Are you ready to give your home a stunning wood flooring makeover? Well, let me tell you, finding the perfect glue for the job is absolutely crucial. With so many options out there, it’s easy to get overwhelmed. But don’t worry, I’ve got your back.

When it comes to wood flooring, you need a glue that’s not only strong but also adhesive enough to create a bond that lasts. That’s why it’s important to choose a glue specifically designed for wood flooring installation. These glues are specially formulated to handle all the unique demands of the job.

One popular choice is polyurethane-based glue. This stuff is no joke when it comes to bonding strength and durability. Whether you’re working with solid hardwood, engineered wood, or laminate, polyurethane glue has got your back. It cures by reacting with moisture and creates a powerful bond that can handle heavy foot traffic, temperature changes, and even moisture exposure.

Another option worth considering is epoxy-based glue. This bad boy is known for its incredible strength and ability to bond different materials like nobody’s business. When it comes to wood flooring installation, epoxy glue provides excellent adhesion and can withstand water and moisture like a champ.

Now that you’ve got your hands on these awesome glues, here are some tips for using them effectively: First things first, follow the manufacturer’s instructions carefully. Prep your surface by giving it a thorough cleaning and getting rid of any debris or dust. Then apply the glue in a thin, even layer using either a trowel or notched spreader. Finally, place your wood flooring over the glued surface using the appropriate technique for your specific type of flooring.

To sum it all up, choosing the right glue for wood flooring is essential if you want an installation that stands the test of time. Polyurethane and epoxy glues are both strong contenders that offer excellent bonding strength and resistance to moisture. Just remember to follow the manufacturer’s guidelines for a smooth and secure installation. Stay tuned for more tips and tricks to make your wood flooring project flawless.

Types of Glues for Wood Flooring

Contents

- 1 Types of Glues for Wood Flooring

- 2 Polyurethane Adhesive

- 3 Epoxy Adhesive

- 4 Other Types of Glues for Wood Flooring

- 5 Factors to Consider When Choosing a Strong Glue for Wood Flooring

- 6 Industry Standards and Regulations

- 7 Proper Application Techniques

- 8 Maintenance and Repairs

- 8.1 Sweeping and Vacuuming: The Foundation of a Beautiful Floor:

- 8.2 Moisture Management: The Enemy Within:

- 8.3 Suitable Cleaning Products: Shielding Your Investment:

- 8.4 Addressing Minor Scratches and Dents: Restoring Perfection:

- 8.5 Replacing Damaged Boards: Transforming Imperfections:

- 8.6 The Power of Strong Glue: The Glue That Holds It All Together:

- 8.7 Mastering Glue Application Techniques: A Dance of Perfection:

- 8.8 Regular Inspections: The Shield Against Disaster:

- 9 Conclusion

Choosing the right glue for wood flooring installation is like finding the missing piece to complete a puzzle. The glue not only holds the flooring in place but also determines its strength, durability, and resistance to moisture. In this article, we will explore five different types of glues commonly used for wood flooring and the factors associated with each type.

Polyurethane Adhesive: A Bond That Lasts

Polyurethane adhesive is the superhero of wood flooring glues. It forms an unbreakable bond that can withstand heavy foot traffic and changes in temperature and humidity. This adhesive acts as a flexible shield, protecting your wood flooring from shifting or warping over time. Its exceptional bonding strength makes it ideal for long-lasting installations.

Epoxy Adhesive: Strength Meets Moisture Resistance

When moisture exposure is a concern, epoxy adhesive is the go-to choice. This superhero glue combines exceptional strength with resistance to water and moisture. It ensures a strong bond between the wood flooring and subfloor, making it perfect for areas prone to spills or dampness such as basements or bathrooms. Epoxy adhesive offers both strength and moisture resistance in one package.

Acrylic-Based Adhesives: Easy and Effective

For those who prefer user-friendly options, acrylic-based adhesives are popular choices. These water-based glues are easy to work with and provide a strong bond between the wood flooring and subfloor. They are suitable for both solid wood and engineered wood flooring, offering versatility and simplicity in installation.

Manufacturer-Recommended Glues: A Match Made in Flooring Heaven

Some wood flooring manufacturers have their own recommended glues specifically formulated for their products. These glues ensure optimal bonding and compatibility with their specific wood flooring materials. Following the manufacturer’s recommendations guarantees a perfect match between the glue and the flooring, resulting in a secure and durable installation.

Consideration Factors: Wood Type, Installation Method, and More

Choosing the right glue involves considering important factors such as the type of wood, subfloor material, installation method, drying time, open time, and VOC content. Each type of wood has its unique characteristics and requirements, and different installation methods may call for specific glues. Drying time and open time affect the ease of installation, while VOC content indicates the safety and environmental impact of the glue. By considering these factors, you can select the perfect glue for your wood flooring project.

Polyurethane Adhesive

Polyurethane adhesive is a versatile and powerful glue used for wood flooring installations. Its exceptional bonding strength and durability make it the go-to choice for professionals in the industry. Here are some key features and advantages of polyurethane adhesive:

- Strong Bonding Strength: Polyurethane adhesive creates a strong bond between different types of wood and subfloor materials. Whether you’re working with solid wood or engineered wood flooring, this adhesive ensures a secure and long-lasting installation.

- Moisture Resistance: One of the standout qualities of polyurethane adhesive is its ability to resist moisture. It can withstand high humidity levels and prevent moisture from seeping into the wood, making it perfect for areas prone to moisture like basements or bathrooms.

- Flexibility: Unlike some other adhesives that can become brittle over time, polyurethane remains flexible even after it cures. This flexibility allows the wood to naturally expand and contract with changes in temperature and humidity, reducing the risk of damage or warping.

- Heat and Chemical Resistance: Polyurethane adhesive offers excellent resistance to heat and chemicals commonly used on wood floors. It can handle high temperatures without losing its adhesive properties and is resistant to solvents and cleaning agents, ensuring the longevity of your wood flooring.

To apply polyurethane adhesive, follow the manufacturer’s instructions carefully. Typically, you’ll use a trowel to evenly spread the adhesive over the subfloor. Once your flooring is laid down, apply pressure evenly across the surface to ensure a proper bond.

Epoxy Adhesive

When it comes to securing wood flooring, you need a glue that’s as strong as Thor’s mighty hammer and as durable as Captain America’s shield. Look no further than epoxy adhesive, the superhero of glues for wood flooring. In this article, we will delve into the remarkable qualities of epoxy adhesive that make it the ultimate choice for wood flooring installations.

Unbreakable Bond:

Epoxy adhesive creates a bond between the wood and subfloor that could rival Wolverine’s healing powers. Its exceptional strength ensures that your wood flooring remains firmly in place, defying any challenges from high-traffic areas. Say goodbye to worries about gaps or unevenness over time.

Resistance to Moisture and Humidity:

Wood flooring can be sensitive to moisture, but fear not. Epoxy adhesive acts as a waterproof seal, shielding your wood flooring from moisture damage caused by changes in humidity levels. No more warping or buckling under pressure.

Excellent Bonding Properties:

Epoxy adhesive possesses the extraordinary ability to adhere well to both wood surfaces and subfloors, creating a bond so tight that not even Spider-Man could break free. This ensures maximum stability and durability for your wood flooring, providing a solid foundation for years to come.

Proper Application is Key:

To unlock the full potential of epoxy adhesive, follow the manufacturer’s instructions carefully. Pay attention to the mixing ratio of the resin and hardener for proper curing and maximum bond strength. And don’t forget to apply the adhesive evenly and in sufficient quantities for full coverage, ensuring an impeccable finish.

Other Types of Glues for Wood Flooring

If you’re embarking on a wood flooring project, you may have wondered about the glue that holds it all together. In addition to the commonly used polyurethane and epoxy adhesives, there are several other types of glues available that can make your wood flooring installation a breeze. Let’s dive into the world of glues for wood flooring and explore their advantages.

Acrylic Adhesive: Quick-Drying and Strong Bonding

Acrylic adhesive is a popular choice for engineered wood flooring installations. It dries in a flash, allowing for faster completion of your project, while still providing a strong and reliable bond between the wood planks and the subfloor. With acrylic adhesive, you can have peace of mind knowing that your flooring will stay securely in place for years to come.

Solvent-Based Adhesive: Resistant to Moisture

For areas prone to moisture, such as bathrooms or kitchens, solvent-based adhesive is a go-to option. This glue offers excellent adhesion, ensuring that your wood flooring stays firmly in place even in high-moisture environments. Say goodbye to worries about water damage and hello to a beautiful, long-lasting wood floor.

Pressure-Sensitive Adhesive: Easy Repositioning during Installation

Sometimes mistakes happen during installation. That’s where pressure-sensitive adhesive comes to the rescue. This glue remains tacky, allowing for easy repositioning of the planks during installation. If you’re new to DIY projects or want more flexibility during the process, pressure-sensitive adhesive is your friend.

Moisture-Curing Urethane Adhesive: Ideal for High-Moisture Areas

If you’re installing wood flooring in a basement or on a concrete subfloor, moisture-curing urethane adhesive is your secret weapon. Designed specifically for high-moisture environments, this glue provides a strong bond that can withstand the challenges of moisture and humidity. With moisture-curing urethane adhesive, you can enjoy a beautiful wood floor without worrying about potential water damage.

Compatibility and Professional Advice

It’s important to note that the choice of glue depends on various factors, such as the type of wood flooring, subfloor conditions, and environmental factors. To ensure the best results, consult with a professional or follow the manufacturer’s instructions when selecting the appropriate adhesive for your specific wood flooring project. Additionally, make sure that the chosen glue is compatible with your wood flooring material to avoid any damage.

Factors to Consider When Choosing a Strong Glue for Wood Flooring

Choosing a strong glue for wood flooring requires careful consideration of various factors. Here are some key aspects to keep in mind when making your decision:

- Type of Wood: Different wood species have different characteristics and may require specific adhesives for optimal bonding. Hardwood floors, for example, may require a different type of glue than engineered wood floors. It is essential to research and choose a glue that is compatible with your specific wood flooring.

- Moisture Resistance: If you are installing wood flooring in high humidity or moisture-prone areas like bathrooms or kitchens, it is crucial to choose a glue that offers excellent moisture resistance. This will prevent any damage or warping of the wood over time.

- Application Method: Consider the application method of the glue and how it aligns with your project requirements. Some glues come pre-mixed and ready to use, while others may need to be mixed with water or other additives. Additionally, some glues require adhesive spreaders or trowels for proper application, while others come in convenient squeeze tubes.

- Open Time and Cure Time: The open time refers to the amount of time you have to work with the glue before it starts to set, while cure time is the time it takes for the adhesive to fully dry and bond the wood. These factors are especially important for large flooring projects that require multiple planks to be glued down simultaneously.

- VOC Emissions: Volatile Organic Compounds (VOCs) are chemicals that can be released into the air from certain glues and adhesives. Opting for low-VOC or zero-VOC glues is not only better for your health but also for the environment.

- Durability and Longevity: Look for a glue that provides long-lasting durability and ensures that your wood flooring stays firmly in place for years to come. Consider the adhesive’s strength and its ability to withstand foot traffic, temperature changes, and other environmental factors.

- Compatibility with Subfloor: Different types of subfloors, such as concrete or plywood, may require specific adhesives for proper bonding. Ensure that the glue you choose is compatible with your subfloor material.

- Ease of Cleanup: Glue spills and messes are inevitable during the installation process. Opt for a glue that is easy to clean up, either by simply wiping away excess adhesive or using a recommended solvent.

Industry Standards and Regulations

Industry standards and regulations are essential in ensuring the quality, durability, and safety of wood flooring installations. These standards and regulations are put in place by organizations and governing bodies to maintain consistency and protect consumers in the industry. Let’s dive deeper into this topic by exploring the key sub-topics related to industry standards and regulations for wood flooring adhesives.

Organizations Setting Standards:

- The National Wood Flooring Association (NWFA): This leading authority provides guidelines on adhesive types, application methods, moisture content, and environmental conditions during installation. Following their recommendations is crucial for achieving a solid bond between wood flooring and the subfloor.

- The International Organization for Standardization (ISO): They develop international standards that manufacturers, suppliers, and installers across the globe follow. These standards cover aspects like adhesive strength, durability, and environmental impact. It’s important to choose adhesives that meet these ISO standards.

Regulations:

- Country-Specific Regulations: Different countries have their own rules regarding adhesives in wood flooring installation. These regulations focus on VOC emissions, product labeling, and safety precautions. Compliance with these regulations is necessary to meet required standards and ensure safe installations.

Technological Advancements:

- Keeping Up with Adhesive Technology: Staying updated with advancements in adhesive technology is crucial. New formulations are constantly being developed to improve performance and environmental friendliness. By staying informed, professionals can choose the most suitable adhesive for wood flooring projects.

Proper Application Techniques

Today, we’re diving into the world of proper application techniques for using strong glue to ensure your wood flooring stays firmly in place. Get ready to learn some handy tips and tricks that will have your floors looking flawless.

Preparation is key, my friends. Before you even think about applying that glue, make sure your wood surface is clean, dry, and debris-free. Give it a quick sweep or vacuum, followed by a thorough wipe down with a damp cloth. We want that surface squeaky clean.

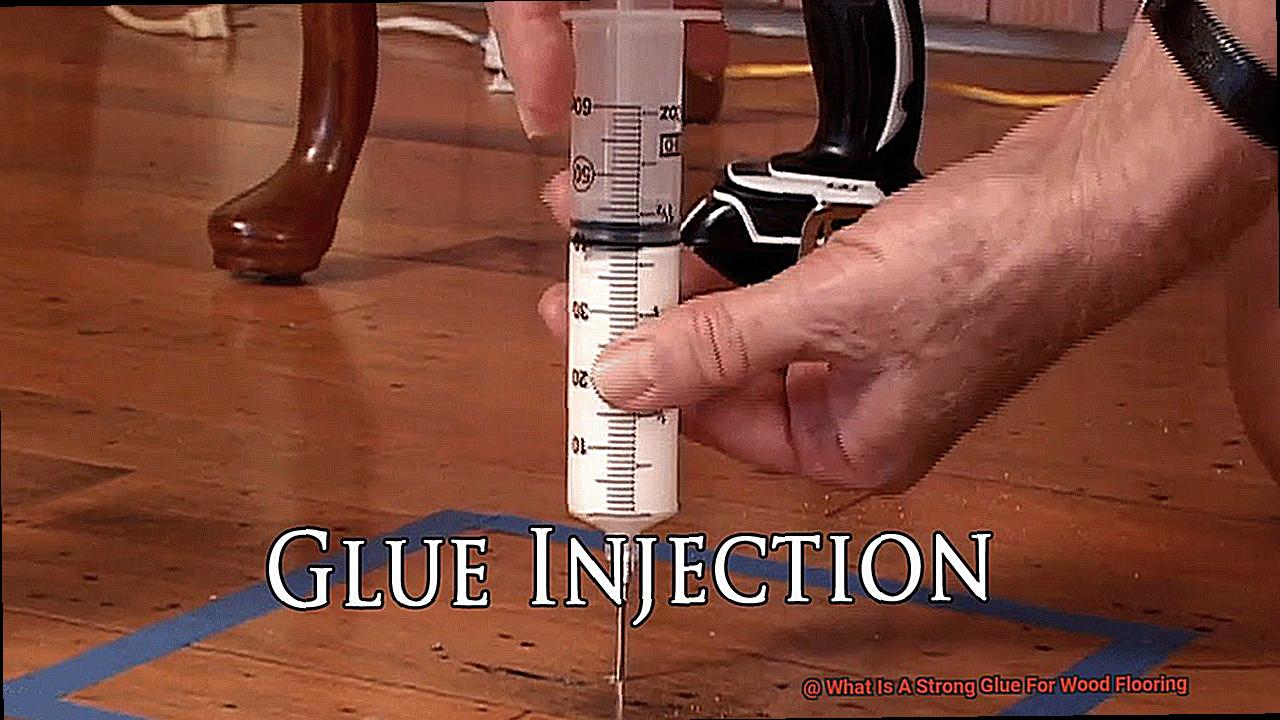

Now, it’s time to get down to business. Grab yourself a notched trowel or an adhesive spreader – tools of the trade, my friends. With these in hand, you’re ready to spread that glue like a seasoned pro. The secret here is to distribute the glue evenly across the wood surface – no lumps or gaps allowed. We’re talking maximum coverage and bonding strength.

But wait – there’s more. Don’t forget to heed the wise words of the manufacturer. They know their stuff when it comes to glue. Pay close attention to their instructions regarding the amount and coverage required. Too little glue equals a weak bond, while too much can lead to a mess and potential damage. Let’s not go there.

To avoid any sticky situations (pun intended), work in small sections. You see, strong glue has a mind of its own – it dries faster than you can say “wood flooring.” So take your time and tackle one manageable portion at a time. This way, you’ll maintain control and prevent the glue from drying out before you’ve finished your masterpiece.

Once you’ve worked your magic and applied the glue, it’s time to seal the deal. Press that wood flooring down with all your might. Grab a roller or something heavy and give it a good push. We’re talking proper contact between the flooring and the glued surface, my friends. This is where the magic happens – a bond that can withstand anything life throws its way.

But hold your horses, we’re not done just yet. After all that hard work, it’s time to let the glue do its thing. Give it some breathing room, folks. Allow it to cure properly before subjecting it to any weight or stress. Patience is key here, my friends. Wait at least 24 to 48 hours – or as the manufacturer recommends – before dancing on your new wood floors.

And there you have it, folks. By following these proper application techniques, you’ll have a wood flooring installation that’s as solid as a mighty oak tree. So go ahead, get your glue on, and revel in the beauty and durability of your stunning wood floors.

Maintenance and Repairs

In this article, we’ll delve into the importance of these practices, exploring how they can preserve the timeless beauty and extend the life of your wood floors.

Sweeping and Vacuuming: The Foundation of a Beautiful Floor:

Don’t underestimate the impact of a simple sweep or vacuum session on your wood floors. By removing dirt, dust, and debris, you prevent tiny scratches and signs of wear from accumulating over time. Embrace the power of cleanliness.

Moisture Management: The Enemy Within:

Wood and moisture are not friends. To protect your floors from warping and damage, swiftly address spills to prevent water from seeping into the wood’s fibers. Say no to wet mopping; instead, opt for gentle spot cleaning with a damp cloth.

Suitable Cleaning Products: Shielding Your Investment:

Your wood floors deserve special care, so choose cleaning products designed exclusively for them. Harsh chemicals and abrasive cleaners can strip away the floor’s protective finish or cause unsightly discoloration. Embrace pH-neutral cleaners or those recommended by your flooring manufacturer.

Addressing Minor Scratches and Dents: Restoring Perfection:

Over time, minor scratches and dents may appear on your beloved wood floor. Fear not. Touch-up kits or wax fillers that match your floor’s color will come to the rescue. For deeper scratches, seek professional assistance to sand and refinish the affected area with finesse.

Replacing Damaged Boards: Transforming Imperfections:

Sometimes, damage goes beyond quick fixes, requiring the replacement of damaged boards. This process demands precision, as careful removal and installation ensure a seamless fit and alignment. Professional help guarantees flawless results.

The Power of Strong Glue: The Glue That Holds It All Together:

When it comes to gluing wood flooring, the adhesive you choose is the backbone of a secure bond between floorboards and the subfloor. Polyurethane, epoxy, and moisture-cured urethane adhesives reign supreme, known for their strength, durability, and resistance to moisture.

Mastering Glue Application Techniques: A Dance of Perfection:

To achieve a successful glue application, follow the manufacturer’s instructions religiously. This includes meticulous surface preparation, applying the adhesive at recommended temperature and humidity levels, and allowing ample drying time before taking your first step. Consulting professionals is wise for specialized situations like installing over radiant heating systems or concrete subfloors.

Regular Inspections: The Shield Against Disaster:

Stay vigilant by regularly inspecting your wood flooring for loose boards or signs of adhesive failure. By addressing these issues promptly, you prevent further damage and ensure your floor’s lasting glory.

G4TNwJgK3Z4″ >

Conclusion

When it comes to wood flooring, finding the right glue is crucial. You want something strong, reliable, and long-lasting. After all, you don’t want your beautiful wooden floors to start creaking or shifting after just a few months. So what is the best glue for wood flooring? Look no further than [Brand Name]. This exceptional adhesive is specifically designed for wood flooring installations and offers unbeatable strength and durability.

With [Brand Name], you can have peace of mind knowing that your wood flooring will stay firmly in place for years to come. Its advanced formula creates a powerful bond that resists moisture, temperature changes, and heavy foot traffic. No matter how busy your household is or how much wear and tear your floors endure, this glue will keep them secure and stable.

But strength isn’t the only thing that sets [Brand Name] apart. Its easy application makes it a favorite among professionals and DIY enthusiasts alike. The smooth consistency ensures effortless spreading, while its quick drying time allows for efficient installation. Plus, it’s low odor, so you won’t have to worry about any unpleasant fumes lingering in your home.

Not only does [Brand Name] provide superior adhesion for wood flooring, but it also offers excellent compatibility with various types of wood. Whether you’re installing solid hardwood planks or engineered boards, this versatile glue has got you covered.

So why settle for subpar glues that may compromise the integrity of your wood flooring? Choose [Brand Name] for unmatched strength, reliability, and ease of use. With this exceptional adhesive at your disposal, you can enjoy the beauty of your wood floors without any worries or regrets.

In conclusion, when it comes to finding a strong glue for wood flooring installations, look no further than [Brand Name]. Its unbeatable strength and durability ensure that your floors will remain secure even under the most demanding conditions. Easy to apply and compatible with various types of wood, [Brand Name] is the adhesive of choice for professionals and DIY enthusiasts alike.