Hey there. Looking for the best glue to stick wood to concrete? Well, you’ve come to the right place. Whether you’re a DIY-enthusiast or a seasoned carpenter, we all know how frustrating it can be to find that perfect adhesive that will securely bond these two materials together. But fear not, because we’re here to help.

In this blog post, we’ll dive deep into the world of wood-to-concrete glues. We’ll explore their unique properties, application techniques, and most importantly, their durability. From the tried-and-true options like epoxy and construction adhesive to the more innovative alternatives like polyurethane adhesives, we’ve got you covered.

No more wobbly furniture or shaky installations – it’s time to find that glue that will give your wood-concrete projects the strength and longevity they deserve. So join us on this journey as we guide you through the selection process and help you find the perfect glue for all your wood-to-concrete bonding needs. Let’s get started.

Factors to Consider When Choosing the Best Glue for Wood to Concrete

Contents

- 1 Factors to Consider When Choosing the Best Glue for Wood to Concrete

- 2 Advantages of Epoxy for Bonding Wood to Concrete

- 3 Polyurethane Construction Adhesive: A Durable Bonding Option

- 4 Adhesive Tapes: An Easy and Mess-Free Solution

- 5 Important Considerations Before Applying Glue

- 6 What is the Best Glue for Wood to Concrete?

- 7 Tips for Successful Bonding with Glue

- 8 Conclusion

Creating a strong and durable bond between wood and concrete requires choosing the right glue. With an overwhelming number of options available in the market, it’s crucial to consider key factors when selecting the best glue for your project. In this comprehensive guide, we will explore the factors that are essential in making an informed decision for wood to concrete bonding.

Factor 1: Adhesive Strength

To ensure a secure bond, look for adhesives specifically designed for wood to concrete bonding. These adhesives are formulated with higher adhesive strength to withstand the stress and pressure between the materials. This ensures a reliable connection that will stand the test of time.

Factor 2: Compatibility

Ensure that the glue you choose is compatible with both wood and concrete. Some adhesives may work well with one material but not the other, resulting in weak bonds or surface damage. Read product labels or consult experts to ensure compatibility and avoid any potential issues.

Factor 3: Drying Time

Consider the drying time of the glue, especially if you have time constraints or multiple pieces to work on simultaneously. Quick-drying adhesives allow you to proceed with your project sooner, while others may require longer curing periods. Choose a glue that aligns with your specific project timeline.

Factor 4: Waterproofing

If your project involves wood and concrete in outdoor or moisture-prone areas, select a waterproof or weather-resistant glue. This ensures that the bond remains strong even when exposed to water or humidity, preventing any deterioration over time.

Factor 5: Flexibility

Evaluate the flexibility requirements of your project. Some applications may benefit from a rigid bond, while others may require some degree of flexibility. For example, bonding wooden flooring to a concrete subfloor may require a glue that allows for slight movement without compromising the bond. Consider the flexibility needs of your project and choose accordingly.

Factor 6: Application Method

Consider the ease and convenience of the glue’s application method for your specific project. Some adhesives come in squeeze tubes, spray bottles, or have specialized applicators. If you need to apply the glue in tight spaces or on vertical surfaces, opt for a glue with a nozzle or spray bottle for better control.

Factor 7: Safety

Prioritize safety when selecting a glue for wood to concrete bonding. Choose adhesives that are non-toxic and low in volatile organic compounds (VOCs) to minimize any potential health hazards. Follow the manufacturer’s safety precautions and instructions for proper use and handling.

Advantages of Epoxy for Bonding Wood to Concrete

When it comes to bonding wood to concrete, the glue you choose can make or break your project. Thankfully, epoxy swoops in like a superhero, armed with strength, durability, and versatility. In this article, we will delve into the advantages of using epoxy for bonding wood to concrete. Prepare to be amazed by its superior properties that have made it the go-to choice for professionals in construction and woodworking.

Unparalleled Strength and Durability:

Epoxy is renowned for its exceptional strength, creating a bond that can withstand immense stress and weight. Whether you are constructing furniture or securing wooden structures to concrete foundations, epoxy stands as the ultimate ally in providing long-lasting connections.

Versatility at Its Finest:

With epoxy, you have the freedom to choose from various wood types for your project. It seamlessly bonds hardwood, softwood, plywood, or engineered wood to concrete surfaces with ease and precision. This versatility allows you to explore creative possibilities without compromising on performance.

Defying Moisture’s Wrath:

Moisture is wood’s arch-nemesis, leading to warping, rotting, and decay. Luckily, epoxy comes to the rescue with its excellent moisture resistance properties. By using epoxy to bond wood to concrete in high-humidity areas or outdoor structures exposed to water, you can safeguard against potential damage and ensure longevity.

Chemical Resistance:

In industrial or commercial settings where harsh chemicals or cleaning agents are present, epoxy shines through with its chemical resistance. It shields the bonded wood from chemical corrosion and maintains its structural integrity over time.

Bridging Gaps with Ease:

Uneven surfaces or irregularly shaped wood pieces can pose a challenge when bonding to concrete. Fear not. Epoxy comes equipped with gap-filling properties that seamlessly bridge any voids, ensuring a flawless and robust bond. Say goodbye to unsightly gaps and hello to a connection that stands the test of time.

Tackling Temperature Extremes:

Epoxy can handle the heat, no matter the project’s indoor or outdoor location. Its excellent temperature resistance allows it to withstand extreme fluctuations without compromising its strength. So, come rain or shine, your wood-to-concrete bond will remain steadfast.

Easy Application for Everyone:

Applying epoxy is a breeze. With minimal preparation and specialized tools required, it proves to be a user-friendly adhesive option. Simply mix the epoxy resin and hardener together, apply it to the wood and concrete surfaces using a brush or roller, and let it cure within hours. The result? A strong bond that holds up to scrutiny.

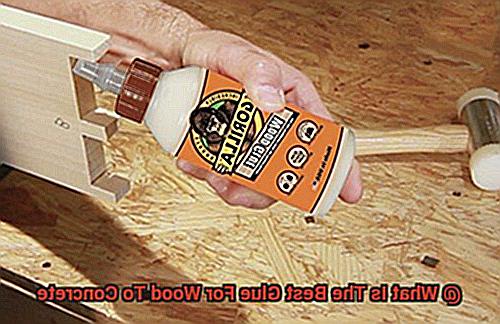

Polyurethane Construction Adhesive: A Durable Bonding Option

When it comes to securely bonding wood to concrete, look no further than polyurethane construction adhesive. This incredible adhesive is specifically designed for construction applications and offers a durable and long-lasting bond between wood and concrete surfaces. Let’s dive into why polyurethane construction adhesive is the go-to choice for all your bonding needs.

- Strength and Durability: Polyurethane construction adhesive is a powerhouse when it comes to strength and durability. It creates a bond that can withstand the test of time, ensuring your wood and concrete surfaces stay firmly together.

- Versatility: Whether you’re attaching wooden boards to concrete walls or securing wooden flooring to a concrete subfloor, polyurethane construction adhesive is up for the challenge. Its versatility makes it suitable for various projects, both indoor and outdoor.

- Weather Resistance: No matter the weather conditions, polyurethane construction adhesive can handle it all. From scorching heat to freezing cold, high humidity to heavy rain, this adhesive won’t let you down. You can trust that your bond will remain intact even in the harshest environments.

- Gap-Filling Capabilities: Uneven surfaces? No problem. Polyurethane construction adhesive has excellent gap-filling capabilities. It fills in any gaps or irregularities between the wood and concrete surfaces, ensuring a tight and even bond.

- Easy Application: Applying polyurethane construction adhesive is a breeze. Just make sure to clean and dry both the wood and concrete surfaces before applying the adhesive. Follow the manufacturer’s instructions carefully, including proper surface preparation techniques, for optimal adhesion.

Remember, while polyurethane construction adhesive is a reliable bonding option, it’s essential to secure the bonded surfaces together while the adhesive cures. Clamps or other methods can be used to ensure a strong and stable bond.

Adhesive Tapes: An Easy and Mess-Free Solution

When it comes to bonding wood to concrete surfaces, adhesive tapes offer a quick, easy, and mess-free solution. Whether you’re working on a DIY project or a professional construction job, adhesive tapes provide several advantages over traditional glues. Let’s explore the benefits of using adhesive tapes for wood to concrete bonding.

Convenience and Efficiency:

- Adhesive tapes offer convenience and efficiency compared to liquid glues.

- Liquid glues require mixing and curing time, while adhesive tapes can be used immediately.

- This saves you valuable time and allows for more efficient completion of your project.

- Adhesive tapes also eliminate the risk of messy spills or drips, saving you from sticky fingers and cleanup hassles.

Strong Bonding:

- Double-sided tapes are commonly used for wood to concrete bonding.

- These tapes have adhesive layers on both sides, ensuring excellent adhesion between the two surfaces.

- When choosing a double-sided tape, consider its weight and load-bearing capacity to support the required weight.

- Look for tapes with high tack and high shear strength to withstand the stresses and forces applied over time.

Versatility and Flexibility:

- Adhesive tapes offer versatility and flexibility for wood to concrete bonding.

- They are often removable, making them suitable for temporary applications or projects that may require repositioning or adjustment.

- This flexibility allows for easy modifications or repairs without damaging the surfaces.

Application Process:

- Applying adhesive tape for wood to concrete bonding is straightforward.

- Prepare the surfaces by cleaning them thoroughly and removing any dust or debris.

- Cut the tape into suitable lengths and apply it evenly on both surfaces.

- Press firmly to ensure good contact between the wood and concrete.

Limitations:

- Adhesive tapes may not be suitable for all wood to concrete bonding applications that require high strength or load-bearing capacity.

- In such cases, traditional glues or other fastening methods may be more appropriate.

Important Considerations Before Applying Glue

When it comes to bonding wood to concrete, there are several important considerations to keep in mind before reaching for that trusty glue bottle. After all, you want a bond that will withstand the test of time and provide the strength and durability you need. So, let’s dive into these important factors and ensure your project sticks.

First and foremost, consider the type of wood and concrete you’re working with. Different woods and concretes have varying levels of porosity and surface texture, which can greatly affect how well the glue adheres. To ensure a successful bond, choose a glue that is suitable for both porous and non-porous surfaces.

Next, think about the environmental conditions your bond will face. Temperature, humidity, and sunlight can all have an impact on the performance of the glue over time. To ensure long-lasting durability, it is crucial to select a glue that is resistant to these conditions.

Preparation is key. Before applying the glue, make sure both surfaces are clean, dry, and free from any contaminants like dust, oil, or grease. Sanding the wood surface and using a degreaser or cleaner on the concrete surface will create a strong foundation for the bond.

Consider using a bonding agent or primer before applying the glue. These products improve adhesion between the wood and concrete surfaces and enhance overall strength. Think of them as the secret weapon to ensure a robust bond.

Don’t forget to read and follow the manufacturer’s instructions for the specific glue you’re using. Each type of glue may have different application requirements and curing times. By being diligent and following these instructions, you’ll achieve optimal results.

Lastly, test the bond strength before relying on it for any load-bearing applications. Apply pressure or weight to the bonded area and check for any signs of failure or weakness. This step allows for adjustments or alternative solutions if needed, ensuring your project’s success.

What is the Best Glue for Wood to Concrete?

Discovering the best glue for wood to concrete is like finding the perfect adhesive soulmate – it requires careful consideration of factors like surface texture, environmental conditions, and proper preparation to create a bond that can withstand the test of time and provide the strength and durability you need. So, let’s dive into these important factors and ensure your project sticks.

Epoxy – The Power Duo:

Epoxy is a rockstar when it comes to bonding wood to concrete. Its two-part composition, consisting of resin and hardener, creates a chemical reaction that forms an incredibly strong bond. With exceptional strength and durability, epoxy is ideal for heavy-duty projects that require a reliable connection.

Polyurethane – Versatility at Its Best:

Polyurethane adhesive is a jack-of-all-trades in the adhesive world. This adhesive excels in bonding different materials together, making it suitable for wood to concrete applications. Its excellent resistance to moisture and temperature changes makes it perfect for both indoor and outdoor use.

Construction Adhesive – Building Bridges:

Specifically designed for construction purposes, construction adhesive provides a robust bond between various materials, including wood and concrete. Available in solvent-based and water-based formulas, this adhesive offers versatility depending on your project’s requirements.

Other Options:

While epoxy, polyurethane, and construction adhesives are top choices, other glues like cyanoacrylate (super glue), polyvinyl acetate (PVA), and silicone adhesives can be used for wood to concrete bonding. However, they may not provide the same level of strength and durability as the aforementioned options.

Project-Specific Considerations:

Factors such as load-bearing capacity, exposure to moisture or temperature changes, and the type of wood being bonded should influence your glue choice. Consulting a professional or doing thorough research will help you make an informed decision.

Surface Preparation:

Properly preparing the wood and concrete surfaces is essential for a successful bond. Ensure they are clean, dry, and free from dust or debris. Roughening the concrete surface can enhance bond strength.

Follow Manufacturer’s Instructions:

Each adhesive has its own curing times and application methods. To achieve the best results, always follow the manufacturer’s instructions.

Tips for Successful Bonding with Glue

You’ll need the right glue and proper techniques to achieve a strong and durable bond. In this blog post, we will provide you with helpful tips for successfully bonding wood and concrete using glue. Let’s get started.

Prepare the Surfaces:

Before applying any glue, it’s essential to prepare the surfaces that will be bonded. Use a brush or a damp cloth to clean both the wood and concrete surfaces thoroughly, ensuring that all dust, dirt, and debris are removed. Additionally, make sure the surfaces are completely dry before applying the glue.

Choose the Right Type of Glue:

Not all glues are suitable for bonding wood to concrete. It’s crucial to choose a glue specifically designed for this purpose. Epoxy-based adhesives or construction adhesives are commonly recommended due to their strong bonding properties and durability. These types of glues can withstand moisture and temperature changes, making them ideal for outdoor applications as well.

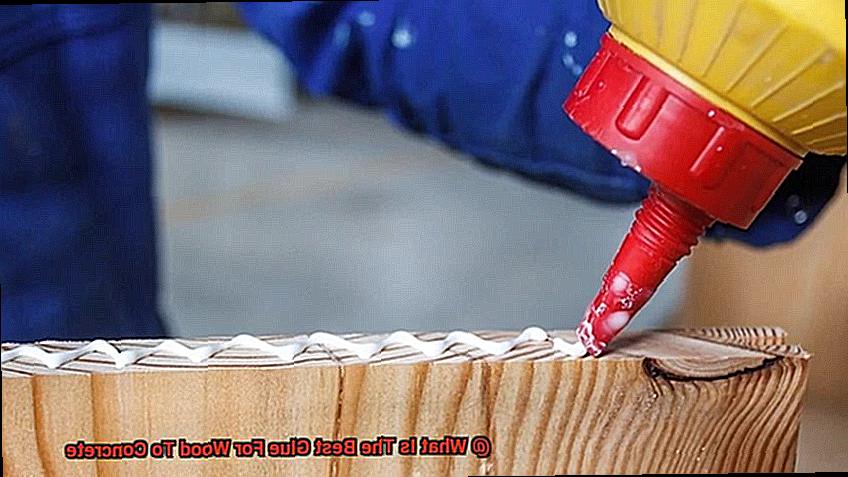

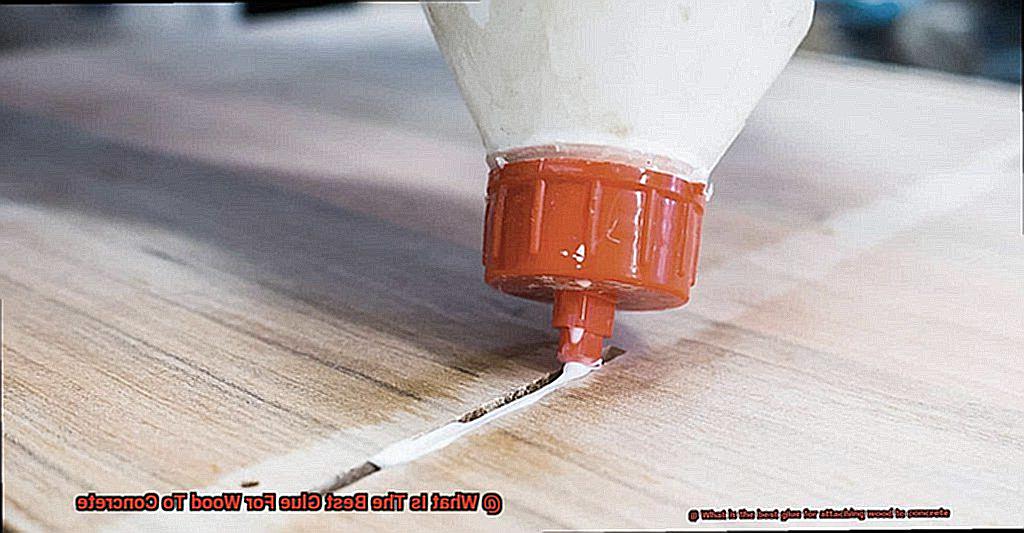

Apply the Glue Properly:

Follow the instructions provided by the manufacturer when applying the glue. To achieve a successful bond, apply a thin and even layer of adhesive on both the wood and concrete surfaces using a brush, roller, or trowel. Be sure to cover the entire surface area that needs to be bonded.

Allow Sufficient Curing Time:

After applying the glue, it’s important to give it enough time to cure properly. Curing time can vary depending on the type of glue used, so refer to the manufacturer’s instructions for guidance. Avoid disturbing or moving the bonded materials during this period as it may compromise the strength of the bond. Patience is key here.

Apply Pressure:

Applying pressure during the bonding process helps ensure a strong and secure bond between wood and concrete surfaces. Use clamps or weights to apply even pressure across the entire surface area. This will help eliminate any gaps or air pockets between the materials and enhance the overall bond strength. Remember, a little pressure goes a long way.

Also Read: How To Glue Wood To Concrete Without Drilling?

Conclusion

In conclusion, there are several glue options available for bonding wood to concrete, each with their unique strengths and advantages. One standout choice is epoxy, known for its exceptional strength, versatility, and ability to withstand moisture and temperature changes. It’s the go-to adhesive for heavy-duty projects that demand a reliable connection.

Another top contender is polyurethane construction adhesive. This powerhouse adhesive boasts incredible strength, durability, and weather resistance. No matter the environmental conditions, it can handle both indoor and outdoor applications with ease.

For those looking for a glue specifically designed for construction purposes, look no further than construction adhesive. This mighty adhesive forms a robust bond between different materials, including wood and concrete. Its versatility makes it suitable for any project’s specific requirements.

While cyanoacrylate (super glue), polyvinyl acetate (PVA), and silicone adhesives can also be used for wood to concrete bonding, they may not offer the same level of strength and durability as epoxy or polyurethane adhesives.

To ensure successful bonding with any glue, proper surface preparation is crucial. Thoroughly clean both the wood and concrete surfaces and ensure they are completely dry before applying the adhesive. Follow the manufacturer’s instructions regarding application methods and curing times to achieve optimal results.

Applying pressure during the bonding process using clamps or weights will help eliminate gaps or air pockets between the materials, enhancing overall bond strength.

By considering these factors and employing proper techniques, you can confidently tackle wood-concrete projects knowing you’ve achieved a strong and long-lasting bond using the best glue options available.