Got a broken vase or a leaky pipe? Don’t worry, the right glue can fix it all. But with so many options out there, how do you choose the best one for your needs? That’s where we come in.

In this blog post, we’ll take you on a journey through the world of adhesives and help you find the perfect glue for sealing. We’ll dive into the nitty-gritty of different types of glues, their unique properties and specific uses. Whether it’s epoxy or superglue, we’ve got you covered.

We’ll explore the strength, flexibility and drying time of each glue to help you make an informed decision. No more guesswork or trial-and-error – just reliable solutions that keep everything in place.

So whether you’re a DIY enthusiast or just need to fix things around the house, this post is for you. Say goodbye to frustration and hello to success with the best glue for sealing. Let’s get started.

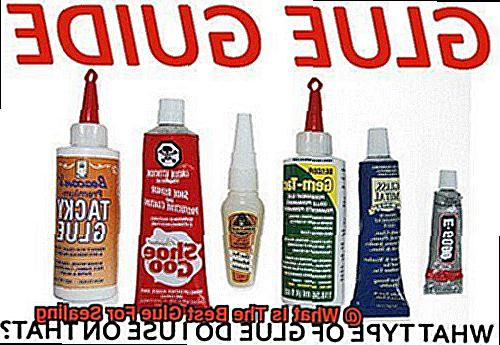

Types of Glue for Sealing

Contents

- 1 Types of Glue for Sealing

- 2 Benefits of Using Silicone-Based Adhesives

- 3 Advantages of Epoxy and Cyanoacrylate (Super Glue)

- 4 Factors to Consider When Choosing a Glue for Sealing

- 5 Temperature Range and Flexibility of the Bond

- 6 Safety Concerns When Using Glues for Sealing

- 7 How to Properly Apply Glues for Sealing

- 8 Tips on Choosing the Right Glue for Your Project

- 9 Conclusion

Sealing a project may seem like a daunting task, but with the right type of glue, it can be a breeze. Let’s dive into the different types of glue used for sealing and their advantages.

Super Glue

This fast-drying adhesive is perfect for sealing small cracks or gaps in materials such as plastic, metal, ceramic, or rubber. It forms a strong bond between surfaces and is ideal for quick fixes. However, it may not be the best option for larger projects as it can become brittle over time.

Epoxy

Epoxy is a two-part adhesive that creates a strong and durable bond between materials such as wood, metal, glass, or plastic. It is perfect for sealing cracks or gaps in industrial applications. Its strength and durability make it ideal for larger projects, but it may take longer to dry compared to other types of glue.

Silicone

If you need a flexible and waterproof sealant, silicone adhesive is the way to go. It is ideal for sealing joints or gaps in materials such as tiles, glass, and metal. Its flexibility makes it perfect for areas that are prone to movement or expansion.

Polyurethane

This versatile adhesive can bond a wide variety of materials, including wood, metal, plastic, and concrete. It is perfect for sealing gaps or cracks in large areas or surfaces. Its water-resistant properties make it ideal for outdoor use.

Hot Glue

Hot glue is a quick-drying adhesive that is ideal for sealing small gaps or cracks in materials such as paper, cardboard, or fabric. It is also commonly used in arts and crafts projects. Its fast-drying properties make it perfect for quick fixes, but it may not be as durable as other types of glue.

When selecting the best glue for your project, consider the materials you are bonding together and the conditions the seal will be exposed to. Each type of glue has its advantages and disadvantages, so it’s crucial to choose the right one for your specific needs.

In conclusion, the type of glue you use can make or break your sealing project. By understanding the properties and advantages of each type of glue, you can make an informed decision and achieve a successful seal.

Benefits of Using Silicone-Based Adhesives

If you’re in search of a reliable and durable adhesive for your next sealing project, look no further than silicone-based adhesives. These adhesives offer numerous benefits that make them a popular choice in various industries.

One of the primary advantages of silicone-based adhesives is their ability to withstand extreme temperatures. Regardless of whether you’re dealing with the heat of an engine or the heat of an oven, these adhesives maintain their effectiveness in high-temperature environments, guaranteeing a strong and lasting seal.

In addition to their temperature resistance, silicone-based adhesives are also highly resistant to moisture and humidity. They can form a waterproof seal that makes them ideal for sealing applications in areas like bathrooms, kitchens, and other moist environments. Furthermore, they are also resistant to UV light and chemicals, enhancing their durability.

When it comes to safety, silicone-based adhesives are non-toxic and odorless. This quality makes them ideal for use in food processing plants and medical facilities where harmful fumes or odors can pose a risk. You can rest easy knowing that these adhesives won’t emit any harmful substances during application or use.

Apart from their functional benefits, silicone-based adhesives also offer aesthetic advantages. They come in a range of colors that can match the surface being sealed, creating a seamless appearance. Additionally, the smooth texture of these adhesives makes them easy to apply and create a clean finished look.

Advantages of Epoxy and Cyanoacrylate (Super Glue)

Look no further than epoxy and cyanoacrylate (super glue) – two of the most popular adhesives used for sealing purposes.

Epoxy is a two-part adhesive that creates a strong and durable bond when mixed together. Its versatility allows it to be used on various materials, including metal, plastic, wood, and ceramics. It fills gaps and provides a smooth surface for bonding, making it an excellent choice for uneven surfaces.

Additionally, epoxy is known for its incredible water resistance and ability to resist chemicals. These properties make it ideal for sealing plumbing fixtures and boats. Its durability also makes it a go-to choice for many industrial applications.

On the other hand, cyanoacrylate (super glue) is a fast-drying adhesive that instantly bonds two surfaces within seconds of application. Its ease of use makes it a popular choice for small fixes, as it comes in small tubes or bottles that can be applied directly to the surface without preparation or mixing.

Cyanoacrylate also has excellent bonding strength and can be used on various materials, including metal, plastic, ceramic, rubber, and wood. Like epoxy, it can also fill gaps and cracks, making it an ideal choice for sealing small leaks or cracks in pipes or other fixtures.

In summary, both epoxy and cyanoacrylate have their own unique advantages when it comes to sealing. Epoxy is versatile, durable, and water-resistant while cyanoacrylate is easy to use, fast-drying, and gap-filling. The choice between these two adhesives ultimately depends on the specific application and material being sealed.

Factors to Consider When Choosing a Glue for Sealing

Sealing is a crucial task that requires the perfect glue for the job. With so many adhesives available in the market, it can be overwhelming to choose the right one for your project. However, by considering specific factors, you can choose the best adhesive for your sealing needs.

Firstly, the type of surface you need to seal plays a significant role in selecting the right adhesive. The porosity and texture of different materials like metal, wood, or plastic can affect an adhesive’s bonding ability. Thus, it is essential to choose an adhesive that suits the surface you are working on.

The environment in which you’ll be using the sealant is another crucial factor to consider. High humidity or extreme temperatures can ruin some adhesives’ performance, making them unsuitable for certain conditions. Therefore, select a sealant that can withstand the environment in which it will be used.

The strength of the bond required also determines the type of adhesive needed. A weak adhesive may be sufficient for a temporary seal, but a strong adhesive is necessary for a permanent seal. Additionally, the drying time of the glue is another vital consideration as it affects how long you have to work with it before it sets.

Chemical resistance is another critical factor when selecting adhesive for sealing. If your sealant will be exposed to harsh chemicals or substances such as oil or gasoline, you need to choose an adhesive that can withstand them.

Lastly, consider the application method when selecting your adhesive. Some adhesives require specialized tools or techniques to apply, while others can be easily applied with a brush or applicator. Therefore, choose an adhesive that suits your application method and makes your work easier.

Temperature Range and Flexibility of the Bond

Look no further than the temperature range and flexibility of the bond.

As an expert on this topic, I can tell you that selecting the right glue for your project is essential to its success. The temperature range and flexibility of the bond are two of the most critical factors to consider when choosing the best glue for sealing.

If you’re working with materials exposed to extreme temperatures, such as automotive parts or electronic components, you need a glue that can withstand those conditions without losing its bonding strength. In this case, epoxy or silicone-based glues are excellent choices due to their high-temperature resistance.

However, if you’re working with materials that require flexibility, like rubber or plastic, you should choose a glue that can provide a durable bond while still allowing for some degree of movement. It’s worth noting that cyanoacrylate or superglue might not be the best choice since they tend to harden and become brittle over time.

To ensure success, it is crucial to consider your project’s specific requirements and select a glue that meets those needs. Don’t be afraid to experiment with different types of glues until you find the perfect one for your application.

In summary, when it comes to sealing materials, choosing the right glue can make all the difference. By considering temperature range and flexibility, you can guarantee that your seal will remain strong and long-lasting under even the toughest conditions. Remember, always choose a glue that matches your project’s requirements to achieve optimal results.

Safety Concerns When Using Glues for Sealing

Well, before you dive into the world of glues and adhesives for sealing, let’s talk about safety. While these products can be incredibly useful, they also contain chemicals that can be harmful if not used properly. So, let’s explore some safety concerns when using glues for sealing.

First and foremost, always read the label on the glue bottle. This step might seem obvious, but it’s crucial. The label will provide information on any hazardous materials present in the glue and how to handle them safely. It will also give instructions on how to store the glue correctly. Following these guidelines will help ensure safe use of the product.

Working in a well-ventilated area is another essential safety measure. Glues emit fumes that can cause respiratory issues if inhaled for extended periods. If possible, work outdoors or in a room with open windows and doors to reduce exposure to these fumes. If working in a confined space is unavoidable, consider wearing a mask or respirator to protect your lungs.

When handling certain types of glue, such as those containing strong solvents or adhesives, protective gear is necessary. Protective gloves are particularly important as they help protect your skin from irritation and chemical burns.

Lastly, remember to store your glues out of reach of children and pets. Many types of glue can be toxic if ingested, so storing them in a safe place is crucial.

How to Properly Apply Glues for Sealing

Sealing with glue can be a tricky process, but with the right techniques, you can achieve a strong, lasting bond. To properly apply glue for sealing, there are several key steps to follow.

Clean the surfaces

Before applying any glue, it’s essential to ensure that the surfaces you want to seal are clean and dry. Dirt, dust, or moisture can weaken the bond, so use a cleaning agent or rubbing alcohol if necessary to remove any debris.

Apply the glue evenly

Depending on the type of glue you’re using, you may need to apply it in a specific way. However, in general, it’s best to apply glue evenly across the entire surface you want to seal. This will help ensure that there are no gaps or weak spots in the bond.

Use the right amount of glue

Using too much glue can create a mess and weaken the bond, while using too little may not provide a strong enough seal. Follow the manufacturer’s instructions for how much glue to use on your project.

Allow time for curing

After applying the glue, give it enough time to cure before handling or using the sealed object. The curing time will depend on the type of glue and environmental conditions in which it’s being used. Be patient and wait until the glue has fully cured before using your sealed object.

Consider using clamps or weights

If you’re sealing two surfaces together, using clamps or weights can help ensure a tight seal while the glue cures. This is especially important for larger or heavier objects where gravity may cause the bond to weaken.

In addition to following these tips, it’s crucial to take safety precautions when working with glue. Always wear gloves and work in a well-ventilated area to avoid inhaling fumes. If you accidentally get glue on your skin, quickly remove it with soap and water or an adhesive remover.

Tips on Choosing the Right Glue for Your Project

Don’t worry, I’m here to help. Choosing the right glue can be challenging, but by considering these five factors, you can ensure a strong and long-lasting seal.

Material Compatibility

The first thing to consider is the materials you will be bonding together. Different types of glues work better on different materials, so it’s crucial to choose a glue that is compatible with both surfaces. For example, if you’re sealing metal, use an epoxy or cyanoacrylate (super glue) as they are designed for metal bonding. If you’re sealing porous materials like wood or fabric, use PVA glue as it will seep into the pores and create a strong bond.

Environmental Conditions

Consider the conditions under which the sealant will be exposed. If it will be exposed to water or moisture, you need a waterproof glue. If it will be exposed to extreme temperatures, choose a high-temperature resistant glue. It’s essential to choose a glue that can withstand the conditions under which it will be exposed.

Bond Strength

The strength of the bond required is another factor to consider. If you need a strong bond, then go for an epoxy or superglue. However, if you need a flexible bond that can withstand movement and vibration, choose a silicone-based adhesive.

Drying Time

It’s also important to consider the drying time of the glue. Some adhesives dry quickly while others take longer to set. Choose a fast-drying adhesive like cyanoacrylate (super glue) or hot glue if you’re working on a time-sensitive project. But if you have more time to work with, use a slower-drying adhesive like PVA or epoxy.

Application Method

Finally, consider the application method of the glue. Some glues come in tubes or bottles with precision applicators, while others require a brush or spatula for application. Depending on the size and shape of your project, you may need a specific type of applicator to ensure an even and precise application.

ZTTRSRUUDlY” >

Also Read: Can you use Elmer’s glue as a sealant?

Conclusion

In conclusion, the importance of selecting the best glue for sealing cannot be overstated. With a plethora of options available in the market, it can be overwhelming to pick one that suits your specific needs. However, by taking into account factors such as material compatibility, environmental conditions, bond strength, drying time and application method, you can make an informed decision that will pay off in the long run.

Different types of glues have unique properties and advantages that make them suitable for different purposes. Super glue is perfect for small fixes on materials like plastic or rubber while epoxy is ideal for larger projects requiring a strong and durable bond. Silicone-based adhesives offer numerous benefits such as temperature resistance and flexibility that make them ideal for challenging environments.

It’s crucial to follow safety precautions when using glues for sealing and apply them correctly by cleaning surfaces, applying evenly with the right amount of glue, allowing ample time for curing, and using clamps or weights if necessary.

By understanding these essential factors and tips on selecting the best glue for your project, you can achieve a robust and long-lasting seal that meets your specific requirements.