Are you a DIY enthusiast or an electronics lover? Have you ever wondered if glue could be the magical solution to secure your electronic components or repair a circuit board? Well, hold on to your soldering iron because I have some electrifying news for you. Not just any old glue will do the trick – you need a special kind of glue that can conduct electricity while providing the necessary adhesive strength. Yes, my friend, there are glues out there that can actually transmit electrical currents. It’s like finding a unicorn in the world of adhesives.

In this blog post, we’re going to take a deep dive into the mesmerizing world of conductive glues. We’ll explore the different types of glues available and uncover the materials they are made of. And hold onto your seat because we’ll even reveal some mind-blowing applications where these electrically charged adhesives play a pivotal role.

So, buckle up and get ready to embark on an electrifying journey with me as we unravel the secrets behind these glues that make connections possible. Whether you’re a hobbyist tinkering with electronics or a professional in need of reliable bonding solutions, this blog post is here to enlighten and empower you. Let’s get started.

What is Conductive Glue?

Contents

- 1 What is Conductive Glue?

- 2 Types of Conductive Glues

- 3 Properties of Conductive Glues

- 4 Applications of Conductive Glues

- 5 Factors to Consider When Choosing a Conductive Glue

- 6 Benefits of Using Conductive Glues

- 7 Proper Application and Handling Instructions for Conductive Glues

- 7.1 Surface Preparation: The Quest for Cleanliness

- 7.2 Adhesive Dispensing: The Art of Precision

- 7.3 Bonding Pressure: The Power of Good Contact

- 7.4 Cure Time: Patience is a Virtue

- 7.5 Temperature Considerations: The Battle Against Heat

- 7.6 Handling and Storage: The Fortress of Effectiveness

- 7.7 Safety Precautions: The Armor of Protection

- 8 Conclusion

When it comes to bonding electronic components or creating circuits, traditional glues fall short in conducting electrical current.

Conductive glue is here to save the day. This remarkable adhesive, also known as electrically conductive adhesive (ECA), contains magical particles that allow the transfer of electrical signals or power. In this captivating blog post, we will embark on a journey into the captivating world of conductive glue, exploring its composition, types, advantages, and applications.

Composition and Types:

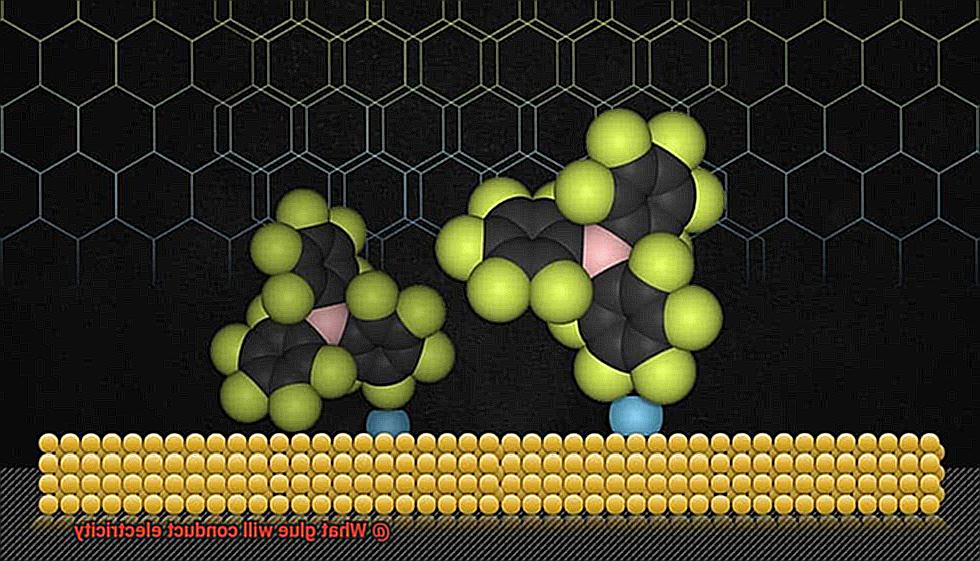

Conductive glue is a fusion of two key components: a polymer resin that acts as the adhesive base and conductive fillers that bring conductivity to life. These fillers, such as silver or carbon particles, play a vital role in making the magic happen. Silver-filled epoxy steals the show with its exceptional conductivity, while carbon-based conductive glues offer affordability and flexibility like no other.

Advantages and Applications:

Prepare to be amazed by the wonders of conductive glue. This adhesive offers a treasure trove of advantages over traditional soldering methods. First and foremost, it brings flexibility to the table, allowing you to bond a wide range of substrates including plastics and glass. Bid farewell to high-temperature soldering processes that wreak havoc on sensitive electronic components. Conductive glue finds its way into electronics manufacturing, automotive engineering, aerospace technology, and even medical devices.

Considerations and Limitations:

Though conductive glue is a versatile adhesive that can work wonders in many applications, it does have its limitations. Its conductivity tends to be lower than traditional solder, making it less suitable for high-power applications or those requiring ultra-low resistance connections. Additionally, while conductive glue is a star in the realm of electrical connections, its adhesive properties may not match those of traditional glues. Therefore, it may not be the best choice for applications that demand mechanical strength.

Types of Conductive Glues

These remarkable adhesives have the power to conduct electricity, making them indispensable in various electronic applications. Let’s delve into the different types of conductive glues and explore their incredible uses.

Silver-based Conductive Glue:

Imagine tiny particles of silver gracefully dancing together, effortlessly conducting electricity. That’s precisely what silver-based conductive glue accomplishes. This type of adhesive is widely favored in electronic circuits due to its robust and reliable connection between components.

With its exceptional electrical conductivity, silver-based glue serves as a superhero, ensuring the smooth flow of electricity.

Carbon-based Conductive Glue:

Flexibility is the name of the game when it comes to carbon-based conductive glue. Composed of carbon particles, this adhesive has the unique ability to bend and stretch without compromising its conductivity.

It finds its niche in wearable electronics and flexible circuits, where durability and flexibility are paramount. Carbon-based glue acts as a trusty companion, always ready for any challenge.

Copper-based Conductive Glue:

Copper-based conductive glue takes the spotlight in both heat dissipation and electrical conduction. With its impressive thermal and electrical conductivity, it becomes the ideal choice for applications that require effective cooling while conducting electricity. Picture copper-based glue as a dynamic duo, effortlessly tackling both heat and electricity at once.

Nickel-based Conductive Glue:

In harsh environments, nickel-based conductive glue stands tall with its corrosion resistance and high-temperature tolerance. It conducts electricity efficiently while providing protection against rust and other forms of degradation.

This adhesive acts as a knight in shining armor, valiantly defending your electronic components from the harshest conditions.

Polymer-based Conductive Glue:

Say hello to the newest addition in town – polymer-based conductive glue. This adhesive combines the strength of polymers with electrical conductivity, making it an ideal choice for applications that require a strong bond alongside conductivity.

Polymer-based glue finds its home in flexible displays, touchscreens, and other electronic devices that demand both flexibility and electrical connection. It acts as a chameleon, seamlessly adapting to any situation.

Properties of Conductive Glues

Conductive glues, those fascinating adhesives specially formulated for electrical conductivity, possess an array of remarkable properties that set them apart from regular adhesive glues. From their low resistivity to their excellent adhesion capabilities, let’s explore the key characteristics that make conductive glues the go-to choice for applications requiring electrical conductivity.

First and foremost, conductive glues boast low resistivity, meaning they efficiently transmit electricity. This property is crucial when creating electrical connections in electronics, circuit boards, and other electronic devices. With conductive glues, you can rest assured that your electrical current will flow smoothly and uninterrupted.

But it’s not just about conductivity; these glues also excel in the bonding department. They have exceptional adhesion properties, allowing them to form strong bonds with different surfaces. This is paramount when you need to establish a reliable electrical connection between components, ensuring long-term performance and durability.

In addition to their conductivity and bonding prowess, conductive glues exhibit outstanding durability and stability. They can withstand harsh environmental conditions, such as temperature changes, humidity, and mechanical stresses, without compromising their electrical conductivity. This means they can tackle the challenges of everyday use without losing effectiveness or reliability.

Flexibility is another fantastic property of conductive glues. Many formulations are designed to be flexible, making them ideal for applications where movement or vibrations may occur. This flexibility ensures that the glue maintains its electrical conductivity even when subjected to mechanical strain, guaranteeing a secure and enduring connection.

Moreover, conductive glues boast impressive thermal conductivity. They efficiently dissipate heat generated by electrical components, preventing overheating and potential damage. This feature is crucial for maintaining the longevity and optimal performance of electronic devices.

It’s important to note that not all glues can conduct electricity. Regular adhesive glues typically lack the necessary properties for electrical conductivity and serve as insulators instead. Therefore, it is crucial to select a conductive glue specifically formulated for electrical applications to ensure successful and reliable connections.

When choosing a conductive glue, consider the specific requirements of your project. Factors such as the materials you are bonding, the environmental conditions, and the level of electrical conductivity needed should inform your decision. By selecting the right conductive glue for your unique needs and following proper safety measures, you can confidently create reliable electrical connections.

Before concluding, it is essential to address safety concerns when working with conductive glues. Some formulations may contain hazardous materials or emit fumes during application. It is vital to carefully read and understand the manufacturer’s instructions and work in a well-ventilated area. If necessary, wear protective gloves and goggles to prevent skin or eye irritation.

Applications of Conductive Glues

Prepare to be captivated by the immense potential of conductive glues. These extraordinary adhesives possess unique properties that make them indispensable in a wide range of industries and creative fields. Join us as we embark on an electrifying journey through the remarkable applications of conductive glues.

- Electronics Industry: In the world of electronic devices, conductive glues are the unsung heroes, bonding tiny components like resistors, capacitors, and integrated circuits to circuit boards. With their adhesive strength and electrical conductivity, these glues ensure reliable connections and facilitate the repair of damaged electrical circuits.

- Flexible Electronics: Imagine wearable technology and flexible displays that can bend and flex without sacrificing electrical connectivity. Conductive glues make this futuristic vision a reality. They enable the creation of intricate circuit patterns on flexible substrates, opening up endless possibilities for innovative gadgets.

- Sensational Sensors: Sensors play a vital role in detecting environmental changes, and conductive glues are essential for attaching sensors to their substrates. By providing electrical connectivity, these glues enable sensors to communicate with the circuitry that processes their signals, ensuring accurate and reliable data collection.

- Automotive Marvels: In the automotive industry, conductive glues bond electronic components such as sensors, control modules, and wiring harnesses. They ensure secure connections while allowing the smooth transmission of electrical signals, powering the sophisticated systems found in modern vehicles.

- Life-Saving Medical Devices: Conductive glues are crucial in assembling medical sensors, electrodes, and other electronic components used in monitoring patients’ vital signs or administering treatments. These glues simplify attachment while maintaining electrical conductivity – a true lifesaver in healthcare settings.

- Renewable Energy Revolution: Conductive glues are making significant strides in the realm of renewable energy. They connect individual photovoltaic cells in solar panels, forming an efficient array that generates electricity from sunlight. Acting as conductors, these glues facilitate the smooth flow of electrical current, contributing to a greener future.

- Aerospace Wonders: In the aerospace field, conductive glues play a vital role in bonding electrical connectors and wiring harnesses. They ensure reliable connections that can withstand extreme conditions experienced during flights or space missions, ensuring the safety and functionality of critical systems.

- Art and Design Innovation: Conductive glues are not confined to industrial applications; they also inspire creativity. Artists and designers utilize these glues to incorporate electronic components into their creations, be it interactive sculptures or wearable technology. The glue provides the perfect balance of structural integrity and electrical conductivity, pushing the boundaries of artistic expression.

Factors to Consider When Choosing a Conductive Glue

When it comes to choosing a conductive glue, there are several important factors to consider. Whether you’re a hobbyist working on a DIY electronics project or an engineer designing complex circuitry, selecting the right conductive glue can make all the difference in achieving reliable and efficient electrical connections. Here are some key factors to keep in mind:

- Conductivity: The conductivity of the glue is crucial as it determines how efficiently it can transmit electricity. Look for glues that contain conductive materials like silver, copper, or graphite, as these provide excellent conductivity. Be sure to check the conductivity rating before making a purchase.

- Adhesion Strength: The glue should be able to form a strong bond between the surfaces it is applied to. This is particularly important in electronic applications where weak bonds can result in poor electrical connectivity and potential failures. Look for glues with high adhesion strength to ensure reliable connections.

- Temperature Resistance: Consider the temperature conditions that the glue will be subjected to in your application. Some conductive glues may become brittle or lose their effectiveness at high temperatures, leading to electrical failures. Choose a glue that can withstand the specific temperature requirements of your project without compromising its conductivity or adhesive properties.

- Chemical Compatibility: If the conductive glue will come into contact with other chemicals or materials, it’s essential to ensure compatibility to prevent adverse reactions or deterioration of the bond. Check for chemical compatibility and consult material safety datasheets (MSDS) to determine if the glue is suitable for your specific application.

- Cure Time: The time required for the glue to fully cure is another crucial factor, especially in time-sensitive projects. Some glues may take hours or even days to reach their maximum strength and conductivity. Consider the cure time and choose a glue that aligns with your project requirements and deadlines.

- Application Method: Different conductive glues may require specific application methods such as syringe dispensing, brushing, or spraying. Consider the ease of application and whether the chosen method suits your project requirements. Also, check if any specialized equipment or techniques are needed for application.

- Cost: Lastly, consider the cost of the conductive glue. Prices can vary significantly depending on brand, quality, and quantity. Determine your budget and compare prices to ensure you get the best value for your money without compromising on quality or performance.

Benefits of Using Conductive Glues

Today, we’ll explore the captivating benefits of using conductive glues instead of traditional methods. So, put on your goggles and get ready for an electrifying journey.

First and foremost, conductive glues are like superheroes when it comes to creating robust and dependable bonds between conductive surfaces. They fearlessly withstand vibrations, shocks, and all kinds of mechanical stress, ensuring that your electrical connections remain intact even in the harshest environments.

But that’s not all – these glues are as versatile as chameleons. They effortlessly connect an extensive range of materials, from metals to ceramics, plastics to glass. So whether you’re constructing an electronic device, engaged in an automotive project, or venturing into aerospace or medical devices, conductive glues have got you covered.

One of the standout advantages of conductive glues is their gentle touch. Unlike soldering or welding, which can be rough on materials, these glues don’t require high temperatures or excessive force. That means delicate components or heat-sensitive materials can be connected without any risk of damage. Phew.

Say goodbye to extra connectors and fasteners. Conductive glues bid farewell to those pesky add-ons. This simplifies the assembly process, slashes costs, and even lightens the load of your final product. Perfect for projects where space is at a premium or weight is a critical factor.

Now let’s discuss electrical conductivity. Conductive glues are virtuosos at efficiently transmitting electrical signals across bonded surfaces. So if you’re working on high-speed data transmission or need precise electrical connections, these glues have got your back.

Conductive glues also boast excellent thermal conductivity. They’re experts at dissipating heat generated by electronic components, preventing overheating issues and ensuring everything functions smoothly. Your devices will thank you.

Applying conductive glues is a breeze. They come in various forms like pastes, adhesives, or films, allowing for flexible application methods tailored to your project’s needs. So whether you’re a small-scale hobbyist or a large-scale production wizard, these glues seamlessly integrate into your workflow.

Proper Application and Handling Instructions for Conductive Glues

In the world of adhesives, conductive glues are the superheroes, capable of creating robust bonds between conductive surfaces without the need for excessive force or high temperatures. Their versatility and efficiency make them a go-to choice for various electronic applications. In this article, we will explore the proper application and handling instructions for conductive glues, ensuring optimal results and safety in your projects.

Surface Preparation: The Quest for Cleanliness

Before applying conductive glue, embark on a quest for cleanliness. Ensure the surfaces are free from contaminants like dirt, dust, oils, or oxidation. Use solvents or cleaning agents specifically designed for electronics to achieve a pristine surface worthy of bonding.

Adhesive Dispensing: The Art of Precision

To apply conductive glue, become an artist of precision. Use a syringe or a similar applicator as directed by the manufacturer. Pay attention to the recommended amount of adhesive and the desired pattern or shape. Applying too little or too much glue can impact its conductivity and bonding strength.

Bonding Pressure: The Power of Good Contact

Applying proper pressure during bonding wields the power of good contact. Ensure that the glue and surfaces unite by using clamps, weights, or applying pressure with your hands. Aim for a uniform pressure across the entire bonding area to forge an unbreakable connection.

Cure Time: Patience is a Virtue

Conductive glues require patience to unleash their full potential. Follow the manufacturer’s recommendations regarding cure time, which may vary depending on the adhesive and environmental conditions. Avoid subjecting bonded components to stress or further processing until fully cured.

Temperature Considerations: The Battle Against Heat

Some conductive glues have specific temperature requirements during application and curing. Engage in battle against heat by ensuring compatibility with materials being bonded and operating conditions. Exceeding recommended temperature limits can compromise adhesive performance, so stay within the boundaries.

Handling and Storage: The Fortress of Effectiveness

Proper handling and storage are the guardians of adhesive effectiveness and shelf life. Store in a cool, dry place away from direct sunlight or extreme temperatures. Tightly seal the container after use to prevent moisture absorption or evaporation, preserving its power for future battles.

Safety Precautions: The Armor of Protection

Observe necessary safety precautions to protect yourself in the adhesive battlefield. Don the armor of protective gloves, goggles, or a mask to shield yourself from direct contact with the adhesive or inhaling any fumes if applicable. Read safety data sheets for specific handling instructions and potential hazards to stay safe.

hFK0CIpTqsE” >

Conclusion

In conclusion, when it comes to finding a glue that conducts electricity, there are several options available.

Conductive adhesives, such as silver epoxy or conductive ink, can be used for various electronic applications. These glues contain particles or fibers that allow the flow of electric current, making them ideal for bonding components in circuits or repairing electrical connections.

Additionally, some cyanoacrylate glues infused with carbon nanotubes have also shown promising conductivity properties. However, it is important to note that not all glues are conductive, so it is essential to choose the right type of adhesive for your specific electrical needs.

By selecting a suitable conductive glue and following proper application techniques, you can ensure reliable electrical conduction and secure bonds in your projects.