Looking for the perfect adhesive to secure your copper pipes? Look no further. In this blog post, we’ll reveal the best glue for copper pipe that will ensure a strong and long-lasting bond for all your plumbing needs. When it comes to connecting copper pipes, using the right adhesive is crucial to prevent leaks and protect your plumbing system.

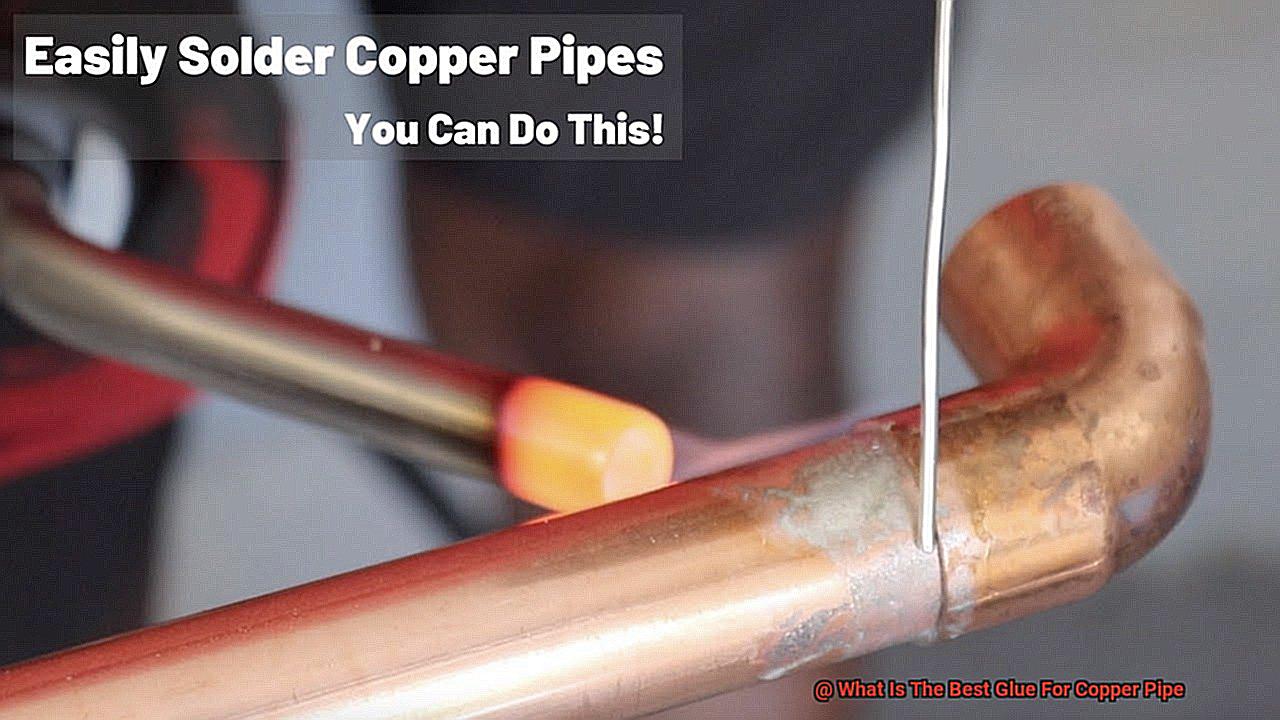

The undisputed champion of glues for copper pipe is soldering with copper pipe solder. This technique involves melting a filler metal into the joint, creating a watertight seal and an incredibly strong bond that can withstand high water pressures. It’s like welding for pipes.

But here’s the catch: soldering requires skill and experience. If you’re new to DIY or don’t have access to specialized tools, soldering might not be your best bet. That’s where epoxy adhesive comes in.

Epoxy is a versatile and reliable glue that effectively bonds copper pipes. It consists of two parts – a resin and a hardener – that you mix together just before applying. Epoxy offers excellent resistance to corrosion, extreme temperatures, and high water pressures, ensuring a secure connection.

However, there are a couple of downsides to using epoxy. First off, it can be messy and hard to clean up since it tends to drip and harden quickly. Secondly, epoxy takes longer to cure compared to other glues – often hours or even overnight – which can be inconvenient if you need to use your plumbing system right away.

In conclusion, if you’re a pro looking for the best glue for copper pipe, soldering with copper pipe solder is the way to go. But if you’re more of a DIY enthusiast or don’t have soldering equipment on hand, epoxy adhesive is an excellent alternative that provides a strong and durable bond. Consider your skill level, time constraints, and project requirements when choosing the best glue for your copper pipe needs.

Stay tuned. In our next section, we’ll walk you through the step-by-step process of soldering and using epoxy adhesive for copper pipes.

What is Soldering Paste?

Contents

Soldering copper pipes may seem daunting, but with the right tools and materials, it becomes a breeze. One of these essential materials is soldering paste, also known as flux paste. In this blog post, we will uncover the magic behind soldering paste and explore its purpose in creating robust and dependable connections between copper pipes.

The Power of Cleaning and Preparation:

To join two copper pipes together, their surfaces must be meticulously cleaned and prepared. Over time, copper develops an oxide layer that hinders solder from adhering effectively. This is where soldering paste steps in. Its primary purpose is to remove this oxide layer and provide a pristine surface for soldering. By applying soldering paste, you guarantee that your copper pipes are primed for a solid bond.

The Flux Factor:

Soldering paste not only cleans but also acts as a flux. Flux is a miraculous substance that reacts with the metal surfaces being soldered, reducing surface tension and enabling the solder to flow effortlessly. The flux in soldering paste works behind the scenes, creating smooth and reliable connections between copper pipes. It’s like having a secret ingredient that ensures a robust bond.

Choosing the Right Soldering Paste:

Selecting the appropriate soldering paste for your project is crucial. Various pastes have different compositions and concentrations of flux. Look for soldering paste specifically designed for use with copper pipes to ensure compatibility and optimal performance. Remember to opt for lead-free options due to safety concerns.

Applying Soldering Paste:

Applying soldering paste is an art in itself. It should be done evenly and sparingly on the surfaces to be soldered. Excessive paste can result in unwanted residue or interfere with the soldering process, while too little may not adequately remove oxidation or promote sufficient adhesion. The key lies in finding the perfect balance.

Professional Tips and Considerations:

When working with soldering paste, always follow the manufacturer’s instructions. Properly clean and prepare the copper pipe surfaces before applying the paste, and ensure even heating for a strong bond. If you’re uncertain about the process, consult a professional plumber or adhere to local building codes and regulations.

Benefits of Using Soldering Paste

Whether you’re a DIY enthusiast or a professional plumber, having a reliable adhesive is essential for joining copper pipes effectively. Look no further than soldering paste, a magical substance that offers a plethora of benefits for creating strong and leak-free connections. Let’s dive into the advantages of using soldering paste.

- Strength and Durability: Soldering paste creates a bond that can withstand high pressure and temperature fluctuations. Say goodbye to worrying about weak joints that might burst under pressure or fail when exposed to extreme temperatures.

- Leak-Free Joints: Unlike traditional glues or adhesives, soldering paste melts and fuses the copper pipes together, creating seamless connections that are impervious to leaks. No more pesky drips or gas seepage ruining your plumbing masterpiece.

- Versatility: Soldering paste isn’t just limited to plumbing; it’s also handy for HVAC systems and electrical work. Whether you’re fixing a leaky faucet or installing a brand-new system, soldering paste has got you covered.

- Ease of Use: With soldering paste, achieving excellent results doesn’t require a PhD in chemistry. It comes in a user-friendly tube or container and can be easily applied using a brush or applicator. Simply heat it up, and voila. You’ve got yourself a secure bond.

- Corrosion Resistance: Copper pipes are notorious for succumbing to corrosion over time. But fear not. Soldering paste creates a protective barrier that shields your pipes from moisture and harsh chemicals, prolonging their lifespan.

- Easy Disassembly: Unlike some glues or adhesives that create permanent bonds, soldering paste allows for easy disassembly when necessary. Just heat it up, and you can separate the copper pipes without breaking a sweat.

- Cost-Effectiveness: While soldering paste may have a slightly higher upfront cost, its durability and long-lasting performance make it a cost-effective choice in the long run. You won’t have to worry about frequent repairs or replacements, saving you money and time.

Choosing the Right Soldering Paste

Welcome to the fascinating world of soldering paste, the magical adhesive that transforms ordinary copper pipes into strong and leak-free connections. In this guide, we will explore the essential factors to consider when selecting the right soldering paste for copper pipe and delve into the different types available.

- Choose a paste specifically designed for copper pipes: This ensures that the paste will adhere well to the surface of the copper and create a secure bond. Using a generic paste may result in weak joints and potential leaks down the line.

- Consider lead-free vs. lead-based pastes: Lead-free pastes are generally recommended as they comply with environmental regulations and are safer to use. However, some professionals still prefer lead-based pastes for their superior performance. Weigh the benefits and risks when making your selection.

- Opt for a high melting point: Copper pipes require high temperatures to achieve proper bonding. Using a paste with a low melting point may result in weak joints that can’t withstand high-pressure situations. Choose a paste with a high melting point to ensure durability and strength.

- Check flux content: Flux is an essential component of soldering paste as it helps clean the surface of the copper pipe by removing oxidation and impurities. This allows for better adhesion of the solder and creates a stronger bond. Look for soldering pastes that have a good amount of flux content to ensure optimal cleaning and bonding.

- Choose reputable manufacturers or brands: Trusted brands often invest in extensive research and development processes to ensure the quality and performance of their products. By opting for products from reputable manufacturers, you can have confidence in the effectiveness of the soldering paste you choose.

While cost is an important consideration, prioritize quality and performance over price. Investing in a high-quality soldering paste may cost a little more upfront but can save you money and headaches in the long run by preventing leaks and ensuring durability.

Lead-Free Soldering Paste

Lead-Free Soldering Paste: A Safe and Effective Solution for Joining Copper Pipes

When it comes to joining copper pipes, safety should always be the number one priority. That’s where lead-free soldering paste comes in, offering a superhero-like solution that eliminates the risks associated with lead-based materials.

So, what makes lead-free soldering paste the ultimate superhero of copper pipe adhesives? Let’s dive into its advantages and explore the reasons why it is the chosen champion in the world of plumbing:

First and foremost, lead-free soldering paste ensures the safety of both plumbers and homeowners by eliminating the risk of lead exposure. With lead being phased out in many industries, including plumbing, it’s crucial to make the switch to a safer alternative. This super soldering paste contains a combination of tin, silver, and copper, providing excellent adhesion and conductivity. Say goodbye to lead and hello to a secure and reliable bond that will stand the test of time.

But that’s not all. Lead-free soldering paste requires a higher heat source such as a torch or soldering iron due to its higher melting point. While this may require some adjustments to your usual soldering process, it guarantees a bond that is strong and resilient. The power of lead-free soldering paste is further amplified by trusted brands such as Oatey, RectorSeal, and Harris. These industry leaders have earned their reputation for quality and performance in the world of plumbing.

However, it’s important to note that this superhero adhesive may leave residues that require additional cleaning steps compared to traditional lead-based soldering paste. But fear not. By following the manufacturer’s instructions, you can ensure optimal performance and longevity of your copper pipe connections.

Melting Point Considerations

It’s not just the work of plumbing superheroes, but rather a crucial adhesive known as solder or copper pipe glue. In the fascinating world of glues, the melting point is a hidden superpower that determines the strength and durability of the bond. Today, we’ll dive into the importance of considering the melting point when bonding copper pipes and explore some top-notch adhesives that come to the rescue.

The Melting Point Dilemma:

Copper pipes boast an impressive melting point of around 1,083°C (1,982°F). To achieve a strong bond, it’s vital to select an adhesive with a higher melting point than copper itself. Regular glues like super glue or epoxy may fall short as they can soften or even melt under high temperatures. This can lead to weak bonds or catastrophic failures – and let’s face it, nobody wants a plumbing system plagued with leaks.

Solder – The Classic Hero:

One popular adhesive for copper pipe bonding is solder. This metal alloy possesses a low melting point, making it perfect for joining two pieces of copper. When heat is applied, solder melts and forms a robust connection that can withstand the high temperatures experienced in plumbing systems.

Copper Pipe Glue – The Specialist:

For those seeking an alternative to solder, specialized adhesives like copper pipe glue or copper pipe cement step up to save the day. These adhesives are specifically designed for bonding copper pipes and boast higher melting points compared to regular glues. They contain solvents that soften the surface of the copper pipe, allowing the adhesive to penetrate and create a robust bond. Once the solvent evaporates, the adhesive hardens and forms a solid connection between the pipes.

Tips for Success:

To ensure a successful bond, it’s essential to follow the manufacturer’s instructions when using copper pipe glue. Clean and dry surfaces, free from grease or debris, provide the best foundation for a strong connection. Applying the adhesive evenly and allowing sufficient curing time before exposing it to water or other stresses is key to achieving a leak-free plumbing system.

Consider Your Needs:

In addition to melting point considerations, other factors like the type of copper pipe (hard or soft) and the intended use of the pipes should also be taken into account when selecting the best glue. Different adhesives may be better suited for specific types of copper pipes or applications, such as drinking water systems or heating systems. When in doubt, consulting a professional plumber or adhering to the recommendations of the pipe manufacturer can provide expert guidance.

Preparing the Copper Pipe Surface

In the world of plumbing, there is one crucial element that often goes unnoticed – the preparation of the copper pipe surface before gluing. This vital step ensures a strong and secure bond, making it an essential part of any plumbing project. In this blog post, we will guide you through the process of preparing your copper pipe surface for gluing, ensuring a professional and long-lasting result.

Step 1: Clean the Pipe

Begin by meticulously cleaning the copper pipe. Grab a clean cloth or paper towel and wipe down the entire length of the pipe, eliminating any dirt, grease, or debris that could hinder the adhesive’s effectiveness.

Step 2: Remove Oxidation

Over time, copper pipes develop a layer of oxidation that can interfere with the adhesive’s ability to create a strong bond. To combat this issue, use sandpaper or a wire brush to gently remove the oxidation. Focus on areas where it is more pronounced, being careful not to scratch the pipe’s surface.

Step 3: Degrease the Pipe

For a proper bond between the adhesive and the copper pipe, it is crucial to eliminate any traces of grease or oil from the surface. Utilize a degreasing agent specifically designed for copper pipes, following the manufacturer’s instructions meticulously.

Step 4: Rinse and Dry

Following cleaning and degreasing, rinse the copper pipe thoroughly with clean water to remove any residue from cleaning agents. It is imperative to dry the pipe completely using a clean cloth or by allowing it to air dry naturally. Moisture on the surface can greatly impact the adhesive’s performance.

Step 5: Sanding (Optional)

Depending on the type of glue being used and the condition of the copper pipe, you may opt to sand the surface for enhanced adhesion. Sanding creates a rougher texture on the pipe, providing more surface area for the glue to bond to. Use fine-grit sandpaper and gently sand the pipe in a circular motion. Remember to clean and degrease the pipe again after sanding before moving on to applying the glue.

Alternative Glues for Copper Pipes

Finding the right adhesive for plumbing projects involving copper pipes is crucial to ensure a secure and leak-free connection. While soldering has been the traditional method, alternative glues are now available and offer convenient and effective solutions. In this article, we will explore various types of alternative glues for bonding copper pipes, discussing their unique characteristics, and identifying situations where they may be particularly useful.

Epoxy Resin:

- Ideal for high-pressure or extreme temperature applications.

- Creates a durable bond when mixed with a hardener and applied to pipe surfaces.

- Quick setting time and forms a strong connection.

Polyurethane Adhesive:

- Offers strength and flexibility, making it suitable for pipes subject to movement or vibration.

- Bonds a wide range of materials, including copper.

- Resistant to water and chemicals.

Silicone Sealant:

- Primarily used for sealing gaps and joints but can also bond copper pipes.

- Forms a waterproof seal that prevents leaks.

- May not provide the same strength as other glues.

Pipe Dope (Pipe Joint Compound):

- Not technically a glue but effective in specific situations.

- Applied to pipe fittings’ threads before screwing together to create a tight seal and prevent leaks.

- Useful when a strong bond is unnecessary.

Professional Guidance and Regulations

Professional guidance and regulations play a crucial role in ensuring the proper use of glue for copper pipes. When working with copper pipes, it is essential to adhere to industry standards and guidelines to maintain the safety and integrity of the plumbing system.

The International Association of Plumbing and Mechanical Officials (IAPMO) is one of the primary organizations that provides professional guidance on this matter. They have established codes and standards that dictate the use of glue or other joining methods for copper pipes. These codes serve as a framework for plumbers to follow, similar to the Jedi code for plumbers.

According to IAPMO, the most commonly used glue for connecting copper pipes is a solvent-based cement specifically designed for copper pipe applications. This adhesive creates a strong bond between pipes and fittings, ensuring a leak-free connection. However, not all glues are created equal. Some glues contain chemicals that can corrode or degrade copper over time. It is essential to choose an adhesive that is labeled for use with copper pipes to avoid any unpleasant surprises down the line.

It’s important to note that different regions have different building codes and regulations. Therefore, it is crucial to check with local plumbing authorities or professionals to ensure compliance with the specific rules in your area. Following these regulations is key to maintaining the safety and reliability of your plumbing system.

For those who may not be plumbing experts themselves, hiring a licensed plumber is always a wise decision. These professionals have undergone training and certification programs to stay updated with the best practices for using adhesives on copper pipes. They have a wealth of knowledge on the best glue choices available and can ensure a proper installation.

zb9mEsRInrk” >

Also Read: How to Glue Metal to Glass?

Conclusion

In conclusion, when it comes to finding the best glue for copper pipe, there is one clear winner that stands above the rest.

That champion is none other than soldering. Soldering provides a strong and durable bond that can withstand high temperatures and pressure.

So, if you’re looking for the ultimate adhesive solution for your copper pipe projects, look no further than soldering.