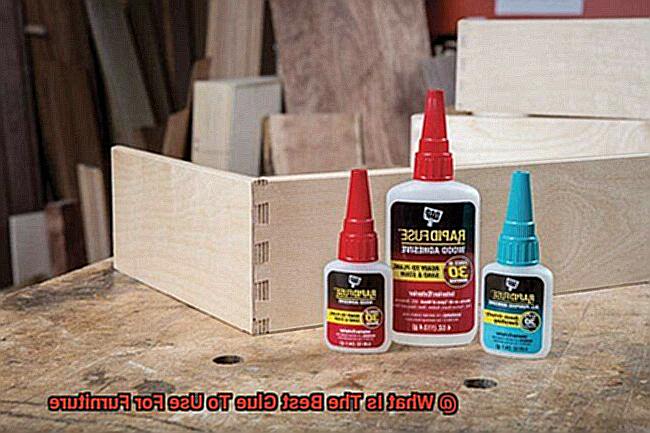

Ever found yourself desperately trying to revive a once-sturdy chair or mend a broken table leg, unsure which glue will provide a lasting solution? Look no further. In this article, we unravel the mystery and guide you towards the holy grail of furniture adhesives.

Furniture, whether it’s a cherished antique or a modern marvel, can encounter unforeseen mishaps. And when it comes to reassembling, repairing, or simply embellishing our beloved pieces, choosing the right glue is vital. But in the realm of adhesives, the multitude of options can be confounding.

In our quest for the best glue for furniture, we’ll demystify the jargon and explore both casual and professional recommendations. Whether you’re a DIY enthusiast or a seasoned furniture maker, this guide promises to simplify your decision-making process.

Join us as we delve into the adhesive world, taking you on an exciting journey through different glue types, their unique strengths, and their specific applications.

Prepare to be captivated by tales of wood bonding prowess as we reveal the secrets of glues that defy time, environmental challenges, and the elements. Discover how the right adhesive can transform your furniture repair projects from mundane to extraordinary.

So fasten your seatbelts and get ready for this engaging expedition. Learn which glue reigns supreme when it comes to furniture restoration and lifelong adhesion. With this knowledge in hand, you’ll wield the power to breathe life into your treasured pieces and leave your friends and family astounded by your newfound mastery.

Stay tuned as we become your trustworthy companion on this journey. We’ll reveal the best glue for various furniture materials such as wood, leather, fabric, and more.

Types of Glue for Furniture

Contents

- 1 Types of Glue for Furniture

- 2 Choosing the Right Glue for the Application

- 3 Preparing the Surface Before Applying the Glue

- 4 Following Manufacturer Instructions for Proper Use of Adhesives

- 5 Tips and Techniques to Achieve Maximum Bonding Strength

- 6 Common Mistakes to Avoid When Using Glues on Furniture

- 7 Benefits of Using Quality Adhesives on Furniture Projects

- 8 Conclusion

When it comes to furniture repair and assembly, choosing the right glue is crucial for ensuring a strong and long-lasting bond. In this guide, we will explore the different types of glue suitable for furniture, their characteristics, strengths, weaknesses, and safety considerations. By understanding the properties of each type of glue, you can make an informed decision and achieve successful results.

Polyurethane Glue

Polyurethane glue, also known as PU glue or poly glue, is a superhero among adhesives. It is a versatile and powerful adhesive that can handle just about anything, making it a must-have for woodworkers and furniture enthusiasts.

First and foremost, let’s talk about versatility. Polyurethane glue is like a chameleon – it can bond wood, metal, plastic, and even ceramics. Whether you’re fixing a wobbly chair leg or attaching decorative elements to your latest masterpiece, this glue has got you covered.

But it’s not just versatile; it’s also incredibly strong. Once cured, the bond created by polyurethane glue is often stronger than the materials being joined together. So if you’re looking to repair a broken table leg or secure a tabletop with confidence, this glue will have your back.

- And here’s where it gets really interesting – polyurethane glue has a secret weapon: expansion. As it cures, it expands, filling in any gaps and providing extra reinforcement to the bond. This can be a game-changer when working with uneven surfaces or joints that don’t fit perfectly together.

- But that’s not all – polyurethane glue is also moisture resistant. Once fully cured, it forms a waterproof and moisture-resistant bond. So if you’re tackling an outdoor furniture project or have a piece that might encounter some spills or humidity, this glue will keep everything nice and secure.

- Now, let’s address the elephant in the room – drying time. Yes, polyurethane glue does take a bit longer to dry compared to other adhesives. But fear not. This extra time can actually work to your advantage, especially when you need to reposition or make adjustments during complex projects.

To use polyurethane glue effectively, follow the manufacturer’s instructions. Apply the glue to both surfaces being joined, ensuring good coverage without going overboard. And don’t forget proper ventilation during the curing process – nobody wants glue fumes ruining their workshop vibe.

Epoxy Glue

When it comes to furniture repairs or construction, finding the perfect adhesive is paramount. Look no further than epoxy glue – the superhero of glues. With its unrivaled strength, durability, and versatility, epoxy glue is the ultimate choice for bonding different materials commonly found in furniture. In this blog post, we will delve into the advantages of using epoxy glue and provide you with essential tips for successful furniture repairs or construction projects.

Advantages of Epoxy Glue for Furniture:

- Exceptional Strength: Epoxy glue forms an unbreakable chemical bond that can withstand heavy loads and extreme conditions. It’s like giving your furniture a suit of impenetrable armor.

- Versatility: Epoxy glue can securely bond various materials such as wood, metal, glass, and plastic. Whether you’re fixing a broken chair leg or joining different pieces of wood together, epoxy glue has your back – or rather, your furniture.

- Resistance to Moisture, Heat, and Chemicals: Unlike inferior glues, epoxy glue doesn’t falter when exposed to moisture, heat, or chemicals. This makes it perfect for outdoor furniture or items that may come into contact with water or liquids. No need to worry about your glued furniture melting under pressure.

Process for Using Epoxy Glue:

- Follow the Instructions: To achieve optimal bonding performance, carefully adhere to the manufacturer’s instructions for accurately mixing the resin and hardener components. This is the key to unlocking the full potential of epoxy glue.

- Prepare the Surface: Before applying epoxy glue, ensure that the surfaces are pristine – clean, dry, and free from any dirt, grease, or remnants of old adhesive. A proper surface preparation sets the stage for maximum adhesion and long-lasting results.

- Allow Sufficient Curing Time: Epoxy glue requires patience and time to reach its full strength. The curing time can vary from a few hours to several days, depending on the specific product and environmental conditions. Give your glue the space it needs to set and solidify – your furniture will thank you.

Fabric Glue/Adhesive Spray

Look no further than fabric glue and adhesive spray – the dynamic duo that will revolutionize your upholstery game. In this comprehensive guide, we’ll explore the numerous benefits of utilizing these magical products, equipping you with all the information you need to transform your furniture into showstoppers. Let’s dive in.

Convenience at Its Finest:

Bid farewell to the tediousness of sewing or stapling fabric onto furniture. Fabric glue and adhesive spray save you precious time and effort by obliterating the need for these traditional methods. With just a few simple steps, you can achieve professional-looking results without breaking a sweat.

The Perfect Bond:

Fabric glue boasts a specially formulated formula that creates an unwavering bond between fabrics, ensuring your upholstery stays firmly in place. On the other hand, adhesive sprays offer a temporary bond, allowing you to reposition the fabric before permanently setting it. This flexibility proves invaluable when working with intricate patterns or complex designs.

Choose Your Weapon:

Fabric glues and adhesive sprays come in a vast array of options tailored to different fabric types. Whether you’re working with delicate cotton, luxurious leather, or versatile synthetic materials, there’s a glue or spray designed to meet your specific needs. Take your time to select the right product for your project, and you’ll be rewarded with a flawless finish.

Durability that Endures:

Furniture is meant to withstand regular use, so you need an adhesive that can keep up with its demands. Premium fabric glues and adhesive sprays provide exceptional durability, ensuring that your upholstery remains intact even after years of use. To ensure you choose reliable products known for their long-lasting performance, consult customer reviews and seek professional advice.

Not One Size Fits All:

While fabric glue and adhesive spray are fantastic options for most upholstery projects, it’s important to understand their limitations. Heavy or thick fabrics may require the strength of traditional sewing or stapling techniques. Be sure to assess your furniture’s specific requirements and consult experts if needed to determine the best approach.

Super Glue

When it comes to furniture repairs and assembly, nothing beats the speed and effectiveness of Super Glue. Also known as cyanoacrylate adhesive, this remarkable bonding agent has gained a reputation for its strength and versatility. In this article, we will delve into the advantages and disadvantages of using Super Glue for furniture projects, exploring its exceptional bonding capabilities and providing expert tips for successful applications.

Advantages:

Unyielding Strength and Durability:

Super Glue is renowned for its exceptional bonding strength, ensuring a tight and long-lasting hold. This powerful adhesive can withstand significant stress and pressure, making it ideal for furniture repairs that demand a sturdy fix. Say goodbye to wobbly chairs and loose table legs.

Lightning-Fast Drying Time:

Time is of the essence when it comes to furniture repairs or assembly, and Super Glue delivers on speed. With a drying time that ranges from seconds to minutes, you can swiftly complete your projects without the hassle of waiting hours for traditional adhesives to set. No more long delays or impatiently watching glue dry.

Master of Materials:

Super Glue is a true jack-of-all-trades when it comes to bonding materials commonly found in furniture. From wood to plastic, metal to glass, this versatile adhesive excels on all fronts. No matter the project at hand, you can rely on Super Glue to deliver outstanding results across a variety of materials.

Formulation Flexibility:

Super Glue is available in liquid and gel formulations, each with its own unique advantages. The liquid form is perfect for seamlessly bonding smooth surfaces or filling small gaps with precision. On the other hand, the gel form shines in vertical applications or when filling larger gaps, providing greater control and versatility. Choose the right formulation based on your specific project needs and let Super Glue work its magic.

Disadvantages:

Bond Strength Variation:

While Super Glue generally offers impressive bonding strength, it’s essential to note that the strength may vary depending on the brand and formulation you choose. To ensure optimal results and a sturdy bond, take the time to research and select high-quality Super Glue that aligns with your requirements.

Preparations and Precautions:

To achieve the best results with Super Glue, proper surface preparation is crucial. Cleanliness is key, as any dust or grease can compromise the adhesive’s effectiveness. Additionally, it is important to work in a well-ventilated area and avoid direct contact with the glue to prevent accidental bonding. By taking these precautions, you can ensure successful and safe applications.

Plastic Adhesive

When it comes to bringing furniture to life or giving it a second chance, the right adhesive can make all the difference. Enter plastic adhesive, the superhero in the world of furniture assembly and repair. In this comprehensive guide, we will dive deep into the realm of plastic adhesive, uncovering its secrets and guiding you towards making the perfect choice for your furniture project.

Consider the Type of Plastic:

Plastics come in a myriad of forms, each with its own unique characteristics. Smooth surfaces, low surface energy – these are just a few challenges that can hamper the bonding process. To ensure a match made in adhesive heaven, select an adhesive specifically formulated for the type of plastic used in your furniture. Compatibility is key to unlocking optimal bonding results.

Strength and Durability:

Furniture endures countless trials and tribulations throughout its lifetime, so it needs an adhesive that can stand up to the test. Seek out a plastic adhesive that boasts high bond strength and unwavering durability. With this dynamic duo by your side, your furniture will remain steadfastly assembled for years to come.

Drying Time:

Timing is everything in furniture bonding. Some adhesives require a leisurely curing period, granting you ample working time to perfect your masterpiece. Others set with lightning speed, allowing for swift and efficient assembly. Choose an adhesive that dances to the beat of your project’s drum, ensuring a flawless bonding process.

Application Conditions:

Is your furniture destined for a life outdoors or in a humid environment? Don’t fret. There are plastic adhesives specially crafted to brave the elements without compromising their bonding prowess. Sunlight, moisture – they’re mere child’s play for these remarkable adhesives. So, if your furniture is destined for adventure, arm it with an adhesive built for the challenge.

Ease of Use:

Crafting furniture is an art form, and the adhesive is your trusty paintbrush. Ensure a seamless creative experience by selecting an adhesive that aligns with your skill level and preferences. Squeeze bottles, applicator tips – these user-friendly features grant you the precision and control needed to transform your vision into reality. Say goodbye to messy mishaps and hello to a hassle-free bonding process.

Choosing the Right Glue for the Application

When it comes to furniture projects, selecting the right glue is crucial for a successful outcome. The glue you choose can impact the strength of the bond, drying time, ease of use, and compatibility with specific materials. To ensure you make an informed decision, let’s delve into some key factors to consider when choosing the right glue for your furniture project.

- Drying Time: The drying time of the glue is an essential consideration, especially if you need to make adjustments or ensure proper alignment before it sets. Some glues have a longer open time, allowing you to work with the materials for an extended period before they dry. On the other hand, certain glues have a quick drying time, which can be beneficial for time-sensitive projects.

- Strength of Bond: The strength of the bond is crucial for furniture projects that require durability and longevity. Different glues offer varying degrees of bonding strength. For wood furniture, carpenter’s glue or yellow glue is an excellent choice as it creates a strong bond between wood pieces. If you’re working with veneer or laminate furniture, contact cement provides a durable bond between the veneer/laminate and the underlying surface.

- Ease of Use: Convenience is another factor to consider when selecting glue for your furniture project. Some glues come in convenient applicators like squeeze bottles or spray cans, making them easy to apply and control. Others may require mixing or special techniques for proper application. Choose a glue that suits your comfort level and experience with adhesive applications.

- Specific Material Requirements: Different materials may have specific requirements when it comes to glue selection. For example, if you’re working with fabrics or upholstery materials, fabric glue or spray adhesive designed for bonding fabric would be ideal choices. Leather glue is specifically formulated for leather furniture, while vinyl adhesive caters to vinyl upholstery. Always check for specialized glues designed for specific materials to ensure optimal results.

Preparing the Surface Before Applying the Glue

In the world of adhesive projects, the key to success lies in the foundation. Just as a sturdy house needs a solid base, preparing the surface before applying glue is essential for creating a lasting and robust bond. Whether you’re working with wood, fabric, or laminate, this comprehensive guide will walk you through the crucial steps to ensure flawless adhesion.

Step 1: Cleanliness is Paramount

Before embarking on your glue application journey, ensure that the surface is squeaky clean and free from any debris or contaminants. Gently scrub away dirt and grime using a mild detergent or soap and water. Thoroughly rinse and let the surface dry completely. Remember, a pristine surface is vital for optimal adhesion.

Step 2: Bid Farewell to Existing Finishes

If your furniture flaunts existing finishes like paint or varnish, bid them farewell before introducing the glue. Employ sandpaper or a paint stripper, depending on the type and thickness of the coating. Follow the manufacturer’s instructions diligently and prioritize safety when handling chemical strippers.

Step 3: Sanding for Enhanced Adhesion

To amplify the grip of your glue on the surface, engage in a delicate dance with fine-grit sandpaper. This dance creates a slightly rough texture that fosters superior adhesion. Beware of excessive sanding, as it may cause damage to your material.

Step 4: Dust Off for Perfection

After your sanding escapade, bid adieu to dust and particles residing on the surface. Employ a soft brush or vacuum cleaner to whisk them away. A pristine and debris-free surface sets the stage for an impeccable bond.

Step 5: Repairing Damaged Areas

Before diving into gluing frenzy, tackle any damaged areas or gaps that your furniture may possess. Wood filler or epoxy putty can be your trusty allies, depending on the material. Follow the manufacturer’s instructions for proper application and drying time, ensuring a seamless repair.

Step 6: Choosing the Right Glue

The glue you choose is the key to unlocking adhesive success. Consider factors such as drying time, bond strength, and material compatibility. Each glue possesses unique properties, so select one that aligns with your specific project needs.

Step 7: Application and Drying

Now it’s time for the grand moment: applying the glue. Abide by the instructions provided by the glue manufacturer for optimal application and drying time. Use a recommended brush, roller, or applicator to evenly distribute the glue on both surfaces. Embrace firm pressure as you press the surfaces together and maintain it until the glue sets.

Step 8: Patience is a Virtue

Before subjecting your furniture to stress or use, exhibit patience and allow the glue to fully cure. Curing time varies based on glue type and environmental conditions. Trust in time to strengthen the bond.

Following Manufacturer Instructions for Proper Use of Adhesives

But did you know that using them incorrectly can lead to disastrous results? That’s why today, we’re diving into the importance of following manufacturer instructions for proper adhesive use. Buckle up, folks.

The Magic Lies in the Details

When it comes to adhesives, manufacturers are like the glue gods. They’ve spent countless hours perfecting their formulas and techniques, and they’ve packed all that wisdom into those tiny instruction manuals. So why not take a moment to read them thoroughly? Trust me, it’s worth it.

Working Conditions

Adhesives have temperature and humidity preferences. Just like a finicky houseplant, they thrive under specific conditions. Make sure your workspace aligns with these requirements for optimal bonding strength. No one wants their project to unravel due to extreme temperatures or a sticky situation caused by high humidity.

Surface Preparation

Think of surface preparation as the foreplay of adhesive application. Cleaning the surfaces that need to be glued is vital to achieve a strong bond. Dust, dirt, grease, or any residue from previous adhesive attempts can hinder your success. Some adhesives might even demand additional prep steps like sanding or priming – don’t skip them.

Application Techniques

Different adhesives have different preferences when it comes to spreading the love. Some want a brush, others prefer a notched trowel, and some may require a specialized applicator. Pay attention to the manufacturer’s recommendations for application techniques and ensure even coverage – no lumpy messes allowed.

Curing Time

Patience is a virtue, especially when it comes to adhesive curing. Rushing this process can result in a flimsy bond that won’t withstand the test of time. Allow the adhesive ample time to cure according to the manufacturer’s instructions before putting any stress or load on it.

The Consequences of Ignoring Instructions

Now, let’s talk about a gloomy topic – warranty voids. Yes, you heard it right. If you don’t follow the manufacturer’s instructions, they have every right to wave goodbye to any warranties or guarantees they’ve promised you. So, play by their rules and protect your investment.

Help is Just a Call Away

If you find yourself stuck with adhesive conundrums or have questions about a particular product, don’t hesitate to reach out to the manufacturer. They’re the experts who can provide you with valuable advice and guidance to ensure your projects are as strong as Hercules.

Tips and Techniques to Achieve Maximum Bonding Strength

Achieving maximum bonding strength is essential in furniture repairs and woodworking projects to ensure long-lasting and durable results. To achieve strong and reliable bonds when using glue, it is important to follow key tips and techniques.

Proper surface preparation, selecting the right glue, applying sufficient pressure during curing, following manufacturer’s instructions, considering environmental factors, testing the bond, and using good technique are all crucial elements in achieving maximum bonding strength. In this article, we will explore these tips and techniques in detail.

Surface Preparation:

Before applying glue, it is crucial to prepare the surfaces that need to be bonded. Cleanliness is key – ensure surfaces are clean, dry, and free from dust, grease, or old adhesive residues. Lightly sanding the surfaces can also improve adhesion by creating a rougher texture for the glue to grip onto.

Choosing the Right Glue:

Different glues have different strengths and weaknesses. Wood glue is suitable for bonding porous materials like wood, while epoxy provides a stronger bond and is ideal for bonding different materials together like wood to metal or plastic. Selecting the right glue for your specific project is crucial to achieving maximum bonding strength.

Applying Pressure:

Applying pressure during the curing process helps ensure a strong bond. For larger pieces or complex joints, using clamps can help distribute pressure evenly across the glued surfaces. If clamps are not feasible, weights can be used instead. Place heavy objects on top of the glued joint and allow them to exert pressure until the glue has fully cured.

Following Manufacturer’s Instructions:

Different glues have different curing times and application techniques. It is important to read and follow the manufacturer’s instructions carefully. This includes applying the correct amount of glue, spreading it evenly on both surfaces, and allowing sufficient drying time before handling or applying further stress to the bonded area.

Considering Temperature and Humidity:

Temperature and humidity levels can affect the curing time and strength of the bond. Most glues work best within a specific temperature range, so it’s important to work in a suitable environment. Extreme temperatures or high humidity can compromise the adhesive’s performance. Some glues may require specific temperature and humidity conditions for optimal bonding, so be sure to check the instructions.

Common Mistakes to Avoid When Using Glues on Furniture

Using glue on furniture is a versatile method for repairing, strengthening joints, or creating new pieces. However, to achieve a successful and long-lasting bond, it is crucial to avoid common mistakes often made when using glues. In this article, we will discuss these mistakes and provide you with valuable tips to ensure the best results for your furniture projects.

Improper Surface Preparation:

Properly preparing the surfaces to be glued is a pivotal step in achieving a strong bond. Failure to clean the surfaces thoroughly and remove any dirt, dust, or old glue residue can result in a weak joint. Take the time to meticulously clean and sand the surfaces before applying the adhesive. This will provide a clean and receptive surface for the glue to adhere to.

Selecting the Wrong Glue:

Using the wrong type of glue for your specific furniture material can jeopardize the bond or even cause damage. Different materials require different glues, such as wood glue for wood surfaces and epoxy for metal or plastic. Always read the instructions carefully and choose a glue that is suitable for the material you are working with. This will ensure compatibility and maximize bond strength.

Applying Too Little or Too Much Glue:

The amount of glue applied plays a significant role in achieving a durable bond. Applying too little glue may result in a weak joint that is prone to breaking, while applying too much can lead to messy excess glue seeping out from the joints. Follow the manufacturer’s instructions and apply an appropriate amount of glue for a clean and long-lasting bond. A thin, even layer of glue will suffice in most cases.

Rushing the Drying Time:

Properly allowing drying time is essential for a strong bond. Rushing this process can weaken the joint and potentially cause failure. It is imperative to follow the manufacturer’s instructions regarding drying times and give the glue ample time to set before subjecting the furniture to stress or use. Patience during this stage will ensure a solid and lasting bond.

Neglecting Clamping or Securing:

To create a tight and strong bond, it is crucial to properly secure the glued parts using clamps or applying pressure. Neglecting this step can result in misalignment or a weak joint. Invest in quality clamps that are appropriate for your project and follow the recommended clamping time to ensure optimal bonding. This will help maintain alignment and enhance the overall strength of the joint.

Benefits of Using Quality Adhesives on Furniture Projects

When it comes to furniture projects, using quality adhesives can make all the difference. Whether you’re a furniture enthusiast or a DIYer, understanding the benefits of investing in reliable adhesives is essential for ensuring the success and longevity of your creations.

First and foremost, quality adhesives provide strong and durable bonds. Imagine sitting on a chair that starts wobbling or a table that collapses under the weight of your dinnerware – not a pleasant experience, right? By using high-quality adhesives, you can rest assured that your furniture pieces will remain sturdy and secure, even under frequent use or heavy weight. These adhesives create bonds that are resistant to stress and strain, ensuring that your furniture can withstand the test of time.

But it’s not just about strength; quality adhesives also offer better resistance to environmental factors. Furniture is often exposed to different weather conditions and levels of moisture, which can weaken the bonds if a low-quality adhesive is used. However, by opting for reliable adhesives, you can ensure that your creations will withstand these challenges and maintain their structural integrity. Whether it’s extreme heat, high humidity, or fluctuating temperatures, quality adhesives provide a barrier against these elements, keeping your furniture in top condition for years to come.

Additionally, using quality adhesives can enhance the overall appearance of your furniture. Low-quality adhesives may leave visible residue or create uneven surfaces, compromising the aesthetic appeal of the piece. On the other hand, high-quality adhesives provide a clean and seamless bond, allowing for a more polished finish that will impress anyone who lays eyes on your work. The smooth and invisible bond created by quality adhesives ensures that your furniture looks professional and well-crafted.

And let’s not forget about the practical benefits – using quality adhesives can save you both time and money in the long run. When furniture joints are securely bonded with reliable adhesives, there is less likelihood of them coming apart or needing frequent repairs. This means fewer maintenance costs and more time to enjoy your beautiful creations. Quality adhesives provide peace of mind, knowing that you won’t have to constantly fix or replace damaged parts.

Furthermore, using quality adhesives contributes to a safer environment for users. Loose or unstable furniture parts can pose a significant safety risk, especially for items like chairs or beds. By using reliable adhesives, you can ensure that your furniture meets safety standards and provides peace of mind to your customers. The strong and secure bonds created by quality adhesives ensure that your furniture is stable and reliable, reducing the risk of accidents or injuries.

Conclusion

When it comes to choosing the best glue for furniture, there are a few factors to consider.

One of the top contenders is epoxy adhesive, known for its strong bonding capabilities and versatility. Another reliable option is polyurethane glue, which expands as it cures to fill gaps and provide a durable hold.

For more delicate or intricate furniture repairs, cyanoacrylate glue, commonly known as super glue, can be effective.