Ready to dive into the fascinating world of construction glue? We all know that construction workers are the unsung heroes behind every sturdy building and impressive structure.

But have you ever stopped to wonder what kind of glue they use to keep everything intact? Well, today is your lucky day because we’re about to spill the beans on the secret sauce that holds it all together in construction projects.

Get ready for a sticky adventure as we uncover the magic behind these essential tools of the trade.

What is Construction Adhesive?

Contents

Construction adhesive, also known as construction glue or construction adhesive, is the unsung hero of construction projects. This versatile adhesive is specifically designed to bond various construction materials together, creating a strong and lasting connection. Whether you’re a construction professional or a DIY enthusiast, understanding the power of construction adhesive can take your projects to new heights.

Versatility and Bonding Strength:

Construction adhesive is a powerhouse when it comes to bonding a wide range of materials. From wood and metal to concrete, stone, and tile, this adhesive can handle them all. It’s like a superhero that brings different elements together seamlessly.

With construction adhesive, you can install drywall, attach trim and molding, secure flooring materials, and even bond heavy objects like countertops or cabinets. No matter what materials you’re working with, construction adhesive provides a reliable bond that prevents movement or separation, ensuring the durability and stability of your project.

Sealing and Protection:

Construction adhesive does more than just bond materials together; it also acts as a sealant. It fills gaps and cracks between materials, adding an extra layer of protection against moisture, air leakage, and noise transmission. Imagine it as a shield that keeps out unwanted elements and ensures your project stands the test of time. Whether you’re weatherproofing your home or soundproofing a room, construction adhesive is an invaluable tool.

Types of Construction Adhesive:

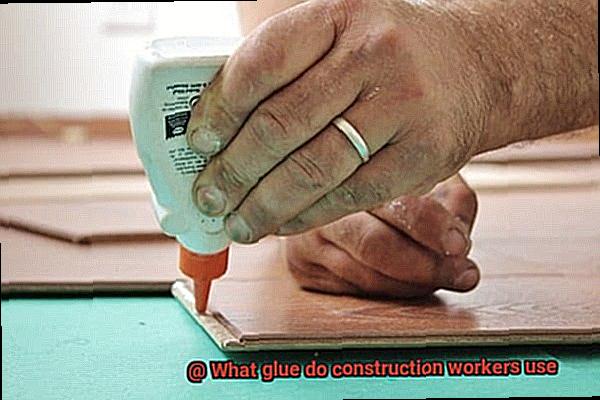

Construction adhesive comes in different forms to suit various needs. The most common type is the liquid form, which is typically dispensed using a caulk gun or applied directly from a tube. Its fluid nature allows for easy application and precise placement. However, there are also paste and tape adhesives available for specific purposes. Each type has its advantages and should be chosen based on the requirements of your project.

Choosing the Right Construction Adhesive:

To ensure you select the right construction adhesive for your project, consider the specific requirements of the job and the materials you’re working with. Different adhesives are formulated for specific applications and surfaces. It’s crucial to read product labels and consult with professionals to make an informed decision. Don’t underestimate the power of choosing the right adhesive—it can make or break your project.

What is Epoxy Adhesive?

When you need to securely bond different materials like metal, wood, concrete, ceramics, and plastics, epoxy adhesive swoops in to save the day.

So, what exactly is epoxy adhesive? It’s a two-part adhesive made up of a resin and a hardener. When combined in the right proportions, these components undergo a chemical reaction that creates an incredibly strong and durable bond. It’s like mixing ingredients for a potent elixir.

The versatility of epoxy adhesive is truly remarkable. It seamlessly bonds various materials together, making it perfect for repairing cracks in concrete structures or attaching metal brackets to wooden surfaces. Whether you’re joining different worlds or blending materials harmoniously, epoxy adhesive is your go-to sidekick.

But here’s where it gets even more exciting – epoxy adhesive has superpowers. It can handle heavy loads, extreme temperatures, moisture, chemicals, and even vibrations. It’s like a construction superhero that defies all odds. Bridges, flooring systems, composite structures – you name it, epoxy adhesive can handle it with ease and strength.

And that’s not all. Epoxy adhesive has another trick up its sleeve – gap-filling properties. By adjusting its viscosity with fillers like silica or microspheres, it can effectively fill voids and gaps between surfaces. This maximizes the contact area between the adhesive and the materials being bonded, resulting in an even stronger bond.

Oh, and did I mention that epoxy adhesive has good dimensional stability? Once fully cured, it doesn’t shrink or expand significantly over time. This is crucial for construction projects where precise alignments are essential. With epoxy adhesive, you can build with confidence, knowing that your bonds will stand the test of time.

Before you embark on your epoxy adventure though, keep in mind that surface preparation is key. Make sure your surfaces are clean, dry, and free from any contaminants or loose particles. Sometimes, you may need to roughen the surface or use primers to enhance adhesion. A little preparation goes a long way in ensuring a successful bonding experience.

What is Polyurethane Glue?

In the realm of construction projects, finding the perfect adhesive is paramount to ensure durable and robust bonds. Polyurethane glue, also known as PU glue or poly glue, emerges as the superhero that construction workers rely on. Join us in this engaging exploration of polyurethane glue’s properties and advantages, revealing why it has become the go-to choice for construction projects.

Versatile Bonding Power:

Polyurethane glue thrives on its ability to forge strong bonds between an array of materials. From wood to metal, plastic to concrete, this adhesive securely joins a wide range of surfaces together. Its versatility makes it an indispensable tool for construction workers who frequently encounter diverse materials in their projects.

Formidable Strength and Waterproof Properties:

Renowned for its exceptional strength and waterproof properties, polyurethane glue forms an impervious bond once cured. It can withstand water, heat, and most chemicals, making it ideal for both indoor and outdoor applications where moisture or extreme conditions may be present. Imagine outdoor furniture, decking installation, or even boat building benefiting from this superpower.

Gap-Filling Abilities:

One of the distinctive features of polyurethane glue lies in its expansion during the curing process. This expansion allows the adhesive to fill gaps or irregularities in the surfaces being bonded, resulting in a stronger and more reliable bond.

Additionally, it helps distribute stress evenly across joints, effectively reducing the risk of failure. Thus, whether you’re joining two pieces of wood with slight imperfections or attaching metal fixtures with small gaps, polyurethane glue becomes your steadfast ally.

Extended Working Time:

Unlike some fast-setting glues, polyurethane glue offers a relatively long open time. This attribute grants ample time for aligning and adjusting the materials being bonded before the adhesive fully sets. With enhanced flexibility during the construction process, the chances of mistakes or misalignments are minimized.

Proper Application:

To ensure a successful bond, it is vital to note that polyurethane glue requires moisture for proper curing. Construction workers often dampen the surfaces to be bonded with a wet cloth or spray bottle before applying the adhesive. This moisture triggers the curing process and guarantees a robust bond. However, excessive moisture can cause foaming or bubbling, potentially affecting the aesthetics of the final result.

What is Super Glue?

In the world of construction, where time is money and reliability is key, there exists a superhero-like adhesive that has proven to be the construction worker’s best friend – super glue, also known as cyanoacrylate adhesive. This extraordinary adhesive possesses the power to create fast-acting and unyielding bonds that can withstand any challenge thrown its way. Join us as we delve into the captivating world of super glue, exploring its versatility, strength, rapid bonding capabilities, practical benefits, as well as its limitations.

Versatility Unleashed:

Imagine having a trusty sidekick that can handle any material you encounter on a construction site. That’s precisely what super glue offers. Whether it’s metal, wood, plastic, glass, ceramic, or even fabrics, this versatile adhesive can flawlessly bond them all. It’s the ultimate companion for construction workers dealing with an array of materials.

Strength Forged in Adhesive Fire:

The standout feature of super glue lies within its indomitable strength. Once fully cured, it forms an unbreakable bond capable of withstanding heavy loads and vibrations. Structural integrity and durability are paramount in construction projects, and with super glue by your side, you can rest assured that your joints and connections will remain steadfast even under the harshest conditions.

Rapid Bonding: A Time-Saving Marvel:

Time is of the essence on construction sites. This is where the rapid bonding capability of super glue truly shines. Within minutes, it dries completely, allowing construction workers to seamlessly progress with their tasks without being tethered by extended curing times. Its ability to swiftly mend and repair makes it an indispensable choice for quick fixes.

Practical Benefits Beyond Bonding:

Super glue’s excellence extends beyond its remarkable bonding properties. Its ability to quickly bond makes it exceptionally effective in tight spaces or hard-to-reach areas where other adhesives falter. Additionally, its liquid form dries clear, leaving no visible residue, providing an aesthetically pleasing result.

Limitations to Keep in Mind:

While super glue is an indomitable force in the construction realm, it does have limitations. It is not suitable for porous surfaces or materials containing moisture, as it can foam and create a weak bond. Furthermore, when flexibility is paramount, super glue may not be the best choice, as it tends to become brittle over time.

What is Hot Glue?

Hot glue, also known as hot melt adhesive, is the superhero of adhesives in the construction world. It has the power to bond a wide range of materials together, making it a go-to choice for construction workers. But what exactly is hot glue and why is it so popular?

Hot glue is made up of a special combination of synthetic polymers, resins, and additives. These ingredients are heated in a hot glue gun until they melt into a liquid adhesive. The glue gun itself has an electric heating element that raises the temperature of the glue to its melting point. Once melted, the hot glue can be easily applied to surfaces by squeezing the trigger on the gun.

One of the biggest advantages of hot glue is its versatility. It can bond materials such as wood, plastic, fabric, ceramics, and even metals. This makes it incredibly useful for construction projects where different materials need to be joined together.

Another great thing about hot glue is its quick setting time. As soon as it is applied, it starts to cool down and solidify, creating a strong bond in no time. This means that construction workers can work efficiently and effectively without having to wait for the adhesive to dry.

Hot glue also creates durable bonds that can withstand various stresses and strains. Whether it’s holding together pieces of wood or securing metal parts, hot glue can handle it all.

Not only is hot glue versatile and efficient, but it is also easy to use. It comes in the form of sticks or pellets that can be loaded into a hot glue gun. Once melted, the glue flows smoothly and evenly onto surfaces, ensuring proper coverage and adhesion.

Hot glue is also resistant to temperature changes and moisture, making it suitable for both indoor and outdoor construction projects. It remains stable even at high temperatures, so you don’t have to worry about your project falling apart when things heat up.

Safety is always a top priority in construction, and hot glue is relatively safe to use. It doesn’t emit harmful fumes or toxic substances when heated, making it a suitable choice for workers. However, it is important to handle the hot glue gun with caution as the melted adhesive can cause burns if it comes into contact with the skin.

Choosing the Right Glue for a Project

Glue is the unsung hero of construction projects, holding everything together with its mighty bond. But with so many options available, how do you know which glue is right for your project? Let’s explore the world of construction adhesives to find out.

First on our list is epoxy, the powerhouse of glues. This versatile adhesive can bond metal, wood, concrete, and plastic with ease. Its durability and resistance to heat, chemicals, and moisture make it ideal for a wide range of construction applications.

Next up is construction adhesive, the go-to choice for heavy-duty bonding. Perfect for materials like drywall, plywood, and concrete blocks, this adhesive provides a strong and long-lasting bond that can withstand water and weathering.

If you’re working with ceramic or porcelain tiles, tile adhesive is your best friend. Specially formulated to withstand moisture and heavy foot traffic, this adhesive ensures your tiles stay in place for years to come.

Foam adhesive is a must-have for bonding materials like foam insulation or polystyrene. Its specialized formula prevents damage to delicate surfaces while providing a strong bond.

For those quick fixes or small repairs, instant adhesives (also known as super glue) are your secret weapon. These fast-drying adhesives create an instant bond between metal, plastic, and rubber.

Now that we’ve explored the different types of adhesives available, let’s talk about why choosing the right glue is so important. The specific requirements of your project play a crucial role in determining which glue to use. Factors like the materials being bonded, environmental conditions (such as temperature and moisture), and the intended use of the project all need to be taken into account.

To ensure successful bonding, it’s also essential to follow the manufacturer’s instructions. Different glues may have specific application techniques, curing times, and temperature requirements.

Of course, safety should always be a priority. When working with glue, make sure to do so in a well-ventilated area and wear appropriate protective equipment like gloves and goggles. Following proper handling and disposal procedures is essential for keeping yourself and the environment safe.

Factors to Consider When Choosing a Glue

When it comes to choosing the perfect glue for your construction project, the decision can feel as weighty as the materials you’re trying to bond. But fear not, because by considering these key factors, you’ll be able to stick with confidence and build something truly remarkable.

First and foremost, material compatibility is paramount. Different glues are designed for specific materials, like wood, metal, plastic, or concrete. So, before you dive into adhesive options, ensure that the glue you choose is compatible with the materials you’re working with. This will guarantee a bond that is both strong and lasting.

Strength and durability are also critical considerations. Construction projects demand glues that can endure heavy loads and withstand various weather conditions. Look for glues with high bond strength and long-lasting durability, especially if you’re tackling a heavy-duty application. Don’t settle for anything less than a glue that can withstand the test of time.

Time is of the essence in construction projects, so setting time should be on your radar. Rapid-setting glues can be a lifesaver when deadlines are looming, but make sure they still provide enough working time for proper application and alignment. After all, precision is key when building something extraordinary.

Consider the application method as well. Glues that come in convenient packaging, such as squeeze bottles or cartridges for caulking guns, can make your life easier and your project more efficient. Especially when working on large-scale endeavors, streamlined application methods can save time and ensure precise bonding.

Environmental considerations shouldn’t be overlooked either. Some glues emit strong odors or harmful fumes that can pose risks to workers’ health. Opt for glues with low VOC content or those labeled as environmentally friendly to ensure a safer working environment. Additionally, assess if the glue is suitable for outdoor applications and whether it can withstand moisture or UV exposure.

While quality is vital, cost-effectiveness should also be factored into your decision-making process. Some glues may have a higher price tag upfront, but their superior performance can lead to long-term savings by reducing the need for repairs or replacements. Consider the overall value of the glue, weighing both quality and cost.

Safety Guidelines when Using Adhesives

Adhesives are the unsung heroes of construction projects, silently holding everything together. However, using adhesives without following safety guidelines can be dangerous. Construction workers must prioritize safety to prevent accidents and injuries. This article will explore essential safety precautions to consider when using adhesives.

Read and Understand Manufacturer’s Instructions:

Before starting any adhesive project, thoroughly read and comprehend the manufacturer’s instructions. Each adhesive product has specific guidelines for safe and effective use. Familiarize yourself with these instructions to ensure proper handling.

Wear Personal Protective Equipment (PPE):

Personal protective equipment is your armor against potential hazards. When working with adhesives, always wear gloves, safety glasses or goggles, and respiratory protection if necessary. Prioritize safety by wearing the appropriate PPE at all times.

Ensure Adequate Ventilation:

Adhesives often release harmful fumes that can be dangerous when inhaled excessively. To combat this, work in a well-ventilated area or use exhaust fans to keep the air fresh and fume-free. Protect your respiratory system by prioritizing proper ventilation.

Avoid Skin Contact:

Adhesive products can cause skin irritation or allergic reactions. Protect your skin by wearing gloves when handling adhesives. If any adhesive comes into contact with your skin, wash it off immediately with soap and water to prevent further irritation.

Illuminate Your Workspace:

Good lighting is crucial when working with adhesives. It ensures accurate application and helps prevent accidents or spills. Make sure your workspace is well-lit to improve visibility and avoid potential mishaps.

Proper Storage:

Adhesive products have specific storage requirements. Store them in a cool, dry place away from direct sunlight and heat sources. Properly label them to avoid confusion and keep them out of reach of children to prevent accidents.

Responsible Disposal:

After completing your project, dispose of waste materials and unused adhesive properly. Adhere to local regulations and avoid pouring adhesives down drains or throwing them in regular trash bins. Dispose of them in accordance with recommended procedures.

Handle Flammable Adhesives with Caution:

Some adhesives are flammable and can pose a fire hazard. Always follow safety precautions when using and storing flammable adhesives. Keep them away from open flames or sparks to maintain a safe working environment.

Conclusion

Construction workers rely on a variety of glues and adhesives to tackle the demanding tasks they face on a daily basis.

From bonding materials together to securing joints and connections, these professionals understand the importance of using the right glue for each job. One commonly used adhesive is epoxy, which offers exceptional strength and durability.

Its ability to bond different materials, such as wood, metal, and concrete, makes it a versatile choice for construction projects. Another popular option is construction adhesive, specifically designed for heavy-duty applications.

Additionally, construction workers often utilize polyurethane adhesive for its excellent bonding properties and resistance to water and chemicals.