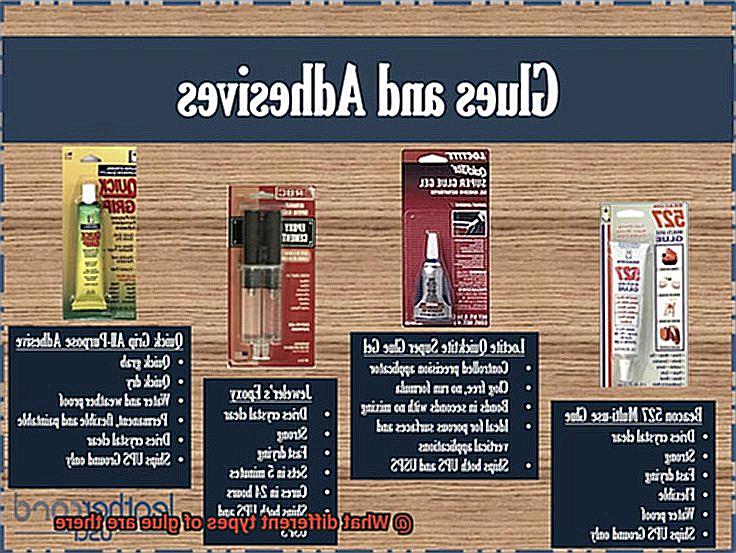

Welcome to our blog post all about glue – the magical adhesive that brings everything together. Whether you’re fixing a broken vase or getting crafty with your art projects, glue is the secret ingredient that holds it all in place. But did you know that there’s a whole world of different types of glue out there? Each one has its own unique superpowers and special uses.

First up, we have the trusty white glue. This stuff is perfect for sticking paper, fabric, and lightweight materials. It’s super easy to use, dries quickly, and best of all, it’s non-toxic. But keep in mind, it might not be the best choice for heavy-duty tasks or anything that’ll get wet.

Next on the list is the speedy superhero known as super glue. This fast-drying wonder is great for bonding small components, ceramics, and plastics. It’s like a magic wand for quick fixes. Just be careful because this stuff can be a bit tricky to control and sometimes leaves behind sticky residue.

When it comes to heavy-duty projects, epoxy glue is your go-to sidekick. This mighty adhesive creates an incredibly strong bond and works wonders on materials like metal and wood. But here’s the catch – you’ll need to mix it precisely and give it some time to cure. Oh, and don’t forget about ventilation because this stuff packs a punch with its strong odor.

Last but certainly not least is everyone’s favorite artsy companion – hot glue. This versatile buddy melts at high temperatures to create a fast and sturdy bond on all sorts of materials. It’s like having a mini volcano of stickiness at your fingertips. Just beware of its messy tendencies and remember that it’s not ideal for things that can’t handle high temperatures.

Now that you’ve got the lowdown on these different glues, get ready for our upcoming blog posts where we’ll dive into each type in more detail. We’ll be sharing expert tips, project ideas, and everything you need to know about the sticky world of glue. So stick around and join us on this adhesive adventure.

White Glue (PVA)

Contents

This adhesive is a household staple and a go-to option for various projects. In this article, we’ll explore the advantages and limitations of white glue and discover its diverse applications in arts and crafts, construction, and repairs.

Advantages of White Glue (PVA):

- Versatility: White glue’s biggest advantage lies in its versatility. This adhesive can bond an array of materials such as paper, cardboard, fabric, wood, and even some plastics. Its adaptability makes it perfect for craft projects, woodworking endeavors, and general repairs.

- Non-Toxic and Safe: Being water-based and non-toxic, white glue is a safe choice for both adults and children. It’s ideal for arts and crafts projects involving kids, providing peace of mind while they unleash their creativity.

- Easy Cleanup: Unlike solvent-based adhesives that require harsh chemicals to clean up, white glue is easily washable with water when wet. This convenient feature eliminates messiness from your creative process.

- Transparent Drying: When white glue dries, it becomes transparent, ensuring a clean and professional finish for your project. This is particularly advantageous when the adhesive might be visible.

Limitations of White Glue (PVA):

- Heat Resistance: White glue isn’t suitable for applications requiring high heat resistance. Excessive heat exposure can cause it to soften or weaken its bond. Thus, it’s essential to consider this limitation when selecting an adhesive.

- Moisture Resistance: Similarly, white glue may not be the best choice for projects that demand high moisture resistance. Prolonged exposure to water can weaken or dissolve the bond created by white glue.

- Drying Time: White glue requires pressure during the drying process to achieve its maximum bonding strength. The drying time varies based on the glue’s thickness and the materials being bonded. Patience is key to ensure a strong and long-lasting hold.

Using White Glue (PVA) in Different Contexts:

- Arts and Crafts: White glue is perfect for various arts and crafts projects, including paper collage, fabric crafts, and creating 3D models. Crafters of all ages rely on its versatility and easy cleanup.

- Construction: While white glue may not be the primary adhesive used in construction projects, it can be a handy tool for bonding lightweight materials like foam, balsa wood, or cardboard. It can also complement other adhesives to enhance strength.

- Repairs: White glue proves useful for general repairs around the house, such as fixing broken wooden furniture, repairing torn pages in books, or regluing loose edges on laminated surfaces.

Super Glue (Cyanoacrylate Adhesive)

Today, we embark on a captivating expedition into the world of Super Glue, also known as Cyanoacrylate Adhesive. Prepare to be amazed as we unravel the history, science, and incredible versatility of this adhesive marvel. Grab your safety goggles, and let’s dive right in.

The Accidental Discovery:

In the 1940s, the brilliant scientist Dr. Harry Coover set out on a mission to find a clear plastic for gun sights during World War II. Little did he know that his quest would lead him to stumble upon an extraordinary compound called cyanoacrylate. Its extraordinary bonding properties would revolutionize the adhesive industry forever. In the 1950s, Coover and his team at Eastman Kodak Company patented it as Super Glue.

The Science Behind the Magic:

Super Glue is like the superhero of adhesives, capable of bonding almost anything together. When this miraculous adhesive comes into contact with moisture – from water vapor to sweat – a chemical reaction takes place. In an instant, its molecules link rapidly, forming an unyielding bond that can withstand immense stress.

Speed Demon Drying Time:

What truly sets Super Glue apart is its lightning-fast drying time. Within seconds or minutes, you’ll have a rock-solid bond at your fingertips. But beware. Once it dries, it’s not budging easily, so handle with care.

Formulations for Every Need:

Not all Super Glues are created equal. Various formulations exist, each with its own viscosity and curing time. Need to fill gaps or bond porous materials? There’s a specially designed Super Glue for that. Just remember to read the instructions carefully, as each formulation may require specific application techniques and safety precautions.

Astonishing Applications:

Now, let’s shine the spotlight on the true star of the show – the incredible uses of Super Glue. It’s the ultimate adhesive for household repairs, crafting projects, and model-making. From fixing cherished jewelry to mending shattered ceramics, Super Glue has your back. And believe it or not, under professional supervision, it even finds its place in the medical field for wound closure.

Epoxy Glue

Get ready to be blown away by the incredible world of epoxy glue. This superhero adhesive combines epoxy resin and a hardener to create an unbeatable bond. It’s like a match made in adhesive heaven. But what sets epoxy glue apart from other glues? Let’s dive into the fascinating details.

First and foremost, epoxy glue is known for its super strength. It can effortlessly bond a wide range of materials like metal, glass, ceramic, wood, plastic, and even concrete. Talk about versatility. No matter what project you’re working on, epoxy glue has got your back.

Now, let’s explore some of the exciting applications of epoxy glue. In woodworking, it’s like a trusty sidekick that can bond joints with unmatched strength. It can also swoop in to rescue cracked or split wooden surfaces, providing a seamless finish that’ll make your project shine.

In the automotive industry, epoxy glue is the go-to hero for repairing plastic parts and securing metal components. Its resistance to heat and chemicals makes it perfect for fixing broken bumpers or attaching trim pieces.

Epoxy glue isn’t just limited to wood and cars though. It’s also a star player in the construction industry. Need to bond concrete surfaces or repair cracks in structures? Epoxy glue has got your back. Its unbreakable bond ensures structural integrity and durability in even the toughest environments.

And here’s the best part: epoxy glue comes in different formulations. That’s right. Whether you’re working with glass, metal, or plastic, epoxy glue has got a specialized variety designed just for your needs. Plus, it comes in different viscosities for precise application and gap filling. It’s like having a whole arsenal of adhesive options at your fingertips.

So whether you’re a DIY enthusiast or a professional in need of a reliable bonding solution, epoxy glue is the ultimate hero you can count on. Its exceptional bonding properties, wide range of applications, and sheer strength make it the go-to glue for any challenge that comes your way.

Hot Glue

Hot glue is a marvel of the adhesive world, a true Swiss Army knife for crafts, repairs, and industrial applications. It’s a versatile adhesive that can be used for a wide range of projects, making it a must-have for crafting enthusiasts, DIY fanatics, and professionals alike. Let’s delve into the world of hot glue and explore its advantages, uses, and some important considerations.

Advantages:

- Lightning-fast drying time: Perhaps one of hot glue’s greatest strengths is its rapid drying time. Unlike other glues that can take hours or even days to set, hot glue solidifies within seconds of application. This means no more waiting around for hours on end, saving you precious time and sparing you the frustration of delayed projects.

- Unyielding bond: When it comes to bonding power, hot glue is a force to be reckoned with. It forms a strong bond with materials such as paper, fabric, wood, plastic, and metal. Once applied, the glued items stay firmly in place, making it perfect for creating decorations, scrapbooking, and assembling intricate models or sculptures.

- Flexibility in every sense: Unlike other adhesives that become rigid once they dry, hot glue retains a certain degree of flexibility. This allows for slight movements or adjustments without compromising the bond. It’s particularly useful when working with materials that expand or contract due to temperature fluctuations.

Uses:

- Arts and crafts bonanza: Hot glue is an essential tool in the world of arts and crafts. Its ability to adhere to a wide variety of materials makes it ideal for creating decorations, attaching embellishments, and assembling various craft projects. Whether you’re making handmade greeting cards or constructing a dazzling paper sculpture, hot glue will be your secret weapon.

- DIY repairs made easy: Have a broken toy? Loose furniture parts? Don’t fret – hot glue is here to save the day. It’s perfect for quick fixes around the house, allowing you to mend items in a flash. From repairing broken ceramics to securing loose fabrics, hot glue is a versatile ally for DIY repairs.

- Industrial powerhouse: Hot glue isn’t just for hobbyists and DIY enthusiasts; it’s also a staple in industrial settings. Its lightning-fast drying time and strong bonding capabilities make it a go-to adhesive for tasks such as packaging, product assembly, and even in the automotive industry. When efficiency and reliability are paramount, hot glue is the glue of choice.

It’s important to note that while hot glue is incredibly versatile, it may not be suitable for all situations. It may struggle to adhere to oily or greasy surfaces, so it’s always wise to test a small area before applying it to larger surfaces.

Wood Glue

Woodworking projects are a labor of love, but they can quickly turn into a nightmare if you don’t have the right adhesive to keep everything together. That’s where wood glue comes in – the unsung hero of the woodworking world. In this article, we’ll take a closer look at the different types of wood glue and their various uses, helping you make informed decisions for your next project.

PVA (Polyvinyl Acetate) Glue:

PVA glue is like the Swiss Army knife of wood glues. It’s easy to use, dries quickly, and forms a strong bond between wood surfaces. Whether you’re joining boards, veneering, or laminating, PVA glue has got your back. Plus, it’s water-based, so you can clean up any spills with ease. PVA glues come in various formulations such as white glue, yellow glue, and waterproof glue, each with its own specific properties for different applications.

Aliphatic Resin Glue:

If you need a longer open time for precise assembly and adjustment, aliphatic resin glue is your go-to option. Commonly known as yellow glue or carpenter’s glue, it creates a strong bond that can withstand moisture and temperature changes. So whether you’re working on an indoor or outdoor project, aliphatic resin glue has got you covered. It’s particularly useful for furniture making and bonding larger wooden surfaces.

Polyurethane Glue:

Polyurethane glue is the superhero of wood adhesives. It expands as it cures, filling gaps and creating an unbreakable bond. This waterproof wonder can handle extreme temperatures and even resist chemicals. Just be careful with its foaming nature – it can get messy if not applied with precision. Polyurethane glues are perfect for outdoor applications, such as decking and outdoor furniture construction.

Epoxy Resin:

When you need industrial-strength bonds and incredible durability, epoxy resin is the way to go. With its two-part formula, epoxy creates a chemical reaction that forms an unbeatable bond between wood surfaces. It’s also resistant to water, chemicals, and extreme temperatures, making it perfect for repairs and structural applications. Epoxy resins are commonly used in boat building and woodworking projects that require high-strength bonding.

Hide Glue:

For the traditionalists out there, hide glue is an ancient adhesive that has stood the test of time. Made from animal collagen, it offers excellent bond strength and reversibility, allowing for easy disassembly and repairs.

However, it requires special preparation and application techniques, so it’s not as convenient as modern wood glues. Hide glue is often used in antique restoration and instrument making.

Specialized Glues

Specialized glues are the superheroes of the adhesive world, swooping in to save the day when regular glue just won’t cut it. These remarkable products are designed for specific applications and materials, providing strong and durable bonds where ordinary glue falls short. So, let’s dive deep into the captivating world of specialized glues and uncover their distinctive properties and areas of application.

First up, we have the mighty epoxy glue. With its exceptional strength and versatility, this adhesive is a force to be reckoned with. It consists of two components – resin and hardener – that combine to form a bond capable of withstanding high temperatures, water exposure, and chemical interactions. Industries like automotive, construction, and aerospace rely on epoxy glue to bond metals, ceramics, and plastics.

Next on our list is wood glue, the loyal companion of carpenters and furniture repair enthusiasts. This adhesive dries clear and forms a robust bond that stands the test of time. White glue, yellow glue (also known as carpenter’s glue), and polyurethane-based glues are all different variations available for various wood bonding needs.

If you’re in need of a quick fix, look no further than super glue. This speedster, also known as cyanoacrylate adhesive, instantly bonds when it comes into contact with moisture. It’s perfect for small repairs or bonding non-porous materials like plastics, rubber, metal, and ceramics.

Fabric glue is a game-changer for all your textile projects. Say goodbye to needles and thread as fabric glue allows you to bond fabrics together effortlessly. Hemming clothing, repairing upholstery, or creating stunning crafts has never been easier.

Glass surfaces require special attention when it comes to adhesion. That’s where glass glue steps in. Specially formulated to bond glass surfaces, this transparent adhesive is perfect for repairing glassware or creating breathtaking glass crafts. It’s UV resistant and can withstand extreme temperatures.

Plastic glue, also known as plastic cement, is a must-have for anyone working with plastic materials. It chemically softens the plastic surfaces, allowing them to fuse when pressed together. Whether you’re building models or repairing plastic items, this glue has got you covered.

Last but not least, we have heat-activated glue. This adhesive transforms from liquid to solid as it cools down after being heated. Arts and crafts projects, DIY repairs, and packaging applications all benefit from the versatility of hot melt adhesive.

Different Forms of Glue

When it comes to bonding materials together, glue is our trusty sidekick. But did you know that not all glues are created equal? Different forms of glue exist, each with its own unique characteristics and areas of application. In this article, we will embark on an exciting journey through the world of glue, exploring the various types and their remarkable uses. So, grab your adhesive superhero cape, and let’s dive in.

Liquid Glue:

Liquid glue is the jack-of-all-trades in the adhesive universe. Whether you’re crafting a masterpiece or repairing a broken item, this adhesive superhero comes to your rescue. Available in bottles or tubes, liquid glue can be used on a wide range of surfaces such as paper, fabric, wood, and plastic.

Glue Sticks:

Glue sticks are every crafter’s best friend. Solid sticks of adhesive that are applied by rubbing them onto the surface, they are perfect for arts and crafts projects. With their child-friendly and mess-free nature, these sidekicks make crafting a breeze.

Spray Adhesive:

Need to bond large areas or tackle irregular surfaces? Enter spray adhesive, your go-to hero. Packaged in aerosol cans, this adhesive provides quick and even coverage. Just remember to use it in a well-ventilated area to avoid any sticky situations.

Epoxy Glue:

For tough bonding challenges, epoxy glue swoops in as the ultimate superhero. This two-part adhesive consists of a resin and hardener that, when mixed together, form an incredibly strong bond resistant to water, heat, and chemicals. Ideal for bonding metal, glass, ceramics, and rigid materials, epoxy glue is a must-have in any toolkit.

Hot Glue:

Hot glue is like the flash of the adhesive world – it dries quickly and provides a strong bond in a flash. Applied using a hot glue gun, this versatile adhesive is perfect for crafts, DIY projects, and minor repairs. With its fast-acting superpowers, hot glue will have your projects completed in no time.

Specialty Glues:

Just like superheroes have their unique powers, specialized glues come to the rescue for specific applications. Wood glue is designed specifically for bonding wood surfaces, while fabric glue ensures seamless adhesion of fabrics and textiles.

Water-based vs. Solvent-based Glues:

Glues can be either water-based or solvent-based. Water-based glues are easily cleaned up with water before they dry, making them convenient and mess-free. Solvent-based glues, on the other hand, require solvents or chemicals for cleanup but often offer superior bonding strength.

Also Read: Can I use normal glue to stick fabric?

Considerations for Choosing the Right Type of Glue

Choosing the right type of glue can make all the difference in the success and durability of your project. Here are some key considerations to keep in mind when selecting the perfect adhesive superhero for your needs:

- Purpose: Determine the specific purpose of the glue. Different glues are formulated for different applications, such as woodworking, fabric repairs, or bonding small items. Knowing the intended use will help you choose the appropriate type.

- Material compatibility: Consider the materials you will be bonding together. Some glues work better with specific materials. For example, epoxy resin is ideal for metal bonding, while hot glue is commonly used for plastics and ceramics. Choose a glue designed for the specific materials involved to ensure a stronger and more durable bond.

- Strength and durability: Evaluate the strength and durability requirements of your project. Some glues offer high strength and can withstand heavy loads, while others are designed for lighter applications or temporary bonds that allow for disassembly. Select a glue that matches your project requirements for a successful bond.

- Application method: Consider the ease of use and precision required for your project when selecting a glue with a suitable application method. Squeeze bottles, spray bottles, or applicator pens are all options to consider. Choose an application method that suits your needs.

- Drying time: Take into account the drying time of the glue. If you have time constraints or need to work quickly, opt for a glue that dries within minutes. However, if time is not a concern, you can choose a glue that requires several hours or even overnight to fully cure.

- Environmental factors: Consider the environmental conditions in which the glue will be used. Some glues are resistant to moisture, heat, or cold temperatures, making them suitable for outdoor or high-temperature applications. Select a glue that can withstand the conditions it will be subjected to.

- Safety considerations: Always prioritize safety when choosing a glue. Some adhesives emit strong fumes or contain hazardous chemicals. If you are working in a poorly ventilated area or have sensitivity to certain chemicals, look for glues that are labeled as non-toxic or low VOC to minimize health risks.

6qutTkJ4rO8″ >