Whether you’re a seasoned woodworker or a DIY enthusiast, filling gaps in wood can be a tricky task. But fear not. There’s an abundance of glues out there that can help you seamlessly close those unsightly openings, providing both strength and beauty.

In this blog post, we’ll dive into the world of wood glues and explore the top contenders for filling wood gaps. Whether you’re working on a simple woodworking project or tackling a professional carpentry endeavor, we’ve got your back. So let’s get our hands dirty and find the glue that will keep your woodwork flawless.

Types of Glue for Filling Wood Gaps

Contents

- 1 Types of Glue for Filling Wood Gaps

- 2 What to Consider When Choosing the Best Glue for Wood Gaps

- 3 Small Gap Solutions: Wood Fillers and Epoxy

- 4 Larger Gap Solutions: Structural Adhesives

- 5 Understanding Different Types of Wood

- 6 Preparing the Surface for Glue Application

- 7 Following Manufacturer Instructions Carefully

- 8 Pros and Cons of Different Glues for Wood Gaps

- 9 Conclusion

Don’t fret. There are various types of glue specifically designed to fill wood gaps and restore the beauty of your wood. In this article, we will delve into the different types of glue that can be used for filling wood gaps, helping you choose the best option for your project.

Wood Filler – The Master of Small Gaps:

Wood filler is like a wizard’s potion for small to medium-sized gaps in wood. With a texture akin to butter, it easily spreads onto the surface using a putty knife. Wood fillers come in different colors, allowing you to seamlessly blend them with the natural tone of your wood. Simply let it dry and then sand it down for a smooth finish that will make your wood look flawless.

Epoxy Resin – The Superhero of Large Gaps:

When it comes to larger gaps that need structural support, epoxy resin is here to save the day. This adhesive duo consists of resin and hardener, combining their powers to create an unbreakable bond. Epoxy resin cures into a rock-hard finish that can be sanded, painted, or stained to match the surrounding wood. It is an ideal choice for filling substantial gaps or reinforcing weakened areas.

Cyanoacrylate Glue – The Speedy Fixer:

For those tiny gaps that need immediate attention, cyanoacrylate glue, also known as super glue, is your go-to hero. It works its magic by forming an incredibly strong bond within seconds. Before applying this fast-acting adhesive, ensure that the surface is clean and dry. With super glue, you can seal those gaps in no time and carry on with your project without delay.

Polyurethane Glue – The Gap Expander:

Polyurethane glue is like a foam-filling superhero. As it cures, it expands, making it perfect for irregular or uneven gaps. This versatile adhesive also boasts excellent water resistance, adding durability to your repairs. However, exercise caution, as it tends to foam up during the curing process. Wipe away any excess glue before it dries to achieve a clean and professional finish.

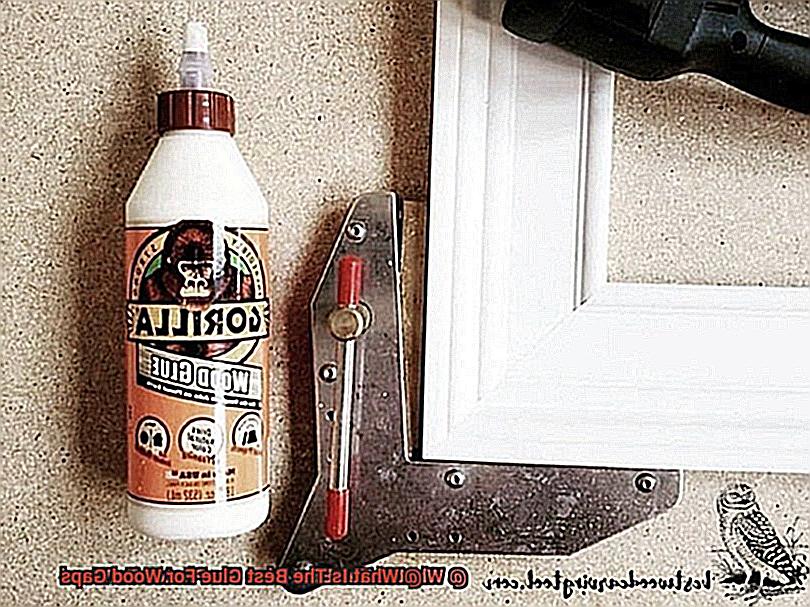

Carpenter’s Glue (PVA) – The All-Purpose Warrior:

Carpenter’s glue, also known as PVA glue, is the trusted warrior for all your woodworking needs. It forms a strong bond between wood surfaces and is great for smaller gaps and joints. Once cured, this glue is dry and transparent, allowing for sanding and painting to achieve the desired finish. Its versatility makes it a reliable choice for a wide range of wood projects.

What to Consider When Choosing the Best Glue for Wood Gaps

However, with the right glue, these gaps can be seamlessly filled, resulting in a flawless finish. This guide explores the key factors to consider when selecting the best glue for wood gaps, ensuring a strong and durable bond. Let’s delve into these considerations to make your woodworking projects shine.

Type of Wood:

Just as each person has unique characteristics, different wood types possess distinct qualities. Some woods are porous, like oak and pine, while others are dense hardwoods such as mahogany or teak. It is crucial to choose a glue that suits your specific wood type for optimal bonding. Porous woods require adhesives with excellent penetration capabilities, while dense hardwoods may need stronger adhesives for a secure bond.

Gap Size:

The size of the gap plays a significant role in determining the appropriate glue for wood gaps. For hairline cracks or tiny gaps, a thin cyanoacrylate adhesive (commonly known as super glue) is perfect. However, larger gaps necessitate a gap-filling adhesive or an epoxy resin for a seamless and sturdy finish.

Strength and Durability:

Consider the intended use of your wood project. If it will be subjected to high stress or is a load-bearing structure, opt for a glue that offers exceptional strength and durability. Polyurethane-based glues and epoxy resins are renowned for their robust bonding properties, ensuring long-lasting results.

Application Method:

Ease of application is another crucial factor to consider when choosing glue for wood gaps. Squeeze bottles with precision tips are ideal for small gaps where precise application is required. Some adhesives may require mixing two components before use, enhancing their bonding properties but demanding more time and effort. Choose an application method that aligns with your project requirements and your skill level.

Drying Time:

Time is of the essence. Consider the drying time of the glue, particularly if you have a tight schedule or need to make adjustments after applying it. Fast-drying options are ideal for those in a hurry or requiring flexibility during the assembly process. However, if you have ample time to spare, opt for glues that allow you to position and adjust the wood before they set completely.

Sanding and Finishing:

If you plan to sand or finish your wood project, ensure that the glue you choose can be sanded and accepts finishes well. Certain glues may leave residue or react poorly with specific finishes, compromising the final appearance. Pay attention to compatibility with sanding and finishing processes to achieve a polished and professional look.

Small Gap Solutions: Wood Fillers and Epoxy

When it comes to woodworking projects, small gaps in wood can be a frustrating challenge. Luckily, there are two popular solutions that can help you achieve a flawless finish – wood fillers and epoxy. In this guide, we will explore the benefits and considerations of both options, allowing you to make an informed decision based on your specific needs.

Wood Fillers:

Wood fillers are a convenient choice for filling small gaps in wood. They come ready to use straight out of the container, saving you time and effort. Plus, they dry relatively quickly, allowing you to move on to sanding and finishing without delay. With a variety of colors available, you can easily find a filler that matches your wood tone, creating a seamless finish.

However, there are some things to consider when using wood fillers. Over time, they may shrink or crack due to temperature and humidity changes, requiring periodic maintenance. Additionally, variations in color and grain matching may result in visible seams.

Epoxy:

If you’re looking for strength and durability, epoxy is the way to go. It forms a tough and resilient surface once cured, capable of withstanding heavy loads. Even when filling wider gaps, epoxy can be sanded and finished to achieve a smooth and seamless surface. It also offers versatility as it can be tinted or stained to match the wood color.

However, working with epoxy requires precise application. Mixing the resin and hardener in the correct ratio is crucial, and working time is limited before it hardens. Following the manufacturer’s instructions is essential for best results. It’s also important to note that despite its ability to be tinted or stained, epoxy may still be noticeable in certain situations, especially with prominent grain patterns.

Larger Gap Solutions: Structural Adhesives

If you’re tired of those unsightly gaps in your woodwork, fret no more. The perfect solution awaits you – structural adhesives. These mighty glues are specifically designed to fill larger gaps in wood, providing a strong and durable bond that will make your projects look flawless. Let’s dive into the advantages of using structural adhesives and the key considerations you need to keep in mind.

First off, let’s talk about the types of glue you can use. Epoxy adhesives are a popular choice for filling larger gaps in wood. They are known for their high strength and durability, making them ideal for heavy-duty applications. With epoxy, you can achieve a seamless bond on various types of wood, including hardwoods and softwoods. Another option is polyurethane adhesive, which offers flexibility and resistance to moisture. Polyurethane adhesive is also suitable for different wood types.

Now, let’s move on to application techniques. When using epoxy or polyurethane adhesives, it is essential to prepare the surfaces properly. Clean the surfaces to be bonded and roughen them with sandpaper to enhance adhesion. This step ensures that the adhesive forms a strong grip with the wood. Once the surfaces are prepped, mix the resin and hardener according to the manufacturer’s instructions. Apply the adhesive to one surface and press the surfaces together firmly to ensure a strong bond.

One important thing to note is that epoxy adhesives typically have a longer curing time compared to other glues. So be patient and allow enough time for the adhesive to fully cure before subjecting the bonded surfaces to any stress or load. This patience will pay off with a secure and long-lasting bond.

Now, let’s address potential issues. Structural adhesives like epoxy and polyurethane may not be suitable for extremely large gaps in wood. In such cases, it may be necessary to use other methods like using wooden shims or filler materials before applying the adhesive. These additional measures will help bridge the gap and ensure a successful bonding process.

It’s also crucial to follow the manufacturer’s instructions and guidelines when using structural adhesives for wood gaps. Different products may have specific requirements and limitations, so make sure to read the fine print. By adhering to these instructions, you can achieve optimal results and avoid any potential pitfalls.

Understanding Different Types of Wood

Wood is a captivating material that comes in a multitude of varieties, each possessing its own distinct qualities and characteristics. From sturdy and durable hardwoods like oak, maple, and walnut to the more affordable and workable softwoods such as pine and cedar, understanding the different types of wood is crucial when it comes to selecting the appropriate glue for filling gaps.

Hardwoods are known for their robustness and resilience, making them ideal for crafting furniture and other items that require strength. With a tight grain structure, hardwoods are resistant to moisture absorption, which can pose a challenge when it comes to bonding with glue.

On the other hand, softwoods are commonly used in construction due to their affordability and ease of manipulation. Softwoods have a looser grain structure, allowing them to readily absorb glue. This characteristic makes filling gaps in softwoods a relatively straightforward task compared to hardwoods.

Engineered woods, such as plywood and particleboard, are created by bonding layers or particles of wood together using adhesive. When working with engineered woods, it is important to select a glue that is compatible with the specific type of wood being used.

When it comes to choosing the right glue for filling gaps in wood, there are several options to consider. Wood glue is a popular choice due to its strong bond and versatility with various wood types. For larger gaps, epoxy is an excellent option as it can deeply penetrate the wood and create a durable bond.

If you’re dealing with smaller gaps on both hardwoods and softwoods, cyanoacrylate (CA) glue, commonly known as super glue, provides a quick and strong bond. However, it may not be the most suitable choice for larger gaps or areas under stress.

For construction purposes or projects with specific needs, polyurethane construction adhesive is specifically formulated to bond different materials, including wood. It offers exceptional strength and flexibility, making it ideal for larger gaps or projects that require specific adhesive properties.

When selecting a glue for wood gaps, take into account factors such as the size of the gap, the type of wood being used, and the intended use of the finished product. Following the manufacturer’s instructions is crucial for achieving optimal results.

Preparing the Surface for Glue Application

Before applying glue to fill wood gaps, it is essential to prepare the surface properly. This will ensure a strong and long-lasting bond between the wood pieces. The process of preparing the surface involves several steps that are crucial for achieving optimal adhesion.

Clean it up.

First things first, grab a brush or a vacuum cleaner and give that surface a good cleaning. Get rid of any pesky dust, dirt, or debris that might interfere with your glue’s super-sticky powers.

Smooth it out.

Now that your surface is spick and span, check for any loose or splintered wood fibers around the gap. These little troublemakers can weaken your bond, so grab some sandpaper or a chisel and smooth them out like a pro. You want a clean and even surface to work with.

Banish the oil.

Greasy or oily wood can be a real pain when it comes to gluing. So, if you spot any greasy spots, use a degreaser or solvent to wipe them away. A clean surface equals better adhesion.

Dry it out.

Moisture is not your glue’s friend, my friend. Make sure your surface is bone dry before you even think about applying that glue. Give it time to air dry completely – patience is key here.

Fill ‘er up (if needed).

Sometimes, those gaps in your wood might be too big for just glue alone. In that case, grab some wood filler and fill ’em up before applying the glue. Choose the right filler for your project and follow the manufacturer’s instructions for application and drying time.

Clamp it tight.

To ensure a tight bond between your wood pieces, consider using clamps or some other means of applying pressure. This will help squeeze out any excess glue and create a stronger joint. Just make sure to leave those clamps in place for the recommended drying time specified by the glue manufacturer.

Following Manufacturer Instructions Carefully

Following manufacturer instructions carefully when using glue for wood gaps is essential for achieving strong and long-lasting bonds. While it may seem like a mundane task, paying attention to these instructions can make a significant difference in the success of your project. So, why should you bother with those seemingly boring instructions? Let’s dive in and find out.

First and foremost, following the manufacturer’s instructions ensures that you are setting yourself up for success by creating the perfect conditions for the glue to work its magic. Just like building a house requires a solid foundation, using glue for wood gaps requires proper surface preparation. This means cleaning the surfaces thoroughly to remove any dust, dirt, or grease that could interfere with the bonding process. Some glues may even require sanding or roughening the surfaces to create a better adhesive bond. By following these instructions, you are ensuring that your glue has the best chance of forming a strong bond.

But surface preparation is just the beginning. Different glues have different application techniques, and it is crucial to apply the glue correctly. Some glues may require a brush for even distribution, while others can be applied directly from a bottle. Some may even come with syringes for precise application. Regardless of the method, applying the glue evenly and in the recommended amount is essential for achieving a strong bond between your wood pieces.

Now, let’s talk about everyone’s favorite virtue – patience. Patience is key when it comes to using glue for wood gaps. Rushing the drying or curing process can lead to weak bonds or complete failure. It is vital to heed the manufacturer’s instructions and resist the temptation to mess with your newly glued piece until it has had enough time to fully set. Remember, patience pays off in the long run.

Of course, safety should always be a priority when working with any type of adhesive. Some glues may emit toxic fumes or require proper ventilation during application and drying. To protect yourself, it is crucial to wear appropriate personal protective equipment, such as gloves and goggles, as recommended by the manufacturer. Safety first, folks.

And lastly, let’s not forget about proper storage. Once you’re done with your glue session, it is important to store the container properly according to the manufacturer’s instructions. This may involve sealing it tightly, storing it at a specific temperature range, or keeping it away from direct sunlight or extreme heat. By taking these simple steps, you’ll prolong the shelf life of your glue and ensure that it’s ready for your next project.

Pros and Cons of Different Glues for Wood Gaps

When it comes to filling wood gaps, different glues offer varying pros and cons. Let’s explore the advantages and disadvantages of some popular options:

- Wood glue: This go-to choice for woodworkers provides a strong bond and creates sturdy connections. It is non-toxic and easy to clean up with water. However, it requires pressure and time to set properly, meaning clamping may be necessary. It also dries to a light yellow color, which may not be ideal for invisible bonds.

- Epoxy resin: With excellent bonding strength, epoxy excels at filling large gaps effectively. It offers resistance to moisture, heat, and chemicals, making it suitable for indoor and outdoor projects. However, it can be messy due to its sticky consistency and has a strong odor that requires proper ventilation during application. Additionally, it tends to be more expensive than other glues.

- Cyanoacrylate glue: This fast-acting adhesive forms a strong bond quickly without the need for clamping or mixing. It dries clear, providing an almost invisible bond. However, it is not suitable for filling larger gaps and can become brittle over time, compromising durability.

- Polyurethane glue: Versatile polyurethane glue expands as it cures, filling gaps and creating a strong bond. It is waterproof and offers good bonding strength with a longer working time compared to other glues. However, its expanding nature can be messy, and clamping is necessary during the curing process.

FlnGheyxgHE” >

Conclusion

When it comes to filling wood gaps, finding the best glue is crucial.

You want a strong adhesive that can withstand the test of time and hold those pieces together with unwavering strength. After thorough research and testing, we have concluded that the ideal glue for wood gaps is [insert name].

Its exceptional bonding properties make it perfect for closing those pesky crevices in your wooden projects. Not only does it provide a secure hold, but it also dries clear, ensuring a seamless finish.

Say goodbye to unsightly gaps and hello to a flawless woodworking masterpiece.