Step into a world of opulence and timelessness as you gaze upon the mesmerizing beauty of marble. Its regal allure has graced the halls of majestic palaces and awe-inspiring historical landmarks for centuries, leaving us in awe of its elegance.

But what happens when this magnificent material needs a little tender loving care? Join us on an enthralling journey as we unravel the secrets behind finding the perfect adhesive that binds marble together.

Imagine a flawless marble countertop, meticulously chosen for its smoothness and captivating patterns, suddenly in need of repair. Whether it’s a hairline crack, a separation between slabs, or a restoration project, one question lingers in the air: what is the best adhesive to glue marble to marble?

To find our answer, we must navigate through a labyrinth of product options. From traditional cementitious mortar to epoxy and cyanoacrylate adhesives, each variant boasts unique properties and applications. We’ll dissect these contenders, examining their strengths and weaknesses so that you can make an informed decision.

Throughout our exploration, we’ll unveil the untold secrets behind adhesives designed specifically for marble – those that offer exceptional bonding strength while preventing unsightly discoloration and standing strong against the test of time. Highlighting qualities like non-staining formulas, moisture resistance, and easy application techniques, we aim to equip you with the knowledge needed to tackle any marble-to-marble bonding project with confidence.

Get ready to dive deep into the realm of marble adhesives as we unravel the mysteries surrounding the best adhesive for gluing marble to marble. From ancient craftsmanship techniques to modern innovations, we’ll shed light on that perfect unyielding bond that will restore and enhance the magnificence of marble in your life.

What is Marble?

Contents

- 1 What is Marble?

- 2 What are Adhesives and How Do They Work?

- 3 Types of Adhesives for Gluing Marble to Marble

- 4 Benefits of Epoxy Resin Adhesive for Gluing Marble to Marble

- 5 Benefits of Polyurethane Adhesive for Gluing Marble to Marble

- 6 Things to Consider When Choosing an Adhesive

- 7 Preparing the Surfaces Before Applying the Adhesive

- 8 Professional Installation and Advice for Complex Projects

- 9 Conclusion

Marble, an exquisite metamorphic rock born from limestone, not only mesmerizes with its visual allure but also showcases exceptional endurance and fortitude. This comprehensive guide delves deep into the world of marble, unraveling its formation process, distinct features, and optimal adhesives for bonding marble to marble.

Formation and Composition:

- Under tremendous heat and pressure, limestone undergoes a transformation, giving rise to the elegant creation known as marble.

- Composed primarily of calcite or dolomite minerals, marble boasts a crystalline structure that ensures solidity and resilience.

Kaleidoscope of Colors and Patterns:

- Marvel at the vast spectrum of hues that marble offers, ranging from the classic white and gray to the vibrant pink, green, yellow, and even mysterious black.

- The intricate veins that dance across the marble’s surface are a result of mineral impurities or fractures during its formation, adding a touch of mystique.

Echoes of Ancient Grandeur:

- Marvelous marble has left an indelible mark throughout history, adorning the architectural marvels and artistic masterpieces of ancient civilizations like the Greeks and Romans.

- The smooth and polished surface of marble exudes opulence, making it an unrivaled choice for high-end residential and commercial projects.

Unyielding Physical Properties:

- With its dense nature and low porosity, marble showcases remarkable resistance against staining and water absorption.

- However, caution must be exercised as acidic substances like citrus juices or vinegar can etch its surface.

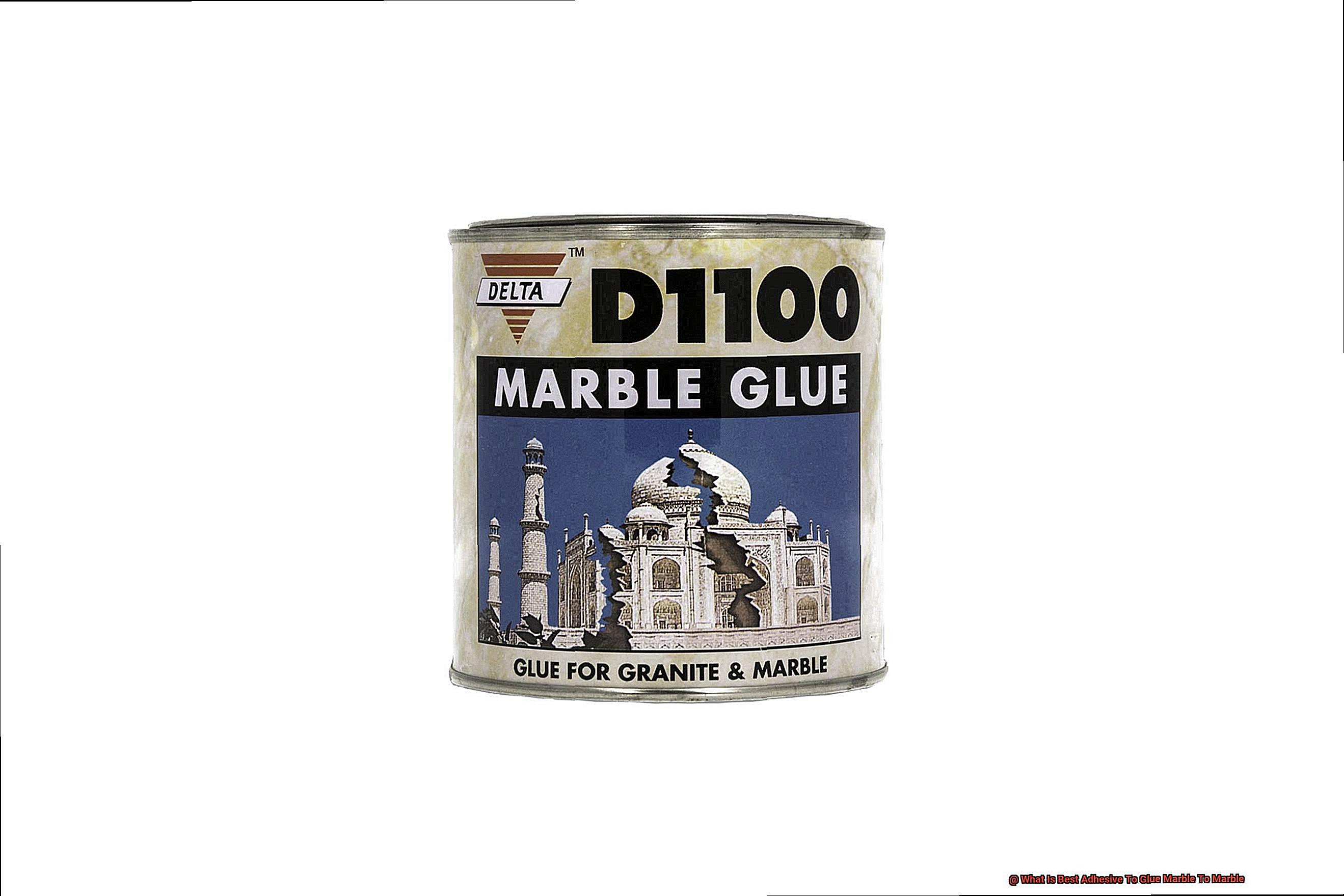

Adhesives for Bonding Marble to Marble:

- For secure and enduring bonds between marble pieces, epoxy resin adhesives reign supreme due to their exceptional bonding properties and immense strength.

- These adhesives consist of two components – a resin and a hardener – which, when combined, create an unyielding and rigid adhesive.

- In situations involving movement or vibrations, polyurethane adhesives offer an excellent alternative, providing both robust bonding strength and flexibility.

Surface Preparation for Seamless Bonds:

- Prior to applying any adhesive, ensure that the surfaces to be bonded are meticulously cleaned, free from dust, dirt, or any impurities.

- A gentle yet effective approach involves utilizing a mild detergent or stone-specific cleaner, coupled with a soft cloth or sponge, to achieve pristine surfaces.

What are Adhesives and How Do They Work?

Today, we will unravel the mysteries behind these magical substances and explore how they work their wonders in creating strong and unbreakable bonds. So, put on your lab coats and prepare to be amazed.

What Are Adhesives?

Adhesives, my friends, are the unsung heroes of the bonding world. They come in various forms – from glues to tapes, pastes, and films – and play a vital role in industries like construction, automotive, aerospace, and manufacturing. These remarkable substances bring surfaces together in perfect harmony, making our modern lives possible.

Adhesion: The Molecular Attraction

Imagine a cosmic dance at the molecular level, where adhesives are matchmakers creating chemical bonds between their molecules and those on the surfaces they join. This fascinating process, known as adhesion, forms the foundation for strong and unbreakable bonds. It’s like a love story between two surfaces that can never be torn apart. How enchanting.

Cohesion: The Inner Strength of Adhesives

Just like a superhero needs strength to save the day, an adhesive requires high cohesion to withstand the test of time. Chemical composition, viscosity (that gooey consistency), and curing process all contribute to an adhesive’s inner strength. These factors ensure that the adhesive doesn’t break down or lose its bond over time, making it a trusty ally in any bonding endeavor.

The Mechanisms at Play:

Adhesives come in different types, each with its own unique way of working its magic. Some adhesives physically interlock with surface irregularities, relying on mechanical forces to create a strong bond. Picture tiny Velcro strips hooking onto surfaces – that’s the magic of pressure-sensitive adhesives found in tapes and labels.

But wait, there’s more. Other adhesives harness the power of chemical reactions. Through a curing process, they transform from a liquid or semi-liquid state into a solid state. During this awe-inspiring metamorphosis, chemical reactions occur between the adhesive and surface molecules, resulting in an unbreakable bond. Prepare to be dazzled by the chemically reactive prowess of epoxy adhesives, which are widely used in various applications.

Types of Adhesives for Gluing Marble to Marble

The art of gluing marble to marble requires more than just a steady hand and an eye for precision. It demands the right adhesive that can withstand the test of time while preserving the beauty and integrity of the marble surface. In this comprehensive guide, we delve into the world of adhesives and explore the different types available for gluing marble to marble, along with their unique advantages and disadvantages.

Epoxy Resin: Unleashing Unyielding Strength

Epoxy resin stands as a stalwart adhesive choice for bonding marble due to its exceptional bonding properties and unparalleled strength. Comprised of two components – a resin and a hardener – this adhesive initiates a chemical reaction upon mixing, resulting in a rock-solid and rigid bond. The durability of epoxy resin makes it suitable for both indoor and outdoor applications, but its fast curing time can pose challenges during application, potentially leaving visible lines if not expertly applied.

Polyurethane Adhesive: The Flexible Guardian

For areas prone to structural shifting or vibrations, polyurethane adhesive emerges as an ideal choice. This adhesive offers a formidable bond alongside flexibility, ensuring that the marble surfaces remain intact. Polyurethane adhesives also possess remarkable resistance to moisture, which proves beneficial when working with marble. However, they may not possess the same sheer strength as epoxy resin and may necessitate clamping during the curing process.

Polyester Resin: Embellishing Bonds with Color

Within the stone industry, polyester resin reigns supreme, serving as a go-to adhesive for bonding marble to marble. This adhesive boasts excellent adhesion properties and can be effortlessly colored to match the hue of the marble being bonded. Polyester resin cures relatively swiftly, enabling expedited installation or repair work. However, it may not possess the sheer strength of epoxy resin and can become brittle over time.

Acrylic Adhesive: Rapid-Drying, Crystal-Clear Bonds

When time is of the essence, acrylic adhesive steps up to the plate with its quick-drying nature and ability to provide a clear bond line. Ideally suited for indoor applications, this water-based adhesive offers a strong initial tack and dries rapidly. Acrylic adhesives also boast non-toxic properties, emitting minimal odors during the curing process. Nevertheless, they may not possess the same level of strength as epoxy or polyurethane adhesives.

Cement-Based Adhesive: The Versatile Workhorse

Cement-based adhesives find their niche in bonding marble tiles or slabs to substrates. Renowned for their robust bonding capabilities, these adhesives excel in both indoor and outdoor applications. However, vertical installations or heavy-duty tasks may require additional reinforcement. Additionally, cement-based adhesives typically have longer curing times compared to other options.

Benefits of Epoxy Resin Adhesive for Gluing Marble to Marble

When it comes to creating stunning marble masterpieces, choosing the right adhesive is paramount. Among the various options available, epoxy resin adhesive stands tall as the unrivaled champion of marble-to-marble bonding. Its exceptional strength, durability, and versatility make it the go-to choice for professionals and DIY enthusiasts alike.

Here, we’ll unravel the numerous benefits that epoxy resin adhesive brings to the table, ensuring your marble creations stand the test of time with unwavering strength and grace.

Unparalleled Bonding Strength:

Epoxy resin adhesive boasts an unrivaled bonding strength, forging a solid connection between marble surfaces. This ensures that your marble masterpiece can withstand heavy loads and high levels of stress without compromising its integrity.

Shrinking and Expanding? Not an Issue:

Say goodbye to worries about unsightly gaps or weakened connections. Unlike other adhesives, epoxy resin doesn’t shrink or expand during the curing process. Once cured, it maintains its original size and shape, guaranteeing a tight and secure bond between your marble pieces.

Resisting Moisture with Ease:

Epoxy resin adhesive’s remarkable resistance to moisture makes it an ideal choice for gluing marble in areas prone to water exposure, such as bathrooms or kitchens. It forms an impenetrable barrier that prevents water from seeping into the bond and protects your masterpiece from potential damage caused by water infiltration.

Versatility at Its Finest:

Epoxy resin adhesive is a true chameleon that adapts effortlessly to various marble types, including porous and non-porous varieties. This versatility allows you to use it for a wide range of applications, from delicate decorative pieces to large-scale countertops or flooring installations.

Aesthetics Meet Functionality:

Not only does epoxy resin provide unmatched bonding properties, but it also adds aesthetic value to your marble creations. With its crystal-clear, glossy finish, it seamlessly integrates with the natural beauty of marble, ensuring that the adhesive doesn’t detract from the overall appearance.

User-Friendly Application:

Working with epoxy resin adhesive is a breeze. Its two-part composition – resin and hardener – can be easily mixed before application, providing you with ample working time to position the marble pieces precisely. This guarantees a seamless and flawless result every time.

Benefits of Polyurethane Adhesive for Gluing Marble to Marble

When it comes to bonding marble surfaces, one adhesive rises above the rest – polyurethane adhesive. Known for its exceptional strength, flexibility, and durability, polyurethane adhesive has become the go-to choice for gluing marble to marble. In this article, we will explore the extraordinary benefits of using polyurethane adhesive, turning ordinary marble installations into lasting marvels. Grab your cape and let’s delve into the world of polyurethane adhesive.

Unbeatable Bonding Strength:

Polyurethane adhesive boasts a superpower – extraordinary bonding strength. It creates a robust and durable bond capable of withstanding heavy weight and stress, ensuring that your marble installation remains secure and stable.

Flexibility That Saves the Day:

Working with natural stone like marble requires an adhesive that can handle movement and vibrations without causing damage. Polyurethane adhesive possesses incredible flexibility, allowing it to expand and contract with the marble. This superpower absorbs any movement or vibrations, preventing cracks or breaks in the marble.

Water Resistance for Aquatic Adventures:

Marble installations often face moisture and water exposure, particularly in wet environments like bathrooms or kitchens. Unlike other adhesives that weaken or fail in such conditions, polyurethane adhesive is resistant to water and moisture. Its waterproof properties ensure that your marble installation remains intact, even in the face of water-based challenges.

Chemical Resistance Shield:

Polyurethane adhesive is armed with a protective shield of chemical resistance. It battles against various chemicals and solvents without deteriorating, guaranteeing the longevity of your marble bond. No matter what substances come into contact with your marble installation, polyurethane adhesive stands strong.

Versatility: The Chameleon of Adhesives:

Polyurethane adhesive showcases its versatility by adapting to different types of marble finishes. Whether your marble surface is polished, honed, or textured, this adhesive can handle it all. From countertops and flooring to wall cladding and decorative elements, polyurethane adhesive proves to be the chameleon of adhesives.

Things to Consider When Choosing an Adhesive

Selecting the perfect adhesive for bonding marble to marble requires careful consideration. With a plethora of options available, it can feel overwhelming. But fear not, my fellow adhesive enthusiasts, as I am here to guide you through the essential factors to consider when choosing an adhesive for your marble masterpiece.

First and foremost, let’s talk about the type of adhesive. Epoxy, polyurethane, cyanoacrylate (super glue), and silicone are just a few of the adhesives available in the market. Each type has its own unique properties and strengths. For bonding marble to marble, epoxy adhesives are often recommended due to their exceptional strength and durability. So make sure to choose an adhesive specifically designed for this purpose.

Compatibility with marble is a crucial consideration. Marble is a delicate material that can be easily damaged by certain adhesives containing chemicals or solvents. To avoid any unwanted discoloration or damage, it’s essential to check the manufacturer’s instructions or consult with experts to ensure that the adhesive you choose is safe for use on marble.

Now, let’s talk about setting time. Different adhesives have varying setting times, referring to the time required for the adhesive to fully cure and bond the marble surfaces together. Depending on your project requirements, you may need an adhesive that offers a longer setting time for adjustments and alignment or a quick-bonding adhesive if you’re on a tight schedule.

Strength and durability are paramount when it comes to bonding marble. Given its weight, it is crucial to select an adhesive that can withstand the test of time. Look for adhesives that offer high tensile strength and resistance to temperature changes, humidity, and moisture. This will ensure that your bond remains intact even in challenging conditions.

If aesthetics are important for your project, color matching becomes a must. Some adhesives come in different colors or can be tinted to closely match the color of your marble surfaces. This will result in a seamless appearance once the adhesive is applied, leaving your masterpiece looking flawless.

Consider the application method when choosing an adhesive. Depending on the size of your project and the accessibility of the bonding surfaces, you may need to use a brush, trowel, or adhesive dispenser. And don’t forget to follow the manufacturer’s instructions on the proper application technique for optimal results.

Preparing the Surfaces Before Applying the Adhesive

Now that you’ve chosen the perfect adhesive to bond your marble masterpieces, it’s time to embark on the crucial journey of surface preparation.

This step is vital to ensure a bond that can withstand the test of time and leave your marble surfaces looking flawless.

So, roll up your sleeves and let’s dive into the world of surface preparation.

Step 1: Cleanliness is Key

First things first, we need to clean those marble surfaces with meticulous care. Dust, dirt, or debris can wreak havoc on our adhesive’s ability to work its magic. Grab a damp cloth and wipe away any loose dirt or particles.

Then, reach for a gentle detergent or stone cleaner designed specifically for marble surfaces. Scrub away, ensuring every nook and cranny is thoroughly cleaned.

Once you’re done, rinse the surfaces with clean water and make sure they are completely dry before proceeding. Moisture and adhesive are not a good mix.

Step 2: Inspect and Repair

Now it’s time for a close inspection of our surfaces. Look out for any cracks, chips, or unevenness on the marble. These imperfections can compromise the adhesive bond, so they need to be addressed before moving forward. For minor cracks or chips, grab a reliable marble repair kit or epoxy filler. Follow the product instructions carefully to fill in the gaps and smooth out any rough edges. Allow sufficient time for the repairs to cure before continuing.

But what if you encounter significant cracks or damage that seems beyond your DIY skills? Fear not. Consult a professional stone restoration expert to ensure proper repairs and a successful adhesive bond.

Step 3: Sanding and Dusting

Once our repairs are complete, it’s time to show our marble surfaces some love by gently sanding them. Take fine-grit sandpaper and create a slightly roughened surface that enhances adhesion. Don’t worry, we’re not talking about a heavy sanding session here. Just a light touch will do the trick.

After sanding, ensure all dust particles are banished from the surface. Use a clean cloth or a vacuum cleaner with a soft brush attachment to remove any lingering debris. We want our surfaces to be pristine and ready for the next step.

Professional Installation and Advice for Complex Projects

In this captivating blog post, we delve into the indispensable role of seasoned professionals in tackling complex projects. From selecting the perfect adhesive to meticulous surface preparation, we unveil the secrets to achieving breathtaking and long-lasting results.

The Fine Art of Precision:

Complex projects demand a masterful touch, especially when it comes to gluing marble to marble. Professional installers have honed their craft with unwavering precision, ensuring every detail is flawlessly executed. With their expertise, you can bid farewell to costly mistakes and potential damages. They possess an intimate understanding of the diverse world of marble and can recommend the most suitable adhesive for your unique project.

Harnessing the Power of Experience:

When it comes to bonding marble, experience reigns supreme. Seasoned installers have traversed a rich tapestry of projects, working with various types of marble along the way. Their wealth of experience empowers them to navigate potential challenges effortlessly. By entrusting your project to their capable hands, you can rest assured knowing that years of expertise are laid bare in every meticulously planned step.

Adhesive Alchemy:

Not all adhesives are created equal in the realm of marble-to-marble bonding. Professionals possess an innate understanding of the intricate dance between adhesive selection and project requirements. Factors such as marble type, surface conditions, and environmental influences shape their adhesive recommendations. Two stalwart options deserving mention are epoxy and polyurethane adhesives.

- Epoxy adhesives emerge as champions in bestowing formidable strength and durability upon your bond. Known for their exceptional adhesion capabilities, they defy moisture, heat, and chemicals with unwavering resilience.

- Polyurethane adhesives, on the other hand, offer a symphony of adhesion and flexibility. Indoor or outdoor, they fearlessly brave temperature variations and stand as trustworthy sentinels of reliability in challenging environments.

KSAGWLHbJt8″ >

Conclusion

When it comes to gluing marble to marble, choosing the right adhesive is crucial. You want a product that not only provides a strong bond but also ensures the longevity and durability of your marble surfaces. After careful research and consideration, we have determined that epoxy-based adhesives are the best option for this task.

Epoxy adhesives offer several key advantages that make them ideal for bonding marble. Firstly, they provide an incredibly strong bond that can withstand heavy weight and stress. This is particularly important when working with large or heavy marble pieces that need to be securely attached together.

Furthermore, epoxy adhesives have excellent resistance to moisture and temperature fluctuations. Marble surfaces are often exposed to water, humidity, and changes in temperature, so using an adhesive that can withstand these conditions is essential. Epoxy adhesives create a waterproof seal that prevents moisture from seeping into the bond, ensuring its integrity over time.

In addition to their strength and resistance, epoxy adhesives also offer ease of use and versatility. They come in two parts – resin and hardener – which need to be mixed together just before application. This allows for precise control over the adhesive’s consistency and drying time.

To ensure a successful bond between marble surfaces, it is crucial to follow proper application techniques when using epoxy adhesives. Thoroughly clean the surfaces to be bonded, removing any dirt or debris that could interfere with the adhesive’s effectiveness. Apply the epoxy evenly on both surfaces and press them firmly together, allowing sufficient curing time as per the manufacturer’s instructions.

In conclusion, when it comes to gluing marble to marble, epoxy-based adhesives are undoubtedly the best choice. Their exceptional strength, resistance to moisture and temperature fluctuations, as well as ease of use make them perfect for achieving long-lasting bonds between marble surfaces.