Step into the world of 3D printed miniatures, where glue is the unsung hero holding together these tiny masterpieces. As the 3D printing craze sweeps across the globe, enthusiasts like you are faced with a daunting task: finding the perfect adhesive to bring your intricate creations to life. With shelves brimming with options, it’s easy to feel lost in a sea of glue choices. But fret not. In this blog post, we’ll embark on a quest to uncover the ultimate glue for your 3D printed miniatures.

Whether you’re crafting epic models for tabletop battles or fashioning delicate figurines that could rival museum artifacts, we’ve got you covered. We’ll dive deep into the realm of glues suitable for 3D printed wonders and unveil the qualities you should seek in your adhesive companion.

Imagine a bond so strong that not even an earthquake could shake it loose. Picture a glue that dries clear, leaving no unsightly residue behind. Envision an adhesive that can withstand the test of time, ensuring your miniatures remain intact for years to come. Sounds like magic? Well, my friend, get ready to witness this enchantment firsthand.

So grab your magnifying glass and prepare to explore a world where every drop of glue matters. Together, we’ll unravel the mysteries of adhesion and discover which glue reigns supreme in the realm of 3D printed miniatures. Get ready to elevate your projects to new heights as we unlock the secrets of this ultimate adhesive solution.

Different Types of Glue for 3D Printed Miniatures

Contents

- 1 Different Types of Glue for 3D Printed Miniatures

- 2 Advantages and Disadvantages of Cyanoacrylate (CA) Glue

- 3 Advantages and Disadvantages of Epoxy Resin

- 4 Other Specialized Adhesives for Specific Applications

- 5 Preparing the Surfaces for Bonding

- 6 Tips and Tricks for Applying Glue to 3D Printed Miniatures

- 7 Conclusion

When it comes to bonding 3D printed miniatures, choosing the right type of glue is essential. There are several different types of glue available, each with its own advantages and disadvantages. In this essay, we will explore some of the most commonly used glues for 3D printed miniatures and discuss their pros and cons.

Super Glue:

Super glue, also known as cyanoacrylate adhesive, is a popular choice for bonding 3D printed miniatures. It is fast-drying and forms a strong bond between the parts. This makes it suitable for small parts and delicate details.

The quick-drying nature of super glue means that you don’t have to wait long for it to set, allowing you to continue working on your miniature without delay.

However, super glue can be brittle and may not work well on certain materials or surfaces. It is important to test it on a small, inconspicuous area before applying it to the entire model.

Epoxy Resin:

Epoxy resin is another option for gluing 3D printed miniatures. It consists of two components that need to be mixed together before application. Epoxy resin provides a strong and durable bond, making it suitable for larger and heavier parts.

It can also fill gaps and uneven surfaces, ensuring a seamless finish. However, epoxy resin has a longer curing time compared to super glue.

It may require clamping during the drying process to ensure a tight bond. Additionally, epoxy resin should be used in a well-ventilated area due to its strong odor.

Plastic Cement:

Plastic cement is specifically designed for bonding plastic materials, making it a good option for 3D printed miniatures. It works by melting the plastic surfaces together, creating a strong and seamless bond.

Plastic cement is especially effective for PLA and ABS prints, but it may not work well on other types of plastics. It is important to exercise caution and skill during application, as the melting process can be tricky to control. However, with practice, plastic cement can provide a reliable and sturdy bond for your miniatures.

UV Resin:

Some hobbyists also recommend using UV-curing resins for gluing 3D printed miniatures. These resins require exposure to ultraviolet light to cure and form a strong bond. UV-curing resins provide precise control during application, as they do not cure until exposed to the UV light source.

This allows you to adjust and position the parts before curing. UV resin also has a fast curing time, allowing you to move on with your project quickly.

However, it should be noted that UV resins tend to be more expensive compared to other types of glue. Additionally, you will need a UV light source for proper curing, which adds to the overall cost.

Epoxy Putty and Modeling Clay:

Another option for bonding 3D printed miniatures is using two-part epoxy putty or modeling clay. These materials can be shaped and molded before hardening, allowing for additional sculpting or filling of gaps.

Epoxy putty and modeling clay are versatile options that provide flexibility in terms of shape and design. However, it should be noted that they may not provide as strong of a bond as other types of glue. If you are looking for a stronger bond, it is recommended to use one of the previously mentioned adhesives.

Conclusion:

In conclusion, there are multiple types of glue available for bonding 3D printed miniatures, each with its own pros and cons. Super glue, epoxy resin, plastic cement, UV resin, and epoxy putty are some of the commonly used options.

The choice of glue depends on the specific materials and requirements of the miniature, so it is important to do some testing and research before making a final decision. Additionally, following the manufacturer’s instructions and safety precautions is crucial for successful bonding and personal safety.

Advantages and Disadvantages of Cyanoacrylate (CA) Glue

When it comes to bonding 3D printed miniatures, cyanoacrylate (CA) glue, also known as super glue, is a popular adhesive choice. It offers several advantages, but it also has its limitations. Let’s explore the advantages and disadvantages of using CA glue for this application:

Advantages:

- Quick bonding: CA glue is renowned for its fast bonding capability. Within seconds, it forms a strong bond, allowing for quick assembly of 3D printed miniatures. This is particularly useful when working on time-sensitive projects or when immediate repairs are needed.

- Versatility: CA glue can bond various materials commonly used in 3D printing, such as plastic, metal, and wood. Its versatility makes it suitable for different types of 3D printed miniatures and allows for seamless joining of different components.

- Clear finish: Upon drying, CA glue becomes clear, leaving behind an almost invisible bond line. This feature is especially important when working with translucent or colored 3D printed parts since it ensures an aesthetically pleasing finish without visible residue.

- Gap-filling properties: One of the remarkable characteristics of CA glue is its ability to fill small gaps and imperfections in the surfaces being bonded. This can be advantageous when working with 3D printed miniatures that may have slight imperfections or gaps between parts. The glue fills in these gaps, creating a stronger bond and improving the overall appearance of the final product.

Disadvantages:

- Brittle bond: A major drawback of CA glue is its tendency to create a brittle bond compared to other adhesives. This means that the bond may be susceptible to breaking or cracking under stress or impact. Care should be taken when handling delicate 3D printed miniatures or parts that require flexibility.

- Limited repositioning time: Once CA glue is applied, there is very little time to reposition the parts being bonded before it sets. This can be problematic if precise alignment is required for intricate assemblies of 3D printed miniatures. It is important to plan and prepare the parts before applying the glue to ensure accurate positioning.

- Sensitivity to moisture: CA glue is sensitive to moisture and can react with it, causing premature curing or the formation of a white, hazy residue. This can affect the strength of the bond and the overall appearance of the glued parts. It is essential to store CA glue in a dry environment and avoid using it in humid conditions.

- Potential health risks: CA glue emits fumes that may cause eye, nose, and throat irritation. It is recommended to use CA glue in a well-ventilated area or wear protective equipment such as goggles and a mask when working with it.

Advantages and Disadvantages of Epoxy Resin

Epoxy resin is a remarkable adhesive with several advantages and disadvantages. On the positive side, epoxy resin creates an incredibly strong and durable bond, ensuring that different parts of 3D printed miniatures stay securely attached.

This is crucial, especially for delicate or intricate designs that require a reliable adhesive. Additionally, epoxy resin is highly versatile and can be used on various materials such as plastics, metals, ceramics, and glass. This makes it suitable for bonding different components of miniatures, regardless of the materials used in their construction.

Another advantage of epoxy resin is its excellent gap-filling properties. It can easily fill in small gaps or spaces between parts during the bonding process, resulting in a seamless and aesthetically pleasing finish, particularly for intricate or detailed miniatures.

Furthermore, epoxy resin is highly resistant to moisture and chemicals, making it ideal for outdoor use or environments where the miniatures may be exposed to harsh conditions. It also ensures that the bond remains strong and intact over time.

However, there are some drawbacks to using epoxy resin. Firstly, it requires precise mixing of two components before application, followed by a curing period that can range from hours to days. This time-consuming process can delay the completion of projects.

Secondly, some epoxy resins release potentially toxic fumes during the curing process. Proper ventilation or protective gear should be used to minimize exposure to these fumes.

Prolonged or repeated exposure to uncured epoxy resin may also cause skin irritation or allergic reactions in some individuals.

Additionally, while epoxy resin creates a strong bond initially, it can be relatively brittle once cured. Excessive force or impact may cause detachment or breakage of miniature parts. Therefore, handling epoxy-bonded miniatures with care is important to avoid accidental damage.

Lastly, compared to other adhesives, epoxy resin can be more expensive. This cost factor may be a consideration for those working on a tight budget or requiring frequent adhesive applications.

Other Specialized Adhesives for Specific Applications

When it comes to 3D printed miniatures, there is a fascinating array of specialized adhesives available for specific applications. These adhesives are designed to cater to the unique needs of bonding different materials or achieving specific effects. Let’s explore some of these remarkable adhesives:

- UV-curing resin: Activate this adhesive with ultraviolet light, and watch it harden into a durable bond. This adhesive is perfect for precise and clean bonding, especially when attaching delicate parts or joining transparent materials. Its exceptional clarity ensures that even after bonding, the intricate details of the miniature remain visible.

- Cyanoacrylate gel: Unlike regular super glue, this adhesive has a thicker and more viscous consistency. It offers greater control during application, minimizing accidental messes or unwanted bonds. With a longer curing time, it provides ample opportunity for adjustments before setting.

- Polyurethane-based adhesive: If your miniature requires flexible joints or moving parts, look no further than this adhesive. It bonds materials with different flexibility properties, ensuring durability while allowing for some degree of movement or flexing. Its resistance to impact and vibration adds an extra layer of strength.

- Solvent welding: When visible seams or future disassembly are concerns, turn to this alternative bonding method. Utilizing a solvent that chemically melts the 3D printed material’s surface, it creates a powerful bond by fusing the pieces together. The result? A seamless and nearly invisible joint, particularly effective when bonding parts made from the same material.

- Material-specific adhesives: For optimum bond strength and long-term durability, specialized adhesives are available for specific materials commonly used in 3D printing. Whether it’s polypropylene or another material, these adhesives are formulated to provide the best possible bond for each material type.

Preparing the Surfaces for Bonding

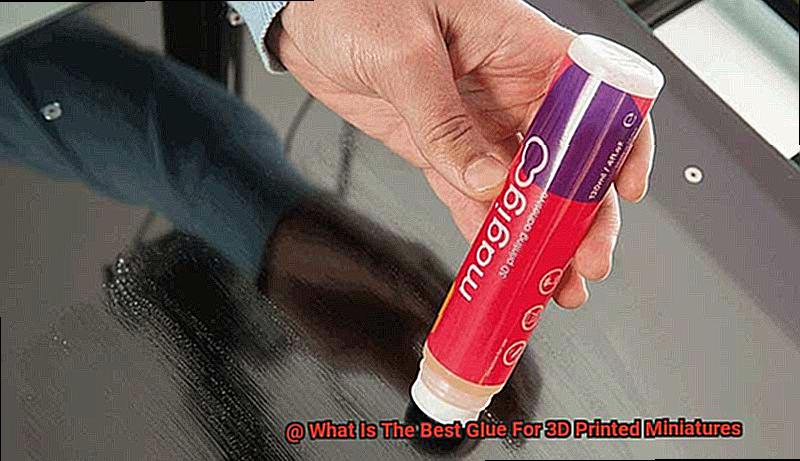

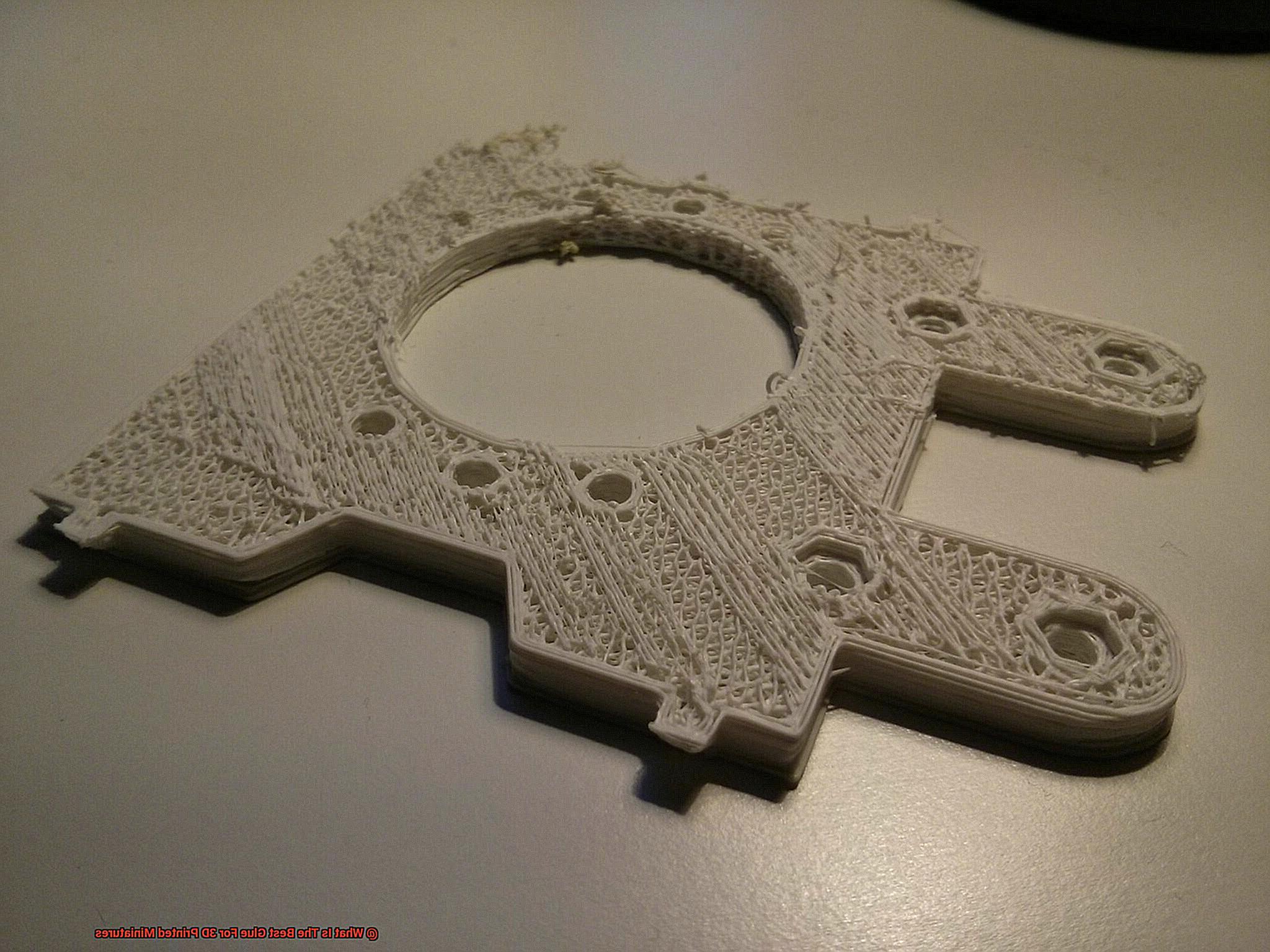

Preparing the surfaces for bonding is a critical and often overlooked aspect of the 3D printing process. To ensure a strong and durable bond between 3D printed miniatures and the glue being used, several factors must be considered.

Firstly, it is important to identify the type of material that the miniature is made of. Different materials require different preparation techniques. For example, if the miniature is made of PLA, lightly sanding the surfaces can create a rougher texture, providing more surface area for the glue to adhere to. On the other hand, for miniatures made of ABS, using an acetone solution to smooth the surfaces can be beneficial.

In addition to material type, texture plays a crucial role in bonding. Smooth surfaces tend to have less surface area for the glue to grip onto, making it challenging for a strong bond to form. To overcome this, sanding or roughening the surfaces can be beneficial. By creating a slightly rougher texture, the glue has more areas to adhere to, ultimately improving its overall strength.

Furthermore, it is essential to ensure that there are no contaminants on the surfaces that could hinder bonding. Dust, oils, or residue from support structures can prevent the glue from effectively adhering to the miniature. Thoroughly cleaning the surfaces with isopropyl alcohol or a mild detergent solution removes these contaminants, allowing for better bonding between the surfaces and glue.

Once the surfaces have been properly prepared, it is time to select an appropriate glue. Different types of glues have their own unique properties and compatibility with specific materials. Whether it’s cyanoacrylate (super glue), epoxy, or plastic cement, choosing the right adhesive is crucial for optimal bonding results.

When applying the glue, following the manufacturer’s instructions is essential. Typically, a small amount of glue is applied to one surface, and then the two surfaces are pressed together firmly. Holding them in place for an adequate amount of time allows the glue to fully cure, resulting in a strong and durable bond.

Tips and Tricks for Applying Glue to 3D Printed Miniatures

Applying glue to 3D printed miniatures requires attention to detail and careful preparation. Before starting, it’s crucial to clean the surfaces that will be bonded. Use a soft brush or compressed air to remove any dirt or debris, ensuring a clean and smooth surface for the glue to adhere to.

To create a strong bond, lightly sand the surfaces with fine-grit sandpaper. This creates a rough texture that improves the glue’s grip and enhances the overall strength of the bond.

When applying the glue, remember that less is more. Use a small amount of glue to avoid excess seeping out and marring the appearance of your miniature. Precision is key, especially when working with delicate parts. Using a precision applicator or a toothpick allows for better control and prevents overapplication of glue.

For larger parts, applying pressure on the joint after gluing helps ensure a secure bond. Consider using clamps or rubber bands to hold the pieces together while the glue dries, providing added stability during the bonding process.

Choosing the right glue is also essential. Different materials require different types of adhesives. Research or consult with other hobbyists to identify which glue works best for the specific materials used in your 3D printed miniatures.

Lastly, don’t forget about safety precautions. Follow instructions provided by the glue manufacturer, such as working in a well-ventilated area and using protective equipment if necessary.

Conclusion

In the captivating realm of 3D printed miniatures, where every intricate detail holds significance, glue emerges as the unsung hero that binds these tiny marvels together. As you embark on your quest to discover the ideal adhesive for your creations, it’s easy to feel adrift in a vast sea of options. But fear not. We have delved deep into the realm of glues suitable for 3D printed wonders and unearthed the qualities you should seek in your adhesive ally.

Imagine a bond so unyielding that even an earthquake couldn’t shake it loose. Envision a glue that dries with crystal clarity, leaving no unsightly residue in its wake. Picture an adhesive capable of enduring the test of time, ensuring your miniatures remain intact for years to come. It may sound like magic, but get ready to witness this enchantment firsthand.

From super glue with its rapid-drying prowess and formidable bonding strength to epoxy resin renowned for its unwavering durability and gap-filling capabilities, a plethora of options awaits. Plastic cement stands primed specifically for bonding plastic materials, while UV-curing resins grant precise control during application. Epoxy putty and modeling clay offer unparalleled versatility in shaping and filling gaps.

However, before making your decision, it’s crucial to weigh the advantages and disadvantages of each type of glue. Super glue may possess brittleness as its Achilles’ heel, while epoxy resin demands patience due to longer curing times. UV resins may bear a higher price tag compared to other alternatives, and plastic cement necessitates deftness during application.

In conclusion, discovering the best glue for 3D printed miniatures hinges upon factors such as material compatibility, bonding strength, curing time, and personal preference. It’s essential to conduct small-scale tests with different glues before committing fully to ensure optimal results. Remember to adhere diligently to manufacturer instructions and safety precautions throughout the bonding process.

So, equip yourself with a magnifying glass and embark on an exploration of this captivating world where every droplet of glue holds significance. Elevate your projects to new heights as you unlock the secrets of this ultimate adhesive solution.