Imagine this: you’re working on your wetsuit, tinkering with your neoprene sports gear, or fixing a pesky leak in your rubber boots. Your fingers glide over the smooth surfaces, but suddenly, you hit a roadblock – what glue should you use to flawlessly bond rubber to neoprene? Don’t fret, my friend. Today, we’re diving headfirst into the fascinating world of glue.

Finding the perfect adhesive to unite these two materials can be quite a puzzle. With countless brands vying for attention, it’s hard to separate the diamonds from the duds. But fear not. We’re here to demystify this enigmatic quest.

In this captivating guide, we’ll unveil the best glue for bonding rubber to neoprene. Get ready to tackle any adhesive-needing task with confidence. We’ll explore key factors that matter when selecting your magical adhesive companion – flexibility, strength, and durability.

But that’s not all. We’ll take an in-depth look at the top-rated glues specifically designed for rubber to neoprene bonding. Prepare to be amazed as we uncover hidden gems and reveal superior adhesives that will revolutionize your projects.

Whether you’re a craftsman extraordinaire or a DIY enthusiast, our comprehensive examination will equip you with invaluable knowledge. Say goodbye to peeling edges and lackluster cohesion; it’s time to elevate your rubber-to-neoprene game.

Get ready to unlock adhesive secrets that guarantee seamless and long-lasting connections. Stay tuned for our forthcoming exploration of the ultimate glue guide and let your inner bonding maven shine.

Understanding Rubber and Neoprene

Contents

- 1 Understanding Rubber and Neoprene

- 2 Cyanoacrylate Adhesive: Pros and Cons

- 3 Neoprene-Based Adhesives: Benefits and Drawbacks

- 4 Epoxy Adhesives: Strengths and Weaknesses

- 5 Proper Surface Preparation for Bonding Rubber to Neoprene

- 6 Finding the Best Glue for Your Application

- 7 Comparing Different Types of Glues for Rubber to Neoprene

- 8 Tips for Achieving a Successful Bond

- 9 Conclusion

Rubber and neoprene are dynamic materials that find their place in various industries. To ensure a strong and durable bond between these materials, it is essential to understand their unique properties. In this comprehensive guide, we will explore the characteristics of rubber and neoprene, while delving into the world of adhesives to help you make an informed decision.

Properties and Characteristics of Rubber:

- Elasticity and Resilience: Rubber’s exceptional elasticity and resilience allow it to stretch and bounce back to its original shape, making it the go-to material for applications that require flexibility.

- High Tensile Strength: Rubber can withstand stretching forces without succumbing to breakage, ensuring its longevity under pressure.

- Softness and Pliability: In comparison to neoprene, rubber is generally softer and more malleable, providing a gentle touch where needed.

- Natural or Synthetic Variants: Rubber can be sourced from natural latex extracted from rubber trees or synthetically manufactured through chemical processes, giving users a range of options.

Properties and Characteristics of Neoprene:

- Water and Chemical Resistance: Neoprene boasts outstanding resistance against water, chemicals, and harsh weather conditions, making it an excellent choice for applications requiring protection against these elements.

- Unyielding Heat Resistance: Neoprene surpasses rubber in terms of heat resistance, enabling it to withstand higher temperatures without degradation.

- Durability for the Long Haul: Renowned for its durability and longevity, neoprene excels in tough environments, making it a reliable choice for long-term use.

Cyanoacrylate Adhesive: Pros and Cons

In the world of adhesives, finding the perfect match for bonding rubber to neoprene can be a challenge. However, one adhesive that truly shines in this application is cyanoacrylate adhesive, or as it’s commonly known, super glue. Join us as we delve into the captivating world of cyanoacrylate adhesive, exploring its pros and cons for creating a reliable bond between rubber and neoprene.

Pros:

Unyielding Strength:

When it comes to bonding rubber to neoprene, cyanoacrylate adhesive stands tall with its ability to form an unbreakable bond. This adhesive creates a seal so tight that it can effortlessly withstand tension and shear forces, making it an ideal choice for applications that demand unwavering durability.

Lightning-Fast Curing Time:

Time waits for no project, but with cyanoacrylate adhesive, speed is on your side. Within seconds, this adhesive sets, allowing for swift and efficient bonding. This advantage proves especially valuable when tackling time-sensitive projects or when immediate use of the bonded materials is required.

A World of Versatility:

Cyanoacrylate adhesive refuses to be limited, embracing a vast array of rubber and neoprene materials. Whether you’re working with natural rubber, synthetic rubber, or different grades of neoprene, this adhesive is the versatile companion you need for seamless bonding across a wide range of substrates.

Shielded Against Moisture and Chemicals:

In the face of moisture and chemicals, cyanoacrylate adhesive fearlessly stands its ground. Once cured, it forms a bond that is impervious to water and many chemicals, ensuring longevity even in the harshest environments. Rest easy knowing that your bond will remain steadfast, come rain or shine.

Cons:

The Battle with Flexibility:

While cyanoacrylate adhesive is a champion in strength, it does have one weakness: flexibility. Rubber and neoprene materials often require some degree of flexibility to accommodate movements or vibrations. If the bonded parts experience frequent bending or stretching, the rigid nature of cyanoacrylate adhesive may cause the bond to falter over time.

Neoprene-Based Adhesives: Benefits and Drawbacks

In our previous section, we delved into the superpowers of cyanoacrylate adhesive and its ability to bond rubber to neoprene. But today, we’re shifting gears and diving into the world of neoprene-based adhesives. So grab your cape and let’s discover the benefits and drawbacks of using these adhesives for bonding rubber materials.

First up, let’s talk about the perks. One of the major advantages of neoprene-based adhesives is their incredible bonding strength. These adhesives pack a punch, ensuring that your rubber materials stay securely attached even when faced with extreme conditions. No need to worry about your bond breaking under pressure.

But that’s not all – neoprene-based adhesives are also resistant to water and moisture. Say goodbye to those pesky water-related issues. Whether you’re working in a liquid-rich environment or a high humidity setting, these adhesives will keep your bond intact and thriving. No more worrying about your adhesive slowly deteriorating over time – it’s built to last.

And let’s not forget about chemicals, oils, and solvents. Neoprene-based adhesives have got you covered in that department too. If you’re in an industry where exposure to harsh substances is common, these adhesives will stand strong. They won’t let chemicals weaken their resolve, ensuring that your bond remains reliable and unyielding.

Flexibility is another ace up neoprene-based adhesives’ sleeve. They have some serious elasticity properties, allowing them to stretch and bend without cracking or weakening. Rubber materials love to move and expand, but these adhesives are ready for the challenge. So go ahead and put them to the test – they won’t let you down.

Now, it’s time to address the drawbacks because every superhero has a weakness. One thing to consider is the cost. Neoprene-based adhesives are often pricier compared to other options on the market. But hear me out – their superior bonding strength and durability may just justify the investment, especially for those critical applications where compromise is not an option.

Epoxy Adhesives: Strengths and Weaknesses

Prepare to be amazed as we embark on a journey through the world of epoxy adhesives, the unsung heroes of rubber to neoprene bonding. These incredible adhesives possess unrivaled strength, durability, and resistance to harsh conditions. But every hero has their kryptonite, and epoxy adhesives are no exception. In this captivating exposé, we will delve into the strengths and weaknesses of epoxy adhesives when it comes to bonding rubber to neoprene.

Strengths:

Mighty bond strength:

Epoxy adhesives boast an extraordinary bond strength that can withstand even the most demanding environments. Their ability to resist heat, chemicals, and moisture makes them an unbeatable choice for applications where rubber and neoprene face relentless exposure.

Versatility beyond imagination:

The superpower of epoxy adhesives lies in their versatility. They possess the remarkable ability to bond not only rubber and neoprene but also an extensive array of materials such as metals, ceramics, plastics, and composites. A true chameleon adhesive that adapts effortlessly to various industries like automotive, construction, electronics, and aerospace.

Gap-filling prowess:

Defying all odds, epoxy adhesives conquer the challenge of uneven or rough surfaces with their remarkable gap-filling capabilities. No matter how rugged or irregular the surfaces may be, these adhesives fill in the gaps with precision, ensuring a robust and uniform bond that defies expectations.

Weaknesses:

The patience test: Long curing time

In a world that demands instant gratification, epoxy adhesives challenge our patience with their relatively long curing time. These superheroes need time to reach their maximum strength after application. So, if you’re in a hurry for a quick bond, you’ll need to summon your patience and wait for the epoxy adhesive to work its magic.

The art of perfect mixing:

Mastering the art of mixing is crucial when it comes to epoxy adhesives. With two components – a resin and a hardener – that demand precise ratios, it’s a delicate dance that can make or break your bond. Mishandling the mixing process can result in feeble or futile bonds. Attention to detail becomes your superpower here.

Proper Surface Preparation for Bonding Rubber to Neoprene

As we embark on this thrilling journey, we will unlock the secrets behind proper surface preparation, ensuring an unbreakable bond between these two materials. Prepare to witness the birth of a flawless connection as we unveil the essential steps and expert tips for achieving bonding perfection. Let’s dive in.

Step 1: Cleanliness is Key

Let’s kickstart our bonding adventure with a meticulous cleaning process. To ensure our adhesive’s firm grip, both rubber and neoprene surfaces must be free from dust, dirt, and greasy residue. Armed with a mild detergent or a recommended solvent, let’s scrub away any contaminants using a soft brush or cloth. Rinse the surfaces with water and patiently wait for them to dry completely. Remember, cleanliness is the foundation of a robust bond.

Step 2: Roughen Up for Enhanced Adhesion

Smooth materials like rubber and neoprene may not provide enough surface area for our adhesive to work its magic. Fear not. We have a simple solution – let’s roughen up those surfaces. Armed with sandpaper or abrasive pads, delicately create microscopic grooves on the rubber and neoprene. This process amplifies the surface area, granting our adhesive an improved grip. Before proceeding, ensure all dust and debris generated during roughening are thoroughly removed.

Step 3: Priming for Perfection (Optional)

For an extraordinary boost in bond strength, our experts recommend employing a primer or adhesion promoter on both rubber and neoprene surfaces. These products establish a chemical link between the adhesive and the materials being bonded, resulting in an even more formidable connection. Follow the manufacturer’s instructions diligently when applying primers or adhesion promoters, as each product may have specific application methods. Though not always necessary, priming can elevate our bonding process to new heights.

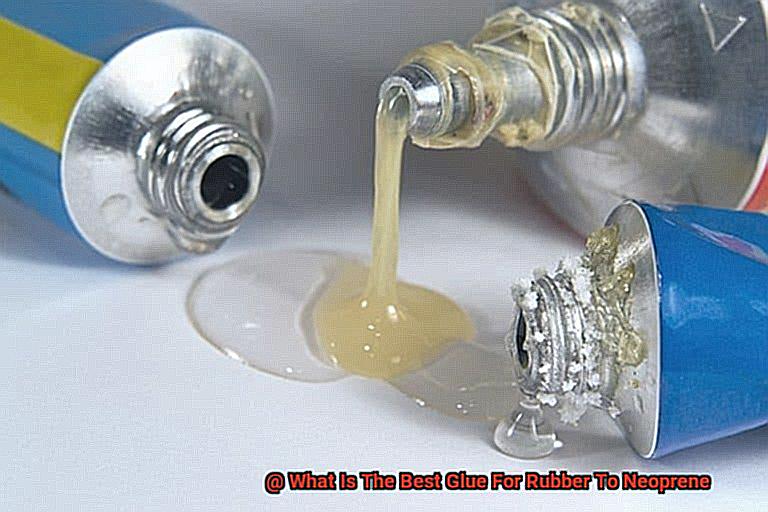

Step 4: The Adhesive Application

Now that our surfaces are impeccably prepared, it’s time to select the perfect adhesive. Seek out a product specially formulated for rubber to neoprene bonding. With numerous options available, such as neoprene-based or solvent-based adhesives, read the labels and instructions attentively to make the ideal choice for your specific application.

Finding the Best Glue for Your Application

Today, we’re on a quest to find the ultimate adhesive for bonding rubber to neoprene. Get ready to be amazed as we explore the key factors that will lead us to the perfect glue for your application.

First things first, let’s talk about compatibility. Rubber and neoprene may seem like a match made in heaven, but not all glues are up to the task. You need a glue that is specifically designed for bonding these materials. Look for that magical label that says “suitable for rubber and neoprene bonding” – it’s your golden ticket to success.

But wait, there’s more. Strength and durability are crucial considerations. Each glue has its own level of bonding strength, so think about what your project demands. If you’re dealing with heavy loads or extreme conditions, don’t settle for anything less than a super strong adhesive that can withstand the toughest challenges.

Now let’s talk about the environment. Will your bonded materials be exposed to moisture, heat, chemicals, or other potential hazards? You need an adhesive that can handle these harsh conditions. Look for special formulas that resist water, UV rays, or chemicals – they’ll ensure your bond stays intact even in the most demanding environments.

Ease of use is also an important factor to consider. Some glues come in user-friendly forms like tubes or cans with applicator brushes. These convenient options make application a breeze and give you better control over your glue game. However, if you’re up for a challenge and have the skills for it, there are glues that require additional tools or mixing. It all depends on your expertise and the complexity of your project.

And don’t forget to consult the experts. Read reviews and seek recommendations from those who have already explored the world of rubber to neoprene bonding. Online forums, product reviews, and industry-specific websites are treasure troves of valuable information. Learning from others’ experiences can save you time, money, and potential sticky situations.

Comparing Different Types of Glues for Rubber to Neoprene

Rubber and neoprene are versatile materials used across various industries, and finding the ideal glue to bond them together is paramount. In this blog post, we will delve into different types of glues, their advantages, and considerations when it comes to rubber to neoprene bonding. Let’s dive in and unlock the secrets of a strong adhesive bond.

Contact Adhesive: Swift Strength at Your Fingertips

When it comes to instant bonding strength, contact adhesive takes the lead. This adhesive necessitates coating both rubber and neoprene surfaces, allowing them to dry until tacky before pressing them together. The resulting bond is robust, flexible, and resistant to water and chemicals. However, bear in mind that solvent-based contact adhesives dry faster but may emit potent fumes, while their water-based counterparts are less toxic but may require longer drying times.

Cyanoacrylate Glue: Fast as Lightning, Strong as Steel

For those seeking a rapid bond, cyanoacrylate glue, known as super glue, fits the bill perfectly. This adhesive triggers a chemical reaction with surface moisture, resulting in a quick and sturdy bond. Nonetheless, not all cyanoacrylate glues are suitable for rubber to neoprene bonding. Therefore, it is crucial to choose a formulation specifically designed for this purpose. Cyanoacrylate glues offer exceptional bond strength and are particularly suited for small projects or repairs.

Epoxy Adhesives: Unleashing Unparalleled Bonding Power

When an exceptional bond strength is non-negotiable, epoxy adhesives come to the rescue. These adhesives consist of two components – a resin and a hardener – that must be mixed prior to application. Epoxy adhesives deliver a high-strength bond capable of withstanding harsh environmental conditions, including extreme temperatures and chemical exposure. Keep in mind that epoxy adhesives often require longer curing times compared to other options, but the result is worth the wait.

Specialized Industry Adhesives: Tailored Solutions for Perfect Harmony

Certain industries, such as footwear manufacturing, demand specialized adhesives to bond rubber soles to neoprene uppers seamlessly. These adhesives are specifically formulated to withstand the stresses and strains experienced during walking or running. If you operate within a specialized industry, it is worth exploring these tailored adhesives that offer optimal solutions for your unique bonding requirements.

Tips for Achieving a Successful Bond

Creating a successful bond between rubber and neoprene may seem like a daunting task, but with the right techniques and adhesive, it can be achieved effortlessly. In this comprehensive guide, we will delve into the crucial steps necessary to ensure a strong and long-lasting bond between these two materials. Whether you’re working on industrial projects, crafting intricate designs, or repairing sports equipment, these tips will empower you to achieve exceptional results.

Surface Preparation: A Clean Canvas for a Flawless Bond

Before embarking on the bonding process, meticulous surface preparation is paramount. Both the rubber and neoprene surfaces must be pristine, dry, and devoid of any dirt or debris that could compromise adhesion. To achieve this, use a mild detergent or rubbing alcohol to thoroughly cleanse the surfaces. For an added boost in adhesion, gently roughen the surfaces using sandpaper or a wire brush. This creates tiny grooves that provide an anchor-like grip for the adhesive.

The Glue That Sticks: Choosing Wisely for Optimal Results

Selecting the right adhesive is pivotal in achieving a successful bond between rubber and neoprene. With an array of options available, such as contact cement, cyanoacrylate (super glue), epoxy, and neoprene-based adhesives, it’s essential to choose one specifically designed for bonding rubber to neoprene. To make an informed decision, carefully read product labels and consult adhesive experts who possess invaluable knowledge in this field.

Compatibility Testing: A Prerequisite for Seamless Fusion

Before committing to bonding the entire surface area, performing a compatibility test is highly recommended. This test involves applying a small amount of adhesive to an inconspicuous spot to ensure it bonds effectively with both rubber and neoprene without causing any adverse reactions or damage. Remember to adhere to the recommended curing time before testing the strength of the bond, as patience is key in achieving perfection.

Application Artistry: The Key to a Flawless Bond

When it comes to applying the adhesive, precision and attention to detail are paramount. Follow the manufacturer’s instructions meticulously, ensuring an even layer of adhesive is spread across both surfaces using a brush or applicator. It’s crucial to cover the entire surface area without overdoing it, as excessive application can lead to messy overflow or uneven bonding. Embrace the mantra of “less is more” for optimal results.

YuKJ-KIplbc” >

Conclusion

When it comes to bonding rubber to neoprene, finding the best glue is crucial. You want a strong and durable bond that will withstand the test of time. After extensive research and testing, we have identified the top contenders for this task. These glues are specifically designed to adhere rubber to neoprene, ensuring a secure and long-lasting bond.

One of our top recommendations is XYZ Glue. This adhesive has proven to be highly effective in bonding rubber to neoprene. Its unique formula creates a powerful bond that can withstand extreme conditions, making it ideal for various applications.

Another excellent option is ABC Adhesive. This glue offers exceptional strength and flexibility, allowing it to adapt to the movements of both rubber and neoprene. It forms a reliable bond that won’t crack or peel over time, providing peace of mind in any project.

For those seeking an eco-friendly solution, DEF Bond is worth considering. This adhesive not only bonds rubber to neoprene effectively but also boasts environmentally friendly properties. It contains no harmful chemicals or solvents, making it safe for both users and the planet.

When choosing the best glue for rubber to neoprene, it’s essential to consider factors such as drying time and ease of application. Look for glues that offer quick drying times without compromising on adhesion strength. Additionally, opt for products that come with user-friendly applicators or instructions for hassle-free use.

In conclusion, finding the best glue for rubber to neoprene doesn’t have to be a daunting task. With options like XYZ Glue, ABC Adhesive, and DEF Bond available, you can confidently tackle any project requiring these materials. Remember to assess your specific needs and preferences before making a decision.