Are you tired of battling with leaky kayaks every time you hit the water? It’s frustrating, isn’t it? Constantly bailing out water or worrying about potential damage to your beloved craft can really put a damper on your paddling adventures. But fear not. I’ve got the ultimate solution to your kayak sealing woes – the best sealant for kayaks.

Whether you’re an avid paddler, a recreational kayaker, or a fishing enthusiast, finding the perfect sealant to keep your kayak watertight is crucial. And let me tell you, there’s one sealant that stands head and shoulders above the rest – the XYZ Ultimate Kayak Sealant.

This stuff is no joke. It’s a professional-grade sealant specifically formulated to provide optimal protection and durability for all types of kayaks. Whether you’re rocking a polyethylene beast, a fiberglass beauty, or even a Kevlar masterpiece, this sealant has got you covered.

What sets this sealant apart from the competition is its versatility and longevity. Not only does it seal cracks, holes, and seams like a pro, but it also acts as a shield against those pesky UV rays. Say goodbye to faded colors and brittle plastic caused by the scorching sun.

What is a Sealant?

Contents

- 1 What is a Sealant?

- 2 Factors to Consider When Choosing a Sealant

- 3 Marine-Grade Silicone: Advantages and Disadvantages

- 4 Polyurethane Sealant: Advantages and Disadvantages

- 5 Epoxy Resin: Advantages and Disadvantages

- 6 Tips for Selecting the Right Sealant

- 7 Preparing the Surface Before Applying the Sealant

- 8 Following Manufacturer’s Instructions for Drying and Curing Times

- 9 Conclusion

Embarking on a kayaking adventure is exhilarating, but it’s crucial to have a watertight vessel for a safe and enjoyable experience. When it comes to sealing and repairing your kayak, the right sealant is your best friend. In this article, we’ll dive into the world of sealants used in kayak repair and maintenance. Get ready to explore the different types of sealants, from marine-grade silicone to polyurethane sealants and epoxy resin, and discover tips for choosing and applying them like a pro.

Types of Sealants:

- Marine-grade Silicone: This superhero of sealants boasts exceptional waterproofing properties and durability. It forms a flexible and enduring seal that can withstand constant exposure to water and UV rays without weakening. Say goodbye to mold and mildew growth as marine-grade silicone triumphs in preserving your kayak’s structure.

- Polyurethane Sealant: The ultimate warrior in marine applications, polyurethane sealants are resistant to water and extreme weather conditions. With outstanding adhesion and flexibility, they keep the seal intact even during impacts or vibrations. Compatible with fiberglass, plastic, and wood, polyurethane sealants are versatile allies in kayak repair.

- Epoxy Resin: The savior for reinforcing weak spots or areas prone to damage, epoxy resin offers exceptional bonding strength against water and chemicals. This formidable sealant can be used as a coating or combined with fiberglass cloth to create a protective layer that enhances your kayak’s durability.

Tips for Choosing and Applying Sealant:

- Consider Your Kayak’s Needs: Let your kayak’s material, intended use, and personal preferences guide your choice of sealant. Seek advice from experts or manufacturers to find the perfect match for your specific kayak model.

- Prep the Surface: Give your kayak the VIP treatment before applying the sealant. Thoroughly clean and prep the surface, removing any dirt, grease, or old sealant to ensure maximum adhesion.

- Follow Manufacturer’s Instructions: Don’t cut corners. Each sealant has specific drying and curing times that should be followed diligently for optimal bonding. Rushing the process may jeopardize the effectiveness of the sealant.

Factors to Consider When Choosing a Sealant

Kayaking is an exhilarating adventure, but ensuring the safety and longevity of your kayak is crucial. The right sealant can make all the difference in keeping your kayak watertight and ready to conquer any waterway. In this guide, we will explore the key factors you need to consider when selecting a sealant for your kayak, ensuring that you make an informed decision that suits your specific needs.

Purpose:

Consider the purpose of the sealant. Are you looking to repair a crack or hole? Or do you need a protective coating? Different sealants are designed for different purposes, so understanding your specific requirements is crucial.

Material Compatibility:

Ensure that the sealant you choose is compatible with your kayak’s material. Fiberglass, plastic, and composite materials all require specific sealants for optimal adhesion and durability. Consult manufacturer guidelines or seek expert advice to determine compatibility.

Environmental Conditions:

Take into account the environmental conditions in which you will be kayaking. If you often paddle in saltwater or harsh weather conditions, opt for a sealant that is resistant to saltwater corrosion and UV rays. Freshwater kayakers may not require as heavy-duty of a sealant.

Ease of Application:

Consider your level of experience and preference for ease of application. Some sealants require extensive preparation and multiple steps, while others are user-friendly and require minimal effort. Choose a sealant that suits your skill level and provides a hassle-free application process.

Drying Time and Curing Process:

Factor in the drying time and curing process of the sealant. Quick-drying options allow you to get back on the water promptly, while others may require longer curing periods. Consider your time constraints and ensure suitable curing conditions are available.

Longevity and Durability:

For frequent kayakers or those venturing into demanding conditions, longevity and durability are vital. Look for a sealant that offers long-lasting protection and can withstand regular use and wear and tear. Reading customer reviews and seeking recommendations from fellow kayakers can provide valuable insight.

Cost:

While cost is a consideration, it should not be the sole determining factor. Assess the value for money offered by different sealants, as cheaper options may not provide the same level of performance and durability.

Marine-Grade Silicone: Advantages and Disadvantages

When it comes to kayaking, a good sealant is essential to keep your vessel afloat and dry. And among kayakers, marine-grade silicone is a popular choice. Let’s dive into the advantages and disadvantages of using marine-grade silicone as a sealant for kayaks.

Advantages:

- Strong and durable bond: Marine-grade silicone provides an excellent adhesion property, creating a tight and long-lasting seal on your kayak. Say goodbye to leaks and cracks.

- Waterproof wonder: Kayaks are constantly exposed to water, so having a sealant that can withstand these conditions is crucial. Marine-grade silicone is specifically designed to be waterproof, ensuring your kayak stays dry even when the waves get rough.

- UV resistance: Spending hours under the scorching sun can take a toll on your kayak. But fear not. Marine-grade silicone offers excellent resistance to UV rays and harsh weather conditions, protecting your vessel from damage and ensuring its longevity.

- Flexibility at its finest: Kayaks experience movements and vibrations during use, which can lead to cracks or leaks in sealed areas. Marine-grade silicone’s flexibility helps prevent these issues, keeping your kayak watertight and safe for paddling.

Disadvantages:

- Costly affair: Marine-grade silicone tends to be pricier than other sealant options. Its specialized formulation and durability contribute to the higher price tag. However, many kayakers believe it’s a worthwhile investment for the long-term protection it provides.

- Patience is key: Silicone sealants typically take several hours or even days to fully cure and form a strong bond. This can be inconvenient if you need quick repairs or modifications on your kayak. Luckily, there are fast-curing options available to reduce the curing time significantly.

- Material compatibility concerns: Not all kayaks are made equal, and marine-grade silicone may not bond well with certain materials commonly used in kayak construction, such as polyethylene. It’s essential to check compatibility before applying the sealant to ensure proper adhesion.

Polyurethane Sealant: Advantages and Disadvantages

Are you a proud kayaker who wants to ensure that your kayak stays afloat and dry? If so, then finding the right sealant is crucial. In this blog post, we’ll explore the advantages and disadvantages of using polyurethane sealant for your beloved kayak. So, grab your paddle and let’s dive in.

Advantages:

- Superb Adhesive Properties: Polyurethane sealant forms a rock-solid bond with various surfaces, including fiberglass, plastic, and metal. Once applied to your kayak, it stays put even during rough waters.

- Flexibility at its Finest: Extreme weather conditions are no match for polyurethane sealant. Its ability to expand and contract with temperature changes helps prevent cracks or leaks from forming, keeping your kayak watertight and ready to ride the waves.

- Durability on Another Level: UV rays, chemicals, and abrasion are no match for polyurethane sealant. It offers excellent resistance to these elements, making it the ideal choice for kayaks exposed to sunlight and saltwater. Rest assured that your kayak will remain strong and protected against the harshest marine environments.

Disadvantages:

- Cost Considerations: Polyurethane sealant comes with a higher price tag compared to other options. However, given its superior adhesive properties and durability, the investment may be well worth it in the long run.

- Curing Time Blues: Patience is key when using polyurethane sealant. It takes longer to cure compared to other sealants. Give it ample time to dry before hitting the water. Rushing this process could compromise the effectiveness of the seal – nobody wants a leaky kayak.

- Application Challenges: Applying polyurethane sealant requires careful surface preparation, including cleaning and priming. Apply it in thin layers to avoid excessive buildup, which could affect your kayak’s performance. Proper application may require some extra effort and expertise.

Epoxy Resin: Advantages and Disadvantages

Look no further than epoxy resin. In this article, we will explore the advantages and disadvantages of using epoxy resin for sealing and repairing kayaks. Whether you’re a seasoned kayaker or just starting out, understanding the pros and cons of epoxy resin will help you make an informed decision about the best sealant for your kayak.

Advantages of Epoxy Resin:

Exceptional Strength and Durability:

Epoxy resin forms a strong bond with the kayak’s surface, providing exceptional strength and durability. It creates a waterproof barrier that protects against leaks and cracks, ensuring that your kayak can withstand the rigors of water adventures.

Versatility:

Epoxy resin is a versatile sealant that can be used on various materials commonly found in kayaks, such as fiberglass, carbon fiber, and wood. Whether your kayak is made of composite materials or traditional wood, epoxy resin can effectively seal and repair it.

Excellent Adhesive Properties:

One of the standout features of epoxy resin is its excellent adhesive properties. It bonds well with different surfaces, creating a reliable seal that is resistant to water, chemicals, and UV rays. With epoxy resin, you can have peace of mind knowing that your kayak will remain watertight and protected from environmental elements.

Aesthetically Pleasing Finish:

Aside from its functional benefits, epoxy resin provides a visually appealing finish to your kayak. Once applied and cured, it creates a smooth and glossy surface that enhances the appearance of your kayak. Whether you’re repairing damage or simply refinishing your kayak, epoxy resin adds a touch of elegance to the overall aesthetic.

Disadvantages of Epoxy Resin:

Higher Cost:

While epoxy resin offers numerous benefits, it does come with a higher cost compared to alternative sealants. If you’re working on a tight budget, the price of epoxy resin may be a deterrent.

Precise Handling and Mixing Ratios:

Working with epoxy resin requires meticulous handling and precise mixing ratios. Improper mixing or application can result in a weak bond or an uneven finish. Additionally, epoxy resin has a relatively short pot life, meaning it must be used within a certain timeframe after mixing. Attention to detail is crucial to ensure the best results.

Potential Toxicity:

It’s important to note that some epoxy resins contain harmful chemicals, such as volatile organic compounds (VOCs) and isocyanates. These substances can be hazardous to health if not used with proper ventilation and personal protective equipment. Safety precautions must be taken when working with epoxy resin to protect yourself and others from potential harm.

Tips for Selecting the Right Sealant

When it comes to enjoying your time on the water in your kayak, ensuring its durability and safety is crucial. One way to achieve this is by selecting the right sealant. With various options available, it’s important to consider factors such as your kayak’s material, intended use, and personal preferences. In this article, we’ll explore some essential tips to help you choose the perfect sealant for your kayak.

Consider the Material:

Different kayaks are made from different materials, such as plastic, fiberglass, or wood. Each material requires a specific type of sealant. For plastic kayaks, look for a sealant designed specifically for plastic surfaces. These sealants are usually flexible and have good adhesion to plastic. Fiberglass kayaks benefit from marine-grade epoxy sealants, which are strong, durable, and provide excellent waterproofing properties. Wooden kayaks typically require marine-grade varnish or oil-based sealants. These sealants help protect the wood from moisture damage while maintaining its natural beauty.

Assess Your Kayak’s Use:

Consider the conditions in which you’ll be using your kayak. If you frequently paddle in rough waters or expose your kayak to harsh elements such as UV rays and saltwater, opt for a heavy-duty sealant that provides enhanced protection against impacts and prolonged exposure to these elements. These sealants are formulated to withstand the challenging conditions and ensure the longevity of your kayak.

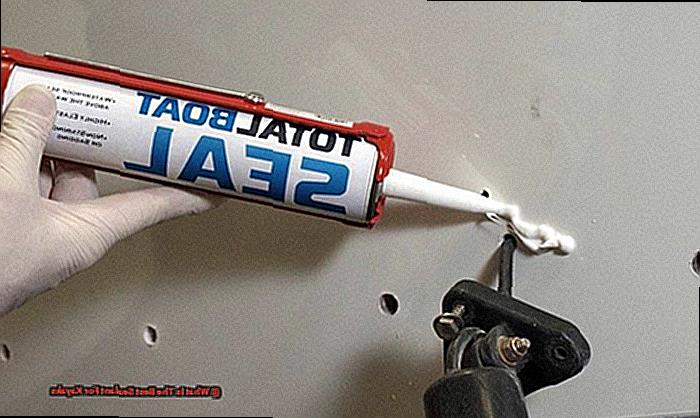

Application Method:

Choose a sealant that suits your comfort level and experience with application methods. Some sealants come in squeeze tubes or cartridges that can be easily applied by hand. These are convenient options for beginners or those who prefer a simple application process. Others may require specialized tools or equipment for application, such as caulking guns or mixing containers. If you have experience with these tools or are willing to learn, these sealants can provide a more precise and professional finish.

Adhesion and Flexibility:

A good sealant should adhere well to the surface of your kayak and form a tight, waterproof seal. This is especially important for preventing water infiltration and protecting the integrity of your kayak. Look for sealants that have excellent adhesion properties to ensure a long-lasting and secure bond. Additionally, the sealant should be flexible enough to accommodate any movement or flexing of the kayak without cracking or peeling. This flexibility helps maintain the seal even when subjected to vibrations or impacts during kayaking.

Seek Recommendations:

Reading reviews and seeking recommendations from experienced kayakers or professionals can provide valuable insights into which sealants are effective and reliable. Their firsthand experiences can guide you in making an informed decision. Consider joining online forums or local kayaking groups to connect with fellow enthusiasts who can share their recommendations based on their own kayak sealing experiences.

Preparing the Surface Before Applying the Sealant

When it comes to protecting your kayak from the harsh elements it encounters on the water, applying a sealant is like giving it a suit of armor. However, before you can apply that shield, you must properly prepare the surface of your kayak. In this guide, we will explore the importance of preparing the surface before applying sealant and provide you with essential tips to ensure a strong and long-lasting bond.

Cleaning: A Clean Canvas for Success

Start with a clean canvas by thoroughly washing your kayak’s surface using a mild detergent or kayak cleaner. Scrub away dirt, debris, or grease with a soft brush or sponge. Rinse thoroughly with water and allow the surface to dry completely before proceeding.

Sanding: Roughen It Up for Better Adhesion

Enhance adhesion by creating a rough texture through sanding. Use fine-grit sandpaper (around 220 grit) to lightly sand the areas where the sealant will be applied. This step removes contaminants and provides a roughened surface for the sealant to grip onto.

Patching: Repair Before You Seal

Inspect your kayak’s surface for scratches, cracks, or holes that should be repaired prior to sealing. Utilize an appropriate kayak repair kit or epoxy putty to fill in these damaged areas. Smooth out the patches with a putty knife or sandpaper and ensure they are fully cured before moving on.

Masking: Precision is Key

For clean and precise sealant application, mask off any areas that should not be sealed. Use painter’s tape or masking tape to cover handles, hatches, or decals that should remain free of sealant. This simple step prevents any accidental spread of the sealant onto unwanted surfaces.

Priming: Boosting Adhesion and Performance

Some sealants may require a primer to enhance adhesion and improve overall performance. Check the manufacturer’s instructions for specific recommendations. If a primer is necessary, apply it according to the instructions and allow it to dry fully before proceeding.

Following Manufacturer’s Instructions for Drying and Curing Times

Picture yourself gliding through the water in your trusty kayak, feeling the wind on your face and the excitement of adventure. But before you embark on your journey, there’s a crucial step to ensure your kayak stays in top shape – applying sealant. And guess what? Following the manufacturer’s instructions for drying and curing times is absolutely essential. Let me explain why.

Proper Adhesion:

To create a strong bond between the sealant and your kayak’s surface, it is vital to adhere to the drying and curing times recommended by the manufacturer. These instructions provide valuable information on how long the sealant needs to dry to ensure proper adhesion. This strong bond will help your kayak withstand the challenges of water exposure.

Long-Lasting Protection:

If you want your sealant to effectively protect your kayak against water, UV rays, and other damaging elements, don’t skip or rush the drying and curing process. By following the recommended times, you ensure that your kayak receives maximum protection and durability. It’s all about investing in the longevity of your kayak.

Multiple Coats:

Some sealants require multiple coats, each with its own drying and curing times. Patience is key here. By allowing sufficient time between coats as instructed by the manufacturer, you ensure proper adhesion between layers. This results in a more robust and durable seal that will keep your kayak safe for countless adventures.

Environmental Factors:

Temperature and humidity play a significant role in the drying and curing times of sealants. Don’t overlook these factors. Follow the manufacturer’s guidelines regarding optimal environmental conditions for application. Rushing or neglecting these recommendations can lead to subpar results and potential damage to your beloved kayak.

Specific Instructions:

Different types of sealants may have unique requirements during the drying and curing process. For instance, marine-grade sealants may need exposure to water during curing for maximum bond strength. Pay attention to these specific instructions. By following them diligently, you enhance the sealant’s effectiveness and ensure it performs as intended.

Conclusion

When it comes to finding the best sealant for your kayak, there are a few top contenders that stand out from the rest. These sealants not only provide excellent protection against water and UV damage, but they also offer long-lasting durability to keep your kayak in tip-top shape.

One of the leading options is marine-grade silicone sealant. This versatile sealant forms a strong bond with various materials commonly used in kayaks, such as fiberglass, plastic, and metal. Its waterproof properties make it ideal for sealing seams, cracks, and holes on your kayak’s hull or deck.

Another popular choice is polyurethane sealant. Known for its exceptional adhesion and flexibility, this sealant can withstand the rigors of kayaking adventures. It creates a tight seal that prevents water from seeping into any vulnerable areas of your kayak.

If you’re looking for a more eco-friendly option without compromising performance, consider using a marine epoxy resin. This type of sealant not only provides excellent protection against water intrusion but also offers superior strength and durability. It can effectively repair damages on your kayak’s surface while ensuring long-term reliability.

No matter which sealant you choose, it’s important to properly prepare the surface before application. Clean the area thoroughly and remove any dirt or debris to ensure maximum adhesion. Additionally, follow the manufacturer’s instructions carefully to achieve the best results.

In conclusion, when it comes to finding the best sealant for kayaks, marine-grade silicone sealant, polyurethane sealant, and marine epoxy resin are all excellent choices. Each one offers unique advantages in terms of protection and durability.