Whether you’re tackling an art project or need a reliable adhesive for a DIY repair, finding the best glue for glass to plexiglass is key.

But with so many options out there, it can be overwhelming. Don’t worry though, I’ve got your back.

In this blog post, I’ll walk you through the top glue recommendations for attaching glass to plexiglass. We’ll consider factors like strength, transparency, ease of use, and durability.

So, let’s jump in and find the perfect adhesive for a seamless and long-lasting bond between glass and plexiglass.

What is Glass and Plexiglass?

Contents

- 1 What is Glass and Plexiglass?

- 2 Advantages of Using Glue for Bonding Glass to Plexiglass

- 3 Types of Glue Suitable for Bonding Glass to Plexiglass

- 4 Clear Epoxy Adhesive for Bonding Glass to Plexiglass

- 5 UV-Curing Adhesive for Bonding Glass to Plexiglass

- 6 Super Glue for Bonding Glass to Plexiglass

- 7 Preparing the Surfaces Before Applying the Glue

- 8 Following Manufacturer’s Instructions for Optimal Results

- 9 Conclusion

Glass and plexiglass are two materials that have revolutionized the way we see the world. From towering skyscrapers to delicate picture frames, these transparent wonders have found their way into our daily lives. But what sets them apart? Let’s dive into the key differences between glass and plexiglass, ultimately helping you make an informed decision for your next project.

Composition:

Glass, made by heating a mixture of silica or sand with soda ash and limestone, is an inorganic material that provides a crystal-clear view without any distortion. Plexiglass, a type of plastic known as polymethyl methacrylate (PMMA), offers good transparency but can be prone to yellowing or hazing under harsh conditions.

Flexibility:

Glass is rigid and brittle, making it susceptible to shattering under significant impact or stress. Plexiglass, however, is more flexible and less prone to breakage, making it a popular choice for applications where durability is crucial.

Weight:

Plexiglass is significantly lighter than glass, making it easier to handle and transport. This advantage makes plexiglass ideal for applications where weight is a concern, such as aircraft windows or display cases.

Durability:

Glass is known for its durability and resistance to scratches, chemicals, and heat. It also provides excellent insulation and can be easily cleaned. Plexiglass offers superior impact resistance and can be easily shaped or cut to meet specific design needs. It is also more affordable than glass in many cases.

Advantages of Using Glue for Bonding Glass to Plexiglass

Glass and plexiglass are like the dynamic duo of transparency, each with its unique strengths. But what if you need to bring them together in perfect harmony? That’s where glue comes in. In this blog post, we’ll explore the advantages of using glue for bonding glass to plexiglass, and why it’s a game-changer for your projects. So let’s dive in and discover the magic of glue.

Advantage 1: Strong and Secure Bond:

Imagine a superhero team-up where the bond between glass and plexiglass is unbreakable. Glue creates just that – a strong and secure bond that holds these two materials together with unmatched strength. No more worries about detachment or accidents; glue ensures a rock-solid connection.

Advantage 2: Versatility:

Glue is like a chameleon, adapting to any situation. Whether you’re working with clear glass, tempered glass, or different types of plexiglass, there’s a glue specially designed to bond these materials effectively. It’s a versatile solution that caters to all your bonding needs.

Advantage 3: Invisible Bond:

Who doesn’t love a little magic trick? With glue, you can create an invisible bond between glass and plexiglass. Once the glue dries, it becomes transparent, blending seamlessly with the surfaces. This means no unsightly marks or visible bonds – just a smooth and flawless connection.

Advantage 4: Easy Application:

Glue takes the hassle out of bonding glass to plexiglass. With convenient applicator tips or nozzles, you can apply the glue precisely and with ease. Plus, many glues have quick-drying formulas, making the process faster and more efficient. Say goodbye to complex techniques or time-consuming methods.

Advantage 5: Resistance to Moisture and Temperature:

Glass and plexiglass often face environmental challenges, like humidity and temperature fluctuations. But fear not – glues designed for bonding glass to plexiglass offer resistance to these factors. This means your bond remains strong, unaffected by moisture or temperature changes.

Advantage 6: Flexibility:

Glue gives you the freedom to let your creativity flow. Unlike other methods like screws or brackets, glue allows for more flexible joint designs and applications. You can create seamless joints, intricate designs, or even curved and irregular shapes. The possibilities are endless.

Advantage 7: Cost-effective:

Saving money is always a superpower. Glue is a cost-effective option compared to other bonding methods like welding or mechanical fasteners. It eliminates the need for extra tools or equipment and can be easily applied without specialized training. Whether you’re a DIY enthusiast or a professional, glue is an affordable choice.

Types of Glue Suitable for Bonding Glass to Plexiglass

Look no further. In this article, we will explore the different types of glue that are ideal for creating strong connections between glass and plexiglass. Whether you’re embarking on a creative project or fixing something at home, finding the right glue is essential. So, let’s dive into the world of adhesives and discover the best options for all your glass and plexiglass bonding needs.

Epoxy Adhesive: Strength that Lasts a Lifetime

If you desire a bond that can withstand the test of time, epoxy adhesive is your go-to option. This glue is renowned for its exceptional strength and durability, making it perfect for bonding glass to plexiglass. It can bravely endure water, heat, and chemicals without breaking a sweat. However, be cautious when handling epoxy resin as it can be messy, requiring careful mixing and application.

Cyanoacrylate Glue: Quick and Convenient Fix

When time is of the essence, cyanoacrylate glue comes to the rescue. Also known as super glue, this adhesive dries rapidly and forms a robust bond between glass and plexiglass. It works wonders for small projects or quick repairs. However, bear in mind that it may not possess the same level of durability as epoxy resin and can become brittle over time.

Silicone Adhesive: Flexibility Meets Outdoor Resilience

If your project demands flexibility or outdoor versatility, silicone adhesive is your best friend. This glue creates a flexible bond capable of withstanding vibrations and movement. Moreover, it resists moisture, making it an ideal choice for outdoor applications. However, keep in mind that silicone adhesive may not match the strength of epoxy resin or cyanoacrylate glue.

UV-Curing Adhesives: The Need for Speed and Efficiency

For those in search of a swift bond, UV-curing adhesives are the way to go. These glues require exposure to ultraviolet light to cure and form a sturdy bond. They offer rapid curing times and exceptional bond strength, making them suitable for various applications. However, keep in mind that UV-curing adhesives can be pricier and require specialized equipment for curing.

Clear Epoxy Adhesive for Bonding Glass to Plexiglass

Look no further than clear epoxy adhesive. This incredible adhesive not only creates an incredibly strong and durable bond, but it also provides a transparent finish, making it ideal for applications where aesthetics truly matter.

Before you jump into the bonding process, there are a few crucial things you need to know. Clear epoxy adhesives consist of two components – a resin and a hardener. These components must be mixed together before application. Be sure to select an epoxy adhesive specifically designed for bonding glass and plexiglass, as not all epoxies are suitable for this purpose.

Once you have your trusty epoxy adhesive in hand, it’s time to prepare the surfaces. Give both the glass and plexiglass a good cleaning using a mild detergent and water. Rinse them thoroughly and let them dry completely before moving on to the next step.

Now comes the exciting part – mixing the epoxy adhesive according to the manufacturer’s instructions. Pay close attention to these instructions, as improper mixing can result in a weak bond. Once your mixture is ready, apply a thin layer of the adhesive onto one of the surfaces using a brush or applicator.

With precision and care, align the second surface with the first and press them together firmly. Any excess adhesive can be easily wiped away with a clean cloth or sponge. To ensure an unbreakable bond, it’s highly recommended to clamp or secure the bonded surfaces until the adhesive cures. The curing time will depend on the specific epoxy adhesive you’re using, so consult the manufacturer’s instructions for guidance.

Once the epoxy adhesive has fully cured, rest easy knowing that your glass and plexiglass are securely bonded. However, handling them with care is still essential to avoid unnecessary stress or impact that could weaken the bond.

UV-Curing Adhesive for Bonding Glass to Plexiglass

When it comes to bonding glass to plexiglass, UV-curing adhesive is the ultimate superhero that can save the day. With its unique properties and exceptional effectiveness, this adhesive offers several advantages for achieving a seamless and strong connection. Let’s explore the benefits of using UV-curing adhesive and why it is the go-to option for bonding glass to plexiglass.

Advantage #1: Unparalleled Strength and Durability

UV-curing adhesive forms a chemical bond with both glass and plexiglass surfaces, creating an unbreakable connection. This is vital when bonding these materials, as they may undergo temperature changes, moisture exposure, and mechanical forces. With UV-curing adhesive, you can have peace of mind knowing that your bond will withstand any challenge it faces.

Advantage #2: Flawless Optical Clarity

Aesthetics matter when bonding glass to plexiglass, and UV-curing adhesive delivers flawless optical clarity. This adhesive remains transparent, ensuring a seamless and visually pleasing bond. Whether you are creating display cases or architectural installations, the adhesive remains invisible, allowing the natural beauty of the materials to shine through.

Advantage #3: Lightning-Fast Curing Time

In today’s fast-paced world, time is of the essence, and UV-curing adhesive rises to the occasion. Once applied and exposed to ultraviolet light, this adhesive rapidly solidifies within seconds, creating a strong bond. Its fast curing time increases efficiency and productivity, making it ideal for production settings where speed is paramount.

Choosing the Right Adhesive:

Not all UV-curing adhesives are created equal. To ensure success in bonding glass to plexiglass, it is essential to select an adhesive specifically designed for this purpose. These adhesives often have enhanced adhesion properties tailored for glass and plexiglass surfaces, guaranteeing a reliable bond.

Proper Surface Preparation:

To achieve optimal results with UV-curing adhesive, proper surface preparation is crucial. Thoroughly clean both the glass and plexiglass surfaces to remove contaminants like oils or dirt. Additionally, slightly roughening the surfaces can improve adhesion. This can be achieved through sanding or using specialized primers designed for glass and plexiglass.

Super Glue for Bonding Glass to Plexiglass

Look no further. Super glue, also known as cyanoacrylate adhesive, is here to save the day. With its strong and fast-drying properties, it’s the perfect choice for this task. However, not all super glues are created equal, so let’s dive into the process of using super glue to bond glass to plexiglass and ensure a successful outcome.

Step 1: Cleanliness is Key:

Before applying super glue, cleanliness is crucial. Any dirt, dust, or oils can compromise the bond. So, grab some isopropyl alcohol and wipe down both the glass and plexiglass surfaces until they shine like diamonds.

Step 2: Roughen the Surface:

To create an even stronger bond, it’s time to roughen things up a bit. Grab some sandpaper and gently roughen the surface of the plexiglass. This step may sound a bit rebellious, but trust me, it provides a better bonding surface for the adhesive.

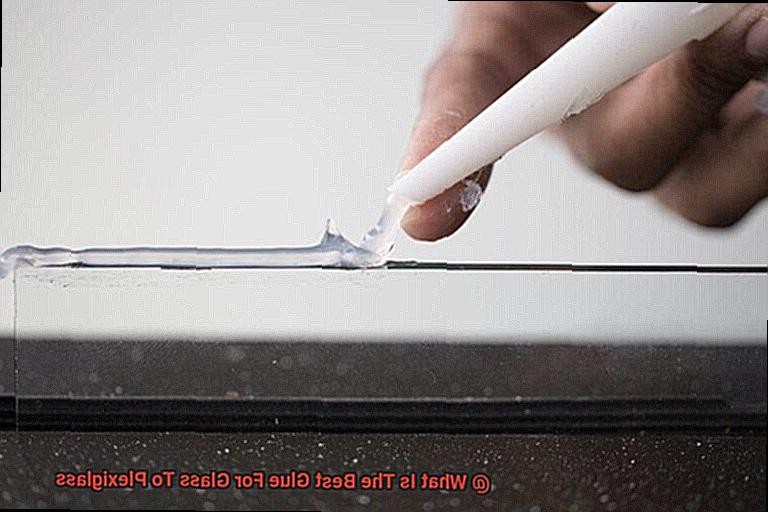

Step 3: Apply the Super Glue:

Now it’s time for the magic to happen. Apply a small amount of super glue on one of the surfaces. Remember, less is more in this case. We don’t want excess glue oozing out and ruining the aesthetics. A thin and even layer will do the trick.

Step 4: Press and Hold:

Carefully press the glass and plexiglass together, ensuring they align perfectly. Hold them in place for a few minutes, like you’re embracing a long-lost friend. This allows the glue to set properly. Patience is key here.

Step 5: Curing Time:

Although super glue dries quickly, it needs time to reach its full potential. Let the bond cure for at least 24 hours before subjecting it to any stress or pressure. This waiting period ensures maximum strength and durability, so resist the temptation to rush.

Step 6: Transparency Matters:

Now, let’s talk about that transparent beauty. Super glue may create a slight haze or fogging effect on glass and plexiglass. It’s like wearing smudged glasses on a sunny day—slightly imperfect. So, be prepared for this, depending on the lighting conditions.

Step 7: Durability Considerations:

Super glue bonds are indeed strong, but they have their limitations. High-stress applications and extreme temperatures may put them to the test. So, if your project involves these factors, it’s wise to explore alternative adhesive options for a more reliable bond.

Preparing the Surfaces Before Applying the Glue

Well, hold on tight because we’re about to dive into the exciting world of preparing surfaces before applying glue to bond glass and plexiglass. Trust me, this is an essential step that you don’t want to skip if you want your project to stick together like peanut butter and jelly.

So why is surface preparation so important? Let me break it down for you. When you’re dealing with glass and plexiglass, you need to ensure that the glue adheres properly. And the only way to do that is by getting rid of any dirt, dust, or oils that might be hanging around on those surfaces.

First things first, grab your cleaning arsenal and give those glass and plexiglass surfaces a thorough scrub. Use a mild detergent or glass cleaner to banish any grime that might be lurking. Rinse them off with water and make sure they’re bone-dry before moving on to the next step.

Now, here comes the fun part. Take out your fine-grit sandpaper and gently roughen up those surfaces. This creates more surface area for the glue to grip onto, ensuring a stronger bond. Just remember to be gentle with your sanding motions – we don’t want any accidents where your glass or plexiglass ends up looking like it went through a blender.

Once you’ve finished sanding, grab a clean cloth or microfiber towel and wipe away any leftover dust or debris. You want those surfaces to be squeaky clean and free from any particles that could interfere with the gluing process.

But wait, there’s more. Some experts recommend using a primer or adhesion promoter on both the glass and plexiglass surfaces. These magical potions enhance the bonding capabilities of the glue, making it stickier than ever before. Just follow the instructions on the bottle and apply it like a pro.

Now, here comes the crucial part. Once you’ve prepared those surfaces, you need to handle them with care. We don’t want any recontamination messing up your hard work. So, put on your superhero gloves and avoid touching the prepared areas with bare hands. Those pesky oils from your skin can wreak havoc on your bonding process.

Following Manufacturer’s Instructions for Optimal Results

In this comprehensive guide, we will delve into the criticality of adhering to the manufacturer’s instructions when it comes to using glue for this purpose. By doing so, you can unlock the potential for optimal results, guaranteeing a robust and enduring bond between these two materials. So, let’s embark on this transformative journey together.

Cleanliness is Key:

Prepare for perfection by embracing cleanliness as the foundation of success. Before applying any glue, it is imperative to meticulously clean both surfaces with precision. The manufacturer’s instructions will serve as your trusty compass, guiding you towards the most effective cleaning methods. Utilize a mild detergent or glass cleaner to banish any impurities or oils that may compromise the bond. Remember to employ a lint-free cloth or paper towel for drying, leaving no remnants of particles behind.

Applying the Right Amount of Glue:

Like a master artist wielding their brush, precision is paramount in achieving the desired outcome. Applying too much or too little glue can jeopardize the strength and longevity of the bond. Fear not, for the manufacturer’s instructions will unveil the secret formula of applying just the right amount. Each specific product may have its own unique requirements. By adhering to these guidelines faithfully, you shall forge an unbreakable union between glass and plexiglass.

Patience is a Virtue: Curing Time Matters:

In this fast-paced world, patience often takes a backseat. However, in the realm of gluing glass to plexiglass, patience reigns supreme. The curing time, akin to a metamorphosis from liquid to strength, holds the key to success. Rushing this process could precipitate the downfall of your bond. Fear not, for the manufacturer’s instructions shall illuminate the path to enlightenment. It may entail leaving the glued surfaces undisturbed for a specific period or applying precise pressure during the curing process. By following these sacred instructions, you grant the glue ample time to mature and manifest optimal results.

Additional Steps and Precautions:

Sometimes, the journey to perfection demands extra steps and precautions. Embrace them as opportunities for greatness. Priming or roughening the surfaces may be necessary for certain glues to unleash their full potential. The manufacturer’s instructions will lay bare these secrets, ensuring that no essential pre-bonding preparations are overlooked. With each additional step, you inch closer towards perfection.

5xRNNXQpkOU” >

Also Read: How to Glue Plexiglass to Glass?

Conclusion

In conclusion, when it comes to bonding glass and plexiglass together, there are a few glues that stand out as the best options.

One such adhesive is epoxy resin. Its strong bond and ability to dry clear make it an excellent choice for this type of project.

Another reliable option is silicone adhesive, which offers flexibility and resistance to moisture. Lastly, UV-curing glue provides a quick and efficient solution with its fast-drying properties.

So, consider the materials involved and choose the adhesive that best suits your requirements.