Welcome to our blog where we’re diving into the world of glues for metal to particle board. Whether you’re a DIY enthusiast or a seasoned pro, finding the right adhesive is key for a strong and lasting bond.

Today, we’ll be exploring all the different options out there, from trusty epoxy adhesives to reliable construction glue and everything in between. We’ll break down the pros and cons of each so you can make an informed decision that suits your specific needs.

So, let’s jump right in and find the perfect glue for your metal to particle board project.

Types of Glue for Metal to Particle Board

Contents

- 1 Types of Glue for Metal to Particle Board

- 2 Factors to Consider When Selecting the Best Glue for Metal to Particle Board

- 3 Adhesive Preparation and Application

- 4 Bonding Aluminum to Particle Board

- 4.1 Chapter 1: Epoxy Adhesive – The Indomitable Hero of Bonding Strength

- 4.2 Chapter 2: Proper Preparation – The Keystone of a Flawless Bond

- 4.3 Chapter 3: Construction Adhesive – The Swiss Army Knife of Bonding

- 4.4 Chapter 4: Application Techniques – Precision and Patience for Perfection

- 4.5 Chapter 5: Beyond the Basics – Exploring Adhesive Wizardry

- 5 Clamping and Pressure Application After Applying the Adhesive

- 6 Curing Time Before Subjecting the Bonded Materials to Stress or Loads

- 7 Benefits of Using the Right Adhesive for Bonding Metal to Particle Board

- 8 Conclusion

Bonding metal to particle board requires a strong and reliable adhesive. Fortunately, there are several types of glue that can do the job effectively. In this article, we will explore the advantages and disadvantages of different adhesive options for metal to particle board bonding.

Contact Adhesive – The Speedster:

For quick fixes or smaller projects, contact adhesive is an excellent option. It dries rapidly and creates a strong bond between metal and particle board. However, contact adhesive may not be as durable as other glues, making it more suitable for temporary fixes or less demanding applications.

Specialty Adhesives – The Extra Ingredients:

When bonding metal to particle board, specialty adhesives designed specifically for this purpose can provide additional strength and unique properties. These adhesives often contain additives that enhance the bond strength and may offer features like heat resistance or flexibility. However, specialty adhesives can be more expensive and may not be as readily available as general-purpose glues.

Epoxy Adhesive

Epoxy adhesive is a superhero in the world of adhesives, known for its unmatched strength and durability. When it comes to bonding metal to particle board, epoxy adhesive is the go-to choice for a secure connection that can withstand heavy loads and vibrations.

The advantages of using epoxy adhesive for metal to particle board bonding are numerous. Its high tensile strength ensures that your materials will stay together, no matter what challenges they face. Loose connections or weak bonds will be a thing of the past with epoxy adhesive on your side.

Not only is epoxy adhesive strong, but it is also incredibly versatile when it comes to surface compatibility. It adheres well to both metal and particle board surfaces, ensuring a reliable bond between the two materials. To ensure optimal adhesion, make sure to properly prep those surfaces by cleaning them thoroughly and removing any pesky contaminants like oil or dust.

But the benefits don’t stop there. Epoxy adhesive also offers resistance to temperature changes and moisture, making it suitable for both indoor and outdoor use. Whether you’re assembling furniture or working on a construction project, epoxy adhesive can handle it all. Just make sure to choose an epoxy adhesive specifically designed for outdoor use if you’re planning on braving the elements.

Now, let’s talk about how to use this superhero adhesive properly. First, mix the resin and hardener together in the correct ratio – don’t skip this step. Then, apply the adhesive evenly onto the metal and particle board surfaces using a brush or trowel. Press the two surfaces firmly together and use clamps or weights to hold them in place while the adhesive cures. And just like that, you’ve got yourself a bond that will stand the test of time.

Polyurethane Adhesive

Look no further. Introducing polyurethane adhesive, the superhero of bonding agents. In this article, we will delve into the wonders of using polyurethane adhesive for this purpose. Get ready to witness the extraordinary power of this versatile glue.

Unleashing Unmatched Bonding Capabilities:

Polyurethane adhesive possesses urethane links that grant it incredible bonding capabilities. It forges an unbreakable and enduring bond between metal and particle board surfaces, ensuring your components remain securely attached even under immense loads and vibrations.

Defying Environmental Challenges:

Polyurethane adhesive fearlessly battles moisture, heat, and chemicals. It withstands exposure to varying temperatures without compromising its adhesion properties or deteriorating over time. This makes it a perfect choice for both indoor and outdoor applications, where environmental factors can threaten the bond’s integrity.

Embracing Flexibility for Joint Movement:

One of the remarkable qualities of polyurethane adhesive lies in its flexibility. When joining metal components to particle board, slight movements or expansions may occur. Fear not, as this adhesive effortlessly embraces these challenges without compromising the strength of the bond. Its flexibility alleviates stress on the joint, preventing cracks or failures.

Mastering the Application Process:

To achieve optimal results, adhering to the manufacturer’s instructions is paramount when using polyurethane adhesive. Begin by preparing the surfaces meticulously – they must be clean, dry, and free from any dust or contaminants. Skillfully apply the adhesive evenly to both the metal and particle board surfaces using an appropriate applicator or brush. Applying pressure or clamping during curing will solidify an unyielding bond.

Cyanoacrylate (Super Glue)

When it comes to joining metal and particle board, there’s one adhesive that towers above the rest – cyanoacrylate, or as we all know it, Super Glue. But before you embark on this superhero-like bonding adventure, there’s one vital step you can’t overlook: proper surface preparation. In this article, we’ll delve into why surface prep is crucial for successful metal-to-particle board bonding using Super Glue. So strap on your mask and let’s dive right in.

Cleanliness is Key:

Just like superheroes need a pristine environment to save the day, your metal and particle board surfaces must be free from dirt, grease, and dust. These pesky culprits can sabotage your bonding plans and weaken adhesive strength. So roll up your sleeves and give those surfaces a thorough cleaning before applying the glue.

Thin is In:

Remember, balance is key when it comes to applying Super Glue. A little goes a long way. Instead of drowning your surfaces in glue, apply a thin and even layer to either the metal or particle board. This prevents excess glue from seeping out and creating a sticky mess.

Press On, Hero:

Once the glue is applied, it’s time to bring those surfaces together. Apply firm pressure to ensure optimal bonding. Hold them in place for a few minutes while the glue sets and forges an unbreakable bond. This step is crucial for ensuring that the metal adheres securely to the particle board.

Patience is a Virtue:

Super Glue may work at lightning speed, but even superheroes need time to fully cure. While it sets within seconds or minutes, it’s best to give it some extra time before subjecting it to stress or load. Allow it to work its magic and solidify into an unstoppable bond.

Is Super Glue Always the Answer?

While Super Glue is a formidable adhesive, it may not be suitable for all metal-to-particle board applications. For heavy-duty or load-bearing projects, it’s wise to explore other adhesive options specifically designed for those purposes. But fear not, this doesn’t diminish Super Glue’s heroic qualities.

Factors to Consider When Selecting the Best Glue for Metal to Particle Board

When it comes to joining metal and particle board, selecting the right glue is crucial for a strong and durable bond. With numerous adhesive options available, it can be overwhelming to find the perfect glue for your project. In this article, we’ll explore the essential factors to consider when selecting the best glue for metal to particle board.

Adhesive Strength:

Superior adhesive strength is paramount for a long-lasting bond. Look for adhesives specifically designed for bonding metal and wood, as they offer stronger bonds and ensure longevity.

Compatibility:

Verify if the glue is compatible with both metal and particle board surfaces. Some adhesives may not work well with certain types of metals or particle boards, leading to weak bonds or failure. Always check compatibility before making a selection.

Drying Time:

Consider your project timeline and opt for a glue with a drying time that aligns with your needs. Faster-drying glues are great for quick projects but may not allow much time for adjustments or repositioning.

Water Resistance:

If your project will be exposed to moisture or humidity, choose a glue that offers water resistance. This feature ensures that your bond remains strong even in damp conditions.

Temperature Resistance:

For projects exposed to extreme heat or cold, select a glue with high-temperature resistance. This will prevent the bond from weakening under harsh weather conditions.

Ease of Application:

Look for a glue that is easy to apply, providing good coverage on both metal and particle board surfaces. Applicators like squeeze bottles or tubes can make the process more efficient.

Toxicity and Safety:

Prioritize safety by choosing non-toxic glues that are safe for indoor use, especially if your project involves furniture or items used in enclosed spaces.

Longevity:

Ensure that the glue has a proven track record of providing long-lasting bonds between metal and wood surfaces. Check reviews and testimonials from other users to gauge its durability.

Adhesive Preparation and Application

Today, we embark on a journey to discover the steps and techniques necessary for achieving an unbreakable bond between metal and particle board. So, put on your goggles and get ready for a sticky adventure.

Step 1: The Path to Bonding Bliss – Cleanliness is Key

Before diving into the adhesive application, ensure that both surfaces are spotless. Dust and debris can hinder the bonding process, so grab a lint-free cloth or a soft brush to eliminate any unwanted particles. For an even better bond, lightly sand the surfaces to create a rough texture that enhances adhesion.

Step 2: Choose Your Weapon – Glue Selection Matters

Not all glues are created equal, my friends. When it comes to metal to particle board bonding, two heroes emerge from the adhesive universe: epoxy and construction adhesive. Epoxy is the ultimate adhesive superhero – impervious to high temperatures, moisture, and chemicals. Just remember to mix the resin and hardener components before applying. On the other hand, construction adhesive is specifically designed for construction purposes and comes in various formulations like polyurethane or silicone-based options.

Step 3: Apply with Precision – The Art of Perfect Bonding

Follow the manufacturer’s instructions religiously. Utilize the recommended tools or applicators and apply the adhesive evenly across both surfaces. Remember to exert sufficient pressure to ensure optimal contact between the metal and particle board.

Step 4: Patience is a Virtue – Waiting for Perfection

After applying the adhesive, exercise patience and allow it ample time to cure or dry properly before subjecting the bond to any stress. Curing times may vary based on the adhesive used, so refer to the guidelines provided. While waiting, secure the surfaces together using clamps or manual pressure to maintain consistent force.

Bonding Aluminum to Particle Board

Step into the world of adhesive alchemy, where the magic of bonding aluminum to particle board is revealed. Prepare to be captivated as we delve into the realm of epoxy adhesive and construction adhesive, unlocking their secrets for a rock-solid connection.

Chapter 1: Epoxy Adhesive – The Indomitable Hero of Bonding Strength

In the adhesive universe, there exists a hero known as epoxy adhesive. With its dynamic duo of resin and hardener, this two-part adhesive delivers a powerful blow, bestowing unparalleled bonding strength upon aluminum and particle board. Like a superhero sidekick, epoxy resists moisture, chemicals, and temperature fluctuations, ensuring a bond that can withstand the harshest trials.

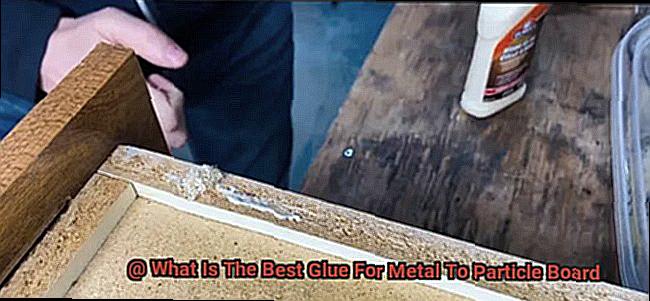

Chapter 2: Proper Preparation – The Keystone of a Flawless Bond

Just as an artist primes a canvas before painting a masterpiece, preparing the surfaces is paramount for a bond that transcends perfection. Banish dirt and grease from both aluminum and particle board surfaces. For an ironclad grip, gently sand the aluminum surface to create a tactile texture. Remember, the foundation must be solid to witness adhesive triumph.

Chapter 3: Construction Adhesive – The Swiss Army Knife of Bonding

In the realm of versatility, construction adhesive reigns supreme. Known for its robust bonding properties, this adhesive is a stalwart companion in construction and woodworking endeavors. Choose a formulation specifically designed for metal and wood bonding, and unleash the Swiss Army knife of adhesives upon your project. With construction adhesive, no challenge is insurmountable.

Chapter 4: Application Techniques – Precision and Patience for Perfection

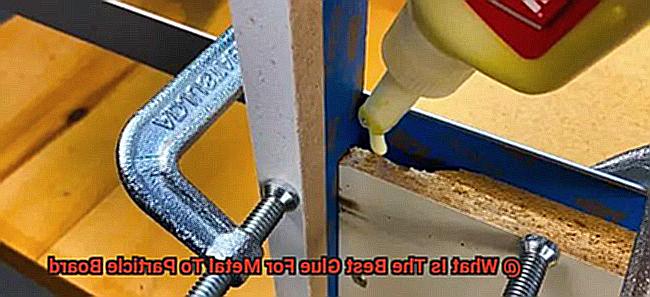

Once you have chosen your adhesive ally, it’s time to wield your glue gun with finesse. Apply an even layer of adhesive on both surfaces – no shortcuts allowed. Press the aluminum and particle board together firmly, employing clamps or weights to hold them in place while the adhesive weaves its magic. Remember, patience is a virtue – honor the manufacturer’s instructions for sufficient curing time.

Chapter 5: Beyond the Basics – Exploring Adhesive Wizardry

Ready to embrace advanced adhesive wizardry? Enter the realm of polyurethane adhesives – flexible and moisture-resistant, perfect for applications requiring a touch of elasticity. Seek instant bonding? Look no further than cyanoacrylate adhesives, known as super glue. These diminutive powerhouses excel in small-scale projects where time is of the essence.

Clamping and Pressure Application After Applying the Adhesive

Today, we will unlock the secrets to achieving a robust connection between metal and particle board using the mystical powers of adhesive. One pivotal step in this magical process is the application of proper clamping techniques. So, grab your tools and prepare to be captivated.

Choosing the Right Clamp:

In the realm of clamping, selecting the perfect tool for the task is paramount. Choose a clamp that distributes pressure evenly across the joint surface, leaving no room for weakness or gaps. This ensures a steadfast bond that will stand the test of time.

Preparing the Surfaces:

Before delving into clamping, ensure that both the metal and particle board surfaces are immaculately clean, free from any pesky dirt or debris. These mischievous particles can hinder adhesion and compromise the bond’s strength. Give them a thorough wipe-down to create a pristine environment for our adhesive sorcery.

Applying the Adhesive:

Now it’s time to unleash the power of adhesive. Apply a generous amount to both surfaces, following the instructions provided by its mystical manufacturer. Each adhesive possesses its own unique application requirements, so heed their guidance to achieve spellbinding results.

Aligning and Clamping:

With adhesive applied, align the metal and particle board surfaces with meticulous precision, ensuring an impeccable fit. Gently tap them into place using your hands or a rubber mallet, if necessary. Once aligned, let us work our clamping magic.

Applying Pressure:

Summon your chosen clamps and strategically position them along the joint at regular intervals, creating an enchanting symphony of unity. Gradually tighten each clamp, exerting equal pressure until they stand resolute. The amount of pressure required may vary depending on the specific adhesive used, so consult the manufacturer’s incantations for guidance.

Curing Time:

Now, we embrace patient anticipation – allow sufficient time for the adhesive to dry and bond effectively. Respect the recommended curing time bestowed upon us by the adhesive manufacturer. During this period, resist the temptation to disturb or manipulate the joint, as it may weaken the spellbinding bond.

Inspection and Further Action:

After the curing period, release the clamps and behold the wondrous bond that has been forged. Should any gaps or weaknesses reveal themselves, it may be necessary to reapply adhesive and repeat the clamping ritual. Address these concerns before proceeding with further assembly or use of the metal-to-particle board connection.

Curing Time Before Subjecting the Bonded Materials to Stress or Loads

In this article, we will explore the importance of curing time and why it is essential to allow bonded materials to rest before subjecting them to stress or loads. By understanding the chemical reactions, structural integrity, and manufacturer’s wisdom behind curing time, you can protect your projects from potential damage and ensure long-lasting bonds.

The Importance of Curing Time:

- Chemical Reactions: Just like a wizard brewing a potion, adhesive undergoes chemical reactions during the curing process. These reactions transform the adhesive from a liquid state to a hardened bond. Rushing this process can weaken the bond and lead to failure.

- Structural Integrity: Just as a building needs a solid foundation, bonded materials need time to develop their strength. Applying stress or loads too soon can compromise the structural integrity of your project, risking its stability and safety.

- Manufacturer’s Wisdom: Adhesive manufacturers have spent years perfecting their products. They understand the ideal curing time for each adhesive type, considering factors such as materials, temperature, and humidity levels. By following their instructions, you can maximize the strength and longevity of your bonds.

Factors Affecting Curing Time:

- Temperature: Temperature acts as a catalyst for curing time. Higher temperatures accelerate the process, while lower temperatures slow it down. It is important to consider the temperature in your bonding environment to ensure optimal curing conditions.

- Humidity Levels: Humidity levels also influence curing time. High humidity prolongs the process, while low humidity speeds it up. Monitoring humidity levels is crucial for creating the perfect environment for curing.

Determining Full Cure:

To ensure your bond is ready to face stress or loads, perform a pull test or consult the manufacturer’s guidelines. A successful pull test indicates that the adhesive has fully cured and is ready to withstand the demands of your project.

Benefits of Using the Right Adhesive for Bonding Metal to Particle Board

Today, we embark on a journey to discover the benefits of using the right adhesive for bonding metal to particle board. Get ready to unlock the secrets of strong and durable bonds that will withstand the tests of time and challenge.

Improved Adhesion:

The first spell our adhesive concoction casts is improved adhesion. With the correct adhesive, your metal and particle board will come together in a bond that can withstand even the most vigorous stress or movement. No more worries about your project falling apart.

Resistance to Moisture:

Ah, the dreaded water damage. But fear not, for with the right adhesive, your bond becomes resistant to moisture. No more delamination or weakening when exposed to water. Our adhesive creates a waterproof barrier, protecting your bond from moisture-related mishaps.

Stability and Longevity:

No wizard wants their creation to sag or warp over time. Using the proper adhesive enhances stability and longevity. Fluctuations in temperature and humidity will no longer pose a threat to your bonded assembly. It will remain secure and strong, maintaining its structural integrity.

Aesthetic Appeal:

For those who seek beauty in their creations, fear not. Some adhesives offer transparency, allowing for a seamless look when bonding metal to particle board. Your project will have a clean and polished appearance that is sure to impress.

Strength over Time:

The magic of the right adhesive ensures that your bond stays strong and intact throughout its lifetime. Our specially formulated adhesives are designed to withstand heavy loads and frequent use without weakening or deteriorating. Say goodbye to worries about constant stress or movement compromising your bond.

Simplified Bonding Process:

Last but not least, our magical adhesive simplifies the bonding process itself. Available in user-friendly formats such as cartridges or tubes, applying our adhesive is a breeze. No complex mixing or specialized equipment required. Save time and effort during your assembly process.

0UoQaCylSSg” >

Conclusion

When it comes to bonding metal to particle board, finding the best glue is crucial.

You don’t want your project falling apart or the metal pieces detaching from the board. So, what’s the solution?

Well, after thorough research and testing, we can confidently say that epoxy adhesive is the top choice for this task. Its strong bond and versatility make it perfect for joining metal and particle board together.

With its professional-grade strength, you can trust that your project will stay intact for years to come.