Ever been in a sticky situation where regular glue just won’t do the trick? You know, like when your favorite coffee mug shatters into a million pieces or that pesky floor tile decides to go on a solo adventure.

Epoxy glue is here to save the day. This magical concoction of resin and hardener packs an adhesive punch that puts ordinary glues to shame.

But what exactly can this wonder glue do? Well, get ready to be amazed as we dive into the incredible world of epoxy glue and uncover its mind-blowing bonding abilities.

From professional projects to wild DIY adventures, epoxy glue has become the go-to choice for countless industries and applications. So hold on tight and get ready for an epic journey through the captivating universe of epoxy glue.

Construction Industry Uses of Epoxy Glue

Contents

- 1 Construction Industry Uses of Epoxy Glue

- 2 Woodworking Projects with Epoxy Glue

- 3 Automotive Industry Applications for Epoxy Glue

- 4 Manufacturing Sector Uses of Epoxy Glue

- 5 Marine Environments and Epoxy Glue

- 6 Arts and Crafts Projects with Epoxy Glue

- 7 Advantages of Using Epoxy Glue

- 8 Types of Materials Suitable for Bonding with Epoxy Glue

- 9 Conclusion

In the world of construction, having a reliable adhesive is paramount to ensuring the durability and longevity of structures. This is where epoxy glue comes into play. With its exceptional bonding properties, epoxy has become a staple in the construction industry. In this article, we will explore the various uses of epoxy glue and how it has revolutionized the way construction professionals tackle projects.

Concrete Repairs and Bonding:

Concrete is a primary building material, but over time, it can develop cracks and gaps. Epoxy glue comes to the rescue by filling these imperfections, providing a strong and long-lasting repair solution. It can also be used to bond concrete elements together, such as joining precast concrete panels or attaching anchor bolts to concrete structures.

Anchoring and Fastening:

When high load-bearing capacity is required, epoxy glue shines. It securely anchors bolts, dowels, and other fasteners into concrete or masonry, ensuring a reliable connection. This feature makes it invaluable in bridge construction and structural steel connections.

Flooring Applications:

Epoxy glue’s strength and durability make it an ideal choice for flooring applications. It can bond various flooring materials, including tiles, wood, or vinyl, to the substrate. This guarantees a strong bond that can withstand heavy foot traffic and other stresses. Moreover, epoxy can be used as a coating for concrete floors, providing a seamless surface that is resistant to chemicals, stains, and wear.

Carpentry and Woodworking:

Epoxy glue is a carpenter’s best friend when it comes to joining pieces of wood together. Its moisture and temperature resistance make it perfect for outdoor applications or areas with high humidity. Additionally, epoxy can fill voids or knots in wood, creating a smooth surface for finishing.

Fiberglass Construction:

In the construction of fiberglass structures such as boats or composite panels, epoxy glue plays a crucial role. It provides excellent bonding for adhering fiberglass laminates together, creating lightweight yet strong structures. Epoxy’s versatility allows for both structural bonding and cosmetic finishing in fiberglass construction.

Plumbing Systems:

Epoxy glue is widely used in the installation and repair of plumbing systems. It can seal and bond various materials like PVC, copper, or stainless steel pipes, ensuring leak-proof connections. With its resistance to water and chemicals, epoxy is a reliable choice for plumbing applications that require long-term durability and tight seals.

Woodworking Projects with Epoxy Glue

Woodworking projects are a labor of love, where craftsmanship and creativity come together to create something truly unique. To ensure the longevity and strength of your creations, using the right adhesive is crucial. Enter epoxy glue – the unsung hero of woodworking projects. In this article, we’ll explore the advantages of using epoxy glue, from its various types to its wide range of applications. Get ready to be inspired as we dive into the world of woodworking projects with epoxy glue.

Types of Epoxy Glue and Applications:

Bonding Different Wood Types:

Epoxy glue possesses exceptional bonding properties, making it perfect for joining different types of wood seamlessly. Whether you’re working with hardwood, softwood, or even exotic species, epoxy glue can create a bond that withstands the test of time.

Benefits:

- High strength: Epoxy glue forms a strong and durable bond between wood surfaces, ensuring your project remains intact for years.

- Moisture resistance: With excellent resistance to moisture, epoxy glue is ideal for projects exposed to water or humidity, such as outdoor furniture or wooden boat repairs.

Filling Gaps and Cracks:

Wood imperfections can be a challenge when it comes to woodworking projects. Fortunately, epoxy glue can come to the rescue by filling gaps and cracks in wood, enhancing overall stability and strength.

Benefits:

- Structural integrity: By filling gaps and cracks with epoxy glue, you can reinforce weak areas and prevent further damage, ensuring your project maintains its structural integrity.

- Aesthetic appeal: Epoxy glue can be tinted or mixed with various additives like dyes or metallic powders, allowing you to create visually stunning effects such as “river tables” or intricate inlays.

Woodworking projects are an opportunity to showcase your creativity while crafting something beautiful and durable. By harnessing the power of epoxy glue, you can achieve both practicality and artistic flair in your creations.

From bonding different wood types with ease to filling gaps and cracks for added strength, epoxy glue is a versatile adhesive that promises outstanding results.

Automotive Industry Applications for Epoxy Glue

Epoxy glue may not be the first thing that comes to mind when you think of the automotive industry, but it plays a crucial role in ensuring the performance, durability, and safety of vehicles. With its strong bonding properties and versatility, epoxy glue is used in a variety of applications throughout the automotive sector.

One of the primary uses of epoxy glue in the automotive industry is for bonding metal parts. Whether it’s body panels, engine components, or brackets, epoxy glue provides a strong and durable bond that ensures structural integrity and stability in vehicles. It can withstand extreme temperatures and vibrations, making it ideal for automotive applications.

In addition to metal bonding, epoxy glue is commonly used for repairing cracked or damaged plastic components in automobiles. From interior trim pieces to dashboard components and bumpers, epoxy glue effectively bonds plastic parts together, restoring their functionality and appearance. This helps save costs by avoiding the need for expensive replacements.

Another application of epoxy glue in the automotive industry is for sealing and filling gaps or cracks. It can be used to seal joints between different materials, preventing leaks and improving overall vehicle performance. Additionally, epoxy glue can fill small cracks or dents in surfaces, providing a smooth and seamless finish.

When it comes to attaching automotive accessories like spoilers, side skirts, and emblems, epoxy glue shines. Its strong bonding properties ensure that these accessories stay securely attached to the vehicle even under harsh driving conditions. This not only adds style but also enhances aerodynamics and performance.

In the manufacturing process of automobiles, epoxy glue is often used for securing electrical components and wiring harnesses. Its excellent electrical insulation properties help protect the wiring system from moisture, corrosion, and short circuits, ensuring reliable electrical connections.

Epoxy glue also finds applications in bonding glass components like windshields and windows. Its high strength and resistance to temperature changes make it an ideal adhesive for ensuring the stability and safety of these components.

When it comes to the repair and maintenance of automotive engines, epoxy glue is a go-to solution. It can fix cracks or leaks in engine blocks, cylinder heads, and intake manifolds. Its ability to withstand high temperatures makes it suitable for engine-related repairs.

Manufacturing Sector Uses of Epoxy Glue

In the fast-paced world of manufacturing, precision and durability are paramount. However, behind the scenes, there is one adhesive that plays a crucial role in various industries – epoxy glue. With its exceptional bonding properties and versatility, epoxy glue ensures the structural integrity and longevity of countless products. In this blog post, we will explore the numerous ways epoxy glue is utilized in the manufacturing sector, from joining metals and composite materials to protecting delicate electronics and even anchoring bolts into concrete structures. Let’s dive in.

Bonding Metal Components:

Epoxy glue is the go-to adhesive for joining metal parts in industries such as machinery, automotive, and aerospace. Its strong and durable bond can withstand heavy loads and vibrations, ensuring utmost strength and reliability.

Enhancing Composite Materials:

Industries like construction and sports equipment manufacturing rely on composite materials such as carbon fiber and fiberglass. Epoxy adhesive plays a vital role in bonding these materials together, enhancing their structural integrity for long-lasting performance.

Protecting Electronic Components:

Delicate electronic components require protection from moisture, heat, and other environmental factors. Epoxy encapsulation provides a protective coating that shields these components, ensuring their proper functioning and preventing damage.

Assuring Consumer Goods Quality:

Epoxy glue is widely used in consumer goods manufacturing for bonding plastic parts. Its excellent adhesion to various plastics ensures reliable assembly and durability of products like toys, electronics, and household appliances.

Woodworking Applications:

Epoxy glue finds its place in the woodworking industry for joining wooden pieces together. It bonds different types of wood, including hardwoods and softwoods, while also repairing damaged wood structures with its ability to fill gaps and cracks.

Ceramics and Glassware:

The manufacturing of ceramics and glassware relies on epoxy glue for bonding ceramic tiles, repairing chipped or broken pieces, and creating decorative items like mosaic art.

Construction Industry:

Epoxy glue is commonly used in the construction industry for anchoring bolts into concrete structures, repairing concrete cracks, and bonding various construction materials together. Its strength and durability ensure the integrity of structures.

Renewable Energy Sector:

Epoxy adhesive plays a significant role in the manufacturing of composite materials for the renewable energy sector, including wind turbine blades and solar panels. It ensures their structural integrity and longevity, contributing to sustainable energy sources.

Marine Environments and Epoxy Glue

In the vast world of marine environments, where water, salt, and UV radiation take center stage, finding an adhesive that can withstand the elements is crucial. Enter epoxy glue, a versatile and powerful adhesive that has become a go-to solution for boat builders, repairers, and enthusiasts. In this article, we will explore the different applications of epoxy glue in marine environments and discuss its advantages and disadvantages.

Boat Building:

Epoxy glue plays a vital role in boat construction by bonding various materials like fiberglass, wood, and metal. Its exceptional adhesive properties ensure a strong bond that can withstand constant exposure to water, preventing leaks and ensuring structural integrity.

Repairs and Maintenance:

Epoxy glue is a trusted companion when it comes to repairing cracks, holes, or damage in boat hulls, decks, and other parts. Its adhesive properties make it ideal for filling gaps and creating a seamless finish, ensuring that your vessel remains seaworthy.

Resistance to Water and Elements:

One of the key advantages of epoxy glue is its resistance to water, saltwater, chemicals, and UV radiation. This makes it the perfect adhesive for marine environments where boats are constantly exposed to these harsh elements.

Sealing and Preventing Water Ingress:

Epoxy glues are often used to seal joints and prevent water ingress in critical areas such as through-hulls, fittings, and seams. This helps maintain the integrity of the vessel while keeping water out of unwanted areas.

Marine Equipment Construction and Repair:

Epoxy adhesives find their way into the construction and repair of marine equipment like propellers, rudders, and keels. Their strength and versatility ensure that these crucial components can withstand the demanding conditions of the sea.

Disadvantages:

- Cost: Epoxy glue can be more expensive compared to other adhesives, which may be a factor to consider for budget-conscious users.

- Pot Life and Curing Time: Epoxy glues have a limited pot life and curing time, meaning users must work quickly and efficiently during the application process.

- Skill and Precision: Achieving optimal results with epoxy glue requires skill and precision. Improper mixing or application can compromise the bond strength and overall effectiveness.

Epoxy glue has become an indispensable tool in marine environments, offering exceptional adhesive strength, resistance to water and elements, and versatility in boat construction, repairs, and maintenance.

While it may come with a slightly higher cost and require skillful application, the benefits it brings to marine enthusiasts far outweigh any drawbacks.

Arts and Crafts Projects with Epoxy Glue

Are you a craft enthusiast looking to elevate your projects to new heights of creativity? Look no further than the transformative power of epoxy glue. This versatile adhesive is a game-changer in the realm of arts and crafts. With its exceptional bonding properties and ability to adhere to diverse materials, epoxy glue is an essential tool for any artist or crafter seeking to bring their visions to life.

In the realm of jewelry making, epoxy glue reigns supreme. Whether you’re attaching metal findings, beads, or gemstones to your jewelry pieces, epoxy glue ensures a bond that is both robust and enduring, guaranteeing that your creations will withstand the test of time. In fact, you can even delve into the world of resin-based jewelry by mixing epoxy resin with vibrant pigments and pouring it into molds.

Decoupage projects offer another avenue for the brilliance of epoxy glue to shine. By expertly adhering paper cutouts or images onto surfaces like wood, glass, or ceramics, you can breathe life into stunning decorative items. With its clear and unwavering bond, epoxy glue securely holds the paper in place while providing a lustrous finish that adds an extra touch of elegance to your creations.

For those exploring the captivating realm of mixed media art, epoxy glue is an indispensable ally. This technique involves harmoniously combining materials such as paper, fabric, metal, and found objects to forge unique artworks. Thanks to epoxy glue’s exceptional adhesive properties, different materials can be seamlessly united, resulting in solid bonds that can endure the test of time.

When it comes to sculpture projects, epoxy glue proves its mettle. Whether you’re fusing different parts together or embellishing your sculptures with decorations, epoxy glue guarantees that your masterpiece remains intact even when exposed to various environmental conditions. Its steadfast bond ensures that your creation maintains its integrity throughout its lifetime.

Mosaic art finds a natural partner in epoxy glue’s exceptional abilities. By artfully arranging small pieces of colored glass, ceramic tiles, or other materials on a surface, you can craft breathtaking images and patterns. Epoxy glue secures the mosaic tiles in place, offering a strong bond that is impervious to moisture and temperature fluctuations.

And let’s not forget about the realm of home decor projects. Epoxy glue proves invaluable in the creation of custom picture frames by expertly bonding different materials together. Additionally, it excels at attaching decorative elements to furniture pieces. With its reliable bond, epoxy glue ensures that your creations can withstand frequent handling and environmental factors, adding a touch of flair and individuality to your living space.

Advantages of Using Epoxy Glue

In the world of crafting, finding the perfect adhesive is like uncovering a hidden treasure. It’s the secret ingredient that can make or break your project. But fear not, fellow crafters, because we have the answer: epoxy glue.

This miraculous adhesive is here to make your creative dreams come true. In this blog post, we’ll explore the advantages of using epoxy glue and how it can revolutionize your crafting experience.

Strong Bonding Strength:

Say goodbye to weak and flimsy bonds. Epoxy glue boasts exceptional bonding strength, creating a connection between materials that is as strong as a knight’s armor. Whether you’re working with metals, plastics, wood, or other materials, epoxy glue ensures a reliable and long-lasting bond. No more worrying about your creations falling apart at the seams.

Versatility:

Crafters, rejoice. Epoxy glue is incredibly versatile, making it suitable for a wide range of projects. It doesn’t discriminate – it can be applied to porous and non-porous surfaces alike, allowing you to experiment with various materials. Whether you’re tackling DIY crafts, home repairs, or even industrial applications, epoxy glue has got you covered. It’s like having a superhero sidekick in your crafting arsenal.

Resistance to Chemicals and Moisture:

Crafting mishaps happen – spills, splashes, and exposure to moisture are inevitable. But fear not. Epoxy glue forms a waterproof barrier that shields your creations from moisture damage. It’s like a force field against water, protecting your projects from the elements. Additionally, it stands up to various chemicals without losing its adhesive properties. So go ahead and create worry-free, knowing that your projects are protected from any chemical villains.

Excellent Gap Filling Properties:

Sick of uneven surfaces ruining your crafty endeavors? Epoxy glue is here to save the day. Its superb gap-filling properties ensure a tight seal and a smooth finish, even on imperfect surfaces. No more unsightly gaps or voids – just seamless craftsmanship that will leave you feeling proud. It’s like a magic potion that transforms imperfections into perfection.

High Temperature Resistance:

Crafting often involves heat or extreme temperatures – think hot glue guns or outdoor projects. Epoxy glue is not one to back down from a challenge. Withstanding temperatures ranging from -50°C to 150°C (-58°F to 302°F), it’s the perfect adhesive for automotive repairs, electrical applications, and any project that requires heat resistance. It’s like having a superhero with ice powers on your side, keeping your creations cool under pressure.

Types of Materials Suitable for Bonding with Epoxy Glue

Epoxy glue is the secret behind strong and reliable bonds. This versatile adhesive has the power to stick together a variety of materials, making it a superhero in the world of bonding. Let’s explore the different types of materials that can benefit from epoxy glue’s magic touch.

Mighty Metal:

Epoxy glue is a superhero when it comes to bonding metals. It can create powerful connections between steel, aluminum, brass, and even copper. Whether you need to repair a metal toy or join metal parts together, epoxy glue saves the day with its strong and long-lasting bond.

Wonderful Woodwork:

Woodworking projects become effortless with epoxy glue. It forms a sturdy bond between wood joints, repairs cracks in wooden furniture, and fills gaps in wood surfaces. With epoxy glue, you can create masterpieces that stand the test of time.

Plastic Perfection:

Surprisingly, epoxy glue can also bond plastic materials. It works wonders with PVC, ABS, acrylics, and more. So, whether your favorite plastic toy breaks or you need to repair something made of plastic, epoxy glue is your go-to hero for sticking things back together.

Ceramics and Glass Sorcery:

Epoxy glue’s magic extends to ceramics and glass too. It can mend broken ceramic mugs and create beautiful pottery. When working with glassware or other crafts involving ceramics and glass, epoxy glue provides a strong and durable bond that ensures your creations last.

Composite Marvels:

Epoxy glue is perfect for bonding composite materials like fiberglass and carbon fiber. From building planes to making car parts, epoxy glue ensures a super-strong bond that can withstand tough conditions. With epoxy glue as your sidekick, composite projects become a breeze.

SEsOwpc8m6g” >

Also Read: How to Glue Fiberglass to Fiberglass? – Glue Things

Conclusion

Epoxy glue is a versatile adhesive that finds its way into countless projects and applications. Its strong bonding properties make it commonly used for repairing broken items, such as ceramics, glass, and plastics. Whether you need to fix a cracked vase or mend a shattered figurine, epoxy glue can be your go-to solution.

But epoxy glue doesn’t just stop at repairs. It also excels in the realm of crafting and DIY projects. From creating intricate jewelry to constructing model airplanes, its ability to bond various materials together makes it an essential tool for any hobbyist or artist.

And let’s not forget about its role in construction and manufacturing industries. Epoxy glue is frequently employed in building structures, reinforcing joints, and securing heavy-duty components. Its durability and resistance to heat, chemicals, and water make it an ideal choice for demanding environments.

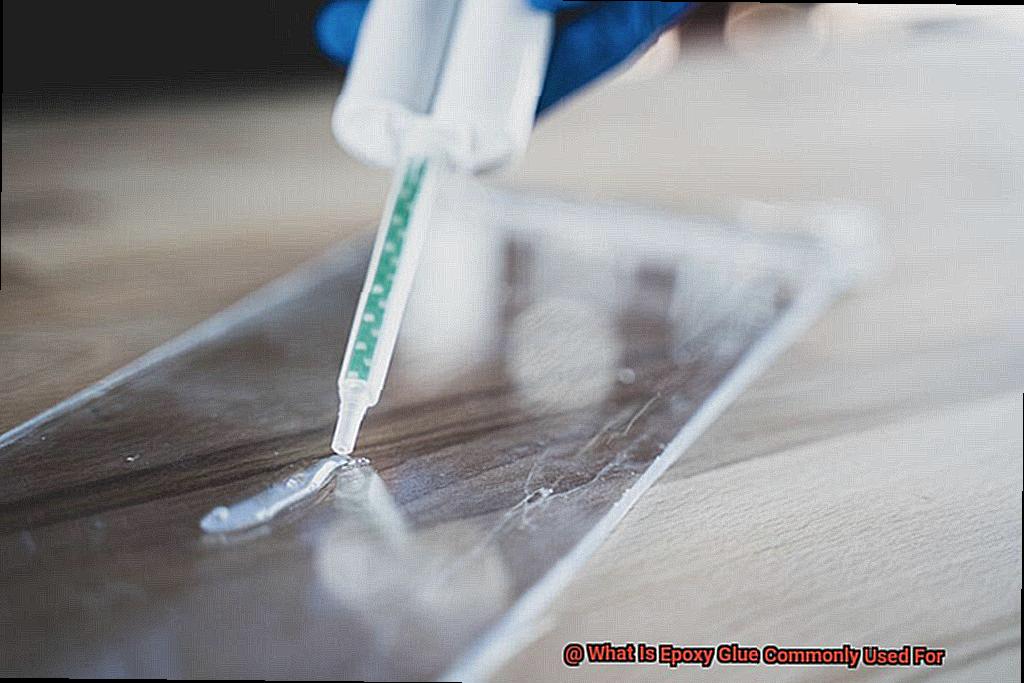

Not only does epoxy glue possess exceptional adhesive qualities, but it also offers versatility in terms of application methods. It can be applied using brushes or syringes, allowing for precise control over the amount of adhesive used.

So whether you’re fixing a treasured heirloom or embarking on a creative endeavor, epoxy glue proves itself to be an invaluable companion.