Ever experienced that heart-wrenching moment when a beloved ceramic masterpiece takes a tumble, shattering into a million pieces? As fellow arts and crafts enthusiasts, we know the pain all too well. But fear not, for we have discovered a golden solution that will reignite your hope and salvage those shattered dreams. Welcome to the enchanting realm of gluing ceramic to ceramic.

In this captivating blog post, we embark on a journey through the intricate world of bonding ceramics. Prepare to uncover the secrets, tips, and tricks that will enable you to mend your broken ceramics with precision and dedication.

But hold on. Before we dive headfirst into the enchantment of ceramic glue, let’s take a moment to marvel at one fascinating fact: ceramics, renowned for their fragility, possess an uncanny ability to capture hearts with their timeless beauty. From ancient pottery to dazzling modern sculptures, ceramics have endured throughout human history, sparking wonder with their delicate craftsmanship.

Now, allow us to whisk you away on an expedition through the essentials of gluing ceramics together. We’ll explore various types of adhesives suited for such endeavors – both traditional favorites and innovative options. From epoxy resins and cyanoacrylate glues to specialized ceramic adhesives, get ready to discover the superpowers of these magical solutions that restore shattered beauty with brilliance.

Furthermore, we’ll delve into the art of proper preparation and application techniques – ensuring seamless adhesion and enduring strength. You’ll learn how to navigate the vast universe of adhesives, selecting the perfect match for your specific ceramic project.

So whether you yearn to revive cherished ceramics or embark on a new artistic venture, join us as we unravel the mysteries of gluing ceramic to ceramic. Get ready to be captivated by the artful world of adhesive mastery – ensuring your beautiful creations withstand the test of time and remain cherished for generations to come.

What is Ceramic?

Contents

For millennia, humans have marveled at the mystique of ceramic, a remarkably versatile material that has left an indelible mark on art, industry, and technology. From ancient civilizations to modern engineering marvels, ceramics have woven themselves into the fabric of human history. This article embarks on a captivating journey through the realm of ceramic, uncovering its composition, extraordinary properties, and the diverse array of ceramics that exist.

Composition and Properties:

Ceramic, an inorganic solid amalgamation of metallic and non-metallic elements, stands as a testament to mankind’s ingenuity. Rooted in tradition, ceramics were once molded from natural clays and minerals. These traditional ceramics, known as earthenware, bear their distinctive porosity and necessitate glazing or sealing to achieve impermeability. Conversely, porcelain reigns supreme in the realm of ceramics, having undergone intense firing at soaring temperatures to yield an impervious and resplendent material renowned for its strength and ethereal translucence.

Types of Ceramics:

- Traditional Ceramics (Earthenware): Embodying centuries-old craftsmanship, traditional ceramics emerge from the earth’s clay-rich embrace. Pottery, decorative tiles, and humble cooking utensils are among their cherished creations. However, these ceramics bear porosity and require meticulous glazing or sealing to shield against permeation.

- Porcelain: Born from a fiery transformation at extreme temperatures, porcelain stands as a pinnacle of ceramic artistry. Its density renders it unyielding and exquisite, making it the perfect canvas for fine china creations, dental crowns that grace smiles, and electrical insulators that silently conduct power.

- Advanced Ceramics (Engineered Ceramics): Embracing cutting-edge techniques and fortified by supplementary elements or compounds, advanced ceramics redefine the boundaries of possibility. Within this realm, alumina (aluminum oxide), zirconia (zirconium oxide), and silicon carbide reign supreme. Exuding unparalleled hardness, boasting high melting points, and showcasing excellent electrical and thermal conductivity, these materials epitomize ceramic innovation.

Types of Adhesives for Gluing Ceramic to Ceramic

When it comes to joining ceramic surfaces, the adhesive you choose can make or break the bond. In this article, we will delve into the world of adhesives and explore the various types that are best suited for gluing ceramic to ceramic. From the reliable strength of epoxy adhesive to the flexibility of silicone adhesive, let’s discover the advantages and disadvantages of each option.

Epoxy Adhesive: The Powerhouse Bond

Epoxy adhesive stands as one of the most commonly used and effective adhesives for ceramic-to-ceramic bonding. This two-part adhesive consists of a resin and a hardener that, when combined, create an incredibly strong and enduring bond. With its high strength, resistance to heat, moisture, and chemicals, epoxy adhesive is a reliable choice for both indoor and outdoor applications. Its versatility is further enhanced by its availability in different viscosities, allowing for various application methods.

Cyanoacrylate Adhesive: Instant Gratification

Known as super glue or instant glue, cyanoacrylate adhesive offers a fast-acting solution for bonding ceramics together. When the surfaces are brought into contact, this adhesive forms an almost instantaneous bond. While cyanoacrylate adhesive works well on smooth ceramic surfaces, it may not be as suitable for porous or rough surfaces. It’s important to note that this adhesive can be brittle and may not withstand high temperatures or exposure to water.

Silicone Adhesive: A Flexible Connection

For those seeking a bond that allows for some movement between the surfaces, silicone adhesive is a top choice. This flexible adhesive provides a strong bond while accommodating slight shifts or flexing of the bonded objects. Additionally, silicone adhesive boasts resistance against heat, moisture, and chemicals, making it suitable for both indoor and outdoor applications. However, it’s worth mentioning that silicone adhesive may require a longer curing time compared to other adhesives.

Polyurethane Adhesive: Strength and Resilience

When it comes to applications that demand a bond capable of withstanding vibrations or movement, polyurethane adhesive shines. This adhesive not only creates a strong bond but also offers remarkable flexibility and impact resistance. With its ability to withstand temperature variations, moisture, and chemicals, polyurethane adhesive is a reliable option for a range of projects. However, keep in mind that it may require a longer curing time compared to other adhesives.

Specialized Ceramic Adhesives: Tailored for Perfection

In addition to the commonly used adhesives, specialized ceramic adhesives cater specifically to bonding ceramics. These formulations offer additional benefits such as high-temperature resistance or compatibility with specific types of ceramics. To achieve optimal results, it is crucial to carefully read and follow the manufacturer’s instructions when using specialized ceramic adhesives.

Epoxy Adhesive

When it comes to bonding ceramic to ceramic, nothing beats the strength and durability of epoxy adhesive. This two-part adhesive, consisting of a resin and a hardener, is a game-changer in achieving long-lasting connections. In this article, we will delve into the world of epoxy adhesive and discover its secrets to creating powerful bonds between ceramic surfaces.

The Dynamic Duo: Resin and Hardener

At the heart of epoxy adhesive’s formidable strength lies the perfect partnership between its resin and hardener components. These two entities must be mixed together in equal proportions before use, forming the foundation for exceptional bonding capabilities.

Unleashing the Alchemical Reaction

Once united, the resin and hardener embark on a chemical journey, undergoing a miraculous transformation that cures the adhesive and creates an unbreakable bond. This alchemical reaction sets epoxy adhesive apart from its counterparts.

Prepping for Success: A Clean Canvas

Before applying epoxy adhesive, cleanliness becomes your ally. Ensuring that the ceramic surfaces are clean, dry, and free from contaminants is paramount. Treat them to a gentle wipe-down with a mild detergent or isopropyl alcohol, allowing them to bask in their pristine state before proceeding.

Mixing Matters: The Art of Fusion

The key to unlocking epoxy adhesive’s full potential lies in following the manufacturer’s instructions for mixing. Pay attention to the recommended ratio, expertly blending the resin and hardener together. A disposable mixing stick or a gentle swirl with a clean tool will do the trick.

Applying with Precision: Thin and Uniform

With your epoxy adhesive concoction ready, it’s time to grace the ceramic surfaces with your artistry. Use a brush, spatula, or applicator to apply a delicate layer of adhesive, ensuring uniform coverage on both surfaces. Embrace the elegance of thinness, avoiding excessive application that could mar the final masterpiece.

The Moment of Connection: Align and Embrace

As the adhesive sets the stage for union, meticulously align the ceramic pieces and press them together with conviction. Utilize clamps or weights to exert even pressure, ensuring that every inch of the surfaces intertwines flawlessly. Any excess adhesive daring to escape can be swiftly wiped away, leaving behind only perfection.

Cyanoacrylate Adhesive (Super Glue)

Unleash the Power of Super Glue: The Ultimate Bond for Ceramic Surfaces

Calling all adhesive enthusiasts. Get ready to explore the remarkable world of cyanoacrylate adhesive, commonly known as super glue, and discover its incredible benefits when it comes to bonding ceramic to ceramic. Don your safety goggles and join us on this captivating journey.

Prepare to be amazed by the lightning-fast drying time of super glue. Unlike its sluggish counterparts that leave you waiting for hours or days, super glue sets in a matter of seconds. This means you can swiftly forge ahead with your project, saving precious time and reveling in your masterpiece sooner than ever imagined.

But don’t let its speed fool you – super glue is a heavyweight champion in terms of strength. Once cured, this adhesive creates an unbreakable bond capable of enduring immense stress and pressure. Whether you’re joining delicate ceramic figurines or heavy-duty ceramic tiles, rest assured that super glue has your back with unwavering support.

Durability is the name of the game, and super glue thrives in the face of temperature changes and moisture. It scoffs at scalding hot mugs or icy cold beverages, boasting unwavering bond integrity even in the harshest conditions. Sip your steaming coffee or savor your refreshing iced tea with confidence, knowing that your ceramic creations are securely fused together.

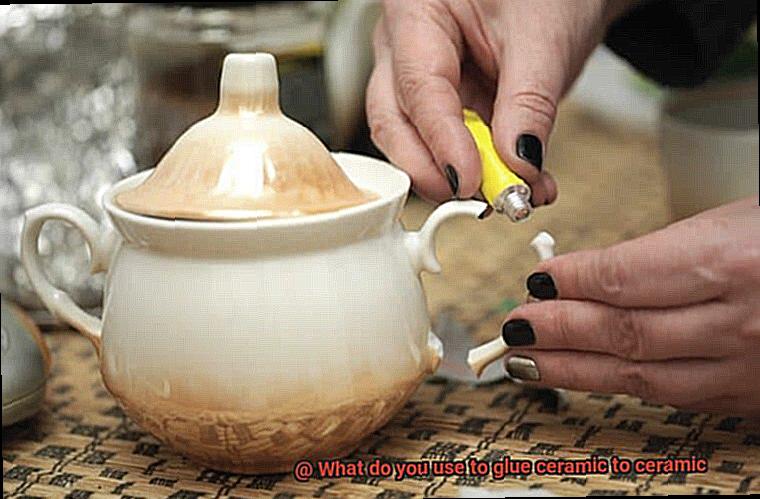

Now, let’s delve into the art of application. Before you uncork that trusty bottle of super glue, ensure your ceramic surfaces are prepared to perfection. Cleanliness is key – rid them of any dirt, dust, or grease that may hinder the adhesive’s magic touch. Treat your ceramics to a spa day before their grand bonding affair.

Remember, less is more when it comes to applying super glue. A small amount is all it takes to forge an indomitable bond. Use excessive amounts at your own peril as it may result in messy applications or unsightly glue seeping out from the joined surfaces. Once the adhesive is applied, press those ceramic pieces together with conviction and maintain pressure for a few moments. This will ensure an initial bond that radiates strength and instills unwavering confidence in your craftsmanship.

Silicone Adhesive

Silicone adhesive has soared in popularity as the go-to choice for bonding ceramic surfaces. Its secret lies in its unique composition, crafted from a powerful blend of silicone polymers, fillers, and curing agents. This dynamic combination forms a bond that is not only strong, but also capable of withstanding the test of time.

One of the standout advantages of silicone adhesive is its ability to create an ultra-strong and durable bond between ceramic surfaces. Regardless of whether you’re working with delicate porcelain or rugged stoneware, silicone adhesive will hold your ceramics together with unwavering strength. It defies stress and laughs in the face of temperature fluctuations, allowing your creations to remain flawlessly intact even in the harshest conditions.

But there’s more. Silicone adhesive boasts exceptional resistance to high temperatures, making it the perfect solution for applications where your bonded ceramics may encounter heat. Whether you’re crafting exquisite pottery or designing functional ceramic pieces for your kitchen, silicone adhesive rises to the occasion with unbeatable performance.

Another remarkable feature of silicone adhesive is its outstanding resistance to water and other liquids. Even if your ceramics come into contact with moisture, rest assured that the bond will remain unyielding. Say goodbye to worries about your cherished creations disintegrating at the slightest hint of water.

Now let’s delve into the application process itself. Before applying silicone adhesive, it is absolutely crucial to prepare the surface meticulously. Cleanliness is paramount – ensure that both ceramic surfaces are pristine, dry, and free from any grease or oil. This meticulous preparation guarantees optimal bonding and ensures that your masterpiece exudes unwavering strength.

When it’s time to apply the silicone adhesive, start by squeezing a small amount onto one of the ceramic surfaces. Take a brush or applicator and spread the adhesive evenly, ensuring complete coverage. Then, with determination, press the two ceramic pieces together firmly, maintaining this pressure until the adhesive sets. Bear in mind that curing times may vary depending on the brand and specific product, so always refer to the manufacturer’s instructions for optimal results.

Polyurethane Adhesive

When it comes to gluing ceramic to ceramic, you need an adhesive that can withstand the test of time, temperature changes, and even the occasional splash of water. That’s where polyurethane adhesive steps in as the superhero of ceramic bonding. With its remarkable strength, durability, and versatility, polyurethane adhesive is the go-to choice for professionals and DIY enthusiasts alike. In this article, we’ll explore the advantages of using polyurethane adhesive for gluing ceramic to ceramic and share some essential tips for a successful application.

Advantage 1: Unbreakable Bond

Polyurethane adhesive emerges as the champion of bonding capabilities. Its chemical reaction with moisture creates an unbreakable bond between ceramic surfaces. Once your ceramics are glued together using polyurethane adhesive, they’ll stay firmly intact for years to come.

Advantage 2: Durability

Ceramic items face scorching heat, damp conditions, and other challenging environments. Fortunately, polyurethane adhesive thrives in such situations. Its resistance to temperature changes, moisture, and chemicals makes it a powerhouse for both indoor and outdoor applications. Delicate porcelain vases or sturdy stoneware mugs, polyurethane adhesive ensures your creations stand the test of time.

Advantage 3: Flexibility

Polyurethane adhesive’s flexibility sets it apart from the rest. It remains pliable even after curing, absorbing shocks and vibrations caused by accidental bumps or movements. This flexibility makes it perfect for items that require a little extra resilience.

Proper Surface Preparation:

To unlock the full bonding potential of polyurethane adhesive, proper surface preparation is key. Begin by ensuring that the ceramic surfaces you plan to glue together are pristine. Clear away any dust or grease by unleashing the power of a solvent-based cleaner or isopropyl alcohol. This meticulous cleaning is essential to achieve optimal bonding strength.

Surface Preparation for Bonding Ceramics

Get ready to discover the secrets of surface preparation that will ensure your ceramics stay firmly bonded for years to come.

Step 1: Cleanliness is Next to Bond-worthiness

To kickstart our bonding adventure, we must clean those ceramic surfaces like never before. Dirt, dust, grease, or oil can wreak havoc on our adhesive’s bonding abilities. So grab some soap and water or a mild detergent, scrub away the impurities, rinse thoroughly, and let those ceramics dry completely.

Step 2: Roughen Up, Buttercup

Now that our ceramics are squeaky clean, it’s time to roughen them up a bit. We want to give them an edge in bonding capabilities. Grab your trusty fine-grit sandpaper and gently sand away or use the power of hydrofluoric acid for etching. But remember, safety always comes first when handling acid solutions.

Step 3: Primed for Success

We’ve cleaned and roughened our ceramics, but we’re not done yet. It’s time to unleash the magic of ceramic primer or conditioner. These enchanting products promote chemical bonding between the adhesive and the ceramic surfaces. Follow the manufacturer’s instructions, let it dry thoroughly, and get ready for the next step.

Step 4: The Right Adhesive for the Job

Prepare for a game-changing moment. Consider using a bonding agent or adhesive specifically designed for ceramic-to-ceramic bonding. These adhesive superheroes have enhanced properties that make them perfect for our ceramic bonding mission. Be sure to choose an adhesive that’s compatible with your ceramics and intended application. No mismatched pairs allowed.

Now that we’ve covered the essential steps of surface preparation, it’s time to put our skills to the test with a small-scale bond. This test will ensure compatibility and evaluate the strength of our bond before we embark on a larger bonding adventure.

Curing Time for Optimal Results

Prepare to embark on a journey that will reveal the hidden secret to flawless ceramic bonding. Get ready to immerse yourself in the world of curing time because it holds the key to unlocking unparalleled results in your adhesive endeavors.

Now, you may be wondering, what’s all the fuss about curing time? Why is it so crucial? Brace yourself, my friend, for curing time is the magical ingredient that transforms your ceramic bond from ordinary to extraordinary. So grab your favorite beverage and join me as we delve deeper into this captivating topic.

Let’s start by breaking it down. Curing time is the pivotal period when your adhesive undergoes a remarkable metamorphosis, transitioning from a liquid state to a solid stronghold. It is during this transformative process that your adhesive forms an unbreakable bond capable of withstanding the trials and tribulations of everyday life. But here’s the kicker – not all adhesives are created equal, and neither are their curing times.

Enter epoxy resin, the superhero of adhesives in the ceramic realm. This mighty contender demands a minimum of 24 hours to achieve its full strength. During this critical phase, handle your glued ceramic pieces with utmost care, treating them as priceless treasures that demand undisturbed stability.

On the flip side, we have cyanoacrylate or super glue, notorious for their lightning-fast drying times that often occur within mere minutes. However, don’t be deceived by their rapid-drying nature; these adhesives still require additional time to reach their peak potency. Remember to heed the manufacturer’s instructions diligently, ensuring you provide them with the nurturing environment they deserve.

But wait, there’s more. External factors hold sway over curing time as well. Temperature and humidity become players in this game of adhesive mastery. Higher temperatures expedite the curing process, while lower temperatures may prolong it. Likewise, elevated humidity levels can impede drying time, while arid conditions foster swift desiccation. Stay vigilant, my friend, monitoring the weather’s whims to create the ideal habitat for your adhesive’s enchantment.

H8LG3lFqQCs” >

Conclusion

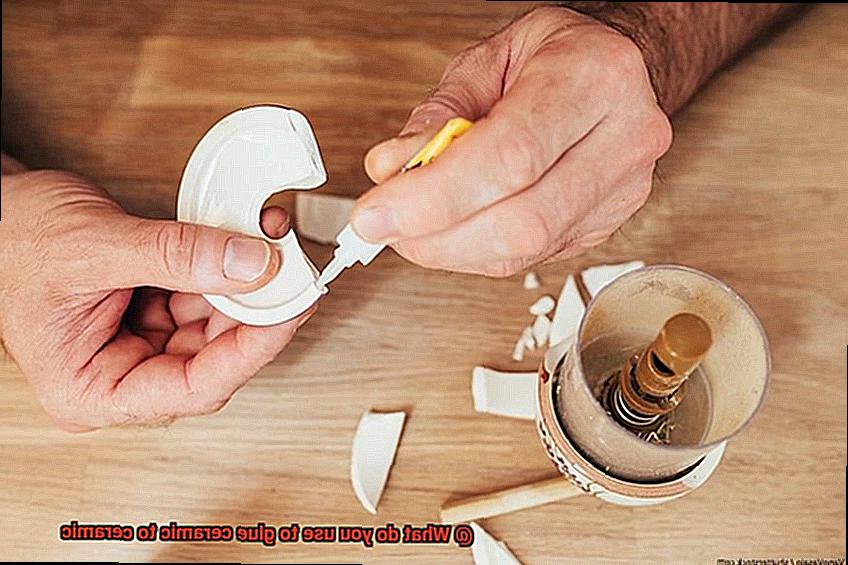

When it comes to bonding ceramic to ceramic, there are a few options that can get the job done effectively.

One popular choice is epoxy adhesive, which provides a strong and durable bond between two ceramic surfaces. Another option is cyanoacrylate glue, commonly known as super glue, which forms an instant bond and dries quickly.

For more specialized applications, you might consider using a high-temperature ceramic adhesive that can withstand extreme heat and maintain its strength. Whichever adhesive you choose, it’s important to ensure that both surfaces are clean and free of any debris or oils before applying the glue.

Additionally, following the manufacturer’s instructions and allowing sufficient time for the adhesive to cure will help ensure a successful bond.