Got a melamine project on your hands and not sure which glue will do the trick?

No worries, we’ve got all the answers right here. Whether you’re a DIY enthusiast or a pro craftsman, finding the perfect glue for melamine is key to nailing your project.

Melamine, that smooth and non-porous material loved by furniture makers and cabinetry gurus, can be a bit finicky to work with. But fear not, because there are glues out there specially designed to bond with melamine like they were made for each other.

So get ready to discover the magical glue that will keep your melamine creations together in style.

What is Melamine?

Contents

In today’s world, melamine has become an indispensable material that finds its way into our everyday lives in numerous forms. From sleek kitchen cabinets to durable dinnerware, this remarkable hard plastic material offers exceptional durability, aesthetics, and heat resistance. However, it is crucial to understand the distinction between melamine as a material and melamine as a chemical compound to avoid any misconceptions.

Melamine as a Material:

- Composition: Melamine is composed of melamine resin, a synthetic compound created by combining melamine, formaldehyde, and other strengthening agents. This unique combination results in a strong and heat-resistant material.

- Durability: With its resistance to moisture, chemicals, impact, and heat, melamine proves itself suitable for an extensive range of applications. From kitchen cabinets and countertops to furniture and dinnerware, melamine products stand the test of time.

- Aesthetics: The smooth and glossy surface of melamine adds an alluring touch to products that demand an appealing appearance. Its versatility allows for endless design possibilities in construction and manufacturing.

Melamine as a Chemical Compound:

- Cyanuramide/Melamine Controversy: It is important to differentiate between melamine as a material and the chemical compound cyanuramide—also known as melamine. The latter has been linked to health concerns when used as an adulterant in food products.

- Food Safety: Due to potential health risks associated with its consumption, the use of melamine as a food additive is strictly regulated in many countries. Ensuring food products are free from traces of melamine contamination is vital.

Choosing the Right Glue for Melamine:

- Epoxy Glue: Known for its strong bond, resistance to moisture and temperature changes, epoxy glue is ideal for bonding melamine surfaces.

- Polyurethane Glue: Offering strength and the ability to withstand moisture and temperature fluctuations, polyurethane glue is another suitable option for melamine bonding.

- Cyanoacrylate Glue: While super glue or instant adhesive can provide a fast and secure bond, it may not be as durable as epoxy or polyurethane glues.

- Contact Cement: This adhesive forms an instant bond when two coated surfaces are pressed firmly together, making it a popular choice among woodworkers and DIY enthusiasts.

Why Use Glue on Melamine?

Glue is used on melamine surfaces for several compelling reasons. Firstly, melamine’s smooth and non-porous surface makes it challenging to bond with traditional adhesives. Glue provides a solution by creating a strong and permanent bond between melamine pieces. Using the right adhesive, such as epoxy glue or polyurethane glue, ensures that the joints remain securely held together, preventing any movement or separation over time.

Beyond creating sturdy joints, glue also plays a crucial role in enhancing the overall aesthetics of the finished product. When attaching edging or trim using glue, it creates a seamless and professional look by hiding visible seams or joints. This can make a significant difference in furniture, cabinetry, or countertop applications where a sleek and clean appearance is desired.

Additionally, using glue on melamine surfaces helps seal and protect the edges of the material. Melamine is vulnerable to moisture and dirt infiltration, which can cause damage over time. Applying glue to the edges creates a barrier that prevents these elements from penetrating the material, increasing its longevity.

Furthermore, using glue on melamine can improve its structural integrity. The adhesive provides added stability and strength to joints, ensuring they can withstand regular use and pressure without warping or cracking. This is especially important in high-traffic areas or heavy-duty furniture applications where durability is paramount.

Epoxy Glue for Melamine

Prepare to witness the dynamic duo of epoxy glue and melamine surfaces, as they join forces to create an unbreakable bond. In this thrilling guide, we will delve into the world of epoxy glue for melamine, exploring its advantages, application techniques, and the necessary steps to achieve a secure bond. Get ready to unleash the power of epoxy glue and conquer all your melamine bonding challenges.

Advantages of Epoxy Glue on Melamine:

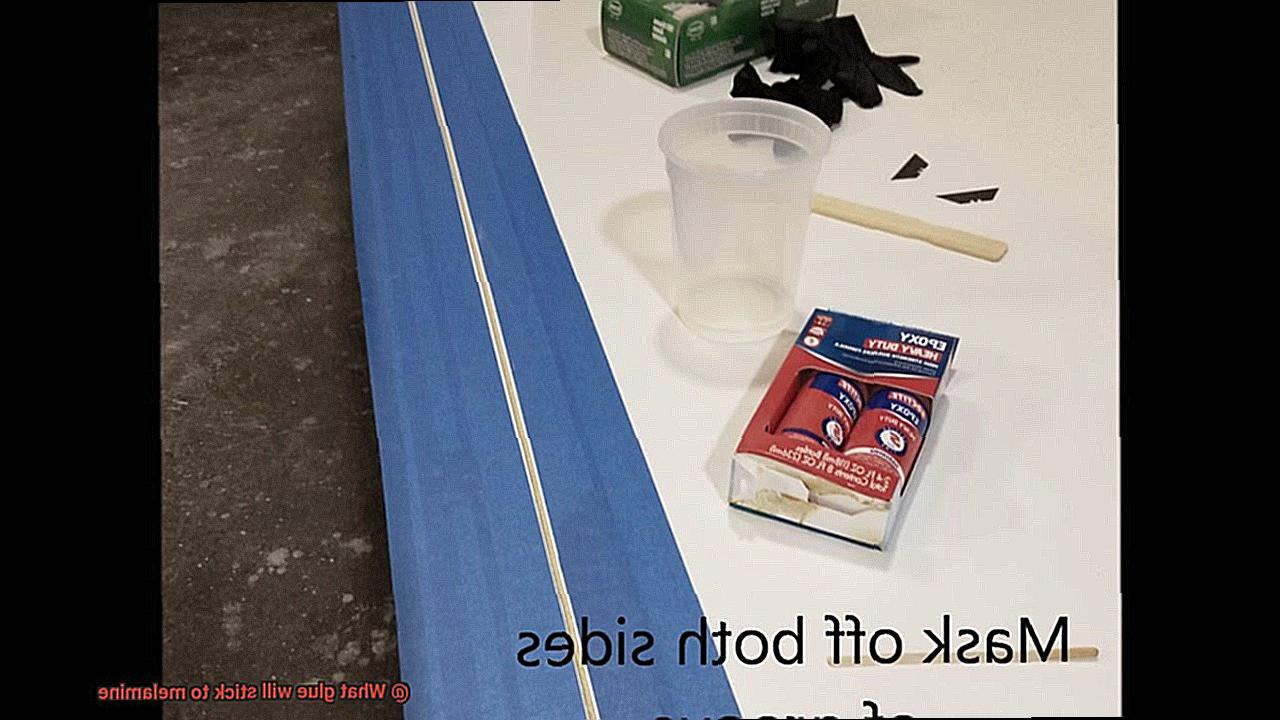

- The Indomitable Bond: With its two-component system consisting of a resin and a hardener, epoxy glue unleashes a chemical reaction that creates an unyielding and durable bond. This superhero adhesive can withstand heavy loads and resist even the most persistent moisture.

- Defying the Elements: Once cured, epoxy glue becomes invincible against moisture, heat, and chemicals. It fearlessly protects melamine surfaces from the harshest conditions, making it the perfect choice for furniture, kitchen cabinets, and laminated surfaces.

- Flawless Finish: Like a master illusionist, epoxy glue magically conceals seams and joints when attaching edging or trim. The result? A seamless and professional finish that will leave admirers wondering how you achieved such perfection.

Steps to Achieve a Secure Bond:

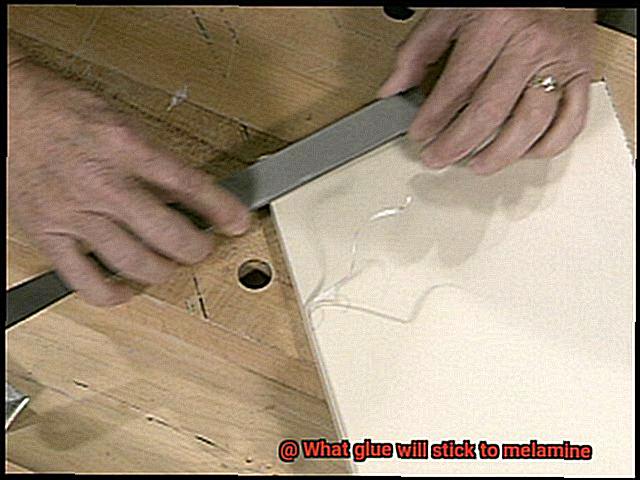

- Surface Preparation: Prepare your melamine surface for bonding by giving it a thorough cleaning. Rid it of any dust, dirt, or grease using a mild detergent or solvent. For an extra boost in bonding strength, lightly sand the surface to create a texture that will make the bond even more unbreakable.

- Application Technique: Equip yourself with a small brush or applicator to artfully spread the epoxy glue onto the surfaces you wish to unite. Follow the manufacturer’s instructions regarding mixing ratio and application techniques, like a true epoxy glue maestro.

- Removing the Excess Glue: Swiftly and skillfully wipe away any excess glue before it has a chance to solidify. This timely act will ensure a seamless and blemish-free finish that will leave your melamine project looking flawless.

- The Curing Ritual: Give your epoxy glue masterpiece the time it needs to cure fully. Each product has its own unique timeline, so consult the manufacturer’s instructions for specific guidelines. Just like a superhero in training, apply pressure or employ clamps on the bonded surfaces during the curing process to ensure an unyielding and secure bond.

Polyurethane Glue for Melamine

Unlock the secret to a strong and durable bond between melamine surfaces with polyurethane glue, the superhero of adhesives. In this blog post, we will explore the advantages of using polyurethane glue for melamine bonding and guide you through the proper application process. Get ready for a bonding adventure like no other.

Advantages of Polyurethane Glue for Melamine:

Polyurethane glue offers exceptional bonding strength, creating a bond that is often stronger than the wood itself. This means your melamine projects will stay intact even under heavy loads and in moist environments. Say goodbye to weak bonds and hello to long-lasting durability.

But that’s not all. Polyurethane glue has a gap-filling superpower that sets it apart from other adhesives. It can fill gaps and uneven surfaces, which is particularly advantageous when working with smooth melamine surfaces that can be challenging to bond. No more unsightly gaps or wobbly joints – just a tight and secure bond that will make your projects look flawless.

Proper Application Process:

To ensure the best results, follow these steps when using polyurethane glue for melamine bonding:

- Read the Instructions: Each brand may have specific recommendations for application, so carefully read and follow the manufacturer’s instructions provided with the polyurethane glue.

- Activate the Curing Process: Polyurethane glue typically requires moisture to activate the curing process. Depending on the brand, you may need to dampen the melamine surface before applying the glue or mist water onto it after application. This step is crucial for achieving a strong bond, so don’t skip it.

- Apply Pressure: To guarantee a strong bond, clamp or apply pressure to the bonded surfaces during the curing process. The manufacturer’s instructions will provide you with the recommended clamping time, so make sure to follow them.

- Wipe Away Excess Glue: As polyurethane glue cures, it may expand and squeeze out from the bond line. Quickly wipe away any excess glue with a damp cloth or sponge before it dries. This will ensure a clean and professional finish.

- Sand or Trim if Necessary: Once the glue has fully cured, you can sand or trim any excess glue to achieve your desired finish. This step will give your project a polished look and make it ready for display.

Cyanoacrylate Glue (Super Glue) for Melamine

Melamine furniture and cabinetry are renowned for their durability and sleek appearance. But what happens when they require repair or assembly? Look no further than cyanoacrylate glue, also known as super glue. In this comprehensive guide, we delve into the advantages and limitations of using cyanoacrylate glue for bonding melamine surfaces. By the end, you’ll have all the knowledge you need to confidently tackle your melamine projects.

Advantages of Cyanoacrylate Glue:

- Instant Bond: Cyanoacrylate glue forms a strong and durable connection in mere seconds, making it perfect for quick fixes or projects that demand immediate fixation.

- Quick-Drying: Unlike other adhesives, cyanoacrylate glue dries rapidly, allowing you to move forward with your project without delay.

- Easy Application: Applying cyanoacrylate glue is a breeze. Just ensure the surfaces are clean, apply a small amount of glue evenly, press the pieces together firmly, and voila.

- Versatility: Cyanoacrylate glue is a jack-of-all-trades adhesive, suitable for use on various materials, including melamine, plastic, metal, and wood.

Limitations of Cyanoacrylate Glue:

- Temperature Sensitivity: High temperatures can weaken or even break the bond created by cyanoacrylate glue. Avoid using it on melamine surfaces exposed to heat sources.

- Limited Bond Strength for Heavy Loads: While perfect for small repairs and projects, cyanoacrylate glue may not provide enough strength for large or heavy pieces of melamine. Consider alternative adhesives like epoxy or polyurethane-based glues for such applications.

Tips for Success:

- Surface Preparation: Ensure the melamine surface is clean, free from dust, grease, or other contaminants that could hinder bonding. Use mild detergent or isopropyl alcohol for cleaning and drying.

- Proper Application: Apply a small amount of cyanoacrylate glue evenly on both surfaces, using a brush or toothpick for precise application. Avoid excessive glue, as it can lead to messy outcomes.

- Pressure is Key: Press the surfaces together firmly for a few seconds to optimize contact and bonding. Consider using clamps or weights to maintain pressure during the curing process if needed.

Contact Cement for Melamine

When it comes to finding the perfect adhesive for your melamine projects, look no further than contact cement. This superhero of adhesives is specifically designed to bond melamine surfaces, making it the go-to choice for woodworking and construction projects.

So, what sets contact cement apart from other adhesives? Let’s dive into its incredible adhesive properties. Unlike other adhesives that may fail over time, contact cement creates a strong and durable bond that stands the test of time. Say goodbye to weak bonds and hello to long-lasting stability for your melamine creations.

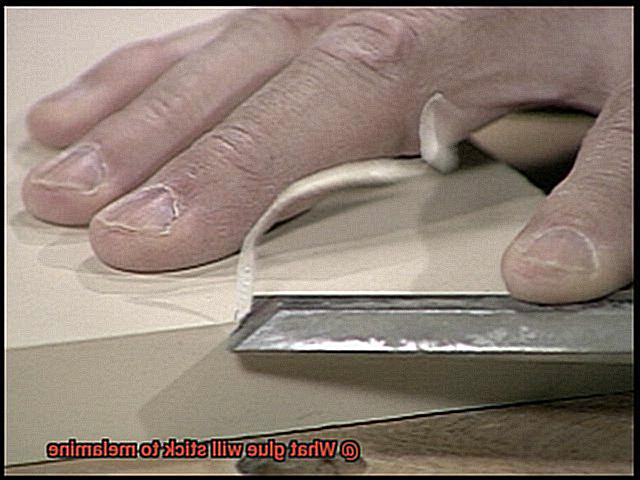

But that’s not all. One of the key advantages of using contact cement is its high initial tackiness. Picture this: once applied to the surfaces being bonded, contact cement becomes sticky, allowing for easy positioning and alignment before the final bond is formed. No more struggling with crooked edges or misaligned pieces. With contact cement, you have full control over the placement of your melamine surfaces.

Using contact cement on melamine is a breeze. Just follow these simple steps: apply a thin and even layer of adhesive to both surfaces, let it dry until tacky, and firmly press the two surfaces together. To ensure a rock-solid bond, it’s recommended to use a roller or apply consistent pressure during the bonding process.

But remember, safety first. Contact cement contains solvents that can release fumes during the drying process. To protect yourself, make sure to work in a well-ventilated area or wear a respirator mask. We want your melamine projects to be showstoppers, not cough-inducers.

Wood Glues to Avoid on Melamine

When it comes to working with melamine, choosing the right wood glue is crucial for a strong and reliable bond. So, let’s dive into the glues that you should avoid when working with melamine, and focus on the ones that will leave you with a smile on your face.

Standard white glue or wood glue may be great for bonding wood surfaces, but they just don’t cut it when it comes to melamine. These glues might stick initially, but over time, they’ll fail you and leave you with a big mess. So, say goodbye to these glues when working with melamine.

Epoxy glue is another glue to avoid when it comes to melamine. While epoxy glues are known for their strength and versatility, they need rough or porous surfaces to create a solid bond. Since melamine has a smooth and non-porous surface, it’s a no-brainer that epoxy won’t adhere well.

Next up are solvent-based glues like contact cement. These glues rely on a chemical reaction between the adhesive and the substrate to create a bond. However, melamine doesn’t react well with these types of glues. So skip the contact cement for your melamine projects if you want to avoid poor adhesion and potential delamination.

Now that we know which glues to avoid, let’s move on to the good stuff. Melamine glue, also known as thermosetting adhesive, is specifically formulated for bonding melamine surfaces. It’s a rockstar when it comes to durability and requires heat and pressure to activate its adhesive properties.

Another great option is polyvinyl acetate (PVA) glue, also known as carpenter’s glue. This versatile adhesive can bond various materials, including melamine. Just make sure you choose a PVA glue specifically labeled for non-porous surfaces. These glues contain additives that improve adhesion to smooth surfaces like melamine.

Preparing the Surface for Bonding

Hold your horses. Before diving into the gluing process, it’s crucial to prepare the surface properly. In this guide, we’ll walk you through the essential steps for achieving a strong and durable bond between melamine and glue. So, grab a cup of coffee and let’s get started.

Step 1: Cleanliness – The First Impression:

Just like meeting someone for the first time, a clean melamine surface sets the foundation for a successful bond. Remove dust, dirt, or grease using a mild detergent or solvent. Rinse thoroughly and allow the surface to dry completely.

Step 2: Sanding – Roughing It Up:

Smooth and glossy melamine surfaces can make it challenging for glue to adhere effectively. Lightly sand the surface using fine-grit sandpaper to create texture. This allows the glue to penetrate and form a stronger bond. Be gentle – we’re aiming for improved adhesion, not a complete makeover.

Step 3: Deglossing – Saying Goodbye to Gloss:

In addition to sanding, deglossing enhances bonding capabilities. Use a deglossing agent or liquid sandpaper to remove the glossy finish and create a more receptive surface for glue application. Follow manufacturer’s instructions carefully.

Step 4: Priming – The Secret Weapon:

Apply a primer specifically designed for melamine surfaces to give your bond an extra boost. This step seals the surface, promotes adhesion, and prevents bleeding or staining from the glue. Choose a primer compatible with both melamine and your chosen adhesive.

Step 5: Test Bonding – Safety First:

Perform a test bonding on a small, inconspicuous area of the melamine surface before starting your project. Evaluate the effectiveness of your chosen glue and ensure it adheres well to the melamine. Address any issues during the test phase for a smooth project.

PzaVyvvWZSU” >

Conclusion

When it comes to finding the right glue for melamine, you need a solution that will bond securely and withstand the test of time.

Fortunately, there are several options available that can get the job done. One reliable choice is a high-quality epoxy adhesive.

With its strong bonding properties, it forms a durable connection between melamine surfaces. Another option to consider is a solvent-based contact adhesive.

This type of glue creates an instant and powerful bond, making it ideal for joining melamine edges or surfaces. Additionally, polyurethane adhesives are known for their excellent bonding capabilities on various materials, including melamine.

These adhesives provide both strength and flexibility, ensuring a long-lasting hold. Lastly, if you prefer a more traditional approach, carpenter’s glue can also be used to adhere melamine surfaces together.

However, keep in mind that this type of glue may require longer drying times compared to other options.