Are you a furniture lover or someone itching to bring an old gem back to life?

Well, let me tell you, understanding the glue choices of furniture restorers is absolutely key. Glue is like the secret sauce in the restoration game—it’s what holds everything together and ensures your masterpiece stands the test of time.

But here’s the million-dollar question: what kind of glue do these furniture wizards actually use? Don’t fret, my friend.

In this blog post, we’ll dive into the world of adhesive wonderland for furniture restorers. From classic hide glue to futuristic epoxy wonders, we’ve got it all covered.

Get ready to make some magic happen.

Types of Glue Used by Furniture Restorers

Contents

- 1 Types of Glue Used by Furniture Restorers

- 2 Factors to Consider When Choosing a Glue

- 3 Benefits of Using the Right Glue for Furniture Restoration Projects

- 4 How to Apply Different Types of Glue Properly

- 5 Tips for Working with Wood Glue and Epoxy Resin in Furniture Restoration Projects

- 6 How to Reversing a Hide Glue Joint if Necessary

- 7 The Best Ways to Use Veneer Glues and Cyanoacrylate Adhesives for Delicate Repairs

- 8 Conclusion

Well, it’s time to unveil the secrets behind the types of glue used by furniture restorers. From wood glue to epoxy resin, let’s explore the various glues that make restoration dreams come true.

Polyurethane Glue: Versatility at Its Best

When it comes to versatility, polyurethane glue takes the spotlight. This adhesive can bond wood, metal, or plastic with ease, making it a reliable choice for various repairs. Its ability to expand as it cures allows it to fill gaps and provide a watertight seal. Perfect for outdoor furniture repairs that can brave the elements.

Cyanoacrylate Glue: Quick Fixes Made Easy

When it comes to quick fixes and bonding small details, cyanoacrylate glue, better known as super glue, is the go-to choice. With its instant bonding power, this adhesive is perfect for repairing loose veneer or attaching small decorative elements. Just a dab, and voila. Your furniture is as good as new.

And there you have it, dear readers – the magical glue secrets of furniture restoration. From wood glue to epoxy resin, each type has its unique benefits and purpose. The art of furniture restoration is brought to life through these remarkable adhesives.

Wood Glue

Wood glue is the secret behind the seamless restoration of furniture, creating a bond so strong that it holds everything together. With a plethora of options available in the market, each with its own unique properties and applications, let’s explore the world of wood glue used by furniture restorers.

First up is PVA (Polyvinyl Acetate) glue, a water-based adhesive that steals the show with its easy application and robust bond. Restorers love PVA glue because it dries clear, ensuring that aesthetics are never compromised. Plus, it’s non-toxic, making it safe for indoor use. This workhorse is perfect for general woodworking projects and excels at bonding wood to wood.

Next on the list is epoxy resin, a dynamic duo of resin and hardener. When these two components unite, they create an invincible bond that laughs in the face of water, heat, and chemicals. Furniture restorers rely on epoxy resin to mend broken joints or fuse pieces of wood together. Its exceptional strength and durability make it suitable for both indoor and outdoor furniture.

But let’s not forget about hide glue, an ancient adhesive derived from animal collagen. This traditional hero has been used in furniture restoration for centuries, and for good reason. Hide glue comes in granules or flakes that need to be dissolved in water before use. What sets it apart is its reversible bonds, allowing repairs to be undone if necessary. It’s a favorite among antique furniture restorers.

And who could forget cyanoacrylate glue, better known as super glue? This fast-setting adhesive works like magic, forming an almost instant bond. Perfect for delicate repairs and bonding fragile parts in furniture restoration projects, this superhero does have a weakness – brittleness. So while it excels at small-scale fixes, it might not be the best choice for larger structural repairs.

But wait, there’s more. Specialized adhesives designed for specific applications in furniture restoration are also available. Veneer and laminate adhesives ensure flawless bonding, while adhesives tailored for loose or wobbly joints come to the rescue when stability is on the line.

When choosing the right wood glue, factors like the type of wood, intended use of the furniture, and level of reversibility required must be considered. Manufacturers’ instructions and guidelines should always be followed for optimal results.

Epoxy Resin

Furniture restoration is an art that requires the right tools and techniques to bring back the beauty of old pieces. When it comes to adhesive superheroes, epoxy resin takes the crown. In this blog post, we will explore the advantages and considerations of using epoxy resin for furniture restoration. So, put on your cape and let’s dive into the world of epoxy resin.

Advantages:

- Versatility: Epoxy resin is a jack-of-all-trades adhesive that can bond wood, metal, glass, and plastic. It’s like having a superhero sidekick ready to tackle any material that needs repair.

- Strength and Durability: Once mixed and applied, epoxy resin undergoes a curing process that results in a strong and rigid bond. It’s like giving your furniture an invincible shield against wear and tear.

- Resistance: Epoxy resin is a superhero that can withstand moisture, chemicals, and temperature variations. It’s like having a protective suit for your furniture, perfect for outdoor pieces or kitchen countertops.

- Gap Filling: Epoxy resin’s adhesive properties make it effective in filling gaps or cracks in wood surfaces. It’s like having a master sculptor that seamlessly restores the integrity of your piece.

Considerations:

- Application Techniques: Proper surface preparation is crucial for successful epoxy resin bonding. Clear away debris and residues to ensure a smooth application.

- Working Time: Epoxy resin has a relatively short working time once mixed, so plan your repair process accordingly. Don’t let time become the villain in your restoration project.

- Precision and Care: Once epoxy resin cures, it becomes challenging to remove or reverse. Take your time during the application process to ensure accurate placement and avoid any mishaps.

Hide Glue

When it comes to the world of furniture restoration, there is an abundance of adhesive options available. However, one glue that has stood the test of time and continues to captivate professionals is hide glue.

Derived from animal hides, this traditional adhesive offers a plethora of advantages that have cemented its place as a favorite among experts in the field. In this blog post, we will delve into the pros and cons of using hide glue for furniture restoration and explore why it remains a formidable contender against modern alternatives.

Advantages of Hide Glue:

- Reversibility: Unlike numerous contemporary adhesives, hide glue can be effortlessly reversed by applying heat and moisture. This unique characteristic renders it ideal for repairs that may need to be undone or modified in the future, without inflicting permanent damage to the furniture.

- Unyielding Bond: Hide glue forms a robust and steadfast bond with wood and other porous materials. This ensures that furniture joints remain secure and long-lasting over time, even when subjected to considerable stress and movement.

- Harmonious with Finishes: As hide glue is a natural substance, it seamlessly accommodates staining or finishing processes without interference. Its easy removal from the wood surface before applying finishes results in a clean and flawless final product.

Disadvantages of Hide Glue:

- Preparation and Application: Hide glue necessitates heating in a double boiler or glue pot prior to use, which can be time-consuming and require specialized equipment. Moreover, its limited working time once mixed with water demands swift execution for optimal adhesion.

- Moisture and Temperature Limitations: The suitability of hide glue is restricted to indoor furniture or pieces shielded from high humidity or extreme temperature fluctuations. In such cases, modern synthetic adhesives may provide more viable alternatives.

Expert Opinion:

As an authority in furniture restoration, I firmly believe that hide glue offers unique advantages that enhance the restoration process. Its reversibility, unyielding bond, and compatibility with finishes make it an ideal choice for numerous projects. However, it is crucial to consider the specific requirements of each restoration job and assess them against hide glue’s limitations. By doing so, furniture restorers can harness the timeless allure of hide glue while ensuring the durability and functionality of their restored pieces.

Specialized Adhesives

In the fascinating world of furniture restoration, specialized adhesives are the unsung heroes that bring old pieces back to life. Today, we’re diving into the world of glue, exploring its different types and unique properties. So grab a cup of coffee, settle into your favorite chair, and join me on this adhesive adventure.

Types of Specialized Adhesives:

Hide Glue:

Let’s start with a classic: hide glue. Derived from animal collagen, this adhesive has stood the test of time in woodworking and furniture making. Its exceptional strength and durability make it ideal for intricate repairs. What sets it apart is its ability to create strong bonds that withstand stress and temperature changes, while also allowing for future disassembly if needed. Plus, it can be reversed with heat and moisture – perfect for adjustments or alterations down the road.

Epoxy Resin:

When it comes to structural repairs, epoxy resin is the go-to adhesive. This versatile glue provides exceptional strength and durability, ensuring long-lasting stability for your restored furniture piece. It’s particularly useful for fixing broken legs or reattaching loose joints. With its ability to withstand heavy loads and be tinted to match the wood’s natural hue, epoxy resin seamlessly blends aesthetics with functionality.

Cyanoacrylate Glue (Super Glue):

For delicate veneer repairs or small cracks in wood, super glue saves the day. Also known as cyanoacrylate glue, this quick-drying adhesive forms an instant bond between surfaces. Its strength and invisible finish make it perfect for rejoining small pieces of veneer or restoring structural integrity to damaged pieces. Just remember to use it sparingly.

Fabric Adhesives:

Don’t forget about upholstery repairs. Specialized fabric adhesives are designed to bond fabric to various surfaces, ensuring a strong and flexible hold. Whether you’re fixing loose upholstery or attaching fabric to wood, metal, or foam, these adhesives provide a clean and professional finish. Say goodbye to unsightly wrinkles and hello to restored elegance.

Exploring Further:

If you’re eager to learn more about specialized adhesives, here are a few additional types worth exploring:

- Polyurethane Glue: Perfect for outdoor furniture repairs due to its water resistance.

- Contact Adhesive: Ideal for attaching decorative elements or laminates.

- Traditional Wood Glue: A reliable option for simpler joinery tasks.

Factors to Consider When Choosing a Glue

Embarking on a furniture restoration project requires careful consideration when choosing the right glue. With an overwhelming number of options available, it’s essential to know the factors that will guide you in making the best choice. Let’s explore these factors in detail, ensuring your project is a success.

First and foremost, bonding strength is crucial. You want a glue that can withstand the test of time. Different glues have varying levels of strength, so choose accordingly. For heavy-duty projects, such as repairing broken furniture joints, epoxy or polyurethane glue is your best bet. Their superior strength ensures a lasting bond. However, if you’re working on delicate pieces or need a temporary bond, opt for weaker adhesives like white glue or hide glue.

Next up, drying time. Time is of the essence, especially when working on time-sensitive projects. Some glues dry within minutes, while others take hours or even days to cure fully. Make sure to choose a glue that aligns with your project timeline and allows for proper bonding before moving on to the next steps of restoration.

Compatibility with materials is another critical factor to consider. Furniture restoration often involves various materials like wood, metal, fabric, or leather. Ensure that the glue you choose is compatible with the specific materials you’re working with. Some glues work better on porous surfaces like wood, while others are designed for non-porous materials like metal or glass. Read labels and consult experts to determine if the glue is suitable for your project’s materials.

Flexibility and durability are essential for furniture that will undergo stress and movement over time. Choose a glue that offers flexibility and can withstand impacts and vibrations. Cyanoacrylate (super glue) or polyurethane glue are excellent options for this purpose.

Ease of application and cleanup should not be overlooked, especially for DIY enthusiasts. Look for glues that come in convenient applicators like squeeze bottles or spray cans for precise application. Consider how easy it is to clean up excess glue or remove accidental spills to save time and effort.

Last but certainly not least, safety considerations. Always prioritize safety when working with glue. Choose a glue that is safe to use, especially in terms of toxicity and fumes. Water-based or low VOC (volatile organic compounds) glues are excellent choices for minimizing health risks.

Benefits of Using the Right Glue for Furniture Restoration Projects

When it comes to furniture restoration projects, selecting the right glue is not just about sticking things together. It’s about ensuring a strong and durable bond that withstands the test of time. In this blog post, we will delve into the benefits of using the right glue for furniture restoration projects, exploring how it enhances aesthetics, provides structural integrity, offers moisture resistance, simplifies application and cleanup, and saves time and money in the long run.

Invisible Bond:

Using the right glue ensures achieving an invisible bond, seamlessly blending with the furniture piece. This professional and visually appealing result is especially crucial when restoring vintage or cherished heirloom furniture.

Versatility:

The right glue offers excellent adhesion to various materials commonly found in furniture, such as wood, metal, glass, and fabric. This versatility allows you to confidently tackle different types of restoration projects without worrying about weak joints or bond failures.

Structural Integrity:

Furniture undergoes constant stress and weight, so it’s crucial to use a strong adhesive that maintains its structural integrity. With the right glue, you can have peace of mind knowing that your restored furniture will stand the test of time.

Moisture Resistance:

Moisture can wreak havoc on furniture, causing warping, swelling, or rot over time. By choosing an adhesive with moisture-resistant properties, you can prevent these issues and prolong the lifespan of your restored furniture.

Easy Application and Cleanup:

The right glue not only provides a strong bond but also offers easy application and cleanup. By choosing a glue that is easy to apply and leaves no mess behind, you can streamline your restoration process and avoid unnecessary frustrations.

Time and Money Savings:

Using the right glue can save you valuable time and money in the long run. A strong and durable bond means fewer repairs or touch-ups, reducing the need for future maintenance. Moreover, the right adhesive eliminates the necessity for additional reinforcement methods like nails or screws, saving both time and money on costly hardware.

How to Apply Different Types of Glue Properly

Unveiling the secret behind furniture restorers’ enchanting work lies in the magic of glue. Glue is the unsung hero that revives old furniture and holds everything together. In this blog post, we will explore the diverse world of glue used in furniture restoration and discover the proper techniques to apply them. So put on your apron and embark on this captivating journey of restoring furniture like a pro.

Wood Glue: The Carpenter’s Best Companion

Wood glue is a carpenter’s best friend when it comes to bonding wood surfaces. Whether in liquid, gel, or paste form, choose the consistency that suits your project. To apply wood glue properly, meticulously clean the surfaces you want to bond, ensuring a tight fit without gaps. Use a brush or spatula to gracefully spread a thin, even layer of glue on both surfaces. Press them firmly together and hold them in place with clamps or weights while the glue sets.

Epoxy Resin: The Superhero Strength Bond

Epoxy resin possesses superhero strength for repairing broken or damaged furniture parts. Mix the resin and hardener in the correct ratio as instructed by the manufacturer. Apply the mixture evenly on the surfaces to be bonded, covering every nook and cranny. Press the pieces together firmly and hold them in place until the epoxy sets, letting it work its magic. Remember, epoxy takes longer to dry than wood glue, so patience becomes your superpower.

Contact Cement: The Instant Bonding Marvel

Contact cement is a marvel for attaching veneers or laminates to furniture surfaces. Coat both surfaces with a thin layer of contact cement using a brush or roller, ensuring they dry completely before joining them together. Once dry, align the two pieces with precision and press firmly for an immediate bond. Beware, once the surfaces touch, there’s no turning back, so accuracy is key.

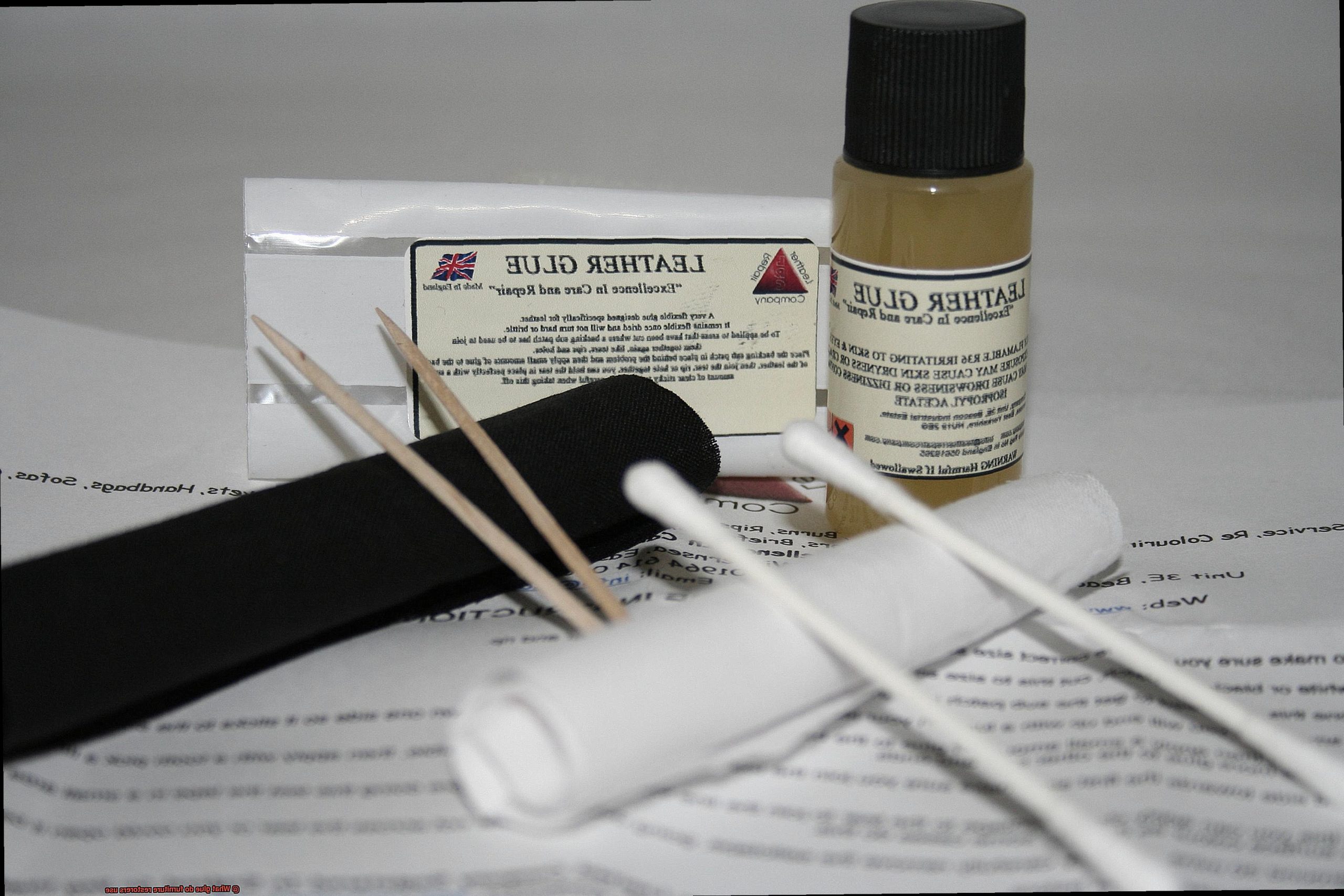

Specialized Glues for Delicate Repairs

Specialized glues come to the rescue for delicate repairs or specific tasks like veneer work. Veneer glue provides a robust bond while accommodating wood movement. Super glue (cyanoacrylate adhesive) works wonders for delicate repairs, and specialized adhesives exist for materials like leather or fabric. Each glue has its unique properties and application methods, so explore them as needed for flawless restoration.

Tips and Tricks from the Masters

Remember to read and follow the manufacturer’s instructions for each type of glue meticulously. Consider temperature and humidity, as they can influence drying time and effectiveness. Proper clamping or weighting may be necessary to achieve a tight bond. Lastly, always wipe away excess glue before it dries to avoid any unsightly residue.

Tips for Working with Wood Glue and Epoxy Resin in Furniture Restoration Projects

Furniture restoration is an art form that requires attention to detail and an understanding of materials and techniques. Wood glue and epoxy resin are essential adhesives in furniture restoration, used to repair broken joints and achieve seamless finishes. In this blog post, we will explore tips for working with wood glue and epoxy resin in furniture restoration projects.

Prepare the Surfaces:

Before applying any adhesive, prepare the surfaces to be bonded. Cleanliness is crucial. Remove dirt, dust, and old adhesive residue by lightly sanding the surfaces. This creates a clean and adhesive-friendly surface for a strong bond.

Apply Evenly, Sparingly:

When using wood glue, apply an even layer on both surfaces to be joined. Spread the glue evenly using a brush or small spatula. Remember, less is more. Applying too much glue can result in messy squeeze-out and compromise the appearance of the finished project.

Clamp for Success:

To achieve a tight bond with wood glue, apply pressure by clamping the pieces together. This ensures close contact between the surfaces while the glue dries. Use clamps or weights to distribute pressure evenly, facilitating a strong bond. Allow sufficient drying time recommended by the manufacturer.

The Power of Epoxy Resin:

Epoxy resin comes to the rescue when wood glue may not suffice. Follow the manufacturer’s instructions for thorough mixing of the resin and hardener to activate its adhesive properties effectively.

Mind Your Safety:

Working with epoxy resin requires safety precautions. Wear protective gloves and work in a well-ventilated area due to the strong fumes emitted during curing. Safety should always be a top priority.

How to Reversing a Hide Glue Joint if Necessary

Furniture restoration requires skill and attention to detail, and one crucial aspect is knowing how to reverse a hide glue joint if necessary. Hide glue has been used for centuries in furniture making for its strength and durability. However, there may come a time when a joint needs to be undone for repair or refinishing purposes. In this guide, we will explore the steps involved in reversing a hide glue joint, providing you with the knowledge to tackle this task with confidence.

Step 1: Identify the Joint

To begin, carefully examine the piece of furniture and locate any visible signs of hide glue. Look for its characteristic yellowish or amber color and distinctive odor. Once you have identified the joint that needs to be undone, proceed to the next step.

Step 2: Apply Heat

Applying heat is a common method used to soften hide glue and make it more pliable for separation. Use a heat gun or a hairdryer set on high heat to warm the joint. Be cautious not to overheat the area, as excessive heat can damage the wood or cause the glue to become too liquid.

Step 3: Gentle Separation

Once the hide glue has been softened with heat, use a putty knife or chisel to gently pry apart the joint. Take your time and work slowly and carefully to avoid damaging the wood or breaking the joint. If needed, apply additional heat to further soften the glue.

Step 4: Remove Excess Glue

As you separate the joint, scrape off any excess hide glue using a putty knife or chisel. This step ensures a clean surface for re-gluing or repairing the joint later on. Removing as much old glue as possible is vital for achieving a strong bond when reassembling the joint.

Step 5: Evaluate Repair Needs

After successfully reversing the hide glue joint, assess whether re-gluing or repairing the joint is necessary. Reversing the joint may be sufficient in some cases. However, if the joint is damaged or needs reinforcement, additional steps may be required, such as filling gaps with wood filler or using dowels or screws for added strength.

Step 6: Re-glue or Repair

If re-gluing is necessary, apply a fresh layer of hide glue to both surfaces of the joint. Ensure proper clamping and allow sufficient drying time according to the manufacturer’s instructions. If repairing the joint, follow appropriate methods based on the extent of damage, such as wood filler application or replacement of damaged parts.

The Best Ways to Use Veneer Glues and Cyanoacrylate Adhesives for Delicate Repairs

When it comes to delicate furniture repairs, selecting the right glue is essential. Veneer glues and cyanoacrylate adhesives are two popular options that offer unique properties and strengths for restoring cherished pieces. In this blog post, we will explore the best ways to use these adhesives to achieve successful and long-lasting results.

Veneer Glues: Bonding Veneer with Precision

Veneer glues are specifically designed to bond thin layers of wood veneer to a substrate. For delicate repairs, cold press veneer glues are recommended due to their strong bond and easy repositioning properties. These glues have a longer open time, allowing for adjustments before setting. Apply a thin, even layer of veneer glue to both the veneer and substrate using a brush or roller. Ensure that surfaces are clean and dry before application to ensure optimal adhesion.

Cyanoacrylate Adhesives: Swift and Reliable Repairs

Cyanoacrylate adhesives, also known as super glues, are ideal for precise repairs on small areas. To achieve the best results, apply a small amount directly to the surfaces being bonded, ensuring a tight fit. These adhesives create a strong and durable bond quickly but require careful handling to avoid skin or eye contact. Speed up the curing process by using an activator or accelerator for an even stronger bond.

Surface Preparation: The Key to Success

Before applying any adhesive, proper surface preparation is vital. Clean both the veneer and substrate by gently sanding or using a solvent to remove dirt, dust, and old glue residue. Thoroughly dry the surfaces before applying glue to ensure maximum adhesion.

Application Techniques: Even and Minimal

When using veneer glues, apply a thin and even layer to both the veneer and substrate. Avoid excessive glue that can cause warping or bubbling. For cyanoacrylate adhesives, apply a small amount directly to the surfaces being bonded, exerting minimal pressure to prevent excess adhesive from seeping out.

Cleanup and Finishing: Handle with Care

After the glue has set, carefully remove any excess adhesive using a sharp blade or sandpaper. Take caution when removing excess glue from veneer surfaces to avoid damaging the delicate material. Follow the manufacturer’s instructions for drying time and curing process to achieve optimal results.

qK0IR8WT_jE” >

Conclusion

Furniture restorers are experts at bringing old pieces back to life, and one of their secret weapons is the glue they use. But what kind of glue do they rely on? Well, there are a few options that professionals swear by.

First up is hide glue. This traditional adhesive has been used for centuries and is made from animal collagen. It’s known for its strength and durability, making it perfect for furniture repairs that need to stand the test of time.

Another popular choice is epoxy resin. This versatile glue is incredibly strong and can bond almost any material together. It’s particularly useful for filling gaps or securing loose joints in furniture.

For delicate projects or intricate details, cyanoacrylate glue, also known as super glue, is the go-to option. Its fast-drying formula allows restorers to quickly and precisely bond small parts without leaving any visible residue.

And let’s not forget about wood glue. This classic adhesive is specifically designed for woodworking projects and offers a strong bond that can withstand years of use.

So, whether it’s hide glue, epoxy resin, cyanoacrylate glue, or wood glue, furniture restorers have a range of options at their disposal. Each one has its own unique properties and benefits, ensuring that every repair or restoration job is done with precision and care.

In conclusion, the type of glue used by furniture restorers depends on the specific project at hand. They choose from a variety of options like hide glue, epoxy resin, cyanoacrylate glue, or wood glue to ensure a strong and lasting bond.