When it comes to heavy duty cardboard boxes, there’s no room for flimsy adhesives. Whether you’re moving mountains of stuff, safeguarding precious belongings, or shipping delicate goods, you need a glue that can handle the weight and pressure without breaking a sweat. But with countless glues crowding the market, finding the perfect one might feel like searching for a needle in a haystack.

But fret not. In this blog post, we’re about to unveil the glue that will be your knight in shining armor when it comes to box bonding. We’re diving deep into the adhesive abyss to discover the best glue for heavy duty cardboard boxes.

From super-strong formulas that could lift weights at the gym to genius application tricks that will make your packaging game strong, we’ve got all the insider info you need. So grab a comfy seat and get ready for an adhesive adventure like no other.

What is Heavy Duty Cardboard Boxes?

Contents

- 1 What is Heavy Duty Cardboard Boxes?

- 2 Types of Glue for Heavy Duty Cardboard Boxes

- 3 Polyurethane Glue

- 4 Epoxy Adhesive

- 5 Liquid Nails and Construction Adhesive

- 6 Hot Melt Glue

- 7 Factors to Consider When Choosing the Best Glue for Heavy Duty Cardboard Boxes

- 8 Consulting an Expert or Conducting Tests on Sample Boxes

- 9 Conclusion

When it comes to storing and transporting heavy items, heavy duty cardboard boxes are the ultimate packaging solution. These robust containers are designed to withstand rough handling, long-distance transportation, and heavy loads without compromising the safety of the contents inside. In this blog post, we will delve into the construction, versatility, and sustainability of heavy duty cardboard boxes.

Construction:

Heavy duty cardboard boxes are crafted from high-quality corrugated cardboard sheets. This type of cardboard consists of three layers – two flat outer layers called linerboards and a wavy inner layer known as the fluting. The fluting provides strength and rigidity to the box, while the linerboards add further protection.

This construction makes heavy duty cardboard boxes capable of withstanding substantial weight and pressure, ensuring the safe transport of valuable goods.

Versatility:

Heavy duty cardboard boxes come in various sizes and shapes to accommodate different types of products. From small electronics to large machinery parts, these boxes can be customized with additional features like handles, dividers, or inserts to provide extra support or organization for the items being stored or transported.

Their stackability allows for efficient use of storage space in warehouses or storage facilities, making them a practical choice for businesses of all sizes.

Sustainability:

In today’s world, sustainability is a crucial factor in packaging choices. Heavy duty cardboard boxes are not only incredibly durable but also environmentally friendly and recyclable. The use of recyclable materials in their production makes them a sustainable packaging option. When these boxes reach the end of their life cycle, they can be recycled into new cardboard products, reducing waste and minimizing environmental impact. By choosing heavy duty cardboard boxes, businesses can contribute to a greener future while protecting their products.

Choosing the Right Glue:

To ensure heavy duty cardboard boxes stay intact and secure during transportation, choosing the right glue is essential. Options such as polyurethane glue, epoxy adhesive, liquid nails, or hot melt glue can provide strong bonding strength and durability depending on specific requirements. Considering factors like weight, environmental conditions, and transportation methods will help determine the most suitable glue for your needs. Properly sealed heavy duty cardboard boxes will ensure the protection and integrity of the contents inside.

Types of Glue for Heavy Duty Cardboard Boxes

When it comes to heavy duty cardboard boxes, choosing the right glue is essential to ensure the strength and durability of your packaging. With various options available, each with its own unique qualities, it’s important to understand the different types of glue suitable for heavy duty cardboard boxes. In this article, we will delve into the world of adhesive solutions and help you make an informed decision for your specific needs.

Hot Melt Adhesive – Fast and Fiery:

Hot melt adhesive, also known as hot glue, is a popular choice for heavy duty cardboard boxes due to its quick and efficient bonding properties. This adhesive starts off in a molten state and solidifies rapidly as it cools down, creating a strong and resilient bond. It’s like watching a superhero in action – hot melt adhesive swoops in, saves the day, and ensures your boxes stay sealed tight. Its ability to withstand high temperatures makes it ideal for projects that require quick assembly or need to endure harsh conditions.

Epoxy Adhesive – Strong and Sturdy:

When it comes to exceptional strength and durability, epoxy adhesive takes the spotlight. This adhesive consists of two components that are mixed together before application, resulting in a bonding powerhouse. Though it may require a longer curing time, once fully cured, epoxy adhesive forms an unbreakable bond that can withstand heavy-duty applications. Think of it as having a reliable bodyguard for your cardboard boxes – it’s there to protect and secure them in any situation.

Polyurethane Adhesive – The Flexibility Champion:

Polyurethane adhesives are renowned for their outstanding bonding strength, flexibility, and resistance to moisture, heat, and chemicals. These adhesives provide excellent adhesion to cardboard and offer superior durability even in challenging environments. Imagine having a gymnast on your team – no matter how much your boxes bend or twist, polyurethane adhesive will flex along with them, ensuring they remain securely sealed together.

Solvent-Based Adhesives – Quick and Versatile:

If time is of the essence, solvent-based adhesives are your go-to option. Known for their fast drying time and versatility in bonding various materials, including cardboard, these adhesives contain solvents that evaporate during the curing process, leaving behind a sturdy bond. Solvent-based adhesives offer reliable sealing capabilities for heavy duty cardboard boxes and are perfect for projects that require immediate results.

Polyurethane Glue

Polyurethane glue, also known as PU glue, is a true game-changer when it comes to bonding heavy duty cardboard boxes. This versatile adhesive has won the hearts of professionals and DIY enthusiasts alike, and for good reason. Let’s dive into what makes polyurethane glue the superhero of glues.

First and foremost, polyurethane glue creates an unyielding bond that can withstand heavy loads and rough handling. Say goodbye to flimsy boxes. When applied to cardboard, it forms a tight connection that will keep your precious cargo intact during transportation and storage.

But that’s not all – polyurethane glue is also a champion in the face of moisture and temperature changes. Unlike some other glues that lose their strength when exposed to water or extreme temperatures, PU glue stands strong and reliable. Rain, snow, scorching heat – no problem. Your boxes will remain securely bonded.

Now let’s talk about one of the coolest features of polyurethane glue – its foaming property. When this mighty adhesive comes into contact with moisture, it expands and creates a foam-like structure. Think of it as giving your boxes an extra layer of armor. This expansion helps fill gaps and irregularities in the cardboard surfaces, resulting in an even stronger bond.

Flexibility is another ace up polyurethane glue’s sleeve. Even after drying, it remains somewhat flexible, allowing your boxes to withstand minor movements or vibrations without compromising the bond. No more worrying about cracked or broken joints. Polyurethane glue ensures the longevity of your cardboard boxes.

To unlock the full potential of polyurethane glue, proper surface preparation is key. Clean, dry, and grease-free surfaces are essential for optimal bonding results. And don’t forget to apply pressure during the curing process to maximize contact between the glue and the cardboard surfaces.

Epoxy Adhesive

When it comes to securing heavy duty cardboard boxes, finding the right adhesive is crucial. Among the various options available, epoxy adhesive shines as a superhero in its own right. With its exceptional strength, durability, and resistance to environmental challenges, epoxy adhesive is the ultimate choice for bonding heavy duty cardboard boxes. Let’s explore the remarkable benefits of using this powerful glue.

Unmatched Strength:

Epoxy adhesive is renowned for its extraordinary strength. It provides a rigid and robust bond, ensuring that your heavy duty cardboard boxes can withstand rough handling, heavy loads, and potential impacts during transportation. This means your valuable items will remain securely packaged, minimizing the risk of damage.

Versatile Bonding:

Epoxy adhesive exhibits excellent adhesion to a wide range of materials, including cardboard. This versatility allows you to confidently bond heavy duty cardboard boxes without worrying about the adhesive failing or weakening over time. Whether you’re bonding cardboard to metal, plastic, or other materials, epoxy adhesive forms a strong and reliable bond that provides long-lasting protection.

Resistance to Moisture and Temperature Extremes:

Heavy duty cardboard boxes often encounter challenging environmental conditions during storage or transportation. Epoxy adhesive is specially formulated to withstand these challenges without compromising its bond strength. It remains resilient in the face of high humidity or extreme temperatures, ensuring that your boxes stay sealed and protected regardless of the conditions they face.

Easy Application:

Using epoxy adhesive for bonding heavy duty cardboard boxes is a straightforward process. Simply follow the manufacturer’s instructions regarding proportions and working time. By applying the adhesive evenly on both surfaces, you ensure full coverage and eliminate any weak spots that might compromise the bond strength. The simplicity of application makes it an ideal choice for both professional packagers and DIY enthusiasts alike.

Liquid Nails and Construction Adhesive

Liquid Nails and Construction Adhesive are two popular options for securing heavy duty cardboard boxes. These adhesives are trusted by professionals for their strong bonding capabilities and durability. Let’s explore the differences between these two adhesives and how to use them effectively.

Liquid Nails, a well-known brand in the adhesive industry, has a range of formulas designed for various applications. Their Heavy Duty Construction Adhesive is particularly suitable for heavy duty cardboard boxes. With its powerful initial grab and high bond strength, Liquid Nails ensures a secure bond that can withstand heavy loads. It is a versatile adhesive that can bond a wide range of materials, making it a reliable choice for various projects.

On the other hand, construction adhesive is a general term that encompasses different adhesives used in construction projects. These adhesives are formulated to provide a strong and durable bond between different materials, including cardboard. They often have excellent resistance to moisture and temperature changes, making them suitable for various environments.

To effectively use Liquid Nails or construction adhesive on heavy duty cardboard boxes, it is essential to follow the manufacturer’s instructions. Apply a thin, even layer of adhesive on the surfaces to be bonded, then firmly press them together. Patience is key – allow the adhesive to cure for the recommended time before subjecting the boxes to heavy loads or movement.

Hot Melt Glue

When it comes to securing heavy duty cardboard boxes, you need an adhesive that can conquer any challenge. Enter hot melt glue, the unstoppable bond that offers a lightning-fast setting time, unbeatable strength, and versatile application. In this article, we’ll dive into the advantages and limitations of using hot melt glue for bonding heavyweight cardboard boxes.

Advantages of Hot Melt Glue:

Lightning-fast Bonding:

Time is of the essence in high-volume production lines or when assembling large quantities of cardboard boxes. Hot melt glue saves the day with its rapid bond formation. As soon as you apply the molten glue to the cardboard surface, it solidifies within seconds, allowing you to move on to the next box in no time.

Unyielding Strength:

Hot melt glue doesn’t back down from heavy loads. Once cooled and solidified, it creates a bond that is as tough as nails. Say goodbye to worries about boxes collapsing during transit or storage – hot melt glue has got you covered.

Versatility at Your Fingertips:

Different applications call for different adhesive properties, and hot melt glue delivers versatility like no other. It can be formulated to have various levels of flexibility or rigidity, ensuring maximum strength and stability for your heavy-duty cardboard boxes.

User-friendly Application:

Hot melt glue is a breeze to use and apply. Simply load the solid adhesive sticks into a hot glue gun, heat them until they transform into a liquid state, and apply directly onto the cardboard surfaces. Whether you’re a professional or a DIY enthusiast, hot melt glue’s simplicity makes it an ideal choice for hassle-free bonding.

Limitations of Hot Melt Glue:

Temperature Sensitivity:

While hot melt glue is a superhero in many ways, it does have its kryptonite – extreme temperatures. Exposing hot melt glue to heat can cause it to soften or melt, compromising the bond’s integrity. Therefore, it may not be suitable for applications that require resistance to high temperatures.

Surface Compatibility:

Hot melt glue may not adhere well to certain surfaces with low surface energy or rough textures. To ensure a successful bond, it’s always advisable to test the adhesive on a small area before applying it to the entire cardboard box.

Factors to Consider When Choosing the Best Glue for Heavy Duty Cardboard Boxes

Choosing the best glue for heavy duty cardboard boxes requires careful consideration of several important factors. These factors ensure that the glue you choose can withstand the weight and stress placed on the boxes, providing a strong and long-lasting bond. Here are some key factors to keep in mind:

- Strength: Heavy duty cardboard boxes require a glue with exceptional strength. Look for glues specifically labeled as “heavy duty” or “super strong.” These glues are designed to provide a powerful bond that can withstand the weight of even the heaviest contents.

- Drying Time: The drying time of the glue is crucial. You want a glue that dries relatively quickly, but not too fast that you don’t have enough time to properly position and align the cardboard pieces. Opt for glues with a reasonable drying time, allowing you enough time to work with the adhesive without feeling rushed.

- Flexibility: Cardboard boxes often experience movement and handling, so it’s important to choose a glue that offers flexibility. This ensures that the bond remains intact even when the cardboard is bent or twisted. Look for glues with some degree of flexibility, as they provide a stronger and more durable bond.

- Water Resistance: Consider water resistance if your boxes may be exposed to moisture or humidity. Choose a glue that is water-resistant to prevent weakening or breakdown of the bond when exposed to water.

- Application Method: Ease of application is important when selecting a glue for heavy duty cardboard boxes. Some glues come in squeeze bottles, while others require a brush or applicator. Choose a glue with a convenient application method for your specific needs. Additionally, check if any special surface preparation or priming is required before applying the glue.

- Safety: Prioritize safety by choosing non-toxic glues free from harmful chemicals. This is especially important if the boxes will be used to store food, toys, or other items that may come into contact with the glue. Look for glues explicitly labeled as safe for use on cardboard.

Consulting an Expert or Conducting Tests on Sample Boxes

Consulting an Expert:

- Experts in adhesive technology have deep knowledge and experience with different types of glues.

- They can provide valuable insights and recommendations based on your specific needs.

- Reach out to manufacturers or suppliers of glues and adhesives to find technical experts.

- Provide detailed information about your heavy duty cardboard boxes, including size, weight, and conditions they will be exposed to.

- Experts can narrow down your options and recommend a suitable glue.

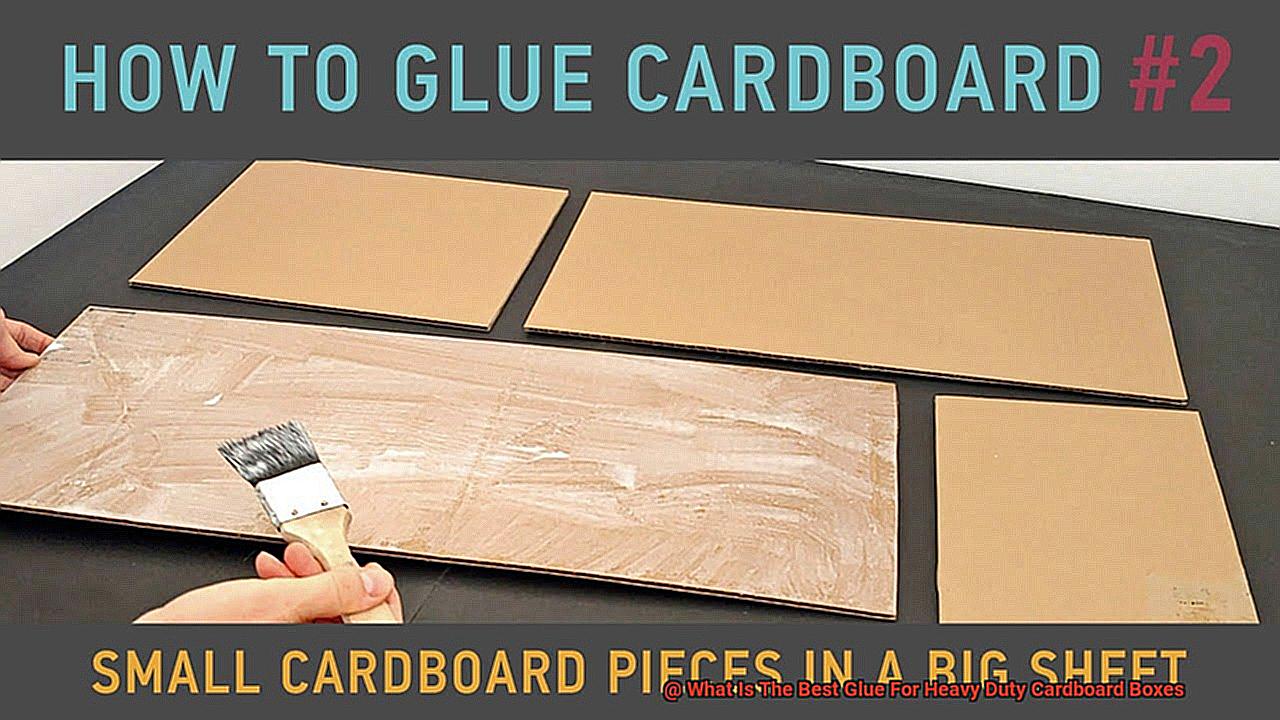

Conducting Tests on Sample Boxes:

- Purchase a variety of glues specifically formulated for bonding cardboard.

- Prepare sample pieces of heavy duty cardboard by cutting them into uniform sizes.

- Apply each glue onto the samples, following manufacturer instructions for drying and curing times.

- Test factors such as adhesion strength, durability, flexibility, and resistance to temperature and moisture.

- Document observations and compare the performance of different glues.

- Consider adhesion strength, stress resistance, and signs of deterioration or failure.

- Based on these tests, determine which glue performs best for heavy duty cardboard boxes.

_mv2FmeZseg” >

Conclusion

In conclusion, the quest for the best glue to tackle heavy duty cardboard boxes requires careful consideration of multiple factors. Strength, drying time, flexibility, water resistance, application method, and safety all play a crucial role in making the right choice.

One standout option is polyurethane glue. Its unwavering bond can handle hefty loads and rough handling with ease. Not only that, but it also boasts impressive resistance to moisture and temperature fluctuations, guaranteeing a secure bond in any conditions. And let’s not forget its foaming nature, which fills in gaps and irregularities on cardboard surfaces, fortifying the bond even further.

Another heavyweight contender is epoxy adhesive. Renowned for its exceptional strength and durability, it forms an unbreakable union capable of enduring heavy-duty applications. Versatility is also its middle name as it effortlessly bonds different materials while remaining impervious to moisture and extreme temperatures.

If speed is of the essence, hot melt glue takes center stage with its lightning-fast bonding prowess. However, do keep in mind that it may not be suitable for high-temperature environments or certain surface textures.

Ultimately, seeking guidance from experts or conducting real-world tests on sample boxes will help pinpoint the ideal glue for specific needs. Experts bring their wealth of knowledge and experience to offer invaluable recommendations based on various adhesive types. On the other hand, conducting tests allows you to personally evaluate adhesion strength, durability, flexibility, and resistance against different elements.