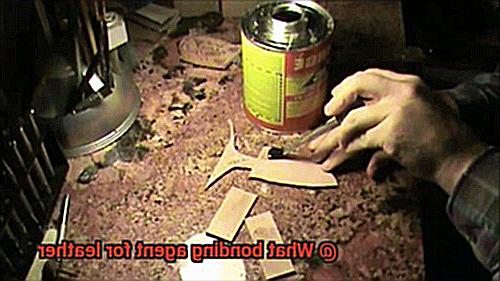

Picture this: the sensuous touch of a supple leather jacket, or the sleek feel of a premium leather handbag. Leather has always held us captive with its elegance and durability. But have you ever wondered what keeps this magical material together? Today, we’re diving into the realm of leather bonding agents, revealing the secret behind the creation of your favorite leather goods.

Think about that one cherished leather possession that has weathered time and still looks as vibrant as ever. Its incredible endurance isn’t just a testament to top-notch craftsmanship; it’s also thanks to the magic woven by the right bonding agent.

In this article, we’ll take an in-depth plunge into the world of leather bonding agents. We’ll explore the vital ingredients that forge an unbreakable connection between leather fibers. Prepare to uncover the captivating chemistry behind these bond enhancers and learn about innovative techniques used to ensure a seamless union.

Join us as we unravel the mysteries behind bonding agents specially crafted for leather. Discover their countless applications, from revamping automotive and furniture upholstery to adding elegance to fashion accessories. We’ll delve into different types of bonding agents available – adhesives, sealants, and compounds – shedding light on their unique strengths and weaknesses.

So whether you’re a die-hard leather aficionado or simply intrigued by the science behind our beloved possessions, buckle up for an extraordinary journey unlocking the secrets of leather bonding agents. Get ready to witness the triumphant bond that guarantees our leather goods endure through time’s relentless test.

Types of Bonding Agents for Leather

Contents

- 1 Types of Bonding Agents for Leather

- 2 Advantages of Contact Cement

- 3 Benefits of Epoxy Adhesive

- 4 Pros and Cons of Polyurethane Adhesive

- 5 Water-Based Adhesives for Delicate Leathers

- 6 Specialized Adhesives for Specific Applications

- 7 Factors to Consider When Choosing a Bonding Agent

- 8 Testing the Bonding Agent Before Application

- 9 Conclusion

Whether you’re an artisan crafting exquisite leather goods or a DIY enthusiast seeking to repair your beloved leather items, this article will unveil the secrets behind different types of bonding agents and their remarkable applications.

Contact Cement: The Mighty Titan of Bonds

Imagine a titan forging an unbreakable bond with a mighty swing of its hammer – that’s contact cement. This formidable adhesive creates an instant and robust bond when applied to both surfaces and joined together.

Its strength and flexibility make it an ideal choice for various leather applications, including shoe repair, upholstery, and the art of leather crafting. With contact cement in your arsenal, you can fearlessly conquer any bonding challenge.

Epoxy Adhesive: The Indomitable Guardian

Seeking a bond that can withstand the test of time and adversity? Look no further than epoxy adhesive, the indomitable guardian of bonds. This exceptional adhesive comprises two components – a resin and a hardener – that combine to form an unyielding chemical bond.

With outstanding resistance to high temperatures, moisture, and chemicals, epoxy is often chosen for industrial applications such as constructing robust leather goods like belts, wallets, and bags.

Polyurethane Adhesive: The Resilient Maestro

When it comes to bonding leather materials with unwavering strength and flexibility, polyurethane adhesive takes center stage as the resilient maestro. Widely used in the footwear industry for shoe sole attachment and the production of leather garments and accessories, polyurethane adhesives offer unmatched durability.

They withstand constant flexing and stretching without compromising the integrity of the bond, ensuring your creations can gracefully weather any storm.

Cyanoacrylate: The Instant Fusion Sorcerer

Behold cyanoacrylate, the sorcerer of instant fusion and quick repairs. Also known as super glue or instant glue, cyanoacrylate adhesives create an immediate bond upon exposure to moisture in the air.

While it may not boast the same strength as other types of adhesives, cyanoacrylates are ideal for small leather projects and urgent fixes. With the wave of your wand, this magical adhesive swiftly mends your leather treasures.

Rubber Cement: The Versatile Craftsman’s Ally

For the crafters seeking flexibility and temporary bonds, rubber cement emerges as a versatile ally. This adhesive allows for repositioning or disassembly when needed, making it perfect for attaching patches, labels, or decorative elements to leather goods.

Applied to both surfaces and left to dry before joining them, rubber cement provides a flexible and removable bond that adds a touch of artistry to your leather projects.

Advantages of Contact Cement

Today, we delve into the captivating world of contact cement and explore its extraordinary advantages when it comes to bonding leather. From its exceptional bonding strength to its water resistance properties, contact cement is a mighty ally in the realm of leather crafting and repair. So grab your tools, buckle up, and let’s embark on this exciting journey.

Strong Bonding:

Contact cement is the Hercules of adhesives, renowned for its exceptional bonding strength. It creates a strong and durable bond between leather surfaces, ensuring that they stay firmly together even under stress or pressure.

Whether you’re repairing a beloved handbag or creating a custom belt, contact cement provides the confidence that your project will stand the test of time.

Versatility:

Leather comes in various forms, from genuine leather to faux leather and everything in between. The beauty of contact cement lies in its versatility – it adheres effortlessly to different types of leather, including suede and bonded leather. This adaptability makes it a go-to choice for a wide range of leather applications such as shoe repairs, upholstery projects, and even crafting leather accessories.

Quick Drying Time:

Time is precious, especially when you’re knee-deep in a leather project. That’s where contact cement shines with its quick drying time.

Once applied to the leather surfaces and allowed to dry for a few minutes, it forms a tacky surface that can be joined together. No more waiting around for hours – with contact cement, you can get back to your creative endeavors in no time.

Heat Resistance:

Imagine crafting a stunning car seat cover or designing unique kitchenware accessories made from leather. With contact cement’s excellent heat resistance once fully cured, your creations won’t fall apart under the heat of the moment. It ensures that bonded leather items can handle high temperatures or hot objects without compromising their integrity. So go ahead and create leather wonders that can withstand the heat.

Water Resistance:

Leather and water don’t always mix well, but contact cement has got your back. Once fully cured, it forms a waterproof bond that shields your precious leather projects from moisture damage. Whether you’re crafting a wallet that braves rainy days or repairing a pair of water-exposed boots, contact cement ensures that your creations stay dry and beautiful, even in wet conditions.

Benefits of Epoxy Adhesive

In our previous adventure, we explored the incredible world of contact cement and its remarkable bonding abilities. But today, we’re going to dive into a different realm and discuss the benefits of using epoxy adhesive for all your leather bonding needs. Trust me; this is one journey you won’t want to miss.

Unbreakable Bonds: Indestructible Connections

When it comes to creating unbreakable bonds with leather, epoxy adhesive takes the crown. Its exceptional strength and durability make it a favorite among leather craftsmen and manufacturers alike. From furniture upholstery to exquisite leather shoes, epoxy forms a chemical bond that withstands the test of time.

Versatility: Conquer All Leather Types and Textures

Leather comes in countless textures and types, but fear not – epoxy adhesive is here to conquer them all. Whether it’s genuine leather, synthetic alternatives, suede, or even exotic leathers like snakeskin or crocodile skin, epoxy can bond them effortlessly. Smooth or textured surfaces? No problem. Epoxy adhesive tackles them all with ease, giving you the freedom to explore various leather bonding applications.

Heat and Moisture Resistance: Brave the Elements

Leather products often face their fair share of heat and moisture challenges. But fear not – epoxy adhesive is up to the task. It boasts excellent resistance to high temperatures, ensuring that your bonded leather stays intact even in scorching conditions. And when it comes to humidity or wet environments, epoxy’s water resistance properties keep your leather bonds strong and unaffected by moisture.

Chemical Resistance: Say Goodbye to Worries

Leather can encounter various chemicals over its lifespan – from cleaning agents to oils and solvents. But with epoxy adhesive, you can bid farewell to worries about discoloration or weakening bonds. Its impressive chemical resistance ensures that your leather remains unharmed by these substances, maintaining the integrity of your bonds for years to come.

Flawless Perfection: Bonding Imperfections Erased

Sometimes, leather surfaces aren’t perfectly even or smooth. But fear not – epoxy adhesive has your back. It excels in gap-filling, effortlessly filling in voids, gaps, or imperfections in the leather. This ensures a flawless and aesthetically pleasing bond that showcases your leather creations in all their glory.

Pros and Cons of Polyurethane Adhesive

Today, we embark on an exhilarating journey into the realm of polyurethane adhesive and its myriad pros and cons when it comes to bonding this luxurious material. As a seasoned expert, I have delved deep into the recesses of knowledge to present you with a captivating and enlightening guide. So, grab your favorite beverage, settle in, and let us commence this riveting exploration.

Pros:

Unyielding Bonding Strength:

Prepare to be amazed by the awe-inspiring bonding strength of polyurethane adhesive. This extraordinary adhesive forms an unbreakable alliance with leather, ensuring that your creations remain intact even under the most demanding circumstances. From regal leather furniture to stylish shoes and bags, rest assured that this adhesive will exceed your expectations in durability and longevity.

Flexibility Unleashed:

Banish rigidity from your bonded leather projects with the unparalleled flexibility of polyurethane adhesive. Even after curing, this adhesive maintains its supple nature, allowing your leather to retain its natural movement and flexibility.

Whether you desire shoes that dance with your every step or accessories that gracefully adapt to your whims, polyurethane adhesive is your steadfast ally.

Impervious to Moisture and Chemical Assaults:

Shield your cherished leather creations from the perils of moisture with the impenetrable armor of polyurethane adhesive. This exceptional adhesive establishes a waterproof barrier that repels water and other liquids, safeguarding your leather from unsightly damage.

Furthermore, it fearlessly withstands exposure to the harsh chemicals found in cleaning agents and environmental factors without compromising its bond strength.

Cons:

The Art of Precision Application:

Polyurethane adhesive demands a deft touch when it comes to application techniques. Unlike more forgiving adhesives, this one requires meticulousness and precision. Failure to execute proper application may result in uneven spreading or excessive glue residue, potentially marring the appearance and quality of your bonded leather. Remember, adherence to the manufacturer’s instructions and mastery of application techniques are crucial for optimal results.

Water-Based Adhesives for Delicate Leathers

Today, we embark on an exciting journey into the realm of water-based adhesives and their extraordinary potential for delicate leathers. So, grab your favorite beverage and prepare to be captivated by the wonders of these gentle yet formidable bonding agents.

Gentle and Non-Toxic:

When it comes to handling delicate leathers, nothing is more important than treating them with utmost care. Enter water-based adhesives, crafted with water as a solvent. Bid farewell to harsh chemicals and embrace the eco-friendly and user-safe nature of these remarkable adhesives.

Strong Bond, No Compromise:

Delicate leathers demand perfection, and water-based adhesives deliver just that. With their low viscosity, these adhesives effortlessly permeate the intricate fibers of the leather, forging an unbreakable bond that remains invisible to the discerning eye. No more sacrificing quality or aesthetics for a steadfast hold.

Flexibility that Embraces Suppleness:

Preserving the natural suppleness of delicate leathers is a daunting task. Fortunately, water-based adhesives rise to the challenge. Unlike their solvent-based counterparts, which can stiffen the leather, these gentle adhesives allow your beloved leather to flex and stretch with ease, all while keeping it unscathed.

Speedy Production, Swift Results:

In the fast-paced world of leather craftsmanship, time is a precious commodity. Fear not. Water-based adhesives come to the rescue with their lightning-fast drying time. Bid farewell to tedious waiting periods – these adhesives will have you swiftly progressing through your projects in mere minutes.

Compatibility Matters:

While water-based adhesives are a dream come true for delicate leathers, it is vital to ensure compatibility with specific types of leather. Porosity and surface finishes can influence adhesive effectiveness, so a small test on an inconspicuous area is wise before embarking on a grand bonding endeavor. Better safe than sorry.

Specialized Adhesives for Specific Applications

When it comes to bonding leather, the choice of adhesive is critical. Specialized adhesives are designed to meet the unique requirements of different materials and applications. In this article, we will delve into the world of specialized adhesives for specific leather applications. From contact cement to epoxy, polyurethane to solvent-based adhesives, we’ll explore the options and highlight the importance of proper surface preparation.

Contact Cement: A Flexible Solution

Contact cement is a go-to choice for bonding leather due to its exceptional flexibility and resistance to temperature changes. This adhesive creates a strong bond when two surfaces are pressed together. Applying contact cement to both the leather and substrate, allowing it to dry, and then firmly pressing them together ensures optimal results. Remember to test compatibility before scaling up the project.

Epoxy Adhesives: Strength and Durability

When maximum strength and durability are required, epoxy adhesives come to the rescue. They create bonds that can withstand heavy loads and extreme conditions. However, not all types of leather are suitable for epoxy adhesives due to natural oils or finishes that may interfere with the bonding process. Conducting a small-scale compatibility test is crucial for success.

Polyurethane Adhesives: Adaptability at Its Best

For leather applications exposed to varying environmental conditions, polyurethane adhesives offer unparalleled flexibility and moisture resistance. Available in liquid or paste form, these adhesives allow for versatile application methods depending on your specific needs.

Solvent-Based Adhesives: Delicate Solutions

Delicate or thin leathers require special attention, making solvent-based adhesives an excellent choice. With their low viscosity, these adhesives penetrate the porous structure of the leather, creating strong bonds without adding bulk or stiffness. While longer drying times might be necessary, the impeccable results make it worthwhile.

Proper Surface Preparation: The Foundation for Success

In achieving successful bonding with leather, proper surface preparation is paramount. Ensure the leather surface is clean, dry, and free from any contaminants or finishes that may hinder adhesion. By laying this foundation, you set the stage for a robust and reliable bond.

Factors to Consider When Choosing a Bonding Agent

Choosing the right bonding agent for leather can make all the difference in creating strong and durable bonds. With numerous options available, it’s crucial to consider several factors before making your selection. Here are the key factors to keep in mind when choosing a bonding agent for leather:

- Adhesive Strength: The adhesive strength of the bonding agent is of utmost importance. Leather’s smooth and non-porous surface poses a challenge when it comes to bonding. To ensure a long-lasting bond, opt for adhesives specifically designed for leather that offer high tensile strength and excellent adhesion. Look for adhesives known for their strong bonding properties.

- Flexibility: Leather is a flexible material that can bend and stretch. Therefore, it’s vital to choose a bonding agent that can accommodate these movements without compromising the bond. Select adhesives that offer flexibility and elasticity, allowing the leather to retain its natural characteristics while maintaining a secure bond. This factor is particularly crucial if the bonded leather will experience frequent movement or stress.

- Drying Time: The drying time of the bonding agent is another factor to consider. Some adhesives may require longer drying times, which can be inconvenient for time-sensitive projects. Conversely, quick-drying adhesives may limit your working time, making it challenging to position and adjust the leather pieces before they set. Assess your project’s requirements and choose an adhesive with an appropriate drying time.

- Compatibility: Ensure that the bonding agent is compatible with both the type of leather you’re using and any other materials or surfaces involved in your project. Different types of leather have varying properties, such as porosity or surface finishes.

If you’re bonding leather to other materials like fabric or metal, verify that the adhesive is suitable for multi-material bonding. Always test the compatibility of the bonding agent on a small, inconspicuous area of the leather before proceeding with the full application.

- Safety and Environmental Impact: Consider the safety and environmental impact of the bonding agent. Look for adhesives that are non-toxic, solvent-free, and low in volatile organic compounds (VOCs). These features not only ensure your safety but also contribute to a healthier environment. Additionally, be aware of any specific storage or handling requirements that the adhesive may have.

Testing the Bonding Agent Before Application

Embarking on a leather project is like embarking on a grand adventure – filled with excitement, creativity, and the promise of a masterpiece. However, before you set sail on this leather voyage, there is one crucial step that ensures your success: testing the bonding agent.

In this captivating journey, we will explore the significance of testing and unveil the secrets to effectively testing your bonding agent, guaranteeing an unbreakable bond for your leather creation.

Why Testing is Essential:

- Compatibility and Effectiveness: Leather, with its delicate and unique nature, demands a bonding agent that harmonizes flawlessly. Testing the bonding agent beforehand shields your leather from potential damage or adverse effects. It ensures that the bonding agent chosen will provide the strength needed without compromising the integrity and natural allure of the leather.

- Unearthing Discoloration and Damage: By selecting a hidden realm within your leather realm for testing purposes, you safeguard its exquisite beauty. This concealed oasis allows you to expose any potential discoloration or damage during the testing process before applying the bonding agent to your entire endeavor.

How to Master the Art of Testing:

- Seek Out an Inconspicuous Realm: Venture deep into your leather kingdom and select an unseen territory for testing. The backside or inner seam offer refuge for this clandestine exploration.

- Purify Your Realm: With utmost care, cleanse the chosen territory using a mild leather cleaner or soap and water. This purification ritual eradicates any dirt, oils, or residues that may disrupt the bonding agent’s prowess.

- A Brushstroke of Promise: Like an artist with his brush, apply a small amount of the bonding agent to your cleansed domain using a pristine brush or applicator. Honor the manufacturer’s sacred instructions regarding application techniques and quantities.

- The Dance of Patience: Allow the bonding agent to dance its way into perfection by granting it ample drying time. Respect the product label’s commandments and let it dry completely, allowing the bond to form with unwavering strength.

vHdGnGuGptY” >

Conclusion

When it comes to finding the perfect bonding agent for leather, there are a few options to consider.

One popular choice is leather glue, which provides a strong and durable bond that can withstand everyday wear and tear. Another option is contact cement, known for its quick drying time and ability to create a long-lasting bond.

Whichever bonding agent you choose, make sure to follow the manufacturer’s instructions for best results.