Are you tired of searching high and low for the perfect glue to bond plastic nylon?

Well, your search ends here. We’ve dug deep into the world of adhesives to bring you the ultimate solution.

And trust us, when it comes to bonding plastic nylon, there’s one glue that reigns supreme – epoxy. This adhesive powerhouse is a game-changer, offering unrivaled strength, chemical resistance, and durability.

So buckle up and get ready to discover the wonders of epoxy adhesive – your nylon projects will never be the same again.

What is Nylon and How is it Used?

Contents

Step into the fascinating realm of nylon, a synthetic polymer that burst onto the scene in the 1930s and forever changed industries across the globe. In this article, we will delve into the multifaceted uses of nylon and uncover its remarkable significance in different applications. Brace yourself for a journey that spans the realms of fashion, manufacturing, automotive engineering, consumer goods, and even 3D printing.

Fashion Forward:

Nylon’s impact on the textile industry cannot be overstated. It is the fabric behind iconic stockings, swimwear that hugs curves flawlessly, and sportswear that endures intense workouts. With its exceptional strength and resistance to wear and tear, nylon stands tall as a reliable choice for products subjected to frequent use or stress.

Mighty Manufacturing:

But wait, there’s more. Nylon’s versatility stretches far beyond textiles. In the manufacturing sector, it reigns supreme in creating mechanical marvels like gears and bearings. Its low friction coefficient ensures smooth operation while its high heat resistance guarantees durability in demanding applications.

The Automotive Enigma:

The automotive industry owes much of its success to nylon’s extraordinary properties. From fuel lines that resist chemicals to airbags that safeguard lives, nylon plays a vital role in ensuring safety and reliability. Its high melting point allows it to withstand extreme conditions, making it an indispensable material for hoses, belts, and other critical components.

Everyday Heroes:

Nylon’s flexibility, durability, and moisture resistance have elevated it to superhero status in the realm of everyday items. Toothbrushes that scrub away plaque with gusto? Made of nylon. Hairbrushes that glide seamlessly through tangles? Nylon strikes again. Even zippers owe their hassle-free operation to this incredible material.

3D Printing Wonders:

As technology leaps forward, so does nylon. In recent years, it has become a favored filament for 3D printing. With its high strength and the ability to produce intricate designs, nylon takes additive manufacturing to new heights.

What is the Best Glue for Plastic Nylon?

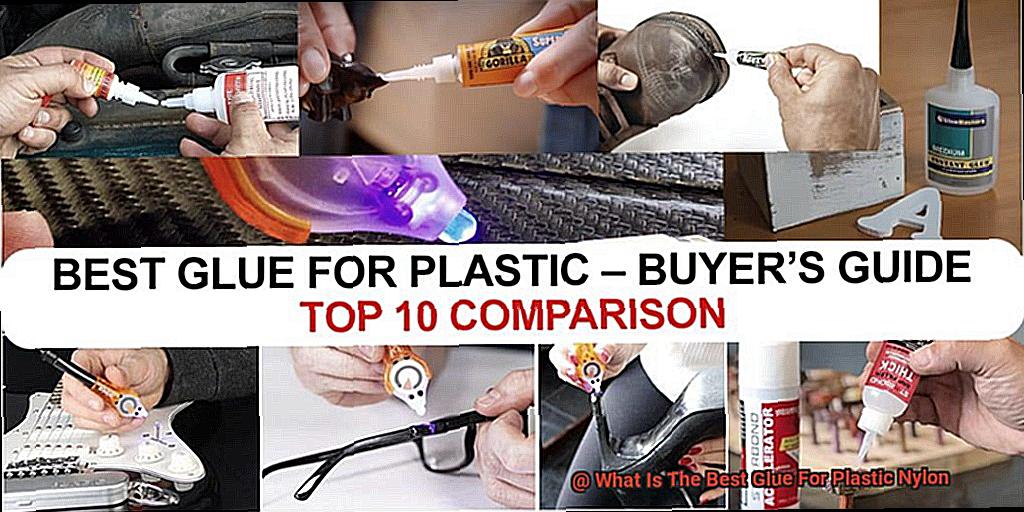

Well, you’ve come to the right place. The key to a durable and long-lasting bond lies in choosing the best glue for your needs. With a plethora of options out there, it can be overwhelming to make the right choice. But fear not, for we have done the research for you.

So, what is the best glue for plastic nylon? Let’s dive into the world of adhesives and explore the criteria for selecting the perfect glue. Here are some key factors to consider:

- Type of adhesive: Cyanoacrylate glue, also known as super glue, is highly recommended for bonding nylon. It forms a strong bond quickly and can withstand high temperatures and chemical exposure. Epoxy glue is another suitable option, known for its high strength and versatility. Polyurethane adhesives are also effective, providing flexibility and resistance to extreme temperatures.

- Material compatibility: It’s crucial to ensure that the adhesive you choose is compatible with nylon. Some adhesives may not adhere well to certain types of nylon, so it’s essential to check the manufacturer’s recommendations or consult adhesive experts for guidance.

- Bond strength: Consider the strength requirements of your application. Different adhesives have varying levels of strength, so select one that can withstand the forces and stresses applied to the bond.

- Environmental conditions: Think about the conditions your bonded materials will be exposed to. If they will face extreme temperatures, chemicals, or moisture, choose an adhesive that can withstand these conditions without compromising the bond.

- Surface preparation: Proper surface preparation is essential for a successful bond. Thoroughly clean the nylon surfaces to remove any dirt or contaminants that could hinder adhesion. Roughening the surface with sandpaper or a file can also enhance the adhesive’s grip.

Remember, when it comes to bonding nylon, consulting adhesive experts or referring to manufacturer recommendations can provide valuable insights and ensure you select the most suitable adhesive for your specific application.

Cyanoacrylate Adhesive (Super Glue)

Finding the right adhesive to repair or join plastic nylon materials can be a frustrating endeavor. But fear not. Cyanoacrylate adhesive, also known as super glue, is here to save the day. In this blog post, we’ll explore the world of super glue and discover why it’s the go-to choice for bonding plastic nylon.

Unbreakable Bond:

Super glue’s most notable advantage is its ability to create a durable and long-lasting bond. Once cured, it forms an unbreakable connection between plastic nylon surfaces, ensuring they stay firmly together even under stress or pressure. Whether you’re fixing a broken toy or joining different pieces, super glue provides a reliable solution.

Quick Curing Time:

Time is of the essence, especially when working on a project. Thankfully, super glue has your back. Unlike other glues that require hours or days to set, super glue bonds almost instantly upon contact with the surfaces. This means you can complete your projects efficiently and move on to the next task.

Proper Surface Preparation:

To ensure a successful bond, proper surface preparation is key. Before applying super glue, make sure the plastic nylon surfaces are clean and free from any dirt or grease. A quick wipe with a mild detergent or alcohol-based cleaner should do the trick. Additionally, roughening the surfaces slightly with sandpaper enhances the adhesive’s grip.

Material Compatibility:

While super glue is an excellent choice for most plastic nylon materials, it’s important to consider compatibility. Some variations of nylon have low surface energy, making it difficult for the glue to adhere properly. In such cases, using a specialized primer or activator designed specifically for bonding nylon materials is recommended.

Epoxy Adhesive

Look no further than epoxy adhesive when seeking a bonding solution for plastic Nylon. This remarkable adhesive is hailed as the superhero of its kind, known for its exceptional strength, durability, and versatility. In this post, we will explore the advantages of using epoxy adhesive for plastic Nylon bonding and provide detailed steps to ensure a robust bond.

Advantages of Epoxy Adhesive for Plastic Nylon Bonding:

- Unparalleled Strength: Epoxy adhesives are renowned for their impressive strength and durability. They create bonds that resist water, chemicals, and heat, making them perfect for a wide array of applications.

- Remarkable Versatility: Epoxy adhesives are incredibly versatile, capable of bonding various types of plastics, including Nylon. This flexibility allows for the seamless bonding of different plastic Nylon parts such as gears, housings, or structural components.

Steps to Ensure a Strong Bond:

- Surface Preparation: Proper surface preparation is crucial before applying epoxy adhesive to plastic Nylon. Thoroughly clean the surfaces to remove any dirt or grease that could hinder the bonding process. Additionally, lightly roughening the surfaces with sandpaper enhances bond strength.

- Precise Mixing Proportions: Epoxy adhesives consist of two components – resin and hardener. Achieving a strong bond requires accurately mixing these components in the correct proportions per the manufacturer’s instructions. Proper mixing ensures optimal bonding properties.

- Expert Application Technique: Apply the mixed epoxy adhesive evenly to both surfaces that require bonding. Adequately covering the surfaces guarantees a robust bond. Consider utilizing a brush or spatula for precise application.

- Secure Clamping or Holding: After applying the epoxy adhesive, firmly clamp or hold the parts together until the adhesive cures. This step ensures a tight bond and prevents any movement during the curing process. Follow the manufacturer’s guidelines for the recommended curing time, as it may vary based on the specific product used.

Epoxy adhesive is undoubtedly the go-to choice for bonding plastic Nylon due to its exceptional strength, durability, and versatility. By following proper surface preparation techniques, precise mixing proportions, and expert application methods, you can ensure a robust and reliable bond. Unleash the superhero powers of epoxy adhesive and conquer any bonding challenge with ease.

In-depth Research:

Epoxy adhesive is a widely chosen option for bonding plastic Nylon due to its remarkable strength and durability. This adhesive consists of two components – resin and hardener. When these components are mixed together, a chemical reaction occurs, resulting in a strong bond.

Polyurethane Adhesive

When it comes to bonding nylon, you need a superhero adhesive that can conquer any challenge. Look no further than polyurethane adhesive. This versatile adhesive possesses extraordinary qualities that make it the ultimate choice for bonding nylon. In this blog post, we will explore the advantages of using polyurethane adhesive and why it should be your go-to glue for all your bonding needs.

Superpower #1: Strong and Flexible Bonds

Polyurethane adhesive forms a powerful chemical reaction with nylon, creating a bond that is not only incredibly strong but also remarkably flexible. This flexibility is essential when bonding plastic materials like nylon, allowing for movement and preventing the bond from becoming brittle or breaking under stress. With polyurethane adhesive, your bonded nylon parts will stay securely fastened even in dynamic environments.

Superpower #2: Resistance to Moisture and Chemicals

Nylon often faces moisture or chemicals in its applications. Luckily, polyurethane adhesive is the ultimate defender. It possesses excellent resistance to water, oil, solvents, and many other chemicals. This means that the bond created with polyurethane adhesive will remain durable and unaffected by these harsh conditions over time. So, whether you’re bonding nylon parts for outdoor equipment or chemical storage containers, polyurethane adhesive has got you covered.

Superpower #3: Temperature Resistant

Nylon’s high melting point demands an adhesive that can brave the heat without compromising its bonding abilities. Polyurethane adhesive is up to the challenge. It can withstand a wide range of temperatures, making it suitable for bonding nylon in various environments. From freezing cold to scorching heat, polyurethane adhesive maintains its strength and integrity, ensuring a long-lasting bond.

Fabric Glue/Textile Adhesive

Fabric glue, also known as textile adhesive, is a remarkable solution specifically designed to bond fabrics and textiles together. It is the ultimate answer to your fraying fabric woes and the perfect adhesive for securing fabric to plastic nylon. But what exactly makes fabric glue so special?

First and foremost, fabric glue offers flexibility like no other adhesive. Unlike traditional sewing methods or other types of glues, fabric glue allows for movement and stretch once it dries. This means that even if you’re working with fabrics that need to stretch or move, like nylon, the bond created by fabric glue will stay strong without compromising the fabric’s integrity.

When choosing fabric glue for plastic nylon bonding, it’s important to consider a few key factors. Compatibility is crucial – make sure to select a fabric glue that explicitly mentions its compatibility with plastic nylon. Not all glues are formulated for all materials, so checking the label is essential.

Drying time is another significant factor to consider. If you’re on a tight deadline, opt for a fabric glue that dries quickly. However, if time is on your side, you can choose a glue with a longer drying time that allows for more precision and adjustment.

Washability is a crucial consideration as well. Depending on your project, you may need a machine-washable fabric glue or one that requires handwashing. Always check the label for washing instructions to ensure the longevity of your bonded fabric.

Transparency is another aspect to keep in mind. For an adhesive that won’t affect the appearance of your fabric, look for a fabric glue that dries clear or is colorless. This way, your bonded fabric will maintain its original aesthetic appeal.

Remember to follow the manufacturer’s instructions carefully when using fabric glue. Each brand and type of fabric glue may have specific application techniques and drying times that maximize bonding and longevity.

Other Glues to Avoid When Bonding Nylon

When it comes to bonding nylon, not all glues are created equal. Some glues may work wonders on other materials, but they can leave you with a weak and flimsy bond when used on nylon. So, if you’re looking to stick it to nylon, here are some glues you should avoid like the plague.

First on the list is our old nemesis, cyanoacrylate glue, also known as super glue. Now, super glue may have its uses in other applications, but when it comes to nylon, it’s a total dud. You see, nylon has a low surface energy that makes it difficult for the glue to adhere properly. So save your super glue for other projects and give nylon the cold shoulder.

Next up is epoxy, the popular adhesive known for its strength and versatility. Unfortunately, epoxy and nylon just don’t play well together. Nylon has a high coefficient of thermal expansion, meaning it expands and contracts significantly with changes in temperature. Epoxy, with its low coefficient of thermal expansion, can’t keep up with nylon’s wild antics, leading to cracks and bond failure over time.

Moving on, we have solvent-based adhesives. These sneaky devils contain solvents that can dissolve or damage nylon. So before you get too carried away bonding nylon with a solvent-based adhesive, make sure to read the fine print and ensure it won’t leave you high and dry.

Hot melt adhesives may be hot stuff in the crafting world, but they are a big no-no when it comes to bonding nylon. Nylon has a relatively low melting point, so the heat required for hot melt adhesives can cause the material to deform or melt. And trust me, nobody wants a bond that’s as weak as melted nylon.

Last but not least, we have rubber-based adhesives. While these glues may work wonders on rubber materials, they won’t give you the same results with nylon. So before you get stuck on the idea of using rubber-based adhesives, remember that nylon deserves a glue that’s made for it.

Preparing the Surface for Bonding Nylon

Look no further. In this comprehensive guide, we will walk you through the essential steps to prepare the surface for bonding nylon effectively. By following these simple yet crucial steps, you can achieve a strong and durable bond that will withstand even the wildest adventures of your nylon creations.

Step 1: Clean the Surface

Start by thoroughly cleaning the surface of the nylon. Remove any dirt, dust, or grease using a mild detergent or a plastic-specific cleaning solution. Gently scrub the surface with a soft brush or cloth to ensure a pristine bonding surface.

Step 2: Roughen the Surface

To improve adhesion, it is recommended to roughen the smooth and non-porous surface of nylon. Use fine-grit sandpaper or a sanding block to create a textured surface without damaging the material. Be mindful not to apply excessive pressure that can result in deep scratches or grooves.

Step 3: Remove Residue

After roughening the surface, eliminate any residue from the sanding process. Use a clean cloth or compressed air to remove dust particles or debris from the surface. This step ensures a clean and optimal bonding surface.

Step 4: Apply Primer

Consider using a primer specifically formulated for nylon. Primers promote chemical bonding between the adhesive and substrate, enhancing adhesion. Apply a thin layer of primer onto the prepared surface and allow it to dry as per manufacturer’s instructions. Ensure compatibility with both the adhesive and nylon material.

Step 5: Heat Treatment (Optional)

In certain cases, heat treatment can further improve bonding capabilities with nylon. Softening the material slightly allows for better penetration and adhesion of the adhesive. Follow temperature guidelines provided by both adhesive and nylon manufacturers to prevent damage or inadequate bonding strength.

Step 6: Select the Right Adhesive

Choosing the appropriate adhesive is crucial for a successful bond. Epoxy, cyanoacrylate (super glue), and polyurethane adhesives are common options for nylon. Consult the adhesive manufacturer’s guidelines to ensure compatibility with nylon and select an adhesive that suits your specific bonding needs.

a-PlBnsP-jQ” >

Conclusion

To sum it up, when it comes to bonding plastic Nylon, nothing beats the unrivaled power of epoxy adhesive. Its strength, resistance to chemicals, and long-lasting durability make it the ultimate solution for all your nylon projects.

Nylon is a material that knows no limits. From fashion to automotive engineering, this versatile substance is used in countless industries. Its exceptional strength and ability to withstand wear and tear make it a reliable choice for products that face constant use or stress.

When choosing the perfect glue for plastic Nylon, there are a few key factors to consider. The type of adhesive you select is crucial; options like cyanoacrylate glue (super glue), epoxy glue, and polyurethane adhesives are highly recommended. Don’t forget to check the manufacturer’s recommendations or consult adhesive experts to ensure material compatibility.

Don’t overlook bond strength and environmental conditions either. Think about the forces and stresses that will be applied to the bond and choose an adhesive that can handle extreme temperatures, chemicals, or moisture without compromising its grip.

Preparing the surface properly is essential for success. Take the time to thoroughly clean your nylon surfaces, removing any dirt or contaminants that could hinder adhesion. If you really want to enhance the adhesive’s grip, roughen up the surface with sandpaper or a file.

In conclusion, epoxy adhesive stands tall as the best glue for plastic Nylon because of its exceptional strength, durability, and versatility.