Have you ever marveled at the flawless bonds of acrylic and wondered how it’s done? Well, get ready for an adventure that will reveal the secrets behind this mesmerizing artistry. Together, we’ll dive into the world of acrylic bonding and discover its infinite possibilities.

Imagine this: You’ve got a breathtaking acrylic sculpture, a stunning display case, or even a practical fish tank that needs assembling – but where do you start? Fear not. We’re about to unveil the key to achieving jaw-dropping connections and rock-solid bonds that will leave everyone in awe.

Acrylic, also known as Plexiglas or Perspex, is a versatile material cherished by artists, architects, designers, and DIY enthusiasts alike. But what’s the secret behind its magical bond? The answer lies in an extraordinary range of adhesive options at your fingertips.

From renowned chemical marvels like cyanoacrylate and epoxy adhesives to hidden gems like solvent cements and UV-curable resins, there are countless ways to bond acrylic. These adhesives work their magic on everything from sheets and rods to intricate shapes and artistic wonders.

In this thrilling journey, we’ll delve deep into each adhesive type’s unique characteristics – exploring their strengths, applications, and limitations. Get ready to unlock the secrets of crystal-clear joints, invisible seams, and unyielding bonds that stand the test of time.

So strap yourselves in tight because we’re embarking on an eye-opening adventure together. Let’s unravel the enchanting world of acrylic bonding and unleash your creative potential like never before.

What is Acrylic?

Contents

Prepare to be amazed by the world of acrylic, a remarkable plastic derived from acrylic acid and related compounds. This extraordinary material has revolutionized various industries with its transparency, strength, and durability. From glass-like appearances to lightweight advantages, acrylic offers an array of benefits that cater to professionals and DIY enthusiasts alike. Join us as we delve into the captivating realm of acrylic, exploring its properties, applications, and the art of bonding.

Properties and Advantages of Acrylic:

Transparency and Clarity:

Step into a world of crystal-clear wonder as acrylic rivals the transparency of glass. From display cases to windows and protective barriers, this material boasts exceptional optical properties that ensure unobstructed visibility.

Lightweight and Resilient:

Leave behind the fragility of glass as acrylic presents a safer alternative. Its lighter weight and reduced risk of breakage make it an ideal choice for environments prone to accidents or impact. With unrivaled durability, acrylic extends its longevity to applications spanning from furniture to automotive components.

Moldability Magic:

Witness the transformative powers of acrylic as it effortlessly takes on different shapes and forms. Whether extruded into sheets, rods, or tubes, this material becomes a playground for creative minds in industries like architecture and signage. Brace yourself for limitless design possibilities.

Defying the Sun’s Wrath:

Unlike its plastic counterparts, acrylic fearlessly withstands the test of time under the sun’s harsh rays. Its unwavering resistance to UV radiation ensures lasting transparency and strength, making it an excellent choice for outdoor applications such as signage or protective barriers.

Chemical Warrior:

Enter the realm of laboratories and industrial settings where chemicals lurk. Fear not. Acrylic’s remarkable chemical resistance shields it from deterioration or adverse reactions when exposed to various substances. It proudly stands as a reliable ally in these demanding environments.

Applications of Acrylic:

Architecture and Construction:

Watch as acrylic gracefully weaves its way into architectural masterpieces. From skylights that illuminate spaces with a touch of elegance to energy-efficient greenhouses, this versatile material offers durability and seamless design possibilities.

Automotive Industry:

Embark on a journey through the automotive world, where acrylic takes center stage in headlight lenses, dashboards, and interior panels. Its lightweight nature and impact resistance make it a preferred choice for manufacturers driving innovation forward.

Advantages of Bonding Acrylic

Embark on a captivating journey into the realm of acrylic, where creativity and durability intertwine. In this exhilarating adventure, we delve into the art of bonding acrylic and uncover its myriad advantages. Brace yourself for a thrilling exploration of seamless aesthetics, unwavering strength, limitless design possibilities, impenetrable resistance, and cost-effective solutions. Prepare to be enchanted by the enchanting world of bonding acrylic.

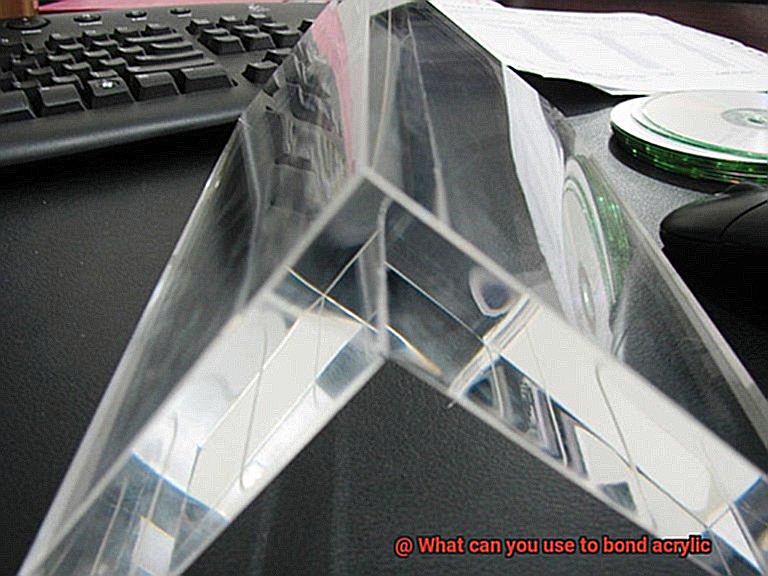

Advantage 1: Seamless and Invisible Bonding

Step into a world where joints vanish, leaving behind a flawless illusion of a single solid piece. With the power of bonding acrylic, witness the transformation as the joint between acrylic pieces becomes nearly invisible. This seamless appearance is a dream come true for applications where aesthetics take center stage, such as displays, signage, and architectural structures. Bid farewell to unsightly seams and embrace the allure of invisibility.

Advantage 2: Unyielding Strength and Longevity

In a world where fragility lurks around every corner, bonding acrylic emerges as an unwavering fortress. Unlike mechanical fasteners or adhesives that may weaken over time or succumb to harsh environmental conditions, properly bonded acrylic joints possess an exceptional ability to withstand substantial stress. Whether in automotive components or aircraft windows, bonding acrylic ensures structural integrity that endures the test of time. Witness strength and longevity that defy expectations.

Advantage 3: Boundless Flexibility and Versatile Design

Set your imagination free as bonding acrylic unlocks a treasure trove of design possibilities. While acrylic itself is known for its versatility, bonding multiple acrylic pieces together takes creativity to new heights. Embrace the freedom to create complex structures with ease, revolutionizing innovative designs and enabling unique applications. From captivating sculptures to futuristic furniture, bonding acrylic empowers you to transform visions into reality.

Advantage 4: Impervious to Moisture and Chemicals

In a world where liquid foes and chemical adversaries threaten to corrode, bonding acrylic emerges as a formidable shield of protection. While acrylic boasts excellent resistance to moisture and most chemicals, mechanically fastening acrylic pieces can create vulnerable gaps. Fear not. By bonding acrylic, these joints are hermetically sealed, preventing infiltration of liquids or chemicals that could harm the material or compromise performance. With bonding acrylic, your creations remain impervious to the elements.

Specialized Acrylic Adhesives/Glue

Prepare to be amazed as we delve into the various forms, advantages, and considerations of these incredible bonding solutions.

Let’s start by uncovering what makes specialized acrylic adhesives so extraordinary. These gems are meticulously crafted to form an unbreakable bond between acrylic surfaces. Whether you’re tackling a DIY project or working in an industrial setting, these adhesives are your secret weapon.

Now, let’s explore the dazzling array of forms that specialized acrylic adhesives come in. We’ve got liquids, pastes, and tapes – each with its own unique powers. Liquids reign supreme when it comes to joining smooth surfaces. With different viscosities to choose from, you’ll have complete control during application. Plus, they dry in a flash and create an invisible bond, making your project look flawlessly seamless.

If you’re dealing with rough or porous surfaces, paste adhesives are here to save the day. With their thicker consistency, they effortlessly fill gaps and provide extra strength to the bond. Just be prepared to exercise a little more patience during the curing process – it’ll be worth it.

But wait, there’s more. For those seeking the ultimate convenience, enter acrylic adhesive tapes. These all-in-one wonders feature adhesive properties on both sides, simply peel off the protective backing and voila. They’re perfect for lightweight components or when you need a temporary fix in record time.

Before you embark on your adhesive adventure, let’s cover a few essential tips. First things first, ensure your surfaces are sparkling clean and free from any dirt or grease. A gentle wipe with a mild solvent or specialized acrylic surface cleaner will do the trick.

Now, get ready to follow the manufacturer’s instructions like a pro. Each adhesive may have specific requirements for application and curing. Some might demand ideal temperature or humidity conditions for peak bonding performance. So be sure to dive into those instructions with gusto.

One of the superpowers of specialized acrylic adhesives is their unwavering resistance to weathering, UV radiation, and moisture. This means they can conquer both indoor and outdoor applications with ease. Just remember to consider the unique demands of your project and select an adhesive compatible with its intended environment.

Solvent-Based Cements

Prepare to embark on a mesmerizing journey into the world of solvent-based cements, where acrylic materials are united in a dance of extraordinary bonding. These cements possess an enchanting ability to dissolve the surface of acrylic, allowing it to merge seamlessly with another piece. Picture the surface softening, like a shimmering mirage, as the cement’s solvent evaporates, leaving behind a bond that is strong and unyielding.

In the realm of solvent-based cements, one name reigns supreme: methyl methacrylate (MMA) cement. This extraordinary adhesive consists of two parts – a liquid resin and a powdered activator. When these elements combine, a chemical reaction occurs, transforming the cement into a force to be reckoned with. Its power lies in its ability to harden and create unbreakable connections between acrylic pieces. From delicate crafts to massive structural projects, MMA cement delivers a bond that can withstand the test of time.

But wait, there’s more magic to be found in the world of solvent-based cements. Enter chloroform adhesive – a true marvel known for its rapid-drying properties and exceptional bonding strength. With chloroform as its secret ingredient, this adhesive works swiftly to dissolve the acrylic surface, creating a bond that appears almost instantaneously. When time is of the essence and security is paramount, chloroform adhesive is the spell you need.

Of course, no magical endeavor would be complete without proper precautions. Solvent-based cements demand respect and caution. Their volatile nature requires careful handling to avoid harm. To ensure your safety, work in a well-ventilated area or summon your protective gear – gloves and goggles will shield you from their potent effects. Remember, safety is the first enchantment to master.

Now, let us delve into the art of preparation – an essential step before casting your adhesive spell. Cleanliness is key; cleanse your acrylic surfaces of any dirt, oil, or debris that may mar the bond. And just like an expert sorcerer, a touch of sanding can create a textured canvas, amplifying the adhesion between the acrylic pieces. It is as if you are creating the perfect backdrop for your adhesive magic to unfold.

Mechanical Methods for Bonding Acrylic

Get ready to unlock the secrets of bonding acrylic with mechanical methods that will leave you amazed. These techniques use physical forces and mechanisms to create strong and permanent connections, without relying on adhesives or chemical processes. Let’s dive in and explore the fascinating world of mechanical bonding for acrylic.

One method that never fails to impress is using screws or bolts. By drilling holes into the acrylic pieces and securing them together with screws or bolts, you can achieve a reliable bond. Remember to make the holes slightly larger than the diameter of the fasteners to allow for expansion and contraction with temperature changes. And be sure to handle your drilling tools with care to avoid any cracks or damage to the delicate acrylic surface.

If you’re looking for an exciting bonding experience, rivets are your go-to solution. These fasteners consist of a cylindrical shaft with a head on one end and a tail on the other. To bond acrylic using rivets, simply drill holes into the pieces and insert the rivets through them. Then, deform or “buck” the tail end of the rivet to secure it in place, creating a bond that can withstand even the toughest challenges. Riveting is ideal when you need a joint with exceptional strength and durability.

But wait, there’s more. Clamps and brackets come to the rescue when dealing with larger or irregularly shaped acrylic pieces. Clamps act as magical hands, holding the acrylic pieces together while they are being bonded. They provide the necessary pressure and ensure a tight fit between the surfaces. On the other hand, brackets are like trusty assistants that can be attached to the edges of acrylic pieces, holding them together at specific angles or positions. These methods offer flexibility and convenience in bonding complex acrylic structures.

Now, let’s turn up the heat. Heat can also be used as a mechanical method for bonding acrylic through solvent welding. Imagine heating the edges of the acrylic pieces until they soften, and then pressing them together to create a bond that is both strong and seamless. Solvent welding requires precise control of temperature and pressure to achieve a successful bond. Keep in mind that this method is suitable for specific types of acrylic and may not be suitable for all applications.

Screws and Bolts for Structural Applications

Brace yourselves as we uncover the boundless advantages and versatility of these mechanical wonders, unleashing their power in structural applications.

Versatility Unleashed:

Prepare to be amazed by the limitless possibilities offered by screws and bolts when bonding acrylic materials. Whether you crave the strength of through holes, the polished perfection of countersunk holes, or the enduring durability of threaded inserts, these mighty fasteners deliver.

Through holes provide an unwavering connection, passing entirely through the material.

Countersunk holes not only secure your structure but also grant it a flawless finish. And threaded inserts? They distribute the load evenly, fortifying your creation for the ages.

Precision Tailored Fit:

In your quest for the perfect bond, remember to consider the thickness of your acrylic and specific application requirements. With acrylic sheets varying in thickness, choosing the ideal length for your fasteners ensures a snug embrace without breaching its boundaries.

This tailored fit guarantees unmatched stability and performance for your structure’s every demand.

Defying Time: Corrosion Resistance:

To defy the relentless march of time, equip yourself with screws and bolts forged from non-corrosive materials like stainless steel or brass. These mighty metals stand strong against nature’s assault, conquering both indoor and outdoor applications with unwavering resolve. Fearlessly venture forth into any project, knowing that strength and aesthetics remain unscathed.

A Ritual of Protection: Pre-Drilling Mastery:

Safeguard your precious acrylic from cracks and splits during assembly with the sacred practice of pre-drilling. This time-honored ritual ensures a seamless installation process while preserving your masterpiece’s structural integrity. Remember, the pilot hole must humbly yield to the fastener’s diameter, embracing it snugly and securely.

Guardians of Stability: The Power of Washers:

Elevate your structure’s stability and shield its delicate surface from harm by enlisting the aid of trusty washers. These unsung heroes evenly distribute the load, preventing screws or bolts from digging into the acrylic’s tender embrace. With their watchful presence, your creation shall endure the ravages of time with unrivaled grace and resilience.

Plastic Welding Techniques

Plastic welding techniques are the magical spells that bring acrylic materials together, forging unbreakable bonds that defy the laws of physics. Prepare to be enchanted as we delve into the secrets of these techniques, unlocking their power to transform ordinary plastic into extraordinary structures.

The first technique in our arsenal is hot gas welding, a fiery dance that involves heating acrylic surfaces with a blazing air gun or torch. As the plastic surrenders to the intense heat, it becomes soft and malleable, ready to be united with its counterpart. With a gentle press, the once-separate pieces meld into one, creating a bond that can withstand the harshest trials. This versatile technique is suitable for projects of all sizes and complexities, making it an essential tool for any plastic wizard.

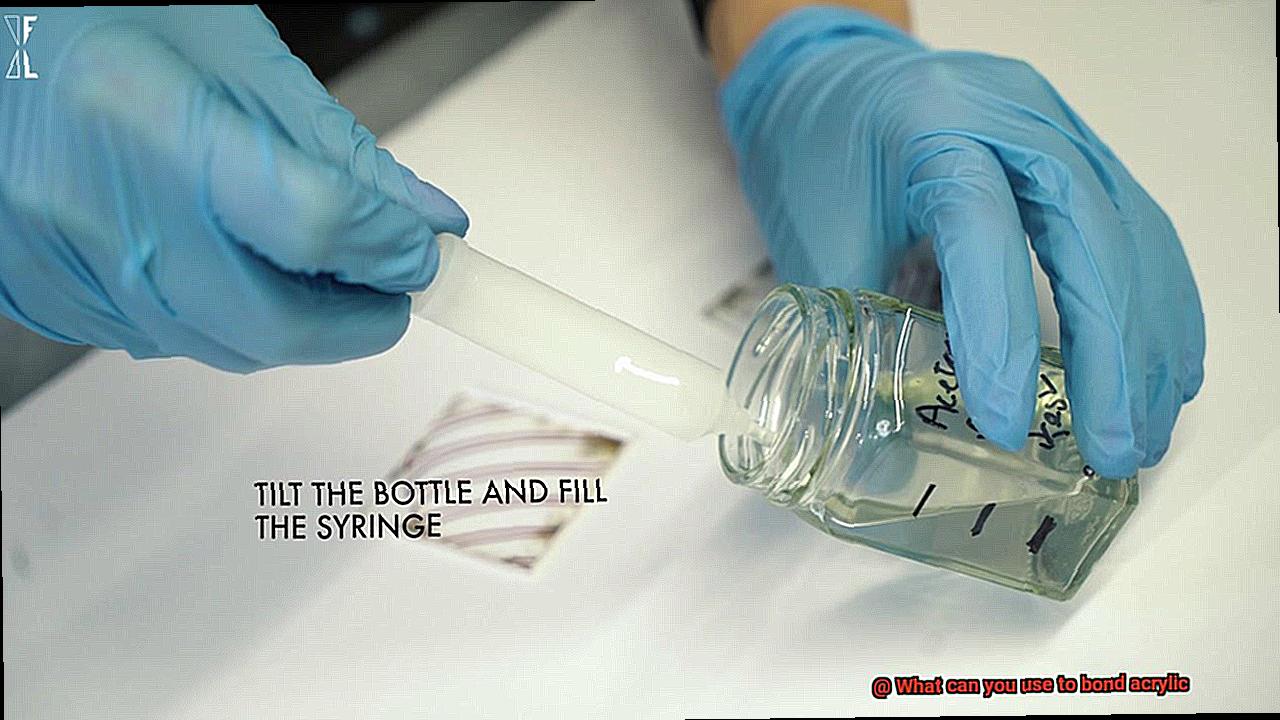

Next up is solvent welding, a technique that relies on the alchemical powers of solvents such as acetone and methyl ethyl ketone (MEK). These potent elixirs dissolve the surface of the acrylic, transforming it into a pliable substance. Like an artist shaping clay, you can mold the softened plastic into any form before the solvents vanish into thin air. The result? A bond that defies logic, perfect for thin sheets and intricate designs. But beware, fellow sorcerers, for not all acrylics yield to these solvents. Choose your concoctions wisely to ensure a successful fusion.

Prepare to be entranced by ultrasonic welding, where vibrations create a symphony of heat at the junction between two plastic pieces. The high-frequency waves generate intense heat that melts the plastic surfaces, allowing them to intertwine in a seamless embrace. This lightning-fast technique requires no additional materials or incantations – just pure energy and precision. It is the favored method in industries that demand speed and efficiency, where every second counts.

Finally, we unveil laser welding – the pinnacle of plastic wizardry. With a flicker of light, a laser beam generates a focused, controlled heat at the joint between plastics. This surgical precision creates bonds so strong they could withstand the weight of a thousand giants. Laser welding is the choice of the masters, capable of uniting even the thinnest acrylic sheets with an invisible touch. But be warned, my fellow enchanters, for this spell requires specialized equipment and a deeper understanding of the arcane arts.

Factors to Consider When Choosing a Bonding Method

Get ready to discover the key factors you must consider when choosing the perfect method for your project. From strength to aesthetics, we’ve got all the information you need.

First and foremost, let’s talk about strength. When it comes to bonding acrylic, you need a method that can create a bond as strong as Hercules himself. Consider the purpose of the bonded acrylic and the kind of stress or load it will face. This will help you determine the level of strength required and select the appropriate bonding method accordingly.

Now, let’s dive into surface preparation. For optimal bonding, acrylic surfaces must be clean, dry, and free from any contaminants or residues. Don’t hesitate to grab some alcohol or specialized cleaners and give that acrylic a thorough scrub before bonding. Trust me, this step is crucial for achieving a strong bond that won’t let you down.

Next up, application method. Some bonding methods call for specialized equipment or tools, while others can be applied by hand. Take into account the size and nature of your project. Do you have easy access to equipment, or are you working on a small-scale DIY masterpiece? The ease of application may influence your decision.

Time is of the essence – cure time, that is. Different bonding methods have varying cure times – ranging from minutes to hours or even days. Consider your project timeline. Do you need a quick fix, or can you afford to wait a bit longer for that bond to reach its maximum strength?

Compatibility is key. Not all bonding agents play well with acrylic materials. Look for adhesives specifically designed for acrylic or ones that have been thoroughly tested and proven compatible. You don’t want your bond to fail because you chose the wrong adhesive – trust me on this one.

Chemical resistance is another critical factor to consider. If your bonded acrylic will come into contact with chemicals or solvents, ensure that your chosen bonding method can handle them like a champion. You don’t want your bond to deteriorate or fail when exposed to harsh substances.

Last but certainly not least, let’s talk about aesthetics. Sometimes, it’s not just about strength – it’s about how it looks. Certain bonding methods may leave visible marks or residue on the acrylic surface, which can affect its appearance. If you’re all about that seamless and visually appealing finish, choose a method that won’t leave a trace.

IRT8pkaYsik” >

Conclusion

When it comes to bonding acrylic, there are several options available that can ensure a strong and reliable connection. One popular choice is using acrylic adhesive or glue specifically designed for this purpose. These adhesives are formulated to create a powerful bond that can withstand various stresses and strains.

Another option is using solvent cement, which involves applying a solvent that softens the acrylic surfaces, allowing them to fuse together when pressed firmly. This method creates a seamless bond and is commonly used in applications where aesthetics are important.

For those looking for an alternative to adhesives or solvents, mechanical fasteners such as screws or bolts can also be used to bond acrylic. This method provides a secure connection and allows for easy disassembly if needed.

Furthermore, ultraviolet (UV) curing adhesives offer a quick and efficient way to bond acrylic. These adhesives cure rapidly when exposed to UV light, creating a strong bond within seconds.

In addition to these options, there are also specialty tapes available that provide an effective bonding solution for acrylic materials. These tapes feature strong adhesive properties and can be easily applied without the need for additional tools or equipment.

Ultimately, the choice of bonding method depends on the specific requirements of your project. Whether it’s an adhesive, solvent cement, mechanical fasteners, UV-curing adhesives, or specialty tapes – each option offers its own advantages and considerations. It’s important to carefully evaluate your needs and select the most suitable bonding solution for your acrylic application.