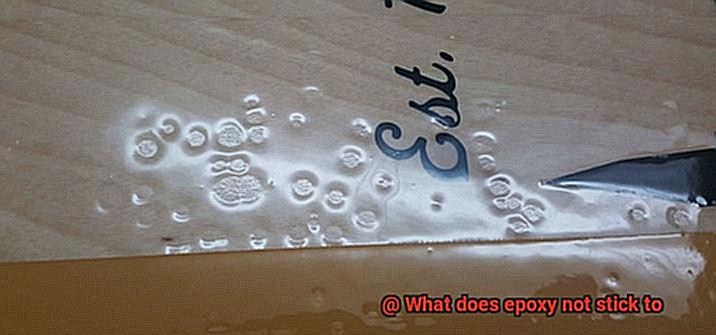

Are you a DIY enthusiast, artist, or handyman who loves to use epoxy for your projects? If so, you probably know that this versatile adhesive can bond almost anything together. But did you know that there are a few materials that epoxy just won’t stick to?

Epoxy is a two-part adhesive made up of resin and hardener. When combined, they create an incredibly strong and durable bond. It’s no wonder why epoxy is widely used in construction, repairs, and DIY projects. However, even with its impressive bonding power, there are some surfaces that it simply cannot adhere to.

In this blog post, we’ll explore the different materials that epoxy does not stick to. We’re talking about surfaces like polyethylene, silicone, and Teflon – all of which present unique challenges when it comes to epoxy adhesion.

But don’t worry – we’ve got you covered with some tips on how to properly prepare these surfaces for epoxy application. By following our advice, you can ensure maximum bonding power and avoid any frustrating mishaps.

So whether you’re a seasoned pro or just starting out with epoxy, keep reading to learn all about what it does not stick to. Trust us – this knowledge will come in handy for your next project.

What is Epoxy?

Contents

Epoxy is a versatile and powerful adhesive, comprised of two parts – the resin and the hardener – that when mixed together creates a strong, durable bond. It is a thermosetting polymer that can adhere to a variety of surfaces, including metal, wood, concrete, and plastic.

Notably, epoxy has become increasingly popular in recent years due to its exceptional bonding properties. It can be used for a wide range of applications, from automotive repairs to marine construction to home improvement projects. Additionally, epoxy can be customized to meet specific needs by adding fillers or modifying the formulation.

Although epoxy is known for its impressive adhesion capabilities, it is important to note that there are some materials that it does not adhere well to. These include smooth surfaces like glass or certain types of plastics. To improve adhesion on these surfaces, they should be roughened or etched before applying epoxy. Additionally, epoxy does not bond well to moist or oily surfaces, so it’s essential to ensure that the surface is clean and dry before applying the adhesive.

Flexible materials like rubber or certain types of plastics may require a different type of adhesive as epoxy is not ideal for bonding these materials.

It’s crucial to understand that different types of epoxy may exhibit varying adhesion properties with different materials. Therefore, testing the adhesive on a small area before committing to a larger project is always recommended.

What Materials Does Epoxy Not Stick To?

Before you dive into the world of strong adhesives, it’s crucial to know that not all materials are compatible with epoxy. As an expert on the subject, I’m here to share some valuable information on what materials epoxy doesn’t stick to.

First and foremost, let’s talk about plastics. Epoxy may be a versatile adhesive, but it doesn’t work well with polyethylene, polypropylene, or PVC. These types of plastics have low surface energy, which makes it challenging for the adhesive to create a strong bond. So, if you’re working with plastic materials in your project, make sure they aren’t made from these specific types.

Moving on to silicone rubber – steer clear of this material when it comes to using epoxy adhesives. Silicone rubber has a slippery surface that can repel adhesives, including epoxy. Additionally, some types of silicone rubber contain oils or other additives that can interfere with the curing process of the adhesive. So, if you’re planning to use silicone rubber in your project, you might want to consider using a different type of adhesive.

Now let’s shift our focus to metals. Certain metals like aluminum and stainless steel have oxide layers on their surfaces that can prevent the adhesive from bonding properly. To get around this issue, it’s crucial to clean and prepare the surface thoroughly before applying epoxy. By doing so, you’ll create an ideal bonding surface for your adhesive.

Lastly, rough or porous surfaces such as concrete or brick may pose a challenge for epoxy adhesion. These surfaces can absorb the adhesive and leave little to no bonding strength. In such cases, applying a primer or sealant before using epoxy is highly recommended.

Silicone

Let’s dive into the world of silicone, a non-stick material that has proven to be quite the challenge when it comes to epoxy adhesion. As an expert on silicone, I’m here to give you the inside scoop.

Silicone’s unique molecular structure makes it a low surface energy material, which means it repels adhesives like epoxy. This makes it difficult to bond two silicone surfaces together with epoxy. However, fear not, as there are specialized epoxies that contain additives designed specifically to bond with silicone.

It’s crucial to note that not all silicone products are created equal. Some may have coatings or additives that could affect their bondability with epoxy. To ensure a strong bond between epoxy and silicone surfaces, proper surface preparation is key. Thoroughly clean the surfaces and potentially use a primer or sealant before applying the epoxy.

Silicone is commonly used in various applications such as kitchen utensils, oven mitts, and medical implants due to its non-stick properties. However, if you’re considering using epoxy as an adhesive for your silicone product, it’s essential to test the bond strength first.

Polyethylene

Polyethylene is a versatile and durable thermoplastic material that is commonly used in packaging and manufacturing. Its resistance to moisture, chemicals, and most solvents makes it an ideal choice for many applications. However, one of its drawbacks is its low surface energy, which makes it difficult for adhesives like epoxy to bond to it.

The non-polar nature of polyethylene surfaces means that they lack the necessary chemical groups for epoxy resins to form a chemical bond with them. As a result, epoxy will not stick to polyethylene surfaces without proper surface preparation. This is where corona or plasma treatment comes in.

Corona treatment involves exposing the polyethylene substrate to a high-frequency electrical discharge. This creates a temporary increase in surface energy by introducing polar functional groups that can react with the epoxy adhesive. Plasma treatment works similarly by exposing the substrate to a low-pressure gas plasma that can also introduce polar functional groups.

It’s important to note that proper surface preparation is key to achieving strong and long-lasting adhesion between polyethylene and epoxy. Even with corona or plasma treatment, adhesion may not be optimal without adequate preparation. Furthermore, not all polyethylene products are created equal, so selecting the appropriate one for your specific application is critical.

Polypropylene and Nylon

Polypropylene and nylon are two versatile materials that are widely used in various industries. However, bonding epoxy to these materials can pose a challenge due to their low surface energy. As an expert in this field, I can tell you that there are solutions available to improve the adhesion of epoxy to polypropylene and nylon.

Firstly, surface treatment is a great option to increase the surface energy of the material. This can involve using a flame or plasma treatment to create a more “magnetic” surface for the epoxy to bond with. By doing so, you’re essentially prepping the material for a strong bond with the epoxy.

Another solution is to use a specialized primer that is specifically designed for bonding epoxy to polypropylene and nylon. These primers work by creating a chemical bond between the surface of the material and the epoxy resin. It’s like giving the epoxy a helping hand in forming a strong and reliable bond with the material.

It’s important to note that without proper preparation, attempting to bond epoxy with polypropylene and nylon will result in a weak bond that will eventually fail. However, with the right surface treatment or primer, you can achieve a strong and reliable bond that will stand the test of time.

Teflon and Other Fluoropolymers

If you’ve ever tried to get epoxy adhesive to bond with Teflon or other types of fluoropolymers, you know the struggle. As an expert in this field, I can attest that this is a common problem with a few key reasons behind it.

Teflon, also known as polytetrafluoroethylene (PTFE), is a fluoropolymer known for its non-stick properties and resistance to high temperatures and chemicals. Unfortunately, these same properties make it difficult for epoxy adhesive to adhere to its surface. Teflon has a low surface energy, which means it doesn’t provide a good surface for bonding. Additionally, its chemical resistance makes it challenging for the adhesive to penetrate the surface.

While Teflon is perhaps the most well-known fluoropolymer in this category, two others that present similar challenges are perfluoroalkoxy (PFA) and ethylene tetrafluoroethylene (ETFE). PFA shares many similar properties with Teflon and is commonly used for applications requiring high-temperature and chemical resistance. ETFE is notable for its transparency and lightweight nature, often used in architectural applications such as roofing and facades.

If you need to bond epoxy adhesive to these materials, it’s important to take their unique properties into account before attempting a bond. While epoxy adhesive can bond with most materials, it may not be suitable for certain types of fluoropolymers such as Teflon, PFA, and ETFE. Instead, it’s best to use an alternative adhesive that’s specifically designed for these materials.

Metals Coated with Oil or Rust

Metals coated with oil or rust can pose a real challenge when it comes to bonding with epoxy glue. These contaminants create a barrier between the metal and the adhesive, making it difficult for them to bond properly. As an expert in this field, I have researched the best ways to overcome this challenge and achieve a strong, durable bond.

To start, it’s essential to prioritize proper preparation. Before applying the epoxy, you need to thoroughly clean and dry the surface. For oil-coated metals, use a high-quality degreaser to eliminate any residue. For rusted metals, a rust remover is necessary to get rid of the corrosion. Once the surface is clean and dry, lightly sand it to improve adhesion. This creates a surface that will give the epoxy something to grip onto, ensuring a strong bond.

Using an epoxy glue specifically formulated for bonding metal surfaces is also crucial for success. These types of epoxies have a higher bonding strength and are designed to adhere to even the most challenging surfaces. By using the right adhesive, you can ensure that your bond will last for years to come.

Plastics Treated with Release Agents or Mold Release Sprays

Plastics are a versatile material that has found its way into various industries, from manufacturing to construction. However, when it comes to bonding plastics with epoxy, certain types of plastic can pose a challenge. Plastics treated with release agents or mold release sprays are among the materials that epoxy may not adhere to properly.

Release agents and mold release sprays are commonly used during the manufacturing or molding process to prevent materials from sticking to surfaces. Unfortunately, these treatments also make it difficult for epoxy to bond with the plastic. Polyethylene, polypropylene, and polystyrene are examples of plastics that are often treated with release agents or mold release sprays, and they are commonly used in products such as containers, packaging, and toys.

The key to bonding these tricky plastics with epoxy is proper surface preparation. Thoroughly cleaning the surface before application is critical since any residual release agents can create a barrier that will prevent the epoxy from adhering properly. Additionally, using specialized primers or adhesion promoters designed specifically for bonding plastics can help break down the barrier created by the release agents and improve the adhesion of the epoxy.

It’s worth noting that not all types of epoxy are created equal when it comes to bonding certain plastics. For example, some epoxies may be better suited for bonding high-density polyethylene (HDPE) than others. So, it’s essential to select the right type of epoxy for the specific type of plastic being bonded.

2dwZbltWIRo” >

Conclusion

In conclusion, while epoxy is a powerful adhesive that can bond almost anything together, it does have its limitations. Certain materials simply won’t stick to it, including polyethylene, silicone, Teflon, metals coated with oil or rust, plastics treated with release agents or mold release sprays, and specific types of plastics like polypropylene and nylon.

These challenging materials often have low surface energy or chemical resistance properties that make them difficult to bond with epoxy. However, with proper surface preparation techniques such as thorough cleaning and using specialized primers or adhesion promoters designed for these materials, you can achieve maximum bonding power.

It’s crucial to keep in mind that different types of epoxy may exhibit varying adhesion properties with different materials. Therefore, testing the adhesive on a small area before committing to a larger project is always recommended.

As an expert in this field, I hope this blog post has provided valuable information on what materials epoxy does not stick to and how to properly prepare these surfaces for optimal bonding.