Picture this: you’re knee-deep in a DIY project or trying to fix something around the house when you suddenly realize you’ve run out of electrical tape.

Cue the panic. How are you supposed to securely fasten those wires without it?

Well, take a deep breath and relax because I’ve got your back. While electrical tape is the go-to solution for many, there are actually several alternatives that can save the day.

In this blog post, we’re going to explore some creative substitutes for electrical tape that will come to your rescue in those unexpected moments. Whether you need a quick fix or a more long-term solution, these alternatives are readily available and might even offer some unique benefits.

So, let’s jump into the fascinating world of alternative options to electrical tape.

What is Electrical Tape and What Does It Do?

Contents

- 1 What is Electrical Tape and What Does It Do?

- 2 Heat Shrink Tubing: An Effective Alternative to Electrical Tape

- 3 Self-Fusing Silicone Tape: A Waterproof Seal for Electrical Connections

- 4 Zip Ties and Twist Ties: Quick Fixes for Loose Wires

- 5 Electrical Liquid Tape: A Protective Coating for Electrical Connections

- 6 Adhesive-Lined Heat Shrink Tubing: An Ideal Outdoor Solution

- 7 Electrician’s Tape and Friction Tape: Temporary Solutions

- 8 Considerations When Choosing an Alternative to Electrical Tape

- 9 Conclusion

In the realm of electrical installations and repairs, there exists a versatile and indispensable tool known as electrical tape. This adhesive wonder not only provides insulation but also offers protection, organization, and identification for a multitude of electrical connections. Join us on an enlightening journey into the world of electrical tape, as we unravel its composition, functions, and alternative options.

Composition and Types:

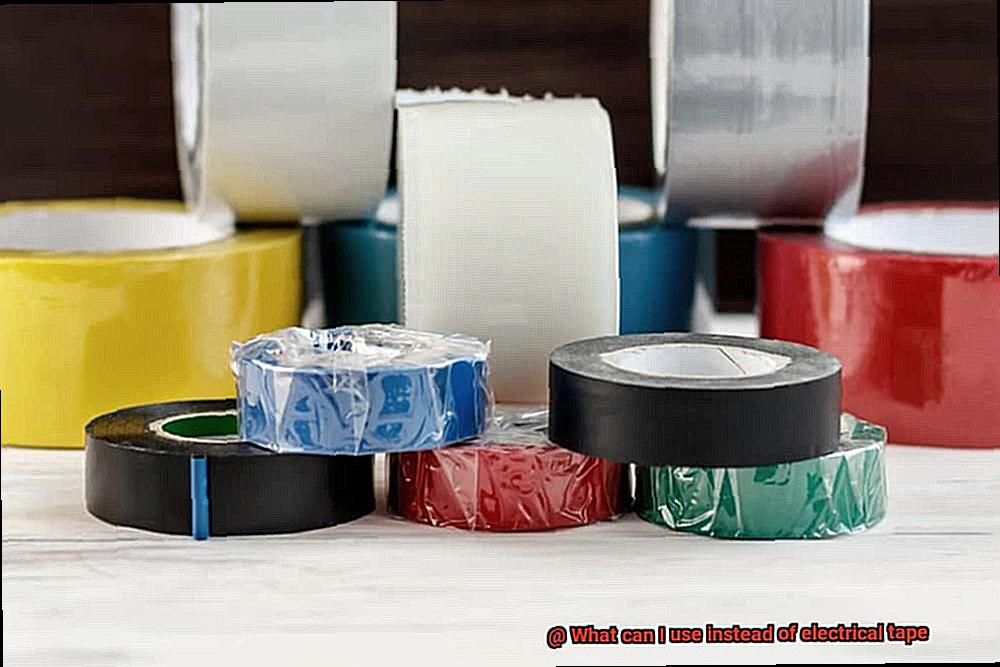

Crafted from thin and flexible vinyl or rubber materials, electrical tape possesses the remarkable ability to conform to the contours of wires and connections, creating a steadfast seal. With black being the prevailing hue, this tape comes in an array of colors, often employed to signify different voltage levels or phases within complex electrical systems.

Functions and Benefits:

- Electrical Insulation: The primary role of electrical tape is to bestow insulation upon connections. By impeding the flow of electricity between conductors, it effectively reduces the peril of short circuits or electrical shocks.

- Physical Protection: Acting as a guardian, electrical tape shields wires from potential harm caused by abrasion, moisture, and other hazards that lurk in the shadows. Its secure wrapping ensures a barrier against damage.

- Wire Bundling: A master of organization, electrical tape excels at bundling multiple wires together. By preventing tangling or accidental disconnections, it maintains order amidst the electrical chaos.

- Wire Marking: Through the creative utilization of various colors or patterns, electricians can employ electrical tape to effortlessly identify specific wires amidst intricate electrical systems.

Alternatives to Electrical Tape:

While electrical tape reigns supreme in its effectiveness, alternatives do exist:

- Heat Shrink Tubing: This magical tubing shrinks when exposed to heat and provides exceptional insulation and protection against moisture.

- Self-Fusing Silicone Tape: Exhibiting extraordinary bond strength, this tape fuses to itself once wrapped around a wire or connection, creating an impermeable seal.

Zip Ties or Twist Ties: Swift solutions for securing wires temporarily or for quick fixes.

- Electrical Liquid Tape: When applied directly to connections, this liquid compound metamorphoses into a protective coating, shielding against moisture and corrosion.

- Adhesive-Lined Heat Shrink Tubing: Boasting an adhesive lining, this tubing forms a formidable bond when heated, offering superb insulation and protection.

Heat Shrink Tubing: An Effective Alternative to Electrical Tape

Heat shrink tubing is not just a trendy alternative to electrical tape; it’s a durable and reliable solution that provides a tight and secure seal around your electrical connections. Let’s explore the research to delve into its many advantages.

Firstly, the durability of heat shrink tubing sets it apart from electrical tape. Unlike tape, which can loosen or unravel over time, heat shrink tubing maintains its integrity, offering excellent protection against moisture, chemicals, abrasion, and other environmental factors. This means less maintenance and longer-lasting results.

Additionally, heat shrink tubing boasts superior insulation properties. It not only helps prevent electrical shorts but also provides additional insulation in high voltage applications. With heat shrink tubing, you can trust that your wires are well-protected.

Installation couldn’t be easier. Simply slide the tubing onto the wire or cable and apply heat using a heat gun or similar tool. The tubing will shrink to fit tightly around the wire, creating a professional-looking finish.

Furthermore, heat shrink tubing offers better strain relief compared to electrical tape. It distributes stress along the length of the wire, reducing the risk of breakage or damage. This makes it an ideal choice for industries such as automotive, aerospace, marine, and electronics.

Now you might be wondering about cost-effectiveness. While heat shrink tubing may have a higher upfront cost compared to electrical tape, its long-term benefits make it a worthwhile investment. Its durability and reliability save you time and money over the long run.

Self-Fusing Silicone Tape: A Waterproof Seal for Electrical Connections

Attention DIYers and electricians. Are you tired of dealing with stubborn electrical connections that refuse to stay dry? Fear not, because self-fusing silicone tape is here to save the day. This incredible tape acts as a superhero, creating a waterproof seal around your electrical connections, shielding them from moisture and potential damage. Let’s explore the advantages and considerations of using this remarkable tape.

First and foremost, self-fusing silicone tape is designed to be completely waterproof. It forms a tight seal that keeps water and moisture at bay, ensuring the safety and longevity of your electrical connections. Not only that, but this tape is also highly resistant to extreme temperatures, capable of braving scorching heat and freezing cold without breaking a sweat. It’s like the Chuck Norris of tapes.

But wait, there’s more. Self-fusing silicone tape isn’t just waterproof and temperature-resistant; it’s also stretchy and flexible. This means it effortlessly conforms to irregular shapes and surfaces, making it a breeze to wrap around wires, cables, and other electrical components. And let’s not forget its impeccable electrical insulation properties. This tape creates a barrier between conductive materials, preventing short circuits and electrical shocks. Safety always comes first.

The application of self-fusing silicone tape is a piece of cake. Simply stretch the tape and tightly wrap it around the electrical connection. As you continue wrapping, the tape fuses to itself, creating a secure seal that can withstand exposure to sunlight, UV rays, chemicals–you name it. And when it’s time to remove the tape, worry not. It peels away cleanly without leaving behind any sticky residue or damaging the underlying surface.

Now, while self-fusing silicone tape is undeniably amazing, there are some factors to consider before using it. Always check the voltage rating, temperature range, and compatibility with specific materials before diving in. After all, you don’t want any shocking surprises.

Zip Ties and Twist Ties: Quick Fixes for Loose Wires

When it comes to securing loose wires, zip ties and twist ties are two ingenious solutions that can save you from a tangled mess. These trusty tools offer convenience, versatility, and ease of use. Let’s examine the advantages of each type and compare them, so you can determine which option is best for your needs.

Zip ties, also known as cable ties or wire ties, are sturdy and dependable. Made of durable nylon with a locking mechanism, they provide a secure hold once tightened. Here are some key benefits of using zip ties:

- Versatility: Zip ties come in a variety of sizes and colors, giving you the freedom to choose the perfect fit for your specific application.

- Ease of use: Installing a zip tie is a breeze. Simply thread it through the designated hole or loop on the wire or cable, pull it tight, and secure it by engaging the locking mechanism.

- Adjustability: Zip ties offer the flexibility to be quickly adjusted or removed if necessary. This makes them ideal for temporary fixes or situations where frequent adjustments are required.

- Neat appearance: Say goodbye to messy wires. Zip ties provide a tidy and organized look to wire bundles, making them a popular choice in automotive, electrical, and computer applications.

On the other hand, twist ties are like the chameleons of wire management. They consist of a flexible metal core covered with a plastic or rubber coating. Here are some advantages of using twist ties:

- Reusability: Twist ties can be undone and re-twisted whenever needed, making them a cost-effective option for securing loose wires.

- Flexibility: With their metal core, twist ties offer effortless bending and twisting around wires, ensuring a snug hold.

- Temporary fixes: While they may not provide as strong of a grip as zip ties, twist ties are perfect for quick fixes or situations where you need a temporary solution.

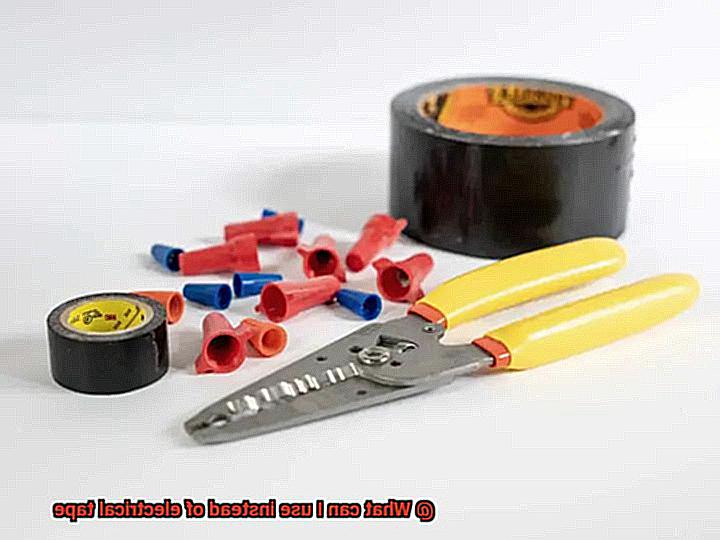

However, it’s crucial to remember that both zip ties and twist ties should be used with caution when securing live electrical wires. These tools are not designed to offer insulation or protection against electrical shocks. If you are working with live wires, it is highly recommended to use appropriate electrical tape or consult a professional electrician for safe solutions.

In summary, zip ties and twist ties are versatile alternatives to electrical tape when it comes to managing loose wires. Zip ties offer versatility, ease of use, adjustability, and a neat appearance. Twist ties provide reusability, flexibility, and convenience for temporary fixes. Consider the specific requirements of your situation and choose the option that suits you best.

Electrical Liquid Tape: A Protective Coating for Electrical Connections

Tangled wires and the potential hazards they bring are a constant annoyance. Luckily, there’s a superhero in the world of wire management: electrical liquid tape. This remarkable solution offers numerous advantages over traditional electrical tape, making it the go-to choice for safeguarding and insulating electrical connections.

Advantages of Electrical Liquid Tape:

Effortless Application:

Say goodbye to the tedious task of wrapping and stretching electrical tape around connections. With electrical liquid tape, all you need is a brush or dip to apply a seamless coating. It’s perfect for irregularly shaped or hard-to-reach connections, saving you time and effort.

Unyielding Seal:

Electrical liquid tape forms a rubbery coating that clings tightly to the surface. No more concerns about tape loosening or unraveling over time. This tight seal ensures long-lasting protection against moisture, dust, and other contaminants.

Exceptional Electrical Insulation:

Boasting high dielectric strength, electrical liquid tape can withstand high voltages without breaking down. Its versatility makes it ideal for a wide range of electrical applications, from household wiring to automotive repairs and electronics.

Resistance to Heat and Cold:

Extreme temperatures are no match for electrical liquid tape. It can endure scorching heat and freezing cold without cracking or melting, offering reliable protection in both indoor and outdoor environments. So whether it’s sweltering summer days or frigid winter nights, your electrical connections remain safe.

Versatility Redefined:

Electrical liquid tape comes in different formulations and colors, empowering you to choose the best option for your specific needs. Whether you require general-purpose protection or enhanced resistance against chemicals or UV radiation, there’s a formulation tailored to meet your requirements.

Adhesive-Lined Heat Shrink Tubing: An Ideal Outdoor Solution

Adhesive-lined heat shrink tubing is here to save the day as the ideal solution for all your outdoor wiring needs.

So what makes adhesive-lined heat shrink tubing so special? Let’s dive into its amazing benefits:

Firstly, adhesive-lined heat shrink tubing provides an unbeatable barrier against the elements. With its adhesive lining and polyolefin material, this tubing ensures protection against moisture, dust, and other environmental factors. Say goodbye to corrosion and damage caused by exposure to the elements.

Secondly, this tubing is designed to withstand extreme weather conditions. Whether it’s scorching hot or freezing cold, adhesive-lined heat shrink tubing can handle it all. Its resilience to extreme temperatures, UV exposure, and harsh weather conditions ensures that your wires will remain safe and secure, regardless of what Mother Nature throws at them.

Additionally, the adhesive lining creates a strong bond with the wires or cables, ensuring a secure and long-lasting connection. You can have peace of mind knowing that your electrical connections are protected and won’t come loose.

Furthermore, installing adhesive-lined heat shrink tubing is a breeze. Simply slide it over the wires or cables and apply heat using a heat gun or other heat source. The tubing will shrink tightly around the wires, creating a waterproof and durable seal. It’s as easy as that.

Moreover, adhesive-lined heat shrink tubing is highly versatile. It comes in various sizes and colors, making it suitable for different wire gauges and applications. Whether you’re working on automotive, marine, or outdoor electrical installations, this tubing has got you covered.

Apart from providing insulation and protection, adhesive-lined heat shrink tubing also helps to organize and bundle wires neatly. No more messy tangles.

Electrician’s Tape and Friction Tape: Temporary Solutions

When it comes to electrical work, choosing the right materials is crucial for safety and effectiveness. Electrician’s tape and friction tape are commonly used as temporary solutions. While they have their benefits, it is important to understand why they are not suitable for long-term use. In this article, we will explore the reasons why electrician’s tape and friction tape should only be used as temporary solutions.

Electrical Insulation Properties:

Electrician’s tape, also known as vinyl tape or PVC tape, is made from durable and flexible vinyl material. It provides excellent electrical insulation properties, making it ideal for securing wire connections. Friction tape, made from cloth or fabric material coated with adhesive, can also provide temporary insulation for low-voltage electrical connections.

Heat Resistance:

While electrician’s tape has good heat resistance, it is not as heat-resistant as electrical tape. When exposed to high temperatures, it may melt or degrade, compromising its effectiveness in insulating wires. Similarly, friction tape is not designed to withstand extreme heat and may lose its adhesive properties when exposed to high temperatures.

Durability and Environmental Factors:

Both electrician’s tape and friction tape are not designed for long-term exposure to moisture, UV rays, or other environmental factors that can cause degradation over time. They may become less effective and lose their adhesive properties when exposed to these elements, potentially leading to safety hazards.

Monitoring and Replacement:

When using electrician’s tape or friction tape as temporary solutions, it is essential to regularly monitor their condition. Check for signs of wear, damage, or degradation and address them promptly. As soon as possible, replace these temporary solutions with more suitable permanent options that can withstand long-term use.

Considerations When Choosing an Alternative to Electrical Tape

When it comes to electrical work, finding the right materials is essential for safety and durability. While electrical tape has been a go-to solution for many, it’s important to consider alternatives that can provide a long-lasting and reliable solution. In this article, we will explore the key factors to keep in mind when choosing an alternative to electrical tape.

Temperature Resistance:

To ensure the alternative can handle the heat generated by electrical currents, look for options labeled as heat-resistant or those with a high temperature rating.

Insulation Properties:

Ensure the alternative offers similar insulation properties to protect against electrical hazards and maintain the integrity of your wiring.

Adhesive Strength:

Select an alternative with a strong adhesive specifically designed for electrical applications to ensure a secure and long-lasting bond.

Flexibility and Conformability:

Choose alternatives that offer flexibility and conformability to ensure easy wrapping around wires of different shapes and sizes.

Durability:

Opt for alternatives that are resistant to tearing, puncturing, and degradation over time to guarantee a long-lasting solution.

Safety Certifications:

Always ensure that any alternative you choose meets safety standards and certifications for electrical applications.

Compatibility with Electrical Systems:

Consider the compatibility of the alternative with your specific electrical systems. Consult professionals or manufacturers to determine which alternative is best suited for your needs.

Conclusion

In conclusion, don’t fret when you run out of electrical tape in the midst of a project. Take a deep breath and explore the plethora of alternatives that can swoop in to save the day and securely fasten those wires.

One such hero is heat shrink tubing. This mighty alternative boasts durability, superior insulation properties, effortless installation, and impeccable strain relief. Sure, it may have a slightly higher price tag upfront, but its long-term benefits make it a worthy investment that won’t let you down.

If you’re seeking an alternative with superpowers against moisture and potential damage, look no further than self-fusing silicone tape. This remarkable option forms a waterproof seal around electrical connections, shielding them from harm while effortlessly conforming to any irregular shapes or surfaces thanks to its stretchiness and flexibility.

For those moments when time is of the essence and loose wires are causing chaos, zip ties and twist ties come to the rescue as quick fixes. Zip ties bring versatility, ease of use, adjustability, and a tidy appearance to the table. Meanwhile, twist ties offer reusability and flexibility for temporary solutions that get the job done.

But wait. There’s more. Enter electrical liquid tape – your knight in shining armor. With its effortless application process and unwavering seal against moisture and contaminants, this protective coating ensures exceptional insulation properties while standing strong against heat, cold, and whatever else comes its way. Plus, it comes in various formulations to suit your specific needs.

If your project ventures into the great outdoors where Mother Nature can be relentless, adhesive-lined heat shrink tubing is your savior. Providing protection against even the harshest elements and extreme weather conditions, this alternative forms an unbreakable bond with wires or cables while offering easy installation options in various sizes and colors.

Now here’s something you should know: electrician’s tape and friction tape may be suitable for temporary fixes due to their insulation properties. However, they aren’t the best long-term options as they may degrade over time when exposed to heat or other environmental factors. So, proceed with caution.

When selecting an alternative to electrical tape, be sure to consider a few key factors: temperature resistance, insulation properties, adhesive strength, flexibility and conformability, durability, safety certifications, and compatibility with your specific electrical systems. It’s important to choose wisely for optimal results.