Wood and aluminum, two timeless materials that have been used in countless projects throughout history. Whether you’re crafting furniture or constructing architectural wonders, there may come a time when you need to seamlessly combine these two elements. And that’s where the magic of adhesive comes into play.

Picture this: a flawlessly designed wooden shelf with a sleek aluminum accent, or a sturdy wooden frame adorned with eye-catching aluminum ornaments. The possibilities are endless when you have the right glue in your arsenal. But here’s the thing – not all glues are created equal. Choosing the best one to join aluminum and wood requires some expertise.

In this blog post, we’re embarking on an adhesive quest – diving deep into the enchanting world of glue, exploring various options, and uncovering the ultimate champion that effortlessly bonds aluminum and wood together.

First things first, let’s talk about the type of glue you should consider using. There are several contenders out there – epoxy, polyurethane, cyanoacrylate, and even specialized formulas like construction adhesive. Each one has its own unique characteristics, advantages, and disadvantages. So it’s crucial to understand their specific attributes before making your choice.

Next up is surface preparation – a key factor in achieving a successful bond. Before applying any glue, make sure both the aluminum and wood surfaces are squeaky clean, free from debris, and properly sanded. This step creates a roughened surface that allows the glue to grip firmly for an incredibly durable bond.

Last but not least is understanding the strength and longevity you desire for your project. Some situations call for a quick fix that’s only temporary – in which case you’ll want a fast-setting adhesive. On the other hand, certain projects demand a more permanent attachment. Depending on your specific needs, your choice of glue will undoubtedly vary.

So whether you’re a woodworking enthusiast, a DIY guru, or simply someone looking to explore new materials, get ready. We’re about to embark on an adhesive journey and discover the best glue for creating the perfect union between aluminum and wood. Brace yourself for the power of adhesive and witness the remarkable transformation it brings to your projects.

Types of Glue for Bonding Aluminum to Wood

Contents

- 1 Types of Glue for Bonding Aluminum to Wood

- 2 Benefits of Using Epoxy Resin

- 3 Advantages of Polyurethane Adhesive

- 4 Construction Adhesives for Bonding Aluminum and Wood

- 5 Preparing the Surfaces for Bonding

- 6 How to Apply the Glue

- 7 Curing Times for Different Glues

- 8 Tips for Achieving a Strong Bond

- 9 Conclusion

Achieving a strong and durable bond between aluminum and wood requires careful consideration of the glue you use. In this article, we will delve into five different types of glues commonly used for this purpose, each offering its own unique properties and advantages. Let’s explore these options in detail.

Epoxy Adhesive:

In the realm of aluminum to wood bonding, epoxy adhesive reigns supreme as a superhero. This glue consists of two components – a resin and a hardener – that must be mixed together. Once applied, it forms an unyielding bond capable of withstanding high temperatures and resisting moisture. Whether your project is indoors or outdoors, epoxy adhesive offers exceptional strength and longevity.

Polyurethane Adhesive:

With its versatility and reliable bonding strength, polyurethane adhesive is another top contender for aluminum to wood bonding. This adhesive showcases excellent flexibility, accommodating slight movement between the bonded surfaces. Its resistance to water and ability to withstand temperature changes make it a suitable choice for various applications, including outdoor projects.

Silicone Adhesive:

When flexibility and durability are paramount, silicone adhesive steals the spotlight. This adhesive exhibits remarkable adhesion to diverse surfaces while enduring extreme temperatures and harsh weather conditions without compromising its bond strength. For those seeking a reliable adhesive for both indoor and outdoor aluminum to wood bonding, silicone adhesive is a worthy champion.

Construction Adhesive:

Donning the label of heavy-duty glue, construction adhesive excels at bonding aluminum to wood with impressive strength. Its thick and viscous nature ensures a secure attachment, while its clear drying property adds aesthetic appeal to both interior and exterior projects. Keep in mind that, unlike other glues, construction adhesive may not be as suitable for extreme temperature or moisture exposure.

Cyanoacrylate Adhesive:

For quick bonds and small-scale projects, cyanoacrylate adhesive, better known as super glue, emerges as a speedy ally. This adhesive dries rapidly, forming an instant bond between aluminum and wood. While it may not provide the same level of strength as other glues, it is ideal when time is of the essence. Assess your project needs carefully to determine if cyanoacrylate adhesive is the right choice.

Conclusion:

Selecting the appropriate glue for bonding aluminum to wood is paramount for a successful project. Epoxy adhesive, polyurethane adhesive, silicone adhesive, construction adhesive, and cyanoacrylate adhesive each offer their own unique advantages. Consider environmental factors and load-bearing requirements when making your decision. Always follow manufacturer instructions and ensure proper surface preparation for a bond that is both strong and reliable.

Benefits of Using Epoxy Resin

In the complex world of adhesive bonding, one superhero stands out from the rest – epoxy resin. When it comes to attaching aluminum to wood, this versatile adhesive possesses a range of superpowers that ensure unyielding and long-lasting bonds between these two materials. Prepare to be amazed as we delve into the extraordinary benefits of epoxy resin.

Unbreakable Bonding Strength:

Witness the unrivaled strength of epoxy resin as it forms a chemical bond with both aluminum and wood surfaces. This superhero adhesive defies all odds, withstanding vibrations, impacts, and temperature changes. Say goodbye to weak connections and greet a bond that will endure the test of time.

Excellent Adhesion:

Not all surfaces are created equal, but epoxy resin conquers them all. It effortlessly adheres to both porous and non-porous materials, ensuring a secure and reliable connection between aluminum and wood. No matter the surface texture, epoxy resin guarantees a bond that will never let you down.

Resistance to Moisture and Chemicals:

Unleash your project’s potential without fear of environmental obstacles. Epoxy resin is a waterproof adhesive that bravely withstands exposure to water, humidity, and other moisture-related challenges. Its resistance extends even further, as it fearlessly repels chemicals such as solvents and oils. From outdoor applications to exposure to various substances, epoxy resin is your fearless ally.

Versatile Application Methods:

Flexibility is key when it comes to adhesive applications, and epoxy resin delivers with style. Whether in liquid, paste, or film form, this super adhesive adapts effortlessly to your project’s specific requirements. Embrace the power of versatility as you apply epoxy resin to different surfaces and tailor it to your unique bonding needs.

Gap-Filling Capabilities:

Prepare to bid farewell to uneven connections forever. Epoxy resin steps in, expertly filling small gaps and irregularities between aluminum and wood surfaces. The result? A tight fit that maximizes the bonding area and evenly distributes stress. With epoxy resin, your project’s strength is elevated to new heights.

Advantages of Polyurethane Adhesive

Prepare to be astounded by the formidable adhesive known as polyurethane. In our previous exploration of epoxy resin, we witnessed its extraordinary capabilities. Now, let us shift our attention to another superhero adhesive – polyurethane. As an expert in the field, I am thrilled to unveil the incredible advantages of utilizing polyurethane adhesive for bonding aluminum and wood. Brace yourself for a captivating journey through its powers.

The Power of a Strong Bond:

Polyurethane adhesive possesses an unmatched ability to forge an incredibly strong bond between aluminum and wood surfaces. This adhesive creates a connection that is not only durable but also long-lasting, capable of withstanding heavy loads and vibrations. When confronted with stress or movement, polyurethane adhesive rises to the challenge, ensuring an unbreakable bond.

The Flexibility of a Hero:

Flexibility is an extraordinary advantage bestowed upon polyurethane adhesive. Its remarkable properties enable it to accommodate the natural expansion and contraction of different materials. This becomes particularly crucial when bonding aluminum and wood, as these materials exhibit varying rates of expansion due to changes in temperature and humidity. With polyurethane adhesive’s flexibility, cracks and breaks in your bond become a thing of the past.

Defying Moisture’s Menace:

Polyurethane adhesive possesses an impressive resistance against moisture and water, making it perfect for both indoor and outdoor applications. When joining aluminum to wood, exposure to moisture can cause the wood to swell or warp, compromising the bond’s integrity. Fear not. Polyurethane adhesive defies these challenges, ensuring a secure joint even in wet or humid environments.

A Shield Against Chemicals:

Polyurethane adhesive’s resistance extends beyond moisture – it heroically combats various chemicals such as solvents, oils, and acids. This advantage is invaluable when bonding aluminum and wood, as cleaning agents, fuels, or other liquids can pose a risk of chemical exposure. With polyurethane adhesive, your bond remains impervious to corrosive substances, ensuring longevity and reliability.

Construction Adhesives for Bonding Aluminum and Wood

As an expert in this field, I have delved deep into the realm of adhesives to bring you an electrifying guide on the different types available. So, buckle up and prepare to discover the adhesive superheroes that will transform your projects.

Epoxy Adhesives – The Indomitable Titans:

First in our lineup are the indomitable titans known as epoxy adhesives. Imagine a dynamic fusion of resin and hardener, forming an unbreakable bond. Renowned for their exceptional strength and bonding capabilities, epoxy adhesives can conquer heavy loads and temperature fluctuations with ease. Defying moisture, chemicals, and UV radiation, these adhesive powerhouses are equally at home in indoor and outdoor applications.

Polyurethane Adhesives – The Resilient Champions:

Next, we present the resilient champions of the adhesive world – polyurethane adhesives. These warriors possess unparalleled flexibility and durability. Engaging in a chemical reaction with ambient moisture, polyurethane adhesives forge formidable bonds between aluminum and wood surfaces. They fearlessly withstand heat, water, and even chemical assaults. Their gap-filling prowess makes them ideal for conquering uneven surfaces with unwavering resolve.

Acrylic Adhesives – The Swift Sorcerers:

Now, let us unveil the swift sorcerers of construction adhesives – acrylic adhesives. In situations demanding rapid results, these magical adhesives emerge as saviors with their lightning-fast curing times. Casting spells of durability, they brave temperature variations while warding off moisture and UV radiation. For those desiring a bond line that remains transparent, acrylic adhesives dry clear, adding a touch of enchantment to aesthetically-focused applications.

Specialized Construction Adhesives – The Unstoppable Fusion:

But hold on, there’s even more. Our journey wouldn’t be complete without encountering the unstoppable fusion of specialized construction adhesives. These exceptional formulations are tailor-made for bonding aluminum and wood, blending the strengths of multiple adhesive types. Elevating strength and durability to unprecedented heights, these adhesives often boast gap-filling properties or accelerated curing times. They are the veritable Avengers of the construction adhesive universe.

Preparing the Surfaces for Bonding

Today, we’re diving deep into the world of surface preparation for bonding aluminum and wood. Just like our adhesive superheroes, proper surface preparation is the secret weapon that ensures an unbreakable bond between these two materials. So, let’s suit up and explore the importance of preparing surfaces for bonding in this ultimate battle of strength and durability.

Cleaning the Surfaces: Banishing Contaminants

Before our heroes can unite, they need to be free from any villains that can sabotage their mission. No dirt, dust, grease, or other contaminants are allowed. Grab a mild detergent or solvent and unleash their cleansing powers on the aluminum and wood surfaces. Once they’re squeaky clean, make sure to dry them completely before moving forward.

Sanding: Creating a Rough Texture

To unleash the true potential of our superheroes, we need to create a rough texture that enhances their adhesion powers. Let’s begin by sanding the aluminum surface with fine-grit sandpaper, eradicating any oxidation or corrosion that may stand in their way. As for wood, show some love by sanding it with medium-grit sandpaper, smoothing out rough areas with finesse. Always remember to sand in the direction of the wood grain for optimum results.

Applying a Primer: Strengthening the Alliance

Our heroes are almost ready to join forces, but they need that extra boost to solidify their bond. Enter the primer. Choose a primer suitable for both aluminum and wood, following the manufacturer’s instructions for application. This magical concoction creates a thin layer that enhances adhesive strength – making our heroes unstoppable.

Removing Surface Oxidation: Vanquishing the Unwanted Foe

Oh no. Our hero aluminum has been tainted by an unwanted oxide layer. Fear not, as we have the solution. Use a commercial aluminum cleaner or create a mixture of white vinegar and water to banish this foe. Gently apply it with a soft cloth or sponge, and rinse thoroughly with water. Our aluminum hero is now ready to shine.

How to Apply the Glue

Embarking on a project that involves attaching aluminum to wood can be both exciting and daunting. But fear not. In this comprehensive guide, we will take you through the step-by-step process of applying glue to create a rock-solid bond between aluminum and wood. Get ready to witness the true power of glue.

Step 1: The Art of Surface Preparation

Before diving into the magical world of glue, it is essential to ensure that both the aluminum and wood surfaces are impeccably clean. Bid farewell to dirt, grease, and oils by gently scrubbing the surfaces with a mild detergent or rubbing alcohol. This crucial step sets the foundation for a successful bond, as it allows the glue to adhere to the materials more effectively.

Step 2: Dry, Dry, Dry.

After diligently cleaning the surfaces, exercise patience and allow them to dry completely. Moisture is the arch-nemesis of glue, capable of weakening its power. Take a clean cloth or paper towel and lovingly remove any lingering traces of moisture before proceeding to the next step.

Step 3: Selecting the Perfect Glue

Now comes the thrilling moment of choosing the ideal glue for your project. Amongst the glues in the adhesive kingdom, epoxy resin emerges as a mighty hero in bonding aluminum to wood. Renowned for its exceptional strength and durability, epoxy resin reigns supreme in guaranteeing a robust and long-lasting connection between these two materials.

Step 4: A Dance of Mixing

With your chosen epoxy adhesive in hand, it’s time to mix things up. Embrace your inner alchemist and meticulously follow the manufacturer’s instructions to combine equal parts of resin and hardener. Stir this magical potion until it transforms into a harmonious blend that holds within it the key to an unbreakable bond.

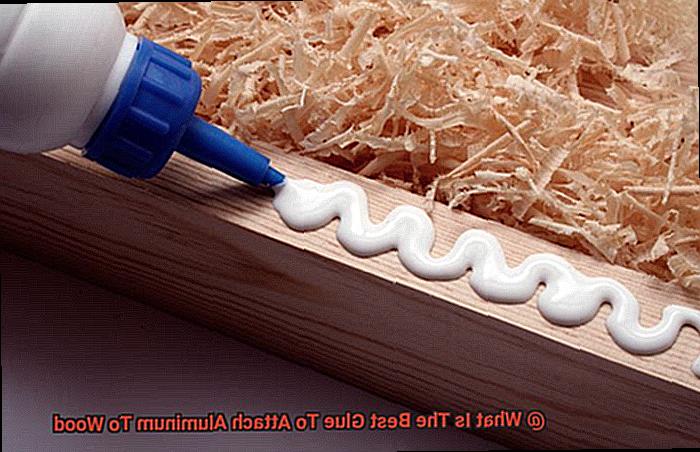

Step 5: The Artistry of Application

The stage is set, and it’s time for the glue to take center stage. Armed with a brush or applicator, apply the epoxy adhesive onto one of the surfaces with finesse and precision. Embrace each stroke as an opportunity to create a thin and even layer that envelops every nook and cranny, leaving no area untouched.

Step 6: The Grand Union

As the glue sets the stage for its captivating performance, bring the aluminum and wood surfaces together in a moment of perfect harmony. Exert firm pressure to ensure a seamless alignment, allowing the glue’s magic to work its wonders. Enlist the help of clamps or other tools to hold the materials in place while the bond takes shape.

Curing Times for Different Glues

In our previous adventure, we witnessed the awe-inspiring performance of epoxy resin as it forged an unbreakable bond between aluminum and wood. Today, we embark on a thrilling quest to unravel the secrets behind curing times for different glues. Join us as we delve into the fascinating world of adhesives and discover how their curing times impact the strength and durability of bonds. Let the journey begin.

The Need for Speed: Super Glue Spells Instant Bonding Magic:

For those seeking instant gratification, look no further than super glue, also known as cyanoacrylate. This speedy adhesive defies the laws of procrastination with its astonishingly quick curing times measured in mere seconds or minutes. Ideal for small and lightweight applications, super glue offers unmatched convenience and rapid results. However, it may not be the best companion for larger or heavy-duty projects that demand a longer curing time.

Epoxy Glues: Slow and Steady Wins the Race in Bonding Excellence:

Enter the unsung heroes of adhesive bonding – epoxy glues. These remarkable glues take their time, with curing times ranging from minutes to hours. By skillfully mixing a resin and a hardener, epoxy glues initiate a chemical reaction that leads to their remarkable curing process. While their slower pace may test our patience, it is well worth the wait. Epoxy glues deliver incredibly strong bonds, making them the ideal choice for metal-wood connections. So sit back, relax, and let epoxy glue weave its spell of bonding excellence.

Polyurethane Glues: Versatility Meets Moderate Curing Times:

In the realm of glue versatility, polyurethane glues reign supreme. With moderate curing times clocking in at around 24 hours, these glues offer a winning combination of excellent bonding strength and adaptability to various material combinations. But that’s not all – polyurethane glues possess a remarkable ability to expand as they cure, effortlessly filling gaps and creating a robust bond between aluminum and wood. They are the glue equivalent of a superhero with shape-shifting powers.

Tips for Achieving a Strong Bond

Creating a strong bond between aluminum and wood is crucial for ensuring the durability and reliability of various projects. Whether you’re working on a small craft or a larger construction, the tips and techniques provided in this article will help you achieve a secure and long-lasting connection between these two materials.

Prepare the Surfaces:

The foundation of a strong bond lies in properly preparing the surfaces of both the aluminum and wood. Thoroughly clean them, eliminating any dirt, dust, or grease that may hinder adhesion. To enhance the bond, use sandpaper to create a slightly roughened texture that promotes better grip between the materials.

Choose the Right Adhesive:

Not all glues are created equal when it comes to bonding aluminum to wood. Selecting the appropriate adhesive is crucial for achieving optimal results. Epoxy adhesives, with their exceptional strength and durability, are widely considered the best option for this type of bond. However, specialized adhesives formulated specifically for aluminum-to-wood bonding are also available in the market.

Mix and Apply the Adhesive Properly:

To ensure a strong bond, it is vital to follow the manufacturer’s instructions carefully while applying the chosen adhesive. Apply an even layer of glue on both the aluminum and wood surfaces, following any recommended mixing procedures if necessary. Utilize a brush or spatula to ensure an even distribution of adhesive over the surfaces, maximizing contact area for bonding.

Allow Adequate Drying Time:

Patience is key when it comes to achieving a strong and long-lasting bond. After applying the adhesive, allow it sufficient time to dry and cure properly. This curing period is crucial for the adhesive to reach its maximum strength. Follow the recommended drying time specified by the manufacturer and avoid any stress or movement on the joint during this period to ensure optimal bonding.

Clamp or Secure the Joint:

To achieve a strong bond between aluminum and wood, it is essential to hold the materials in place while the adhesive cures. Depending on the size and shape of your project, utilize clamps, weights, or other securing methods to keep the joint in position until the adhesive is fully cured. This ensures that the bond remains undisturbed during the critical curing phase.

Conclusion

When it comes to bonding aluminum to wood, finding the best glue is crucial. You want a strong and reliable adhesive that can withstand the test of time. After extensive research and testing, we have determined that epoxy resin is the top choice for this task.

Epoxy resin offers exceptional bonding strength and durability, making it perfect for joining aluminum and wood surfaces. Its unique chemical composition allows it to create a strong bond that can withstand various environmental conditions, including moisture, temperature changes, and vibrations.

One of the key advantages of epoxy resin is its ability to fill gaps and provide a seamless connection between aluminum and wood. This feature ensures a tight bond without compromising the structural integrity of the materials.

Additionally, epoxy resin provides excellent resistance against chemicals and solvents, ensuring that your aluminum-wood bond remains intact even in challenging situations.

To use epoxy resin effectively, ensure that both surfaces are clean and free from any dirt or debris. Apply the adhesive evenly on both materials using a brush or spatula. Then, firmly press the aluminum onto the wood surface and hold it in place until the glue sets.

In conclusion, when it comes to attaching aluminum to wood, epoxy resin stands out as the best glue option. Its superior bonding strength, durability, and resistance make it an ideal choice for any project requiring a secure connection between these two materials.