If you’re a DIY fanatic like me or a seasoned plumber, you’ve probably come across PEX (cross-linked polyethylene) pipe. It’s the superhero of plumbing materials – strong, flexible, and resistant to cracks and leaks. But here’s the thing: even superheroes need a sidekick. And for PEX pipe, that sidekick is glue.

Now, I know what you’re thinking – glue? Really? Can’t I just rely on those fancy compression fittings? Well, my friend, let me tell you this: while compression fittings are great for some applications, there are times when glue is your best bet for creating leak-free connections.

But before we jump into the nitty-gritty details of different types of adhesives for PEX pipe, let’s take a moment to appreciate the importance of choosing the right glue. Picture this: you spend hours installing your brand new PEX plumbing system with all the precision and care in the world. You turn on the water, expecting a smooth flow through your pipes. But instead, you’re greeted with a not-so-welcome surprise – water spewing out from every connection like an overzealous fountain.

That nightmare scenario is precisely why it’s crucial to choose the right adhesive for your PEX pipe connections. And lucky for you, I’m here to guide you through the maze of options available.

In this blog post, we’ll explore various types of adhesives suitable for PEX pipe and dive deep into their advantages and disadvantages. Whether you’re working on a small DIY project or tackling a massive plumbing overhaul, we’ve got you covered. So grab yourself a cup of coffee (or tea if that’s more your style), sit back, and let’s embark on this adhesive adventure together. Trust me; by the end of it, you’ll be armed with all the knowledge needed to keep your PEX pipe connections secure for years to come.

What is PEX Pipe?

Contents

PEX pipe, short for cross-linked polyethylene pipe, has gained widespread acclaim as a flexible plumbing material for residential and commercial applications. With its numerous advantages over traditional copper or PVC pipes, PEX has become a top choice for homeowners and plumbers alike. Let’s delve into what PEX pipe is and explore why it has garnered such popularity.

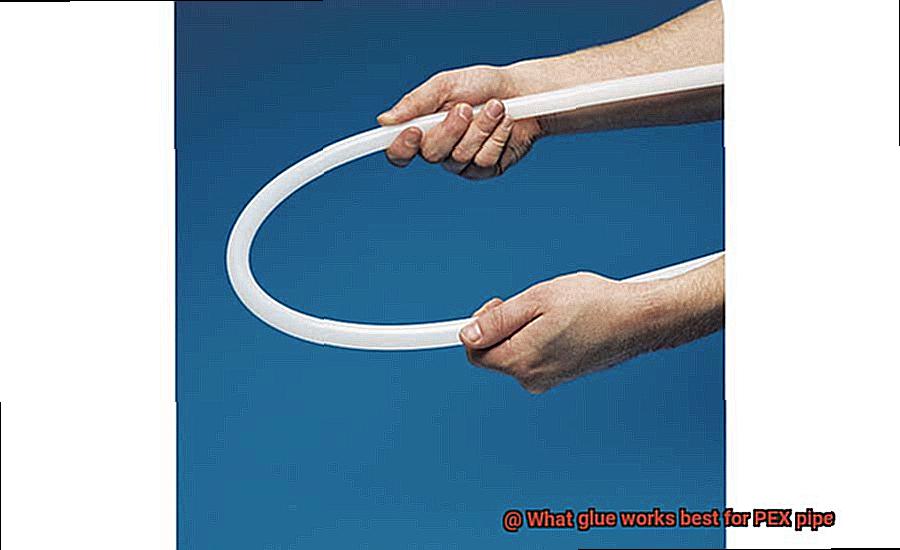

First and foremost, PEX pipe boasts incredible flexibility. Unlike rigid pipes, PEX can be bent and curved to fit around obstacles, making installation easier and more cost-effective. Its pliability also reduces the need for fittings and connectors, minimizing the risk of leaks or other plumbing issues.

Another notable advantage of PEX pipe is its resistance to freezing and bursting. The material can expand and contract without causing any damage, making it ideal for colder climates where freezing temperatures are common. This property also makes PEX a popular choice for outdoor applications such as irrigation systems.

Furthermore, PEX pipe is highly durable and corrosion-resistant. Unlike copper pipes that can develop pinhole leaks over time due to corrosion, PEX is immune to rust and other forms of degradation. This not only extends the lifespan of the pipe but also ensures a consistent flow of water without any impurities.

In terms of installation, PEX pipe is known for its ease. Its lightweight nature and simple connection methods make it a favorite among DIY enthusiasts and professional plumbers alike. Whether using crimp rings, push-fit connectors, or expansion fittings, PEX pipe can be easily installed to meet the specific requirements of any project.

Moreover, PEX pipe offers versatility in its compatibility with various plumbing systems. It can be used for both hot and cold water applications, handles high-pressure situations with ease, and is resistant to chemicals commonly found in household plumbing systems.

When it comes to connecting PEX pipes, using the right glue is crucial for secure and leak-free joints. One common option is PEX adhesive or PEX cement, which is specifically designed for bonding PEX pipes and fittings together. This two-part epoxy resin adhesive provides a strong bond that is resistant to high temperatures, chemicals, and pressure variations commonly found in plumbing systems.

Alternatively, crimp rings or clamps can be used to connect PEX pipes. These stainless steel rings are placed over the PEX pipe and fitting, providing a reliable connection that ensures long-lasting performance.

Benefits of Using PEX Pipe

PEX pipe has emerged as a popular choice for plumbing systems due to its range of benefits and advantages over traditional materials. This flexible and durable material offers homeowners and businesses numerous advantages that make it a top choice for plumbers and builders alike.

One of the primary benefits of using PEX pipe is its exceptional resistance to freezing temperatures. While copper or PVC pipes can be vulnerable to damage from freezing, PEX can expand and contract without any adverse effects. This makes it an ideal option for areas with cold climates, where frozen pipes are a common concern. With PEX, homeowners can rest assured that their plumbing system will not be compromised during frigid winter months.

In addition to its resistance to freezing, PEX pipe also boasts remarkable resistance to corrosion and scale buildup. Traditional metal pipes, such as copper, are prone to corrosion over time, impacting water quality and leading to leaks. However, PEX is resistant to corrosion and does not accumulate scale. This ensures a clean and safe water supply for households and businesses.

Moreover, using PEX pipe proves to be cost-effective compared to other materials. The material itself is relatively inexpensive, and its installation requires fewer fittings and joints, resulting in reduced labor costs. Additionally, PEX is lightweight and easy to handle, making the installation process quicker and more efficient.

A standout feature of PEX pipe is its flexibility. Unlike rigid metal or PVC pipes, PEX can bend and curve without the need for additional fittings or connectors. This flexibility allows for easier installation around obstacles and corners, resulting in a more streamlined plumbing system.

Furthermore, PEX pipe exhibits excellent resistance to chemicals commonly found in plumbing systems. It can withstand exposure to various chemicals without deteriorating, ensuring long-term durability and reliability.

In addition to its durability, PEX pipe has excellent insulation properties. Its thermal resistance helps maintain the temperature of hot water as it travels through the pipes, reducing heat loss and energy consumption. This can lead to significant cost savings over time.

Lastly, PEX pipe is renowned for its quiet operation. It minimizes noise caused by water flow or water hammering, providing a more comfortable living or working environment.

While the benefits of using PEX pipe are numerous, it is important to consider potential drawbacks. PEX pipe is susceptible to UV damage and should not be exposed to direct sunlight for extended periods, as it can degrade over time. Additionally, local building codes may restrict the use of PEX pipe in certain applications, so it is essential to consult with local authorities before incorporating PEX into a plumbing system.

Types of Glue for PEX Pipe

The secret lies in the glue they use. In this comprehensive guide, we will delve into the different types of glue available for PEX pipe connections. By understanding the advantages and disadvantages of each type, you’ll be able to make an informed decision for your plumbing needs.

PEX Adhesive: The Reliable Choice

PEX adhesive, also known as PEX cement, is the go-to glue for PEX pipe connections. This specialized glue is designed specifically for bonding PEX pipes and fittings together. With its two-part epoxy resin formula, PEX adhesive ensures a secure and leak-free joint that can withstand high temperatures, chemicals, and pressure variations commonly found in plumbing systems.

PVC Cement: A Versatile Alternative

PVC cement, primarily designed for PVC pipes and fittings, can also be used with PEX pipes in certain cases. However, it is crucial to choose a PVC cement explicitly stating its compatibility with PEX. Following manufacturer instructions is vital to ensure a proper application and avoid weak joints or leaks.

Solvent-Based Glues: Proceed with Caution

Some plumbers may opt for solvent-based glues like ABS or CPVC cement when bonding PEX pipes. However, it is essential to confirm their compatibility with PEX beforehand. Always check with the manufacturer or supplier to ensure the glue is suitable for your specific application.

Crimp Rings or Clamps: No Glue Required

For those seeking a glue-free option, crimp rings or clamps can create secure connections between PEX pipes and fittings. These stainless steel rings are placed over the pipe and fitting and compressed using a specialized tool, providing a tight seal without the need for glue. However, keep in mind that this method requires specific tools and may not be suitable for all plumbing applications.

Considerations and Precautions

When choosing a glue for PEX pipe connections, it is crucial to select one specifically designed for PEX. Generic adhesives may not provide the same level of performance and reliability. Always follow the manufacturer’s instructions regarding application, drying time, and curing before pressurizing the system. Consulting a professional plumber or adhering to local plumbing codes and regulations is also advisable.

Advantages of Using PEX Adhesive

PEX adhesive, also known as PEX glue or PEX cement, offers a multitude of advantages that make it the ideal choice for bonding PEX pipes and fittings. The first and most notable advantage is its ease of use. Unlike other joining methods like soldering or crimping, PEX adhesive comes in a convenient squeeze tube or bottle, making it incredibly easy to apply directly onto the pipe or fitting. This eliminates the need for complex techniques and saves valuable time during installation.

Moreover, PEX adhesive creates a strong and durable bond between PEX pipes and fittings. It forms a chemical bond with the material, ensuring a secure connection that is resistant to leaks and failures. With this adhesive, you can have peace of mind knowing that your plumbing system is built to last.

Another great advantage of PEX adhesive is its compatibility with different types of PEX pipes and fittings. Whether you are working with PEX-A, PEX-B, or PEX-C, the adhesive can be used with all of them. This versatility ensures that you can use PEX adhesive for any plumbing project, regardless of the specific materials involved.

In addition to its compatibility with various types of PEX pipes and fittings, PEX adhesive is also suitable for use with different installation methods. Whether you prefer crimping, compression, or push-fit connections, this adhesive has got you covered. Its versatility makes it a reliable choice for different plumbing applications.

One standout feature of PEX adhesive is its ability to withstand high temperatures and pressures commonly found in plumbing systems. Unlike some other types of glue or sealants, PEX adhesive is specifically formulated to handle hot water and high-pressure conditions without losing its bonding strength. This ensures that your plumbing system remains intact and reliable over time.

PEX adhesive is also resistant to corrosion and chemical degradation. This means that the bond between the pipes and fittings remains intact even when exposed to harsh chemicals or corrosive substances. So you won’t have to worry about your plumbing system deteriorating over time.

Another advantage of using PEX adhesive is the time and effort it saves during installation. Unlike complex and time-consuming soldering or welding techniques, PEX adhesive provides a quick and efficient method for joining PEX pipes and fittings. This means you can get the job done faster, without sacrificing quality.

Furthermore, PEX adhesive is versatile in both residential and commercial plumbing applications. Whether you are working on potable water supply lines, radiant heating systems, or hydronic systems, PEX adhesive can be used in various systems. Its versatility makes it a go-to choice for plumbers in a wide range of projects.

In terms of compatibility with existing plumbing infrastructure, PEX adhesive is compatible with different types of materials commonly used in plumbing systems, including copper, brass, and PVC. This allows for easy integration with existing plumbing infrastructure.

How to Apply PEX Adhesive

Properly applying PEX adhesive is crucial for creating a secure and leak-free connection between PEX pipes and fittings.

By following these steps, you can ensure a strong bond and a successful plumbing project.

Choose the right adhesive

Not all adhesives are suitable for PEX pipes, so it’s important to choose one that is specifically designed for this purpose. Always read the manufacturer’s instructions and specifications to ensure compatibility.

Prepare the surfaces

Before applying the adhesive, clean and dry both the PEX pipe and fitting surfaces. Use a clean cloth or sandpaper to remove any dirt, grease, or moisture. This step is essential for proper adhesion and a strong bond.

Apply the adhesive

Using a brush or applicator designed for PEX adhesive, apply a thin and even layer of glue to both the pipe and fitting. Avoid applying too much adhesive, as it can lead to excess buildup and weak joints. A thin layer is sufficient for a strong bond.

Insert the pipe into the fitting

After applying the adhesive, quickly insert the pipe into the fitting while twisting slightly to evenly distribute the glue. Make sure the pipe is fully inserted into the fitting until it reaches the stop inside.

Hold in place

Hold the pipe and fitting together firmly for a few seconds to allow the adhesive to set. This ensures a secure bond between the pipe and fitting.

During the application process, there are a few safety precautions to consider:

- Wear gloves to protect your hands from the adhesive.

- Work in a well-ventilated area to avoid inhaling fumes.

- Avoid contact with skin or eyes; if contact occurs, rinse thoroughly with water.

- Store the adhesive in a cool, dry place away from direct sunlight and extreme temperatures.

Alternatives to Glue for Connecting PEX Pipes

There are several alternatives that provide a secure connection without the hassle of adhesive. Let’s dive into these glue-free options and explore their advantages and disadvantages.

- Crimp rings or cinch rings: These metal rings are placed over the PEX pipe and fitting, then compressed using a special tool. This creates a tight connection that is resistant to leaks. Advantages include affordability and compatibility with various PEX pipe sizes. However, they do require a specialized tool for installation.

- Push-to-connect fittings: These handy fittings have a built-in mechanism that allows for quick and easy installation. Simply insert the PEX pipe into the fitting, and the internal locking mechanism holds it in place securely. Push-to-connect fittings are ideal for tight spaces and time-sensitive projects. However, they may be more expensive than other options.

- Compression fittings: These fittings have a compression nut and ring that create a watertight seal when tightened onto the PEX pipe. The advantage of compression fittings is that they can be easily removed and reused if necessary. However, they do require some manual effort for installation.

- Heat fusion or expansion fittings: For a more permanent solution, consider heat fusion or expansion fittings. Heat fusion involves using a specialized tool to heat the ends of the pipes and fittings, which are then pressed together to create a fused joint. Expansion fittings use a heated expanding ring that is inserted into the pipe, creating a secure connection when it cools down. Both methods provide strong connections but may require additional equipment and expertise.

Important Considerations When Choosing a Glue for PEX Piping

When it comes to PEX piping, selecting the right glue is paramount for a successful and durable installation. With a myriad of options available, it’s crucial to consider several key factors before making your decision. In this comprehensive guide, we will dive into the world of glues for PEX piping, exploring the important considerations and providing expert advice to help you make an informed choice.

Type of PEX Pipe:

There are three main types of PEX pipe – PEX-A, PEX-B, and PEX-C. Each type has its own unique characteristics and may require a specific type of glue. It is imperative to consult the manufacturer’s guidelines or specifications for the specific type of PEX pipe you are working with to ensure compatibility and optimal performance.

Temperature and Pressure Rating:

PEX piping is commonly used in hot and cold water applications, necessitating a glue that can withstand temperature fluctuations without losing its adhesive properties. Furthermore, the glue must handle the pressure that the PEX pipe will be subjected to without causing leaks or failures. Look for glues specifically formulated to withstand the temperature and pressure requirements of your specific application.

Compatibility with Other Materials:

PEX pipes are often connected to other materials such as brass fittings or copper tubing. It is critical to choose a glue that is compatible with these materials to ensure a secure and long-lasting connection. Seek out glues specifically designed for use with PEX piping that are also compatible with other common plumbing materials, such as metal alloys or PVC.

Ease of Use:

Consider the ease of application and working time of the glue. Look for glues that are easy to apply, providing a reasonable working time before they set. This allows for proper alignment and adjustment of the pipes before the glue fully cures, ensuring precise connections. Be mindful of glues that may require special tools or equipment for application, and carefully follow the manufacturer’s instructions for best results.

Industry Standards and Certifications:

Ensure that the glue you choose meets industry standards and certifications. Look for glues that are approved by reputable organizations such as ASTM International or NSF International. These certifications guarantee that the glue has undergone rigorous testing for performance, durability, and safety, providing peace of mind for your installation.

YgkagZj7cOE” >

Conclusion

When it comes to choosing the perfect glue for your PEX pipe, you have several options at your disposal. One top contender is PEX-specific adhesive – an exceptional choice tailor-made for bonding PEX pipes and fittings. With its robust formula, this adhesive forms an unyielding bond capable of enduring high pressure and temperature fluctuations commonly found in plumbing systems.

Another viable option is solvent cement – a chemical marvel that dissolves the surface of your PEX pipe before solidifying into an indomitable connection. However, keep in mind that not all solvent cements are compatible with PEX pipe; hence it’s crucial to carefully scrutinize product labels before making your selection.

For added peace of mind, many experienced plumbers advocate employing mechanical fittings and crimp rings alongside adhesives or cement. This dynamic duo ensures an extra layer of security that bolsters the integrity of your PEX pipe installation.

Ultimately, the choice of the best glue for your PEX pipe hinges on various factors, including the nature of your project and personal preference. To make an informed decision, it’s always prudent to consult a professional plumber or refer to manufacturer guidelines.