When it comes to bonding materials together, traditional adhesives have always been the go-to solution. But what if I told you there’s a new adhesive on the block that’s about to revolutionize the game? Say hello to hydro glue – a cutting-edge innovation that’s making waves in construction, manufacturing, and crafting.

You might be wondering, “What exactly is hydro glue?” Well, it’s not your ordinary adhesive. It’s a next-level formulation that harnesses the power of advanced technology to create bonds like never before. With its exceptional strength and versatility, hydro glue is quickly gaining recognition across industries worldwide.

Whether it’s fixing cracked machinery or assisting in delicate surgical procedures, hydro glue has become an indispensable asset in countless applications. Its incredible properties and uses are enough to leave even the most seasoned professionals amazed.

In this blog post, we’re going to dive deep into the world of hydro glue. We’ll explore its mind-boggling capabilities and uncover why it’s becoming an essential tool for experts from all walks of life. Get ready to be blown away as we unravel the mysteries behind this extraordinary adhesive and discover how it’s set to change the game for both professionals and DIY enthusiasts alike.

Composition of Hydro Glue

Contents

Look no further than hydro glue, the water-based adhesive that is revolutionizing the world of bonding. In this blog post, we will delve into the composition of hydro glue and explore its incredible properties that make it a game-changer in both industrial and household settings.

The Science Behind Hydro Glue

Hydro glue, also known as water-based glue or waterborne adhesive, is primarily composed of water as its solvent. Unlike traditional solvent-based adhesives, hydro glue is free from harmful chemicals and volatile organic compounds (VOCs), making it safe to use and environmentally friendly. The main adhesive components in hydro glue are polymers, which provide the bonding properties. These polymers can be derived from natural materials like starch or synthetic materials like polyvinyl acetate (PVA) and ethylene-vinyl acetate (EVA).

Versatility and Applications

Hydro glue exhibits excellent versatility and can be used on various materials, including paper, cardboard, wood, fabric, and some plastics. It forms a strong bond between surfaces, creating a durable and long-lasting connection. Its low viscosity allows for precise application without clumps or uneven patches. Hydro glue dries relatively quickly compared to solvent-based adhesives, reducing waiting time before handling or moving glued objects. Once fully dried, hydro glue exhibits good water resistance, making it ideal for projects exposed to moisture.

Ease of Use and Safety

Hydro glue is conveniently packaged in squeeze bottles or tubes with applicator tips for easy and controlled application. Cleaning up excess or spills is a breeze with just water and soap, as the glue is water-soluble. It is generally non-toxic and emits minimal odors, making it safe to use in various settings, including schools and homes.

Versatility of Hydro Glue

Look no further than hydro glue, the ultimate adhesive superhero. Hydro glue, also known as water-based adhesive, is a versatile and eco-friendly alternative to traditional solvent-based adhesives. Let’s dive into the world of hydro glue and discover its incredible versatility.

Hydro glue’s versatility knows no bounds. It has the remarkable ability to bond a wide range of materials, from paper and cardboard to fabric, wood, and even certain plastics. This makes it the go-to adhesive for various applications, whether you’re working on arts and crafts projects or tackling industrial tasks.

In the world of arts and crafts, hydro glue is highly prized for its effectiveness in bonding lightweight materials. It is a staple in scrapbooking, card making, and other paper crafts. Its water-based formula allows for easy application and cleanup, making it an ideal choice for use with children or in a classroom setting.

But hydro glue’s versatility doesn’t stop there. It is also a game-changer in woodworking and furniture manufacturing. The adhesive creates strong bonds between wooden pieces, ensuring stability and durability. Plus, its low odor makes it safer to work with compared to solvent-based adhesives that can leave you gasping for fresh air.

The textile industry also benefits greatly from hydro glue. It is commonly used to bond fabrics together during the manufacturing process. Whether it’s for clothing, upholstery, or accessories, hydro glue provides a strong and reliable bond that can withstand washing and wear.

Not only is hydro glue versatile in terms of the materials it can bond, but it also offers flexibility in its application methods. Whether you prefer using brushes for precision, rollers for speed, or spray guns for larger surfaces, hydro glue can adapt to your needs and achieve the best results.

In addition to its versatility, hydro glue is also environmentally friendly. Unlike solvent-based adhesives that release harmful volatile organic compounds (VOCs) into the atmosphere, water-based adhesives have lower VOC emissions. This not only makes them safer for users but also contributes to a healthier environment.

Ease of Use

Ease of use refers to the simplicity and convenience with which a product or tool can be used, allowing users to easily and efficiently accomplish their tasks or goals. In the context of hydro glue, ease of use is one of its standout features that make it a popular choice among DIY enthusiasts and professionals alike.

One of the key advantages of hydro glue is its simple application process. Unlike traditional glues that require mixing and measuring, hydro glue comes ready to use straight out of the bottle or tube. This eliminates the need for any additional preparation, saving users time and effort. Whether you’re in a hurry or just want to save some time, hydro glue has got your back.

Furthermore, hydro glue bonds quickly and securely. It forms a strong adhesive bond within minutes, allowing users to proceed with their projects without any delays. This quick bonding feature is particularly useful for tasks that require immediate results or when working on time-sensitive projects. With hydro glue, you can keep the creative momentum going.

In addition to its fast bonding capability, hydro glue offers excellent versatility in terms of materials. It can be used on various surfaces such as wood, plastic, metal, fabric, and more. This versatility makes it suitable for a wide range of projects, including woodworking, crafting, repairs, and more. It’s like having a superpower that adapts to any situation.

Moreover, hydro glue comes in user-friendly packaging. Most hydro glues are available in squeeze bottles or tubes with precision applicators, ensuring controlled and mess-free application. The packaging often includes clear instructions on how to use the glue effectively, making it accessible even for beginners who want to dive into the world of gluing without any confusion.

Last but not least, cleanup is a breeze with hydro glue. Unlike some glues that leave behind sticky residue or require harsh solvents for removal, hydro glue can be easily cleaned up with just water. It’s not only convenient but also environmentally friendly. Saving the planet one craft project at a time.

Drying Time

Today, we embark on a thrilling journey into the captivating realm of drying time for hydro glue. As we all know, time is of the essence when it comes to gluing projects. Fear not, for I shall reveal the hidden secrets behind drying time and equip you with the knowledge to achieve unparalleled results. Prepare yourself as we delve into the intricate interplay of humidity, temperature, and material porosity in this fascinating process.

- Humidity: Picture yourself transported to a tropical rainforest or a parched desert—can you fathom which environment would expedite the drying of your clothes? Precisely. Humidity levels wield an undeniable influence over drying time. Higher humidity hampers evaporation, extending the drying process. Conversely, low humidity can accelerate drying but may prematurely form a skin on the adhesive surface. Strive for equilibrium by working in a well-ventilated space with moderate humidity levels.

- Temperature: Much like Goldilocks fervently searching for her perfect bowl of porridge, temperature plays a pivotal role in drying time. Warmer temperatures accelerate evaporation, resulting in swifter drying times. In contrast, colder days demand patience as they elongate the process. Take heed of the ambient temperature and adjust your expectations accordingly.

- Material Porosity: Imagine endeavoring to dry a sponge versus a sheet of glass—can you envision which material would retain moisture for longer? Bravo. The porosity of the materials being glued bears directly upon drying time. Porous surfaces greedily absorb moisture from hydro glue, leading to protracted drying durations. Non-porous materials necessitate less drying time since they exhibit limited moisture absorption.

To maximize triumph with hydro glue, adhere diligently to the manufacturer’s instructions regarding recommended drying times and application techniques. Haste may compromise the bond, yielding feeble outcomes.

Remember, when wielding hydro glue, prioritize safety by donning appropriate protective gear and operating in a well-ventilated domain.

By unraveling the secrets of how humidity, temperature, and material porosity intertwine with drying time, you shall ascend to gluing mastery, achieving resolute and enduring bonds. Embrace your boundless creativity and allow hydro glue to become your irreplaceable ally in all your DIY exploits.

Water Resistance

Water resistance is a crucial property when it comes to adhesive products, and hydro glue, also known as water-based adhesive, is the ultimate solution for this need. So sit back, relax, and prepare to become a glue guru as we dive deep into the world of hydro glue.

What sets hydro glue apart from other glues is its composition. Unlike glues that use harsh chemicals as carriers, hydro glue is water-based. This means it is non-toxic and emits low levels of volatile organic compounds (VOCs), making it safe for both you and the environment. Say goodbye to nasty fumes and hello to a healthier adhesive option.

But how does hydro glue achieve its water resistance superpower? Let’s break it down.

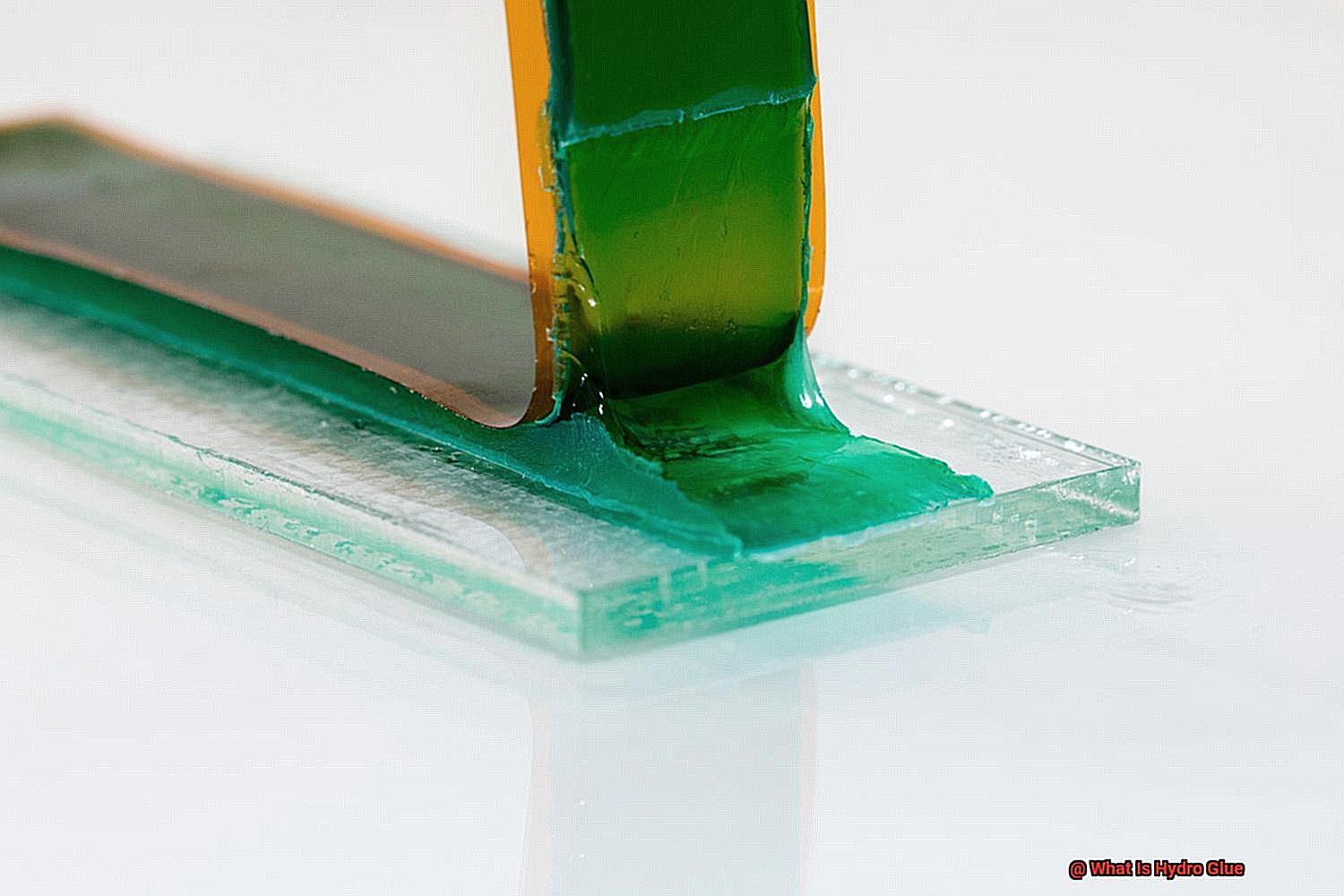

Bonding Process: When you apply hydro glue, the water acts as a solvent for the adhesive polymers. As the water evaporates during drying, the adhesive forms a strong bond between surfaces. It’s like magic happening right before your eyes. This bonding process ensures that your glued projects stay intact even in wet conditions.

Now, let’s talk about the advantages of hydro glue. Here are three reasons why it should be your go-to adhesive:

- Water Resistance: Hydro glue laughs in the face of moisture. It maintains its bond even in wet conditions, making it perfect for outdoor projects or areas prone to humidity. No more worrying about your hard work going down the drain.

- Versatility: Need to stick wood, paper, fabric, leather, or even some plastics? Hydro glue has got you covered. Its wide range of applications makes it an all-around superstar in the adhesive world. From crafting to repairs, hydro glue can handle it all.

- Easy-peasy: Applying hydro glue is a breeze. You can brush it on, roll it on, or even spray it on – whatever floats your boat. Plus, cleanup is a cinch since it washes away with just water. No more struggling with messy cleanup or harsh solvents.

To maximize the water resistance of your hydro glue, it’s important to follow the manufacturer’s instructions and properly prepare your surfaces. Trust me, these simple steps will ensure that your projects stand the test of time.

Clean-up and Safety

In this blog post, we will delve into the importance of clean-up and safety measures when using hydro glue, providing you with tips and tricks to ensure a smooth and secure bond. Let’s dive in.

Protective Gear:

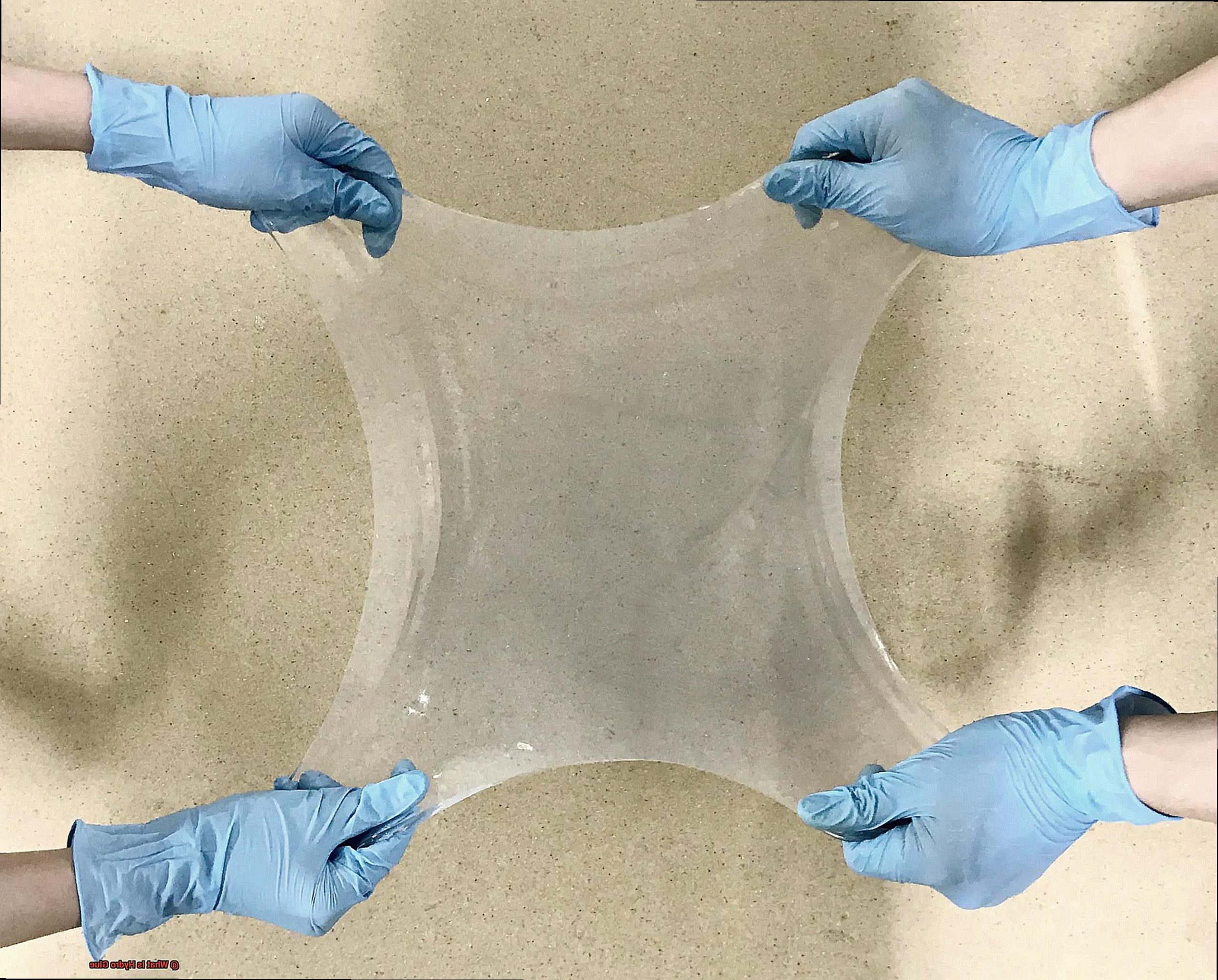

Gear up for your glue adventure. Prioritize your safety by wearing gloves, goggles, and a respirator if necessary. Shielding your skin and eyes from potential irritants is crucial for a safe gluing session.

Easy Clean-up:

Hydro glue’s water-based formula makes clean-up a breeze compared to other adhesives. All you need is warm soapy water. Grab a cloth or sponge, wet it with soapy water, and gently scrub away the adhesive. Act quickly before the glue dries or hardens, as it becomes harder to remove once it cures.

Dried Glue Removal:

Don’t panic if hydro glue has already dried on a surface. There are solutions. Apply a mild adhesive remover or rubbing alcohol to a cloth and gently rub the dried glue until it starts to loosen. Remember to be gentle to avoid damaging the underlying surface.

Stubborn Layers:

For those stubborn or thicker layers of hydro glue, scraping may be necessary. But proceed with caution. Use a plastic scraper or putty knife to safely remove the adhesive without causing any harm. Avoid scratching or damaging the surface underneath.

Ventilation Matters:

Keep your workspace well-ventilated when working with hydro glue. Good airflow prevents the accumulation of potentially harmful fumes, ensuring a safer environment for everyone involved. Open windows or use fans to circulate fresh air – your lungs will thank you.

Proper Storage:

Storing hydro glue correctly is vital for maintaining its quality and preventing accidents. Keep it in a cool, dry place away from direct sunlight and heat sources. Always tightly seal the container after each use to prolong its shelf life and avoid spills or leaks.

Advantages of Hydro Glue

From its impressive water resistance to its versatility and quick drying time, hydro glue is a game-changer in the world of adhesives.

First and foremost, hydro glue’s water resistance sets it apart from other glues on the market. While traditional glues cower in the face of water, hydro glue stands strong, maintaining its adhesive properties even in wet conditions. Whether you’re working on a project in a humid environment or need something durable for outdoor use, hydro glue won’t let you down.

But wait, there’s more. Hydro glue is also incredibly versatile. It can bond together a wide range of materials, from wood and metal to plastic and ceramics. No matter the project at hand – whether you’re building furniture, fixing your car, or getting crafty with DIY projects – hydro glue has got you covered.

Speed is another advantage of hydro glue. With its quick drying time, this adhesive allows you to complete projects in record time. Say goodbye to waiting around for hours on end – hydro glue gets the job done efficiently and effectively.

Not only is hydro glue practical, but it’s also safe to use. This non-toxic adhesive eliminates harmful chemicals and toxic fumes from your workspace, ensuring your health and safety while you unleash your creativity.

Of course, an adhesive is only as good as its bonding strength, and hydro glue doesn’t disappoint. It can withstand all kinds of stresses and strains without breaking a sweat. From lightweight crafts to heavy-duty construction projects, hydro glue has the strength to keep everything firmly in place.

Applying hydro glue is a breeze too. Whether you prefer brushes, rollers, or sprays, this adhesive spreads smoothly and evenly for an optimal bond. So whether you’re a seasoned pro or a glue newbie, you’ll find hydro glue easy to work with.

But hydro glue doesn’t stop there. It’s built to withstand extreme conditions, from scorching heat to freezing cold. No matter the temperature variations you encounter, hydro glue remains steadfast in its bonding properties. So whether you’re working on a car engine or building something for outer space, hydro glue has got your back.

And for those who enjoy outdoor projects, there’s even hydro glue with UV resistance. This means it won’t lose its strength or integrity when exposed to sunlight or other sources of UV radiation. So go ahead and take your projects outdoors – hydro glue will keep them strong and secure.

Disadvantages of Hydro Glue

Hydro glue, also known as water-based glue, may seem like a superhero among adhesives, but it does have a few kryptonite-like weaknesses that are important to consider before slapping it on your next project. Let’s dive into the world of hydro glue and explore its disadvantages.

First up on our list of drawbacks is the longer drying time. Unlike other glues, hydro glue needs moisture to evaporate in order for the bond to set. This can be a real bummer when you’re in a hurry and need your project glued up and ready to go in a jiffy.

Next, let’s talk about strength. Hydro glue is not known for its Hulk-like power. It generally has lower tensile and shear strength compared to solvent-based adhesives. So, if you’re working on heavy-duty construction or industrial projects that require a rock-solid bond, hydro glue might not be up to the challenge.

Another disadvantage of hydro glue is its susceptibility to moisture. While it needs moisture to bond surfaces together, that same moisture can weaken or break down the bond after it has dried. So, if you’re planning on using hydro glue for an outdoor project or something that will be exposed to water, you might want to think twice.

Temperature resistance is another Achilles heel of hydro glue. When things heat up, this adhesive can soften or lose its adhesive properties, resulting in a weakened bond or complete failure. So, if you’re working on something that will be exposed to high temperatures, you might want to explore other adhesive options.

Last but not least, let’s talk about swelling. Hydro glue has been known to cause certain materials like wood or fabric to swell or distort when applied. This can lead to an uneven or unsightly finish, which is definitely not what you want for your masterpiece.

hU9oPIKTQD8″ >

Conclusion

Hydro glue, also known as hydrophobic glue, is a remarkable adhesive that repels water.

It is designed to bond materials together in wet or humid environments where traditional glues may fail. This innovative adhesive forms a strong and durable bond, even when submerged in water.

Hydro glue is a game-changer in the world of adhesives, providing a reliable solution for bonding in challenging conditions.