Picture this: you’re in the midst of a DIY project, and you reach for that trusty epoxy glue to bond your materials together. Ah, the wonders of epoxy glue – renowned for its unrivaled strength and adaptability. But hold on just a minute.

Before you dive headfirst into that sticky situation, let’s shed some light on the not-so-glamorous side of this adhesive superstar.

Brace yourself as we unravel the lesser-known disadvantages of epoxy glue, from its potential hazards to its frustratingly short shelf life. It’s time to uncover the truth and make an informed choice about using this adhesive marvel.

Get ready for an eye-opening journey through the drawbacks of epoxy glue.

Long Curing Time

Contents

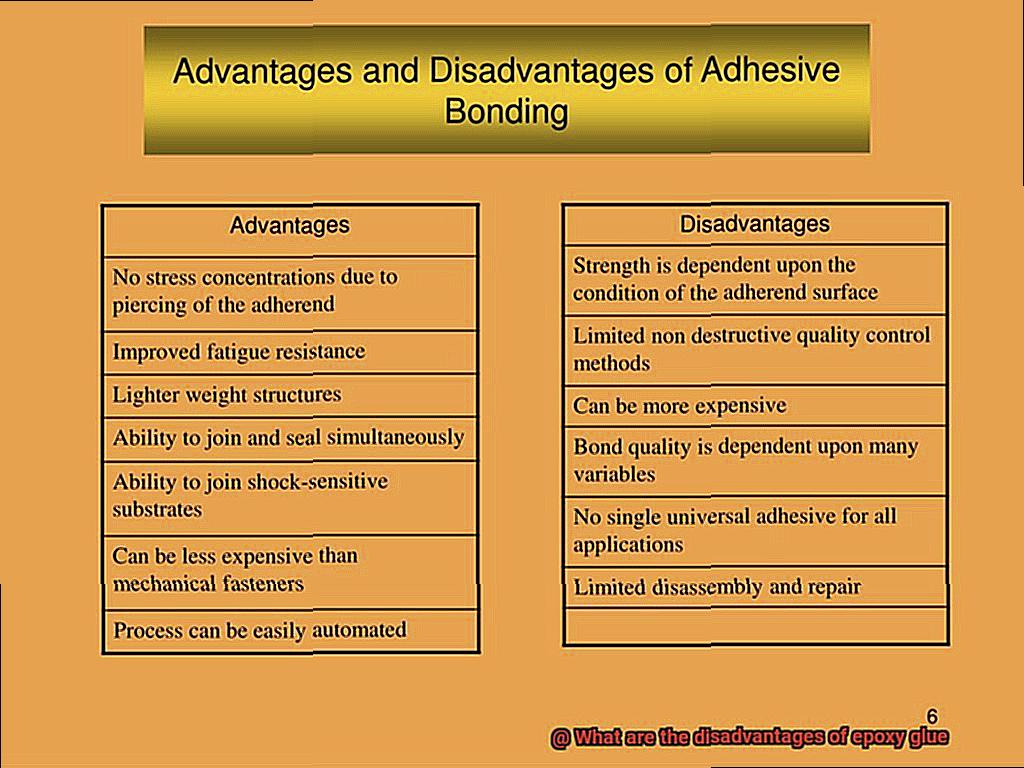

Epoxy glue is renowned for its strong bond and durability, making it a popular choice for various projects. However, one significant drawback of this adhesive is its long curing time. In this article, we will explore the disadvantages of epoxy glue’s extended curing time and its impact on users.

Frustration of Waiting:

Unlike other adhesives that dry or set within minutes, epoxy glue can take hours or even days to fully cure. This can be incredibly frustrating for individuals who require quick results or have time-sensitive projects. The anticipation and impatience can cause anxiety and hinder progress.

Delayed Finishing Touches:

The prolonged curing time of epoxy glue can result in longer wait times between application and finishing touches such as painting or further assembly. Users may need to wait overnight or longer before proceeding with their project. This delay can disrupt productivity and prolong the completion of the project.

Inability to Correct Mistakes:

Once the epoxy starts to harden, any mistakes or misalignments made during the application become permanent. Users need to carefully plan and execute their project to ensure proper alignment and avoid irreversible errors. The lack of flexibility in correcting mistakes can lead to frustration and wasted time.

Strong Odor:

Epoxy resins contain volatile organic compounds (VOCs) that emit strong fumes during the curing process. These fumes can cause irritation to sensitive individuals, resulting in headaches, dizziness, or discomfort. The overpowering smell can make working with epoxy glue in enclosed spaces unpleasant and potentially harmful to one’s health.

Brittle Bond:

Once cured, epoxy glue can become rigid and brittle. While this makes it suitable for applications requiring strength, it may not be ideal for materials that undergo frequent flexing or impact, as it can lead to cracks or breakage. The lack of flexibility in the bond can limit its use in certain projects and reduce its overall effectiveness.

Difficulty in Removal:

Unlike some other adhesives, removing or undoing epoxy glue can be challenging once it has fully cured. This can be problematic if adjustments need to be made or if the bonded items require separation in the future. The strong bond created by epoxy glue can make it nearly impossible to disassemble or remove without damaging the materials involved.

Sensitivity to Temperature Changes:

Extreme heat or cold can weaken epoxy glue or cause it to lose its bond strength. This limitation restricts the use of epoxy in applications exposed to varying temperatures or extreme weather conditions. Users must carefully consider the environmental factors that their project will encounter before deciding to use epoxy glue.

Unpleasant Odor

Unpleasant odors. We’ve all encountered them at some point in our lives – that foul stench that makes our noses wrinkle and our stomachs churn. But have you ever wondered what causes these odors? Today, we’re diving into the world of unpleasant smells, specifically focusing on the notorious scent of epoxy glue.

Now, let’s not sugarcoat it; when we say epoxy glue has an unpleasant odor, we’re not talking about a mere hint of something off-putting. Oh no, my friend. We’re talking about a pungent, chemical-like aroma that can make even the toughest DIY-er cringe. It’s as if someone took a potent solvent and decided to unleash its full force upon us.

But here’s the kicker – this smell doesn’t just vanish into thin air. No, it lingers around for hours, sometimes even days after application. Imagine trying to work in close quarters with that offensive odor constantly invading your nostrils – not exactly the most delightful experience, right?

To make matters worse, some individuals are more sensitive to this odor than others. For these unfortunate souls, exposure to epoxy fumes can result in pounding headaches, queasy stomachs, or even respiratory irritation. Not exactly the side effects you want from your crafting session, am I right?

So what’s the solution? Well, my friends, it all boils down to one key factor: proper ventilation. Ensuring you’re working in a well-ventilated area is absolutely crucial when dealing with epoxy glue. Think opening windows wide, utilizing fans to promote air circulation, or better yet, taking your crafts outdoors if possible – anything to minimize the impact of that offensive scent.

And if you really want to take it up a notch, investing in protective equipment like masks can further shield you from those pesky fumes. Trust me when I say your nose and lungs will thank you.

Now, if you’re particularly sensitive to smells or simply can’t tolerate the stench of epoxy glue, fret not. There are low-odor epoxy glues available on the market that can make your crafting experience a little less nostril-assaulting. And if push comes to shove, there’s a plethora of alternative adhesive options out there that may better suit your needs.

Rigidity and Brittleness

Today, we’re diving deeper into the world of adhesives to discuss the potential disadvantages of everyone’s favorite strong-bonding superhero – epoxy glue. While epoxy glue boasts exceptional adhesive capabilities, it’s important to be aware of its rigidity and brittleness, which can sometimes put a damper on its effectiveness. So, let’s get into the nitty-gritty.

Rigidity: A Double-Edged Sword

Epoxy glue’s rigidity is both a blessing and a curse. On one hand, its unwavering stiffness ensures a durable bond that can withstand significant pressure. You can trust epoxy glue to hold things together with an iron grip.

However, this inflexibility becomes problematic when flexibility is required. Imagine using epoxy glue to join plastic parts in a moving mechanism – the rigid nature of the glue would cause it to crack or break under stress. Ouch. So, while it excels at creating unyielding bonds, it falls short in situations that demand a little give and take.

Brittleness: Handle with Care

Brittleness is another drawback of epoxy glue. Once hardened, it tends to become relatively brittle. This means that it may struggle to endure sudden impacts or constant vibrations without succumbing to cracks and fractures.

Industries like automotive and aerospace demand adhesives that can withstand such challenges, making epoxy glue less suitable for these applications. Picture your spaceship hurtling through space, relying on epoxy glue to hold everything together – not the best image, right?

The Repair Predicament

When repairs or maintenance are necessary for objects bonded with epoxy glue, removing the hardened adhesive can be quite the challenge. The brittle nature of epoxy makes it prone to chipping or breaking off in fragments when attempting to separate bonded parts. Consequently, repairs become more time-consuming and costly. It’s like trying to extract a piece of concrete from a delicate sculpture without damaging it – a delicate dance indeed.

Variations and Trade-offs

Before we write off epoxy glue entirely, it’s worth mentioning that not all epoxy glues are created equal. Some manufacturers offer formulations that provide enhanced flexibility or impact resistance. These specialized options may come at a higher cost and may not be as readily available as standard epoxy adhesives, but they could be worth considering for specific projects. It’s like having a secret weapon in your arsenal when you need to tackle a particularly challenging bonding task.

Difficult to Remove or Undo Mistakes

This powerful adhesive, known for its strength and durability, presents unique challenges when it comes to undoing mistakes. In this article, we will delve into the difficulties of removing or rectifying errors made with epoxy glue, providing tips for avoiding such predicaments.

The Indestructible Bond:

Epoxy glue’s greatest asset is also its Achilles’ heel. Once cured and hardened, it forms an almost invincible bond that proves incredibly resistant to breakage. While other glues can be peeled off or dissolved with solvents, epoxy glue demands mechanical means for removal, often resulting in material damage or even complete destruction.

Stubborn Residue:

Unbonding epoxy glue typically leaves behind stubborn residue or marks on surfaces. This residue proves tenacious and challenging to clean, necessitating specialized cleaning agents and additional effort for complete removal. Precautions must be taken to safeguard surfaces before bonding to minimize the aftermath.

Limited Adjustments:

Unlike some glues, epoxy offers little flexibility for adjustments or repositioning once items are bonded. Once contact occurs between the two surfaces, there is limited time for corrections before the bond becomes irreversible. Meticulous planning, precise measurements, and thorough dry fitting are indispensable in avoiding mistakes.

Time-Consuming Curing Process:

Patience becomes paramount when working with epoxy glue. Depending on the product and conditions, it may take several hours or even days for the glue to fully cure and achieve its maximum strength. Consequently, rectifying mistakes during this period proves arduous without jeopardizing the bond’s integrity.

Epoxy glue stands as a versatile and reliable adhesive; however, comprehending its limitations is crucial. Undoing mistakes made with epoxy glue poses challenges that may result in additional damage or repair work.

To minimize the chances of difficult-to-remove mistakes, meticulous planning, precise measurements, and adherence to manufacturer instructions are vital. When in doubt, seek professional advice to rectify the situation safely.

Sensitive to Temperature Changes

Today, let’s delve into the fascinating world of epoxy glue and its intriguing sensitivity to temperature changes. While epoxy glue can perform wonders in bonding materials, extreme temperatures can turn it from a superhero into a sidekick with limited powers. So, brace yourselves as we explore the dramatic effects temperature can have on this adhesive marvel.

Extreme Heat: Softening and Losing Grip

Picture this: you’ve achieved a flawless bond with epoxy glue, only to subject it to scorching temperatures. Enter the softening effect. When exposed to extreme heat, epoxy glue loses its adhesive properties, rendering it weak and prone to breakage.

It’s like watching your favorite action hero melting away under the scorching summer sun – not a sight for sore eyes.

Brittle Bonds in Freezing Temperatures

On the flip side, frigid temperatures can transform epoxy glue into a brittle nightmare. When confronted with freezing conditions, epoxy becomes susceptible to cracking, leading to weakened bonds or complete adhesive failure. It’s akin to fighting crime in sub-zero temperatures – your superpowers won’t last for long.

Curing Conundrum: Temperature Fluctuations

Temperature fluctuations throw another wrench into the works of epoxy glue. The curing process of epoxy necessitates specific temperature ranges for optimal bonding. Straying from these ranges results in incomplete or drawn-out curing times – not quite what you signed up for when choosing epoxy as your adhesive ally.

Thermal Stress: A Recipe for Disaster

Rapid temperature changes present yet another challenge for epoxy bonds. These fluctuations subject the adhesive to thermal stress, causing cracks and delamination. It’s as if we subject our superhero to extreme physical strain – no wonder they crack under pressure.

Conclusion:

While epoxy glue has its limitations when it comes to temperature changes, don’t lose hope. By understanding its vulnerabilities, you can select the appropriate epoxy for each application and take measures to minimize the impact of temperature.

Remember to store and use epoxy in controlled environments within the recommended temperature range. And, if extreme temperatures are unavoidable, explore alternative adhesive options that can handle the heat (or cold) better.

Mixing Two Components Can be Messy

When it comes to adhesives like epoxy glue, the process of combining two components can be a messy and intricate affair. Whether you’re a novice or an experienced user, it’s crucial to understand the potential challenges and techniques required to ensure a successful bond. Let’s explore why mixing two components, especially glue, can be such a messy task.

One of the primary reasons mixing epoxy glue can be messy is because it demands precise proportions. Achieving the correct ratio requires accurate measuring and balancing of the resin and hardener components.

If the ratio is off, the adhesive may not cure properly, resulting in a weak bond. To ensure accuracy, small measuring cups or syringes are often employed, although this can be a time-consuming and tedious process for small projects that necessitate frequent mixing.

Another challenge with mixing epoxy glue is its limited working time once the components are combined. The adhesive begins to cure and harden shortly after mixing, necessitating quick application before it becomes too stiff to use effectively. This time constraint adds pressure and increases the likelihood of mistakes.

Moreover, air bubbles frequently form during the mixing process, which can compromise both the strength and appearance of the bond. Eliminating these bubbles requires careful stirring or specialized techniques like vacuum degassing. Neglecting this step can result in an adhesive with compromised integrity and a less-than-desirable outcome.

Spills and accidental drips are also common issues when mixing epoxy glue. It is inherently sticky and challenging to clean up, especially if it comes into contact with unintended surfaces or materials during the mixing process. This adds an extra layer of frustration for users striving for clean and precise application.

Furthermore, some individuals may experience skin irritation or allergic reactions when handling epoxy glue. Taking necessary precautions such as wearing gloves and working in a well-ventilated area is essential in minimizing potential health risks.

Despite these challenges, epoxy glue offers exceptional bonding strength, durability, and resistance to various environmental factors. Therefore, while the mixing process can be messy and challenging, the benefits often outweigh the disadvantages for many users.

Expensive Compared to Other Adhesives

When it comes to adhesive options, epoxy glue stands out for its exceptional performance. However, its higher price compared to other adhesives begs the question: why is epoxy glue so expensive? Let’s explore the factors that contribute to its higher cost and discover why it’s worth the investment.

Firstly, the manufacturing process of epoxy glue involves a specialized chemical formula and careful combination of two components – resin and hardener. This meticulous process not only adds to its production expenses but also ensures its superior bonding capabilities. Think of it as the caviar of adhesives – meticulously crafted for exceptional quality.

Epoxy glue’s versatility is another reason behind its higher price. It can bond various materials like metal, wood, plastic, and glass. This wide range of compatibility increases its demand and subsequently drives up the price. It’s like having a Swiss Army knife in your adhesive toolbox – capable of tackling any bonding task.

The strength and durability of epoxy glue also contribute to its higher cost. It is designed to withstand extreme conditions such as heat, moisture, and chemicals, making it ideal for projects that require long-lasting bonds. However, this durability comes at a price, making it less budget-friendly for projects that don’t necessitate such high-performance characteristics. It’s like buying a luxury car when all you need is a bicycle.

Furthermore, compared to other adhesives, epoxy glue requires careful mixing and precise application. This additional step can be time-consuming and may require some level of expertise. So, the overall cost of using epoxy glue includes not only the price of the adhesive itself but also the time and effort required for proper application.

Lastly, epoxy glue often comes in larger quantities or kits, which is beneficial for large-scale projects or professional users. However, for small DIY projects that only require a tiny amount of adhesive, this can be inconvenient and wasteful. It’s like buying a gallon of milk when you only need a splash for your morning coffee.

Alternatives to Epoxy Glue

While epoxy glue is undeniably a top-notch adhesive, there are several alternatives that can get the job done just as effectively, depending on your specific needs. Let’s delve into these alternatives and explore their advantages and limitations.

First in line is the trusty super glue, also known as cyanoacrylate adhesive. Super glue boasts lightning-fast drying times and forms a strong bond on various materials such as metal, plastic, and wood. It’s perfect for those urgent fixes or bonding lightweight materials. Just exercise caution to avoid sticking your fingers together.

If you’re working with wood, consider employing wood glue. Specifically formulated for bonding wood surfaces, this adhesive provides a robust bond and exhibits resistance to moisture and heat. It’s a staple in woodworking projects and furniture repairs. Additionally, it’s more budget-friendly than epoxy glue, ensuring it won’t break the bank.

For applications requiring flexibility, silicone adhesive is the go-to option. This adhesive forms a flexible and waterproof bond, rendering it ideal for outdoor projects or materials that necessitate movement. Whether you’re bonding rubber or leather, silicone adhesive has got you covered.

In search of versatility? Say hello to polyurethane adhesive. This adhesive can bond an extensive range of materials including wood, metal, plastic, and concrete. Renowned for its high strength and resistance to moisture, heat, and chemicals, polyurethane adhesive acts as the Swiss Army knife of adhesives.

At times, mechanical fasteners such as screws or nails can serve as excellent alternatives to epoxy glue. They offer a firm and dependable bond, particularly for structural applications or scenarios where future disassembly may be required. Furthermore, they are user-friendly and readily available.

When working with metal parts, welding or soldering might be your best bet. Welding creates a robust bond by melting the base materials together, while soldering utilizes lower temperatures to join metal parts with the aid of a soldering iron and solder. These techniques are perfect for heavy-duty metal projects.

Always bear in mind the particular requirements of your project and the materials you’re working with when selecting an alternative to epoxy glue. Certain adhesives may have limitations in terms of temperature resistance, curing time, or compatibility with specific materials. Prior to use, carefully read the manufacturer’s instructions and conduct a small-scale test to ensure compatibility and bond strength.

PngkSCzURBw” >

Also Read: How to Glue Fiberglass to Fiberglass? – Glue Things

Conclusion

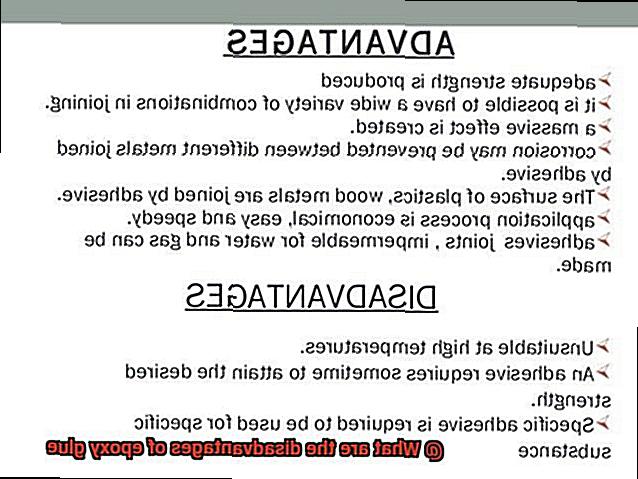

In conclusion, epoxy glue does have its fair share of disadvantages.

Firstly, it can be quite messy to work with due to its thick and sticky consistency. This can make it difficult to apply evenly and may result in a messy application process.

Additionally, epoxy glue has a strong odor that can be unpleasant and potentially harmful if used in poorly ventilated areas. Furthermore, epoxy glue can take a long time to cure completely, sometimes requiring up to 24 hours or more.

Lastly, once epoxy glue is cured, it becomes extremely hard and rigid, making it difficult to remove or repair if necessary.