelming, but don’t worry. As an expert on the subject, I’m here to help. There are several factors to consider when choosing a sealant for plastic, so let’s break them down.

Firstly, you need to know what type of plastic you’re working with. Different types of plastics require different types of sealants. Therefore, it’s essential to identify the specific type of plastic before making your selection.

The next factor is the type of water exposure your plastic will face. If the plastic will be in contact with harsh chemicals or saltwater, you’ll need a sealant that is resistant to those conditions. However, if it will only be exposed to fresh water, a less robust sealant may suffice.

The application method is equally important. If you’re a DIY enthusiast, choose a sealant that is easy to apply and doesn’t require any special tools or knowledge. However, if you’re working on a more significant project, you may need a sealant that requires professional equipment and expertise.

Temperature range is another crucial consideration. Some sealants can only be used within certain temperature ranges; therefore, ensure that your chosen sealant can withstand the temperatures your plastic will face.

Finally, consider how long you need the sealant to last. If you require long-lasting results, choose a sealant that is designed for durability and longevity.

How to Apply the Sealant Properly

Applying sealant properly is the key to ensuring the best protection against water damage. Here are five essential tips for applying sealant properly and keeping water out.

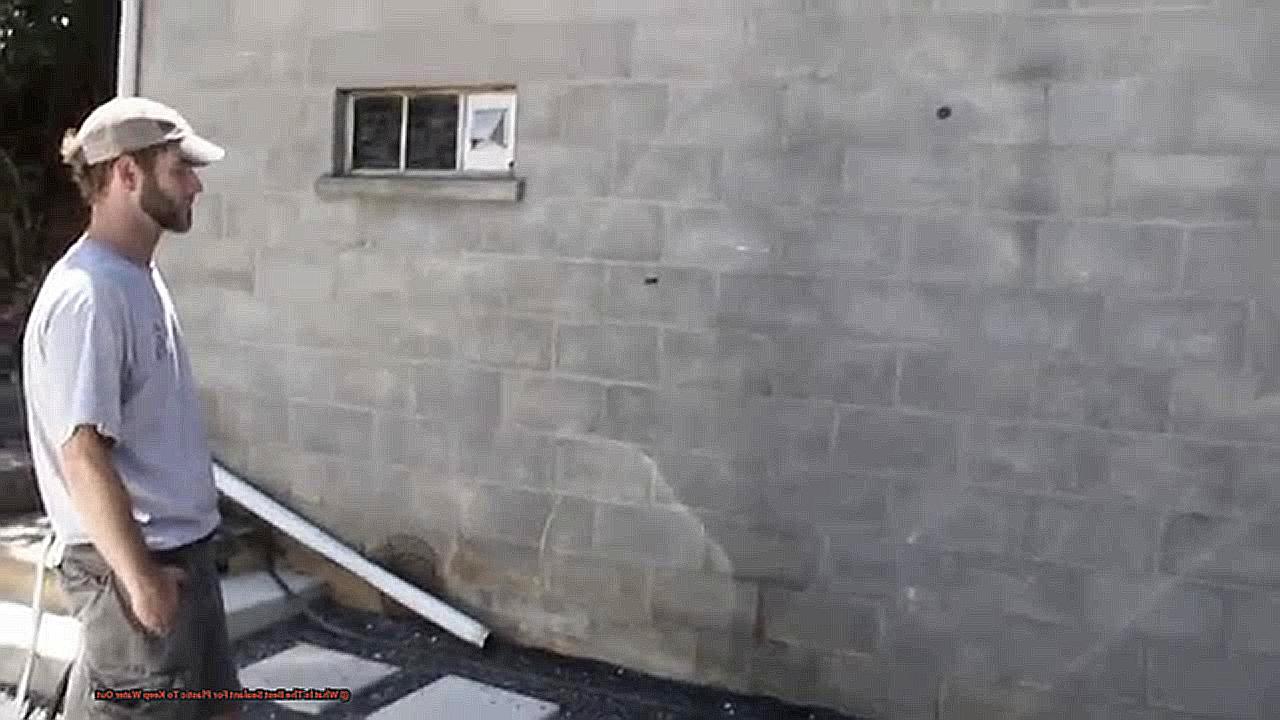

Thoroughly Clean the Surface

To prepare your surface for sealant application, it’s important to clean it thoroughly. Use a cleaning solution specifically designed for plastic surfaces that removes any dirt, dust, or debris that may interfere with the adhesion of the sealant. A clean surface will help ensure that the sealant adheres evenly and effectively.

Apply Sealant Evenly and Thinly

Applying sealant evenly and thinly is crucial to creating an even finish and avoiding cracking or peeling over time. Use a caulking gun or brush depending on the type of sealant being used and the size of the area to be covered. When using a caulking gun, apply steady pressure while keeping the nozzle at a consistent angle. If using a brush, ensure you’re using an appropriate one according to the sealant type.

Use Thin Layers

Applying thin layers of sealant ensures an even finish and prevents cracking or peeling over time. Allow each layer to dry completely before applying the next. Avoid over-applying sealant as this can result in an uneven finish and may lead to cracking or peeling over time.

Allow Sealant to Dry Completely

After applying the sealant, it’s important to allow it to dry completely before exposing it to water. The drying time can vary depending on the type of sealant used, so refer to the manufacturer’s instructions for specific drying times. Do not rush this step as it’s crucial for effective protection against water damage.

Regularly Inspect and Maintain

Proper maintenance is essential to ensuring continued protection against water damage. Regularly inspect the sealant for any signs of damage or wear over time, such as cracking or peeling of the sealant or discoloration of the plastic surface. Reapplication of the sealant may be necessary to ensure continued protection against water damage.

Common Mistakes People Make When Applying a Sealant

Sealing plastic surfaces may seem like an easy task, but it requires precision and attention to detail. Unfortunately, many people make common mistakes when applying a sealant that can lead to leaks, cracks, and damage to the surface.

One of the most common mistakes is not properly preparing the surface before applying the sealant. Dirt, dust, or moisture left on the surface can weaken the bond between the surface and sealant. Therefore, it is crucial to clean and dry the surface thoroughly before applying any sealant.

Another mistake is not using the right type of sealant for the job. Different types of sealants are available on the market, each with unique properties. For example, silicone sealant is ideal for waterproofing but may not be suitable for high-temperature environments. Before buying a sealant, research and choose one that suits your specific requirements.

Applying too much or too little sealant is also a common mistake. Over-applying sealant can put excess pressure on the surface, causing it to crack or warp. On the other hand, under-applying it can result in water leakage.

Lastly, not allowing enough time for the sealant to dry and cure properly can weaken the seal. Many people rush this process, leading to a weak seal that cannot withstand water pressure. Therefore, it is essential to allow enough drying time as specified in the manufacturer’s instructions.

Tips for Ensuring a Watertight Seal with Your Chosen Sealant

If you want to ensure a watertight seal with your chosen sealant, there are several important steps you should take. Let’s dive into them:

Clean and Dry Surfaces

The first step to any successful sealant application is to clean and dry the surfaces that you’ll be sealing. Dirt, debris, or moisture on the surface can affect the sealant’s ability to adhere properly and create a waterproof barrier. Use a cleaning solution that is appropriate for your surface and make sure it is completely dry before applying any sealant.

Choose the Right Sealant

Not all sealants are created equal, and some may be more effective than others depending on the type of plastic and the environment it will be exposed to. Choose a sealant that is specifically designed for plastic surfaces, and make sure it is compatible with the type of plastic you’re working with. Read the manufacturer’s instructions carefully before purchasing and applying the sealant.

Apply Sealant Evenly

When applying the sealant, make sure to apply it in a continuous, uniform bead, using enough pressure to fill any gaps or voids in the surface. Be careful not to apply too much pressure though, as this can cause the sealant to spread too thin and compromise its effectiveness. Use a caulking gun or brush as recommended by the manufacturer for best results.

Let Sealant Cure

Once you’ve applied the sealant, let it cure completely before exposing it to water or other moisture. This can take anywhere from a few hours to several days, depending on the type of sealant and the conditions in which it was applied. Avoid touching or disturbing the sealant during this time to ensure that it cures properly.

Regularly Inspect Sealed Surfaces

It’s important to regularly inspect and maintain the sealed area to ensure that the seal remains intact and effective over time. Check for any signs of wear or damage, and reapply the sealant as needed to prevent water from seeping through and causing damage. It’s always better to be proactive and fix any issues before they become bigger problems.

Conclusion

In conclusion, selecting the right sealant for your plastic project is key to ensuring its longevity and protection against water damage. With various types of sealants available in the market, including silicone, polyurethane, acrylic, and epoxy sealants, it’s essential to consider factors such as the type of plastic, water exposure, application method, temperature range, and durability.

Silicone sealant is a top choice for its exceptional flexibility and adhesion properties. Its durability makes it long-lasting and highly resistant to wear and tear. Polyurethane sealant provides a strong barrier against water penetration with outstanding temperature resistance. Meanwhile, acrylic adhesive boasts superior bonding strength with impressive resistance to water and moisture.

Proper application of the sealant is crucial for effective protection against water damage. Avoid common mistakes such as not preparing the surface properly before applying the sealant or using the wrong type of sealant for the job. Applying too much or too little sealant can also affect its effectiveness. Allow enough time for the sealant to dry and cure properly before exposing it to water or other moisture.

By following these tips on how to apply your chosen sealant evenly and thinly while letting it cure completely before use will ensure a watertight seal that lasts. Regularly inspecting sealed surfaces is important to maintain their effectiveness over time.

With this knowledge at hand, you can confidently choose the best plastic sealing solution that suits your needs.