When it comes to building or repairing structures made of bricks, finding the right adhesive is key. You want a bond that’s reliable, strong, and built to last. But with so many adhesive options out there, how do you know which one is best for brick-to-brick connections? Whether you’re a seasoned DIY enthusiast or a professional mason, understanding the ins and outs of different adhesives is crucial.

In this comprehensive guide, we’ll take a deep dive into the world of adhesives and explore their suitability for bonding bricks together. We’ll uncover the secrets to achieving robust connections by considering factors like ease of use, compatibility with different brick materials, resistance to weathering, and more. By the end, you’ll have all the knowledge you need to confidently choose the perfect adhesive for your brick projects – ensuring both structural integrity and aesthetic appeal.

So if you’re ready to unlock the secrets of this essential construction process and discover your perfect adhesive match for brick-to-brick bonding, let’s dive in.

Types of Adhesives for Brick to Brick Bonding

Contents

In conclusion, when it comes to bonding bricks together, there are several types of adhesives to choose from. Cement-based adhesives are strong and durable, making them ideal for outdoor applications. Epoxy adhesives offer exceptional strength and resistance to moisture and chemicals. Polyurethane adhesives provide flexibility and good bond strength for applications with movement or vibration. Acrylic adhesives are easy to apply and have a fast curing time, making them suitable for interior brick bonding. Silicone adhesives offer flexibility and resistance to moisture, making them suitable for both indoor and outdoor applications.

The choice of adhesive should be based on factors such as the type of bricks, the environmental conditions, and the desired strength and durability of the bond. It is important to follow the manufacturer’s instructions and conduct a small test on a sample brick before proceeding with the full application. Consulting with a professional or adhesive manufacturer can provide valuable guidance in selecting the right adhesive for your specific project.

Remember, the adhesive you choose will play a crucial role in the longevity and stability of your brick structure. So take your time, do your research, and select an adhesive that meets your project requirements.

Considerations for Choosing an Adhesive

Choosing the perfect adhesive for bonding bricks together requires careful consideration of various factors. Let’s explore some key considerations to help you make an informed decision.

Firstly, bond strength is paramount. Bricks are heavy and robust, so you need an adhesive that can withstand the weight and pressure. Look for adhesives specifically formulated for brick bonding, as they are designed to provide a strong and long-lasting bond.

Compatibility is another crucial factor. Different types of bricks have varying porosity and composition, so it’s essential to choose an adhesive that can effectively bond with your specific type of brick. Consider environmental conditions like temperature and moisture levels as they can impact adhesive performance.

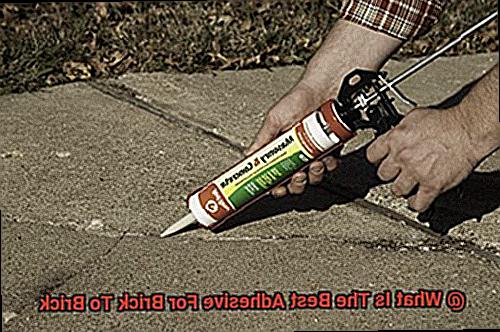

The method of application is also important. Some adhesives come in tubes or cartridges for easy application with a caulking gun, while others require mixing. Choose an adhesive that suits your preferred method and follow the manufacturer’s instructions for optimal results.

Consider the setting time, too. Depending on your project timeline, you may need an adhesive that sets quickly or allows more time for adjustments before fully curing.

Flexibility is essential for accommodating slight movements in brick structures over time. Look for adhesives designed for flexible applications or those with elasticity to ensure the bond remains intact.

For outdoor structures, opt for weather-resistant adhesives that can withstand extreme temperatures, moisture, and UV exposure without deteriorating.

Lastly, prioritize safety. Read product labels and safety data sheets to understand any potential hazards associated with the adhesive. Take appropriate safety measures during application and consider any special handling precautions.

Surface Preparation

Surface preparation is a critical step in the bonding process when joining two bricks together using adhesive. The strength and durability of the bond heavily rely on the proper preparation of the surface. To ensure a successful bond, there are several key points to consider:

- Cleaning: Thoroughly cleaning the surfaces of both bricks is essential before applying any adhesive. Dirt, dust, oil, or loose particles can create barriers that hinder the adhesive’s ability to form a strong bond. Use a stiff-bristled brush or a pressure washer to effectively remove any debris from the brick surfaces.

- Removing existing coatings: If there are any existing coatings, such as paint, sealants, or other adhesives on the bricks, they must be completely removed. These coatings act as barriers between the adhesive and the bricks, compromising the strength of the bond. Utilize appropriate tools like scrapers or chemical strippers to effectively eliminate these coatings.

- Roughening the surface: Enhancing the bonding strength requires roughening the surface of the bricks. This can be accomplished by using sandpaper or a wire brush to create a slightly rough texture. The roughened surface provides more area for the adhesive to grip onto, resulting in a stronger and more reliable bond.

- Moistening the bricks: Moistening the bricks before applying the adhesive can improve bonding. However, it is crucial not to saturate them with water as excessive moisture can dilute or weaken certain adhesives. Lightly dampen the surface to ensure that there is no standing water on the brick.

- Priming: Depending on the type of adhesive being used, priming may be necessary. Some adhesives require a primer to be applied before bonding to enhance adhesion and prevent any chemical reactions between the adhesive and the bricks. Always follow the manufacturer’s instructions for the specific adhesive being used.

Following Manufacturer Instructions

Following manufacturer instructions is crucial when it comes to using adhesive for brick to brick applications. Manufacturers provide specific guidelines and recommendations for their products, which should be followed carefully to ensure the best results and optimal bond strength.

One important aspect of following manufacturer instructions is to understand the surface preparation requirements. Most adhesives require a clean and dry surface for proper bonding. This may involve removing any existing paint, dirt, or debris from the bricks using a wire brush or sandpaper. It is also essential to ensure that the bricks are structurally sound and free from any cracks or loose mortar.

Additionally, the manufacturer’s instructions will provide guidance on the application process. This includes the recommended temperature range for application, as extreme temperatures can affect the adhesive’s performance. The instructions may also specify the appropriate tools or equipment to use, such as a notched trowel or a caulking gun. It is important to use these tools as directed to achieve even coverage and proper adhesion.

Drying and curing times are also critical aspects mentioned in the manufacturer’s instructions. Adhesives typically require a specific amount of time to fully cure and develop maximum bond strength. It is essential to allow sufficient curing time before subjecting the bonded bricks to any stress or load. Rushing this process can compromise the adhesive’s performance and result in a weak bond.

Furthermore, some adhesives may require additional steps or precautions, such as mixing two components before application or applying multiple layers for enhanced strength. These specific instructions should be carefully followed to ensure optimal bonding performance.

Testing the Adhesive

Testing the adhesive is an essential process that cannot be overlooked when it comes to brick-to-brick applications. It is the key to ensuring that the bond between the bricks is not only strong but also durable. By following a systematic approach, one can test different adhesives and select the most suitable one for their specific needs.

The first step in this process is to carefully select a few types of adhesives that are specifically formulated for bonding bricks together. It is important to choose adhesives that are known for their high-strength bonding capabilities and are suitable for outdoor use. By opting for adhesives with these qualities, you can ensure that your brick-to-brick bond will withstand the test of time.

Once you have chosen the adhesive options, the next step is to prepare test samples. This involves applying the selected adhesives to small sections of bricks, taking care to follow the manufacturer’s instructions for application. These test samples should then be left to cure for a minimum of 24 hours or as recommended by the manufacturer. This allows enough time for the adhesive to reach its full strength.

After the curing period, it is crucial to assess the strength and durability of the adhesive bond. This can be done by applying pressure or conducting stress tests on the test samples. By doing so, you can determine how well the adhesive holds up under different conditions.

In addition to bond strength, it is also important to evaluate the adhesive’s resistance to environmental factors such as temperature changes, moisture, and UV exposure. This will help determine whether the adhesive is suitable for outdoor brick-to-brick applications in various environments.

To ensure thorough testing and make informed decisions, it is advisable to seek guidance from professionals or experts in the field who have experience with different adhesives. Their insights and recommendations can provide valuable information and save you from potential pitfalls.

Benefits of Using Mortar for Brick to Brick Bonding

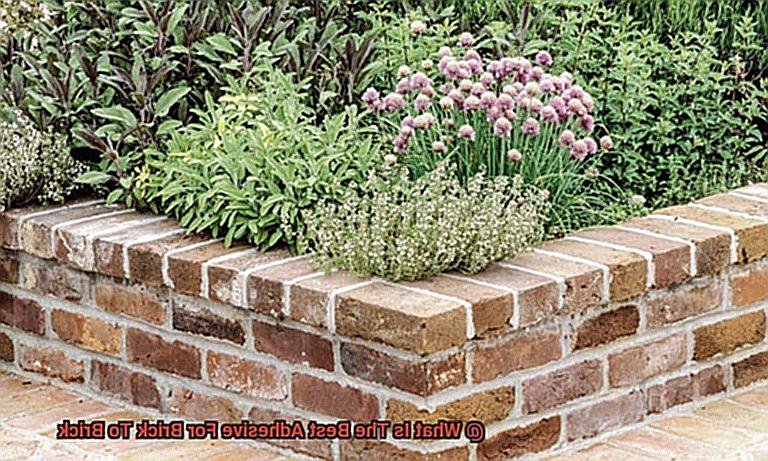

Mortar is a traditional and widely used adhesive for brick to brick bonding, offering numerous benefits in construction projects. Firstly, mortar provides exceptional strength when mixed properly. This strong bond can withstand the weight and pressure of the bricks, making it ideal for load-bearing structures where stability and durability are crucial.

Another advantage is mortar’s excellent weather resistance. Designed to withstand extreme heat, cold, rain, and wind, mortar ensures that the bond between the bricks remains intact and secure over time. This reduces the risk of deterioration or damage caused by various weather conditions.

Moreover, mortar offers versatility in construction projects. It can be used with different types of bricks, including clay, concrete, and stone. Whether it’s a residential building, commercial structure, or outdoor landscaping, mortar is suitable for various applications.

Furthermore, mortar provides flexibility during the construction process. It allows for slight adjustments and alignments of the bricks before it sets, ensuring a precise and visually appealing finished product. This flexibility also accommodates any movement or settling that may occur over time without compromising the bond’s integrity.

In terms of cost-effectiveness, mortar is readily available and relatively affordable compared to other adhesive options. This makes it a practical choice for both small-scale and large-scale projects. Additionally, once applied, mortar requires minimal maintenance, saving both time and money in the long run.

Lastly, using mortar for brick to brick bonding allows for easy repairs and modifications if needed. When a brick becomes damaged or needs replacement, mortar can be easily removed and reapplied without affecting the surrounding bricks. This simplifies repairs and reduces time-consumption compared to other adhesives that may require complete removal or replacement of the entire bond.

Benefits of Using Epoxy for Brick to Brick Bonding

Epoxy has emerged as a formidable contender to traditional mortar in the realm of brick-to-brick bonding. Its numerous benefits make it a highly desirable option for securing bricks together effectively in construction and repair projects. Let’s delve into the advantages of using epoxy for brick-to-brick bonding.

First and foremost, epoxy is renowned for its exceptional strength and durability. This adhesive forms an incredibly strong and permanent bond between bricks, capable of withstanding heavy loads, temperature fluctuations, and moisture exposure. It provides the structural integrity necessary for long-lasting brickwork.

In addition to its strength, epoxy offers excellent resistance to chemicals. This property makes it perfect for applications where the bonded bricks may come into contact with harsh substances. The resistance ensures that the adhesive remains intact and does not degrade over time, ensuring the longevity of the brickwork.

One of the most impressive features of epoxy is its versatility. It can be used with various types of bricks, including clay bricks, concrete bricks, and even stone bricks. This adaptability makes epoxy a flexible choice for different construction or repair projects involving brickwork.

Moreover, epoxy demonstrates remarkable adhesion to different surfaces. It excels at bonding bricks together, even if they have uneven surfaces or irregular shapes. This capability ensures a strong and secure bond, contributing to the overall structural integrity of the brickwork.

Epoxy also possesses excellent gap-filling properties. It can fill in small gaps or voids between bricks, enhancing the overall bond strength and preventing potential weak points in the structure. This feature is particularly valuable for achieving a seamless and robust brick-to-brick connection.

Furthermore, epoxy provides a long working time. Users have ample time to adjust the position of the bricks before the adhesive fully cures. This attribute proves invaluable when working on complex or intricate brick patterns that require precise alignment.

Lastly, epoxy offers various curing options. Contractors can choose from different formulations, including fast-curing options for projects that require quick completion. This flexibility in curing time allows for the selection of the most suitable epoxy formulation based on specific requirements and project timelines.

C3tygDHdDc8″ >

Conclusion

In conclusion, choosing the perfect adhesive for brick-to-brick connections requires careful consideration of multiple factors. When it comes to outdoor applications, cement-based adhesives reign supreme with their unbeatable strength and durability.

If you’re looking for exceptional strength, resistance to moisture and chemicals, and the ability to bond different types of bricks, epoxy adhesives are your go-to option.

For applications that involve movement or vibration, polyurethane adhesives offer flexibility and robust bond strength. Need something quick and easy for interior brick bonding? Look no further than acrylic adhesives with their effortless application and fast curing time. And if you want a flexible adhesive that can withstand moisture in both indoor and outdoor settings, silicone adhesives are your best bet.

When selecting an adhesive, keep in mind important factors like bond strength, compatibility with different brick materials, ease of application, setting time, flexibility, weather resistance, and safety precautions.

Don’t forget about surface preparation. To achieve a strong bond between bricks, make sure to thoroughly clean the surfaces, remove any existing coatings or debris, roughen the surface for better grip, lightly moisten the bricks (but don’t saturate them), and use primers if necessary.

Following manufacturer instructions is key to achieving optimal results. These instructions will guide you on surface preparation requirements, application process, necessary tools or equipment, drying and curing times.

It’s always a good idea to test the adhesive on small-scale samples before diving into the full application. This way you can assess its bond strength and resistance to environmental factors.

If you’re looking for exceptional strength combined with weather resistance and versatility in construction projects at an affordable cost, mortar is your best friend. It also offers flexibility during installation adjustments or repairs/modifications if needed.

For unmatched strength and durability along with excellent chemical resistance, epoxy is the way to go. It’s perfect for bonding different types of bricks with uneven surfaces or irregular shapes. Plus, it has gap-filling properties and a long working time for precise alignment before full curing.

Ultimately, the best adhesive for your project depends on your specific requirements.