We all know that epoxy is the glue that holds our projects together. But what happens when this sticky wonder gets a little too hot to handle? Buckle up, because we’re about to uncover the scorching secrets of overheated epoxy.

Whether you’re a DIY fanatic or just love learning new things, get ready for a wild ride through the blazing world of epoxy gone hot. So, grab an ice-cold drink, kick back, and let’s jump into this fiery adventure.

What is Thermal Degradation?

Contents

Thermal degradation poses a significant challenge when it comes to epoxy resins. These versatile materials find applications in diverse industries, including construction, automotive, electronics, and crafts.

However, subjecting epoxy to high temperatures can trigger a cascade of undesirable effects, such as alterations in physical properties, compromised adhesion strength, color distortion, and even complete material breakdown. In this article, we will delve deeper into the intricate concept of thermal degradation and emphasize the paramount importance of temperature management when working with epoxy.

Effects of Thermal Degradation:

Structural Weakening:

The intricate chemical bonds within epoxy resins begin to unravel when subjected to elevated temperatures. This gradual disintegration undermines the overall structural integrity and can compromise mechanical properties like strength, flexibility, and stiffness. The degradation process is often accelerated by prolonged exposure to heat and rapid temperature fluctuations.

Erosion of Adhesion Strength:

Epoxy finds extensive use as an adhesive or bonding agent across various applications. However, excessive heat disrupts the adhesive capabilities of epoxy, leading to weakened bonds and potential failure of bonded components. To maintain optimal adhesive strength in epoxy joints, precise temperature management is indispensable.

Chromatic Metamorphosis:

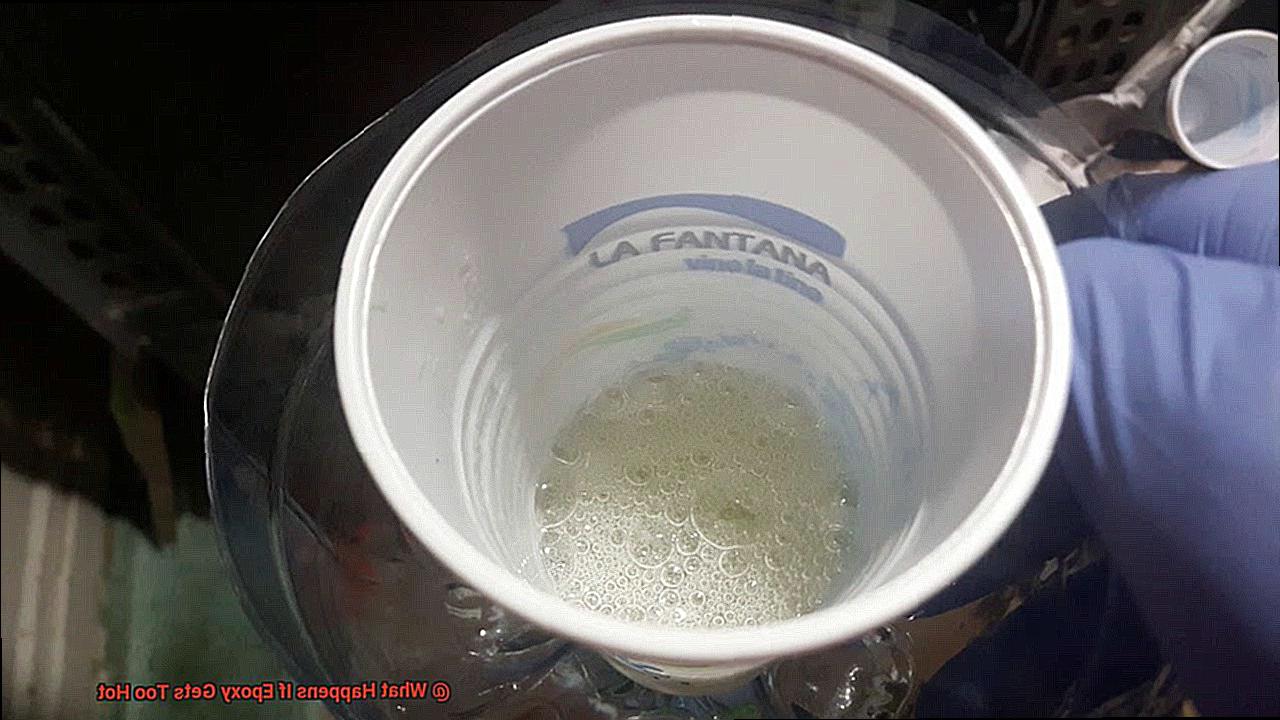

An unmistakable consequence of thermal degradation is the alteration in the color of epoxy resins. When exposed to high temperatures, chemical reactions occur within the material, causing it to darken or yellow. This metamorphosis not only affects the visual appeal but also serves as an indicator that the epoxy’s properties have been irrevocably transformed.

Utter Material Breakdown:

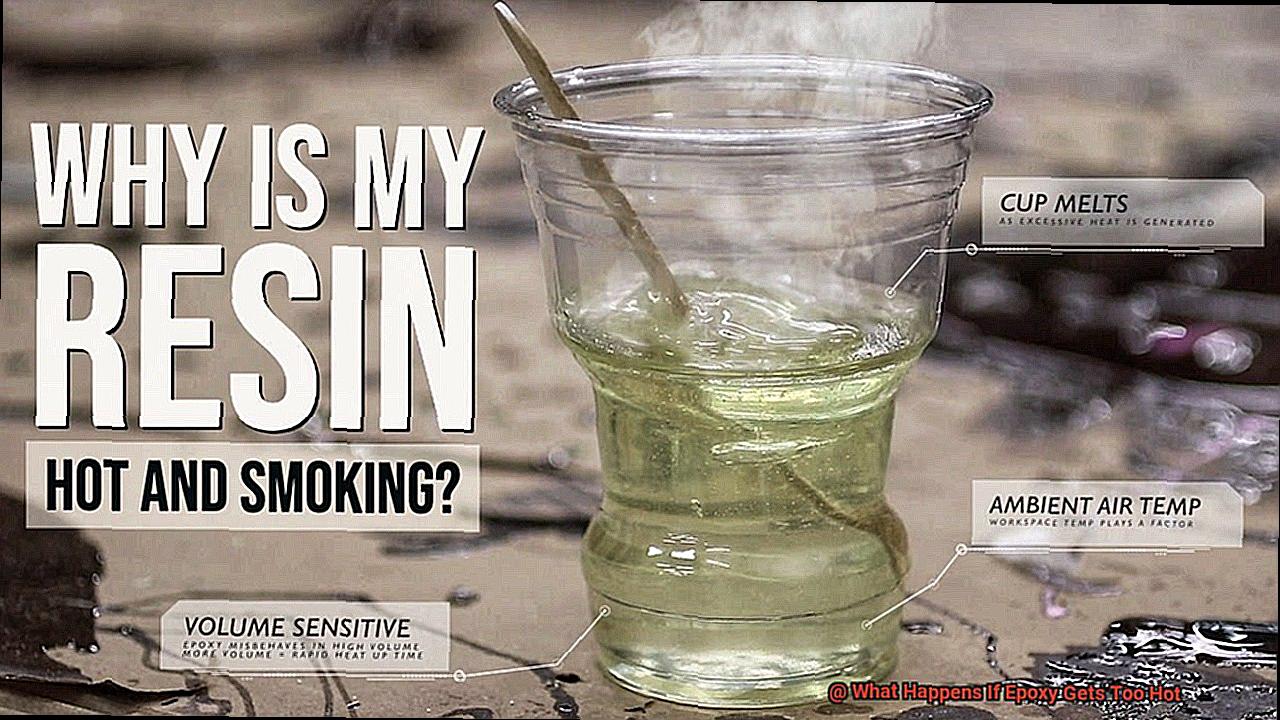

In severe cases of thermal degradation, where epoxy is subjected to prolonged extreme temperatures, it undergoes complete breakdown. The material loses its structural integrity and becomes brittle or crumbly. It may even melt or form bubbles due to excessive heat exposure. Once epoxy reaches this point, its original properties are irretrievable, even upon cooling.

Importance of Temperature Management:

To avert the detrimental consequences of thermal degradation, a profound understanding of epoxy’s thermal limitations and meticulous temperature management strategies are vital. Key considerations include:

- Adhering to manufacturer-recommended temperature guidelines.

- Avoiding prolonged exposure to high temperatures and rapid fluctuations.

- Ensuring adequate ventilation during epoxy work to minimize exposure to harmful fumes.

- Storing epoxy resins away from direct heat sources or open flames to mitigate fire hazards.

Decrease in Viscosity

Imagine this: you’re engrossed in a project, carefully applying epoxy glue to create a bond that’s as strong as steel. But suddenly, the epoxy turns into a thin, watery mess, slipping through your fingers like a mischievous eel. What caused this frustrating situation? One possible culprit is a decrease in viscosity due to excessive heat. In this article, we’ll delve into the various problems that arise when epoxy viscosity decreases and explore the critical role of temperature management in epoxy applications.

Uneven Coverage:

When epoxy becomes thin and runny, achieving a smooth and uniform coverage on surfaces becomes an uphill battle. The rapid flow of the epoxy may result in haphazard distribution, leaving weak spots that can undermine the integrity and longevity of your project.

Gap Filling Challenges:

Epoxy is often used to fill gaps or act as a structural adhesive. However, decreased viscosity can hinder its ability to fill voids effectively and provide robust strength. Thinner epoxy lacks the necessary thickness to create sturdy bonds or adequately bridge gaps, potentially compromising the structural integrity of your masterpiece.

Dripping and Sagging:

Another consequence of decreased viscosity is the increased likelihood of dripping or sagging. Thin and runny epoxy has a sneaky tendency to succumb to gravity’s pull, creating unwanted drips or sagging on vertical surfaces. This not only leads to uneven finishes but can also compromise adhesion, leaving you with a less-than-perfect result.

Accelerated Curing Time:

As epoxy becomes thinner, its chemical reaction accelerates due to heightened molecular mobility. This means that your working time or pot life shrinks, making it challenging to complete your project before the epoxy thickens beyond usability. When dealing with lower viscosities, speed and efficiency become paramount.

Prevention Tips:

To steer clear of these issues, proper storage and handling of epoxy are paramount. Keep your epoxy in a cool, dry sanctuary, far from the clutches of direct sunlight or scorching heat sources. Pay heed to the recommended temperature range specified by the manufacturer – it’s your epoxy’s comfort zone. And if your epoxy overheats, let it cool down before wielding it, allowing its viscosity to return to its natural state.

Reduction in Strength and Structural Integrity

Intro:

Welcome to the intriguing world of adhesives. Today, we will delve into an often overlooked yet critical factor that can spell disaster for your epoxy glue – excessive heat. Whether you are a do-it-yourself enthusiast or a seasoned professional, understanding how heat impacts the strength and structural integrity of epoxy is essential for successful bonding. So grab a cup of coffee and prepare to explore the fascinating relationship between temperature and glue.

The Versatile Power of Epoxy:

Before we uncover the effects of heat, let’s acquaint ourselves with the remarkable properties of epoxy. Renowned for its unparalleled bonding capabilities, epoxy is a versatile adhesive used across diverse industries such as construction, automotive, and electronics. Its resistance to chemicals and moisture makes it an ideal choice for countless applications.

When Heat Unleashes Havoc:

When epoxy encounters excessive heat, trouble looms on the horizon. Heat causes epoxy to soften and lose its original integrity, jeopardizing its strength and structural stability. This degradation process occurs when the epoxy resin succumbs to the relentless assault of high temperatures.

The Ramifications of Thermal Degradation:

Thermal degradation wreaks havoc on epoxy, primarily resulting in a significant reduction in strength. Epoxy exposed to excessive heat becomes feeble, unable to withstand applied forces or loads. This poses serious implications for crucial structural components like bonded joints or composite materials.

A Battle for Structural Integrity:

Beyond weakened strength, excessive heat relentlessly assaults the very essence of epoxy’s structural integrity. Cracks, delamination, and other forms of damage become imminent as the epoxy softens under the relentless heat.

Dimensions Under Siege:

Epoxy’s vulnerability to high temperatures extends beyond compromised strength and structural integrity. Heat-induced softening can lead to dimensional changes within the adhesive. As a result, epoxy may expand or contract, causing distortions or misalignments in the bonded surfaces. This further jeopardizes the overall bond integrity.

Temperature Limits and Compatibility:

It is crucial to note that not all epoxies possess the same temperature resilience. Some epoxies are specially formulated to endure extreme heat without significant degradation. Understanding the operating temperature range of the epoxy you are using is imperative to ensure optimal performance and longevity.

Safeguarding Against Heat’s Wrath:

To shield epoxy from the detrimental effects of excessive heat, it is vital to adhere to the manufacturer’s guidelines regarding maximum operating temperatures. Additionally, employing thermal barriers or insulation materials to minimize direct heat exposure, and implementing cooling mechanisms whenever feasible can provide additional protection for the epoxy.

Discoloration of Epoxy Resin

In this exploration, we will uncover the mysteries of discoloration and its detrimental effects on the performance of this versatile material. Prepare to delve into the scorching temperatures that can lead to the downfall of epoxy resin.

Causes of Discoloration:

Excessive heat exposure is the primary culprit behind the discoloration of epoxy resin. When temperatures soar beyond the recommended range, typically above 150°F, thermal degradation sets in. This process triggers chemical reactions that alter the resin’s molecular structure, resulting in the appearance of chromophores – the culprits responsible for the dreaded yellowing or browning effect.

Effects on Performance:

Discoloration goes beyond mere aesthetics; it has a significant impact on the performance of epoxy resin. The thermal degradation weakens vital mechanical properties such as strength and flexibility. This compromise undermines the resin’s ability to provide optimal protection and durability, rendering it less reliable in demanding applications.

Additional Factors:

While heat is the primary driver of discoloration, other factors can exacerbate this issue. Exposure to UV radiation from sunlight or artificial sources accelerates degradation, hastening the discoloration process. Prolonged exposure to chemicals or solvents can also cause deterioration and discoloration of epoxy resin, further compromising its integrity.

Prevention and Solutions:

To minimize or prevent discoloration, adherence to manufacturer guidelines regarding temperature limits during curing and storage is crucial. Shielding epoxy resin from direct sunlight or UV radiation by storing it in a cool, dark place or using UV-resistant coatings or additives effectively combats discoloration.

Additionally, avoiding prolonged exposure to chemicals and solvents helps maintain both the resilience and color of your epoxy masterpiece.

In conclusion, discoloration of epoxy resin occurs when exposed to high temperatures, triggering thermal degradation and altering its appearance. This phenomenon significantly impacts both the aesthetics and performance of the resin.

By following temperature guidelines, protecting against UV radiation, and minimizing exposure to chemicals, you can ensure your epoxy resin remains visually appealing and at its peak performance level.

Release of Potentially Harmful Fumes or Vapors

Fumes and vapors may seem harmless, but when released into the environment, they can pose significant health risks. From toxic chemicals to air pollution, the potential harms associated with these releases are far-reaching. In this article, we will explore the dangers of releasing fumes or vapors and provide practical tips for prevention.

Health Risks:

- Respiratory Problems: Inhalation of fumes or vapors can lead to respiratory irritation and difficulty breathing. Chemicals like benzene, ammonia, and formaldehyde commonly found in industrial processes can cause long-term damage to the lungs and other organs.

- Neurological Effects: Certain fumes, such as those from solvents and heavy metals like lead or mercury, can affect the nervous system. Exposure to these substances may result in headaches, dizziness, confusion, and even neurological disorders.

- Allergies and Sensitization: Repeated exposure to some fumes can trigger allergic reactions or sensitization in individuals. This can lead to asthma attacks, skin rashes, and other allergic symptoms.

Environmental Impacts:

- Air Pollution: Fumes or vapors released into the air contribute to air pollution. Volatile organic compounds (VOCs) are a major source of air pollution, leading to smog formation and the creation of ground-level ozone.

- Global Warming: Some fumes contain greenhouse gases like carbon dioxide or methane, which contribute to global warming and climate change.

Prevention Measures:

- Proper Ventilation: Ensure that workspaces are well-ventilated to prevent the buildup of harmful fumes. Install exhaust systems or use fans to circulate fresh air.

- Personal Protective Equipment (PPE): Use appropriate PPE such as gloves, goggles, masks, or respirators when working with substances that generate fumes or vapors.

- Chemical Substitution: Consider using less toxic alternatives or finding alternative processes that eliminate or reduce the release of harmful fumes or vapors.

- Safe Handling and Storage: Follow proper procedures for handling, storing, and disposing of substances that may release fumes. Store chemicals in well-sealed containers to prevent leaks.

- Regulatory Compliance: Adhere to local and national regulations regarding the release of fumes or vapors into the environment. Obtain necessary permits and ensure compliance with emission standards.

Fire Hazards

Epoxy, the adhesive powerhouse that holds industries together, possess a fiery secret. When subjected to high temperatures, this versatile glue can transform into a potential fire hazard. In this blog post, we will delve into the dangers of overheating epoxy and explore necessary precautions to ensure safety.

Toxic Fumes and Gases:

Overheated epoxy releases a toxic cocktail of gases and fumes, which bring forth severe health risks. Carbon monoxide, formaldehyde, and acrid smoke are just a few of the harmful substances that may permeate the air. Inhaling these noxious vapors can lead to respiratory issues and, in extreme cases, prove fatal.

Property Damage and Personal Safety:

Fires sparked by overheating epoxy not only endanger lives but also ravage properties. Extinguishing epoxy fires poses a formidable challenge due to their specialized nature, demanding specific firefighting techniques and equipment.

Proper Handling and Storage:

To minimize fire hazards, meticulous handling and storage of epoxy are paramount. Keep this volatile substance in a cool, well-ventilated area, far away from any potential heat sources. Adhering to the manufacturer’s guidelines concerning temperature limits for curing or using epoxy is non-negotiable when it comes to safety.

Emergency Response:

In the event of an epoxy fire, swift evacuation is critical. Instead of attempting to tackle the blaze independently, contact emergency services for professional assistance.

Understanding the fire hazards associated with overheating epoxy is vital for those who work with this adhesive marvel.

By following proper handling and storage procedures while remaining cognizant of the potential dangers, we can prevent accidents, safeguard ourselves and our surroundings, and cultivate a safer working environment. Remember, caution always triumphs over fiery consequences.

Preventing Overheating of Epoxy Resin

Epoxy resin is a remarkable adhesive that finds its way into numerous industries. However, when things get a little too hot for epoxy to handle, it can lead to a sticky situation. In this blog post, we’ll delve into the factors that contribute to overheating and explore practical tips to prevent this issue. So, grab your protective gear and let’s dive in.

Understanding the Factors:

One of the main culprits behind epoxy overheating is the exothermic reaction that occurs during the curing process. To keep things under control, it’s crucial to stick to the manufacturer’s recommended mixing ratio. Deviating from this ratio can disrupt the delicate balance of the reaction and cause excessive heat buildup.

Next up is the ambient temperature and humidity. High temperatures can speed up the curing process, increasing the risk of overheating. Similarly, low humidity levels can cause solvents in the epoxy to evaporate faster, leading to a higher exothermic reaction. So be mindful of these environmental conditions during application.

Prevention is Key:

Now that we understand the factors, let’s explore some preventive measures:

- Thin is In: Applying epoxy resin in thin layers can help dissipate heat more efficiently. Instead of one thick layer, consider applying multiple thin coats.

- Ventilation Matters: Proper ventilation is a must when working with epoxy resin. Adequate airflow helps disperse excess heat and prevents localized overheating. Crack open a window or use fans to keep things cool.

- Keep an Eye on the Temperature: Monitoring the temperature during curing is essential. Invest in infrared thermometers or thermal imaging cameras to ensure you stay within the recommended range.

- Storage Savvy: Proper storage techniques are essential for maintaining epoxy resin’s integrity. Store it in a cool, dry place away from direct sunlight and extreme temperatures.

sQe-PF4jXC4″ >

Conclusion

In conclusion, subjecting epoxy to excessive heat can have severe repercussions on its properties and performance. The consequences of thermal degradation are far-reaching, resulting in weakened structures, diminished adhesion strength, color transformations reminiscent of a chameleon’s hues, and even complete material breakdown. The viscosity of epoxy decreases under scorching temperatures, leading to uneven coverage, frustrating gap-filling challenges, unsightly dripping and sagging, and a hastened curing process. The once sturdy epoxy loses its strength and structural integrity when exposed to high heat, compromising its ability to withstand applied forces or loads while causing unwelcome dimensional changes within the adhesive. Beware the discolored aftermath of overheated epoxy resin – not only does it tarnish aesthetics but also undermines mechanical properties.

But wait. There’s more. Overheating epoxy doesn’t just harm your projects; it releases noxious fumes that endanger your health and contribute to air pollution. And let’s not forget about the fire hazard aspect – when set ablaze, epoxy emits toxic gases and fumes that spell danger.

To prevent this inferno of troubles, temperature management is key. Abide by the manufacturer’s recommended temperature guidelines with unwavering devotion. Ensure ample ventilation during epoxy work – let fresh air breathe life into your project. Store epoxy far away from heat sources or open flames – keep it cool as a cucumber. If possible, employ cooling mechanisms to maintain optimal conditions for your precious epoxy. And above all else, follow proper handling and storage procedures like a seasoned pro.

By comprehending the potential cataclysm brought on by overheating our dear friend epoxy resin and implementing preventative measures with gusto, we guarantee longevity, performance excellence, safety assurance, and an aesthetic appeal that will make others green with envy.