Ready to dive into the captivating world of 3D printing? Get ready for a thrill like no other as your ideas materialize before your eyes. But what happens when it’s time to put those intricate printed parts together? That’s where our unsung hero comes in – the glue.

In this blog post, we’re unraveling the mystery behind finding the best glue for assembling your 3D prints. Whether you’re a seasoned pro or a curious newcomer, nailing down the perfect adhesive is crucial.

But why do you even need glue for 3D prints? Let’s face it – not every part can be printed as one solid unit. Sometimes, you’ve got to print components separately and rely on glue to keep them firmly intact through thick and thin.

We’ll delve into key factors to consider when choosing your go-to glue. From material compatibility to bond strength and application techniques, we’ve got all bases covered. No more wasting time and materials on endless trial and error.

Furthermore, we’ll explore leading glue options available today. Cyanoacrylates, epoxy resins, and more await their moment in the spotlight as we uncover their unique advantages and disadvantages. Find the perfect fit for your project with confidence.

So buckle up and get ready to take your 3D printing game to new heights. Join us on this journey as we unlock the secret to impeccable adhesion and flawless assembly of your 3D prints. Stay tuned for our upcoming blog post, where we leave no stone unturned in exploring the world of glues.

What is 3D Printing?

Contents

Step into the mesmerizing world of 3D printing, also known as additive manufacturing, where imagination comes to life. From simple toys to awe-inspiring prototypes and even the possibility of creating human organs, this groundbreaking technology has captivated our collective imagination. In this article, we will delve into the depths of 3D printing, exploring its essence, mechanics, and the myriad of industries that have embraced its transformative power.

Unveiling the Essence of 3D Printing:

At the heart of 3D printing lies the artistry of bringing digital designs into tangible existence. Unlike traditional manufacturing methods that rely on subtracting material, this revolutionary process builds objects layer by layer, adding material to form a three-dimensional masterpiece. The journey begins with a meticulously crafted digital design file, sculpted using computer-aided design (CAD) software or sourced from online repositories.

The Dance of Creation:

Once the design file is perfected, it undergoes a process of slicing into delicate layers, akin to peeling back the secrets of a captivating story. These ethereal slices become the guiding instructions for the 3D printer, orchestrating its movements as it constructs the object layer by layer. The printer deftly deposits or solidifies various materials depending on the desired outcome, from versatile plastics and robust metals to exquisite ceramics and even edible and biological substances.

Empowering Designers and Innovators:

One of the most enchanting aspects of 3D printing lies in its unparalleled design freedom. It unlocks a treasure trove of possibilities, enabling creators to fashion intricate geometries that were previously unattainable or financially prohibitive. This newfound freedom gives birth to innovative designs and customized products that captivate and inspire. Moreover, 3D printing offers rapid prototyping capabilities, reducing time-to-market and allowing for swift iterations. It also promotes sustainability by minimizing waste and revolutionizing the production of low-volume or one-of-a-kind parts.

Different Types of Materials Used in 3D Printing

In this captivating article, we will delve into the distinct types of materials utilized in 3D printing and their remarkable properties. Strap on your 3D glasses, and let’s embark on an exhilarating journey.

Thermoplastics: The Versatile Foundation of 3D Printing

Envision a material that metamorphoses into a pliable state when heated, only to solidify when cooled – that’s the marvel of thermoplastics. These flexible materials are widely employed in 3D printing due to their malleability.

ABS, PLA, and PETG are renowned thermoplastics revered for their strength, biodegradability, and flexibility respectively. ABS excels in crafting functional prototypes, while PLA’s eco-friendly nature makes it ideal for consumer products.

Meanwhile, PETG showcases resistance against chemicals and moisture, making it suitable for various industrial applications.

Mighty Metals: Forging Resilience and Precision

When it comes to manufacturing robust and intricate objects, metals emerge as the superheroes of 3D printing. Stainless steel, titanium, aluminum, and cobalt-chrome are just a few examples of the metals employed in this process. Metal 3D printing entails selectively melting powdered metal alloys layer by layer, revolutionizing industries such as aerospace and healthcare. With this technique, intricate parts once deemed impossible can now be realized with precision and strength.

Composite Materials: The Fusion of Excellence

Sometimes, combining different materials can yield extraordinary results. Composite materials used in 3D printing involve blending two or more materials together to create enhanced properties. Carbon fiber-reinforced polymers exemplify composite materials that fortify strength and stiffness. These composites are ideal for applications demanding durability, such as high-performance sports equipment or automotive parts.

Beyond Plastics and Metals: Exploring Uncharted Territories

Did you know that 3D printers can also use ceramics, resins, and even edible materials? Ceramics can be intricately printed to create mesmerizing objects like decorative vases or exquisite jewelry. Resins are employed in high-resolution prints, boasting smooth surfaces and making them highly sought-after in the dental and jewelry industries. And yes, you read correctly – delectable treats can be printed too. Chocolate and sugar can be transformed into mouthwatering delights or personalized cake toppers, tantalizing both our taste buds and imaginations.

Glue Options for ABS Prints

Today, we embark on a thrilling journey into the realm of gluing ABS prints together. As an expert in the field, I am here to unveil the secrets of choosing the perfect glue for ABS prints. Prepare to be amazed as we explore an array of glue options that guarantee robust and long-lasting bonds. Let’s dive right in.

Super Glue – Swift and Trustworthy:

First on our list is the ever-reliable cyanoacrylate adhesive, commonly known as super glue. This fast-drying wonder creates a rock-solid bond between ABS surfaces through a magical chemical reaction with air moisture. Its easy application, transparent drying, and exceptional adhesion strength make it a fan favorite. However, remember to select a super glue that explicitly states its compatibility with ABS plastic for optimum results.

Epoxy Adhesive – Withstanding the Heat:

For those seeking unparalleled strength and resistance to high temperatures, behold the two-part epoxy adhesive. Comprising a resin and a hardener that must be skillfully mixed before application, this adhesive offers unrivaled durability. While it may require longer curing time compared to super glue, its superior bonding strength justifies the wait. Remember to choose an epoxy adhesive specifically formulated for ABS plastics.

Polyurethane Adhesive – Flexibility and Gap-Filling Wizardry:

If you crave flexibility and the ability to rectify gaps in your ABS prints, look no further than polyurethane adhesive. Renowned for its flexibility, impact resistance, and remarkable gap-filling capabilities, this adhesive forges unbreakable bonds between ABS surfaces. It even boasts the ability to bond ABS with other materials such as wood or metal. Bear in mind that polyurethane adhesives often necessitate clamping during curing and may have longer curing times compared to other options.

ABS Cement and ABS-Specific Adhesives – Tailored for Success:

In addition to our main contenders, there are two specialized options worth mentioning: ABS cement and ABS-specific adhesives. ABS cement, a solvent-based adhesive, wields the power to chemically melt ABS plastic, resulting in an ironclad bond as the melted plastic solidifies. On the other hand, ABS-specific adhesives are meticulously formulated to seamlessly interact with ABS materials, ensuring steadfast bonding properties.

Glue Options for PLA Prints

Today, we embark on an exciting quest to discover the ultimate glue options for assembling PLA prints. In this journey, we’ll unravel a plethora of adhesive possibilities, each with its own unique strengths and weaknesses. So, grab your favorite beverage and let’s dive into the world of perfect bonds for PLA prints.

Cyanoacrylate Glue – The Speed Demon:

First on our exploration is cyanoacrylate glue, fondly known as super glue. This lightning-fast adhesive boasts unparalleled drying speed and formidable bonding prowess. However, when it comes to PLA prints, we must exercise caution. While super glue can work wonders on other materials, it has been known to render PLA prints brittle and prone to breakage. Therefore, tread carefully and consider alternative options for your precious PLA creations.

Epoxy Adhesive – The Temperature Warrior:

Next in line is the mighty epoxy adhesive. This two-component marvel thrives in extreme temperature conditions, making it a formidable ally for PLA prints. Once the components are mixed, epoxy forms an unyielding bond that can withstand the test of time. However, be forewarned that curing may demand a little extra patience, and working with epoxy can get a tad messy. But fear not. The rewards of a solid connection far outweigh the small price of a little controlled chaos.

Polyurethane Adhesive – The Versatile Champion:

Now, brace yourselves for the polyurethane adhesive, epitomized by the revered Gorilla Glue. This two-part wonder showcases unparalleled versatility and gap-filling capabilities that make it a force to be reckoned with in various applications. As an added bonus, polyurethane adhesive expands during the drying process, forging a robust bond even in imperfect mating surfaces. And fear not the elements. This adhesive is water-resistant, ensuring your prints stay intact even when faced with moisture’s wrath.

Biodegradable Glues – Environmentally Conscious Options:

For those of you who champion sustainability, we bring forth the environmentally conscious glues designed specifically for PLA prints. These biodegradable wonders, crafted from organic materials free from harmful chemicals, offer both reliability and a clear conscience. With these green glues, you can assemble your PLA prints with confidence, knowing that you’re preserving our precious planet while creating something extraordinary.

Glue Options for PETG Prints

Prepare to embark on an exhilarating journey as we unravel the secrets of assembling PETG prints with the perfect glue. If you’ve been struggling to find the ideal adhesive for your durable and robust PETG creations, fret no more. We have meticulously gathered invaluable research notes that will guide you through a realm of glue options specially tailored for PETG prints. So grab your preferred beverage, sit back, and let’s delve into this captivating world.

Cyanoacrylate Adhesive – The Super Glue Solution:

When it comes to joining PETG parts together, one option reigns supreme: cyanoacrylate adhesive, better known as super glue. This superhero among adhesives swiftly forms an unyielding bond, making it the ultimate choice for assembling PETG prints. Yet, do bear in mind that not all super glues possess equal powers. To ensure optimal results, search for a product explicitly designed for bonding plastic materials.

Epoxy Resin – A Strong and Reliable Bond:

For those seeking a bond that exudes strength and reliability, enter the world of epoxy resin. This versatile adhesive crafts a formidable connection between PETG parts, ensuring durability and longevity. To unlock its full potential, carefully select an epoxy compatible with plastics and faithfully follow the manufacturer’s instructions.

Two-Part Polyurethane Adhesives – Unleashing Unrivaled Strength:

When intricate assemblies or smaller parts demand additional fortitude, behold the power of two-part polyurethane adhesives. These dynamic concoctions blend a resin and hardener, resulting in a bond of unrivaled strength. Impervious to impact and vibrations, they stand tall as perfect allies for demanding PETG print applications.

Solvent Welding Techniques – Merging PETG Parts Seamlessly:

For those venturing into delicate or intricate assemblies, prepare to unlock the secret of solvent welding techniques. By deploying a specific solvent, such as acetone, you can artfully melt the surface of PETG parts, melding them together flawlessly. However, always exercise caution when handling acetone, for its potency demands respect.

Glue Options for Nylon Prints

Today, we embark on an exciting journey into the world of bonding nylon prints with the perfect glue. Just like assembling a team of superheroes, choosing the right glue is essential to ensure a strong and durable bond between your nylon parts. So, grab your capes and let’s explore the different glue options available for your nylon prints.

Cyanoacrylate – The Speedy Super Glue:

Our first hero in the glue universe is cyanoacrylate, also known as super glue. This fast-drying adhesive forms a robust bond between nylon parts, making it a popular choice. It excels on smooth surfaces and boasts excellent resistance to heat and moisture. Remember, my friends, less is more when using this glue. Apply it sparingly to avoid brittleness and don’t forget to roughen those nylon surfaces with sandpaper for enhanced adhesion power.

Epoxy – The Mighty Two-Part Adhesive:

Next up, we have epoxy adhesive, the dynamic duo of resin and hardener. When these two components combine forces, they create a bond that can withstand heavy loads and vibrations. Perfect for large or complex nylon parts, epoxy adhesive fills gaps like a true superhero. However, patience is required as it takes several hours or even overnight to fully harden. So, grab a cup of coffee and let it work its magic.

Polyurethane – The Flexibility Master:

When flexibility is key, polyurethane adhesive swoops in to save the day. This adhesive forms a flexible bond that can handle movement and bending without cracking or breaking. It also boasts resistance to chemicals and moisture, making it ideal for outdoor or high-humidity environments. But beware, brave makers, for polyurethane adhesives often have longer curing times and may require clamping or support during the process. Just a small price to pay for its incredible flexibility.

Factors to Consider When Choosing the Best Glue

Choosing the best glue for your project can truly make or break your creations. With so many options available, it’s important to consider several factors that will ensure a strong bond, optimal compatibility, and overall success. Let’s dive into the key factors to consider when choosing the best glue for assembling 3D prints.

First and foremost, adhesive strength is paramount. You need a glue that can hold your prints together with an iron grip. Look for glues specifically designed for bonding plastic materials or those that boast high adhesive strength. This will ensure that your assembled parts stay firmly in place, no matter what challenges they may face.

Next on the list is compatibility with your 3D print material. Different materials, such as PLA, ABS, or PETG, have unique properties and may require specific types of glues. It is crucial to choose a glue that is compatible with the material you are working with to ensure optimal bonding. You want your prints to stick together like peanut butter and jelly.

Consider the drying time of the glue as well. If you’re working on larger or more complex 3D prints, you don’t want to wait forever for the glue to set. Opt for glues that dry quickly, allowing you to proceed with further assembly steps sooner. However, be mindful of your project timeline and requirements when selecting a glue with an appropriate drying time.

The application method is another important aspect to consider. Glues come in various forms – liquid, gel, or adhesive tapes. Liquid glues are versatile and work well for general assembly tasks while providing more control and are great for intricate or vertical bonding. Adhesive tapes offer convenience but may not be suitable for all types of 3D print assembly. Choose the application method that suits your needs best and get ready to stick it to ’em.

Flexibility and impact resistance should also be taken into account. Depending on the purpose of your assembled 3D print, you may need a glue that can withstand bending, impacts, or vibrations. Opt for a glue that offers these properties to ensure the longevity and durability of your creations. You want your prints to be able to handle life’s little bumps and twists.

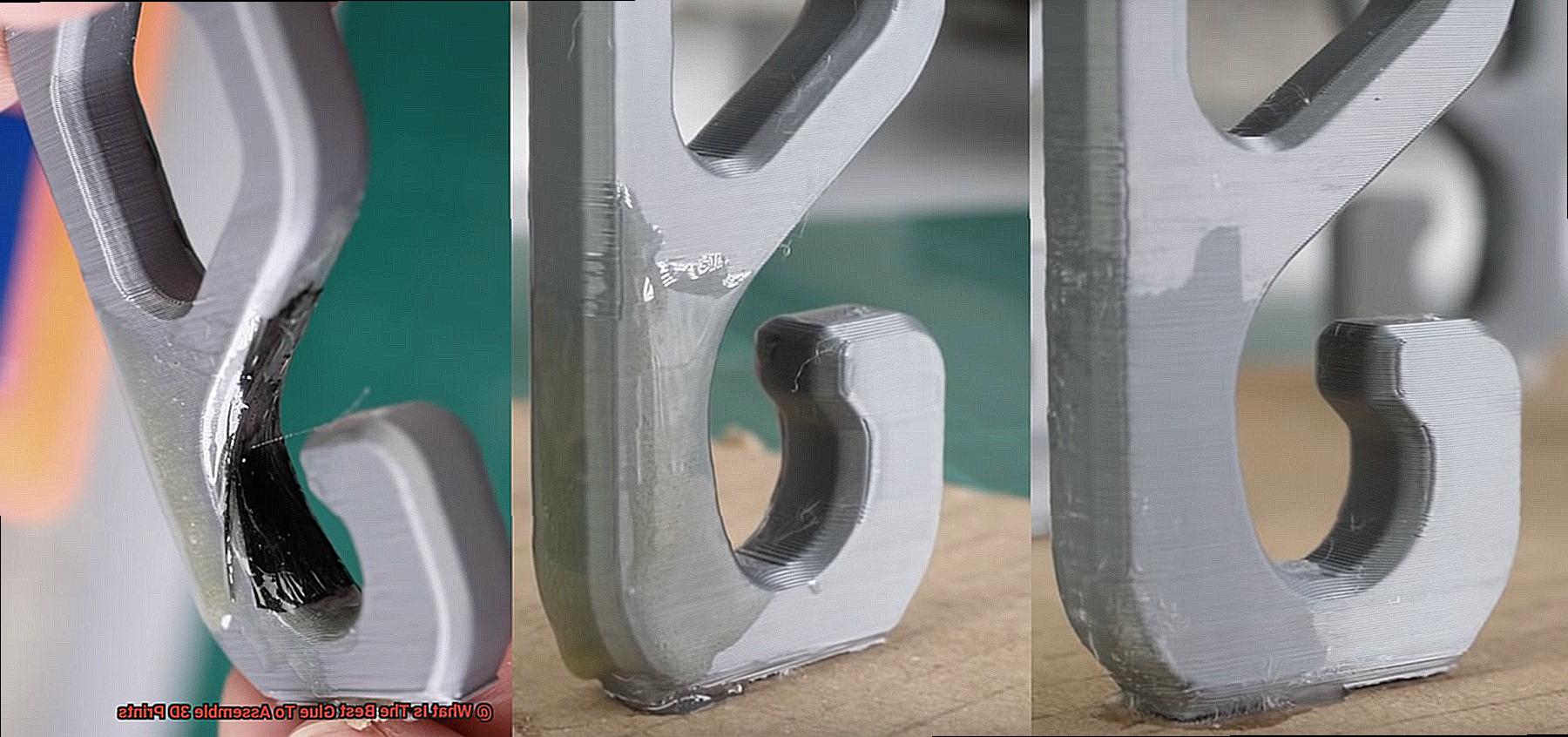

Preparing Surfaces for Bonding

Now that you’ve got the perfect glue for your 3D prints, it’s time to dive into the exciting world of surface preparation for bonding. This is where the magic happens, where the strength and durability of your creations truly take shape. Let me guide you through the key steps and expert tips to ensure a bond that will withstand the test of time.

- Step one: Cleanliness is non-negotiable. Before we even think about applying any glue, let’s make sure those surfaces are spotless. Dirt, dust, or any pesky debris can seriously mess with the adhesion process and weaken the bond. Grab a mild detergent or alcohol solution and give those surfaces a thorough scrub. Rinse them with water and don’t forget to let them dry completely. We want those surfaces squeaky clean and ready for action.

- Step two: Time to roughen things up a bit. No, we’re not starting a fight with our 3D prints. Gently sanding the surfaces with fine-grit sandpaper will create a slightly roughened texture that works wonders for bonding. Think of it as increasing the surface area available for that glorious glue to adhere to. Remember, the goal here is to enhance adhesion, not to strip away material. So go easy on that sandpaper.

- Step three: Bid farewell to residue. After our little sanding adventure, it’s crucial to remove any lingering particles from the surface. Grab a clean cloth or unleash compressed air to blow away those loose bits. We want our surfaces pristine and free from any contaminants that could sabotage our bond. Nothing should come between you and your masterpiece.

- Step four: Prime time. While not always necessary, priming can be a game-changer for certain materials. Consider it as playing Cupid between your glue and difficult-to-bond materials like certain plastics or metals. Check with your 3D print manufacturer or glue supplier to see if a primer is recommended and, if so, which type would be the best match. It’s like bringing in a wingman for your glue – a guaranteed recipe for success.

Conclusion

When it comes to assembling 3D prints, choosing the right glue is crucial. With a plethora of options available, finding the best one can be overwhelming. However, fear not. I’m here to guide you through this sticky situation and help you find the perfect adhesive for your 3D creations.

One top contender in the world of 3D print glues is cyanoacrylate, commonly known as super glue. Its fast-drying nature and strong bond make it an excellent choice for joining different parts together. Whether you’re working with PLA, ABS, or other common filaments, super glue has got your back.

But wait, there’s more. If you’re looking for a more flexible bonding solution, epoxy resin might be your go-to option. This versatile adhesive not only provides a durable connection but also allows for some wiggle room when it comes to adjusting and aligning your prints.

Now, let’s talk about polyurethane-based adhesives. These bad boys are known for their exceptional strength and ability to fill gaps between parts. If you’re dealing with larger or heavier prints that require added reinforcement, polyurethane glues will be your best friend.

And last but not least, we have solvent-based adhesives like MEK (methyl ethyl ketone) and acetone. These powerful solvents can chemically weld certain types of plastics together, creating an incredibly strong bond. However, caution is advised when using these substances as they can potentially damage or dissolve certain materials.

In conclusion, there isn’t a one-size-fits-all answer to the question of which glue is the best for assembling 3D prints. It ultimately depends on the specific materials being used and the desired strength and flexibility required. So take into consideration the characteristics of each adhesive mentioned above and choose accordingly.