Are you tired of struggling to remove epoxy resin without damaging the surface it’s attached to? Look no further than acids. These powerful chemicals can break down the toughest epoxy adhesives, but with so many options out there, it can be hard to know which one to choose.

Fear not. In this blog post, we’ll delve into the world of epoxy dissolving acids and explore their pros and cons. From hydrochloric acid to sulfuric acid, we’ll cover everything you need to know about each option.

But before you start pouring acid willy-nilly, it’s important to remember that safety always comes first. We’ll provide crucial tips on how to handle these potent chemicals safely and effectively.

Whether you’re a DIY enthusiast or a professional contractor, this information is essential for tackling even the most stubborn epoxy removal projects. So don’t wait – read on for expert advice on using acids to dissolve epoxy like a pro.

Epoxy Adhesive

Contents

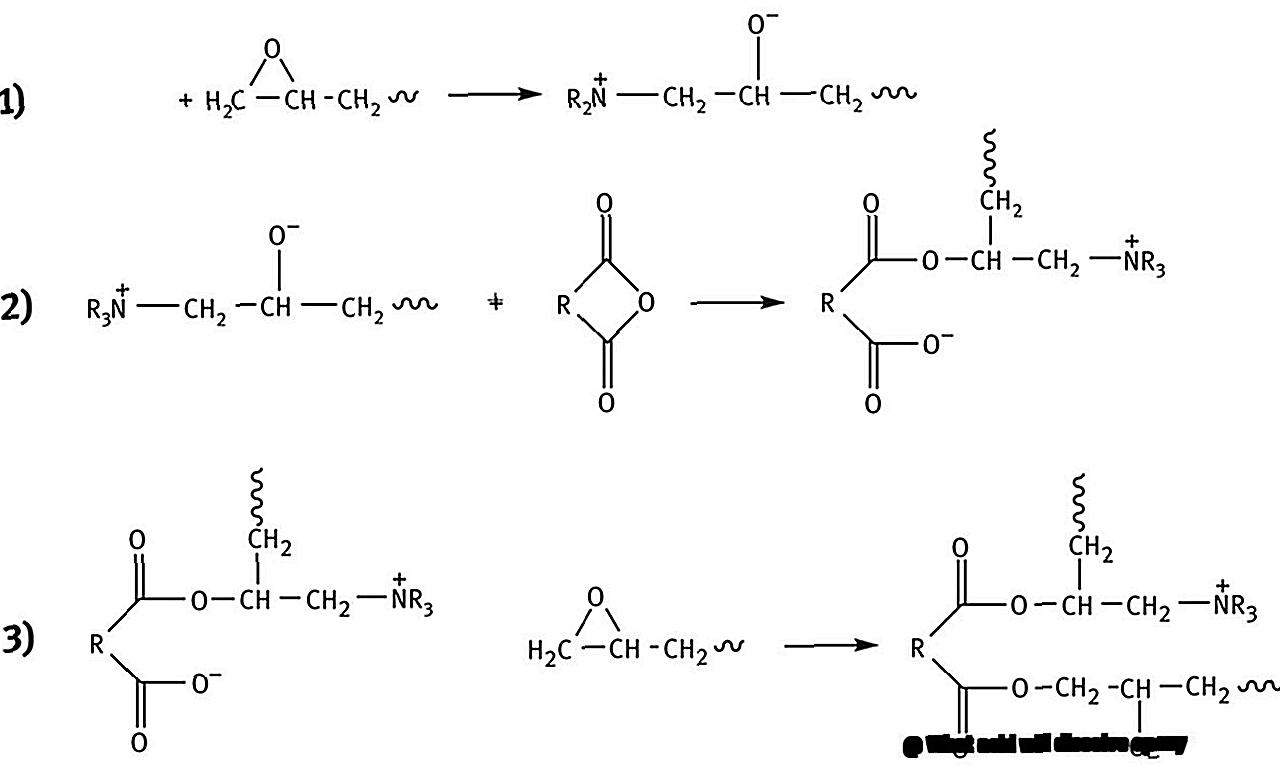

Epoxy adhesive is a versatile two-part adhesive that has become a popular choice in various industries due to its excellent bonding capabilities, durability, and resistance to chemicals and moisture. This adhesive consists of two components, a resin and a hardener, which are mixed together in a specific ratio to form a strong bond. Its versatility allows it to be used for bonding metals, plastics, composites, and other materials. It is also used for repairing and filling gaps or cracks in surfaces.

One of the main advantages of epoxy adhesive is its high strength, making it ideal for applications that require heavy loads and stresses without breaking or coming apart. It also has excellent resistance to chemicals and moisture, making it a preferred choice for use in harsh environments.

However, despite its many benefits, one of the major challenges with epoxy adhesive is its removal once it has cured. It forms a strong bond with the surface it is applied to, making it difficult to remove. In some cases, it may be necessary to dissolve the adhesive using an acid.

Hydrochloric acid, sulfuric acid, and phosphoric acid are common acids used to dissolve epoxy adhesive. However, it is crucial to note that using acids can be dangerous and should only be done by professionals with proper safety equipment and precautions.

Epoxy adhesive offers several advantages such as high strength, resistance to chemicals and moisture, versatility in bonding various materials, and repair capabilities. However, it requires proper mixing and can take several hours or even days to fully cure. Despite these drawbacks, with proper application and handling, epoxy adhesive can be an excellent choice for bonding materials in various industries.

What Are Acids?

At its core, an acid is a chemical compound that can donate hydrogen ions (H+) during a chemical reaction. When mixed with water, an acid releases hydrogen ions that can interact with other chemical compounds. Acids are found in an array of substances, ranging from everyday foods and cleaning products to industrial chemicals.

However, not all acids are created equal. Some acids are weak, like vinegar and lemon juice, while others are strong, such as hydrochloric and sulfuric acid. The strength of an acid is measured by its pH level, with stronger acids having lower pH levels. But be warned – certain acids can be corrosive and hazardous if not handled properly.

Now let’s talk about using acids to dissolve epoxy. While some acids can break down the chemical bonds that hold epoxy together, not all acids are equally effective for this purpose. It’s important to choose the right type of acid for the specific type of epoxy being used. Plus, always follow safety guidelines when handling and using the acid to avoid any accidents.

In summary, acids are a fascinating class of chemical compounds that impact many aspects of our daily lives. Whether it’s cleaning products or industrial chemicals, acids are ubiquitous. And while they can be powerful tools for dissolving certain substances like epoxy, it’s crucial to handle them with care and respect their potentially dangerous properties.

Types of Acids That Can Dissolve Epoxy

Epoxy is an incredibly strong adhesive that is widely used in various industries. However, there may be times when it becomes necessary to remove epoxy from a surface. In such cases, acids can be used to dissolve epoxy. But what are the types of acids that are best suited for this job? Let’s explore some of the most common types of acids that can dissolve epoxy.

Hydrochloric acid

Hydrochloric acid, also known as muriatic acid, is a strong acid that can quickly dissolve epoxy. It is commonly used in the cleaning and maintenance of concrete surfaces and swimming pools. However, it can cause severe burns and should only be handled by professionals with proper safety equipment and precautions.

Acetic acid (vinegar)

Acetic acid, also known as vinegar, is a milder acid that can dissolve epoxy. It is commonly found in households and is relatively safe to use. However, its effectiveness in dissolving epoxy may depend on the type and thickness of the epoxy. Despite its mild nature, it should still be handled with care.

Phosphoric acid

Phosphoric acid is a weaker acid compared to hydrochloric and sulfuric acid but can still dissolve epoxy. It is commonly used as a rust remover and in the food industry as an additive. Phosphoric acid is less hazardous compared to other strong acids but should still be handled with care.

Sulfuric acid

Sulfuric acid is highly corrosive and can dissolve many materials, including epoxy. However, it should only be used by professionals due to its hazardous nature and potential to cause severe burns if not handled properly. This strong acid has a high concentration of hydrogen ions and requires special handling.

Formic acid and nitric acid

Formic acid and nitric acid are other types of acids that can dissolve epoxy but are generally more hazardous than the acids mentioned above. They are not commonly used for this purpose and should only be used by professionals who understand their chemical properties and safety precautions.

When using acids to dissolve epoxy, safety precautions must be taken. Appropriate protective equipment should be worn, such as gloves and goggles, and the work area should be well-ventilated.

Additionally, the type and concentration of the acid used should be carefully chosen based on the specific application and the material being treated. It is also recommended to test the product on a small area first before using it on a larger scale to ensure compatibility and prevent any unwanted damage.

Hydrochloric Acid

The solution lies in hydrochloric acid. As an expert, I can assure you that hydrochloric acid is not only effective but also cost-efficient for dissolving epoxy.

However, before we dive into the details of how to use hydrochloric acid, it is important to prioritize safety measures. Hydrochloric acid is highly corrosive and can cause severe burns if mishandled. Therefore, it is essential to take appropriate precautions such as wearing protective gear like gloves, goggles, and a face mask. Always ensure that you work in a well-ventilated area to avoid inhaling harmful fumes.

Now that we have established safety measures, let’s get started on using hydrochloric acid to dissolve epoxy. The first step is to apply the solution directly to the adhesive surface. The acid will gradually break down the chemical bonds of the epoxy, causing it to soften and eventually dissolve. However, patience is key as the process may take some time depending on the strength of the epoxy.

It is important to note that while hydrochloric acid can dissolve epoxy effectively, it may also damage surfaces underneath the adhesive. For this reason, it should only be used on surfaces that can withstand the corrosive properties of the acid. Always test a small area before using it on a larger scale to avoid damaging surfaces unintentionally.

Sulfuric Acid

While it can be an effective method, it’s crucial to understand the potential hazards involved. As an expert in this field, I’ve researched and compiled some essential information to help you make an informed decision.

Sulfuric acid is a highly corrosive and strong acid that can dissolve many materials, including epoxy. As a result, it’s commonly used in various industries such as battery manufacturing, fertilizer production, and chemical processing. However, its power comes with a cost – it can cause severe burns and damage to the skin, eyes, and respiratory system. The fumes released when exposed to other chemicals are toxic and pose a significant risk.

To protect yourself while using sulfuric acid, it’s essential to wear protective gear such as gloves, goggles, and a respirator. You should also work in a well-ventilated area and avoid inhaling any fumes or vapors. Diluting the sulfuric acid with water before use and following the manufacturer’s instructions carefully is also critical.

Despite these precautions, using sulfuric acid should be a last resort due to its potential hazards. Mechanical methods or specific epoxy removers are safer alternatives and should be considered first. For example, sanding or scraping are mechanical methods that can remove epoxy without the use of dangerous chemicals. If you do decide to use sulfuric acid, be sure to handle it with extreme care and caution.

Phosphoric Acid

Look no further than phosphoric acid. This colorless, odorless liquid is commonly used as a rust converter and cleaning agent, but it also has the ability to break down the chemical bonds that hold epoxy together, causing it to weaken and eventually dissolve.

However, it’s important to handle phosphoric acid with care, as it can be harmful if ingested or inhaled. Before you start working with this chemical, be sure to take the following safety precautions:

Wear gloves, goggles, and a respirator to protect your skin, eyes, and lungs from exposure.

Work in a well-ventilated area to minimize fumes.

Keep the temperature below 80°F (27°C) to prevent the acid from becoming too concentrated.

Store the acid in a cool, dry place away from children and pets.

Phosphoric acid is readily available and relatively inexpensive, making it a popular choice for DIY projects involving epoxy adhesives. However, keep in mind that it may not work on all types of adhesives. To avoid any unwanted surprises, test a small area first before applying it to a larger surface.

Safety Precautions When Using Acids to Dissolve Epoxy

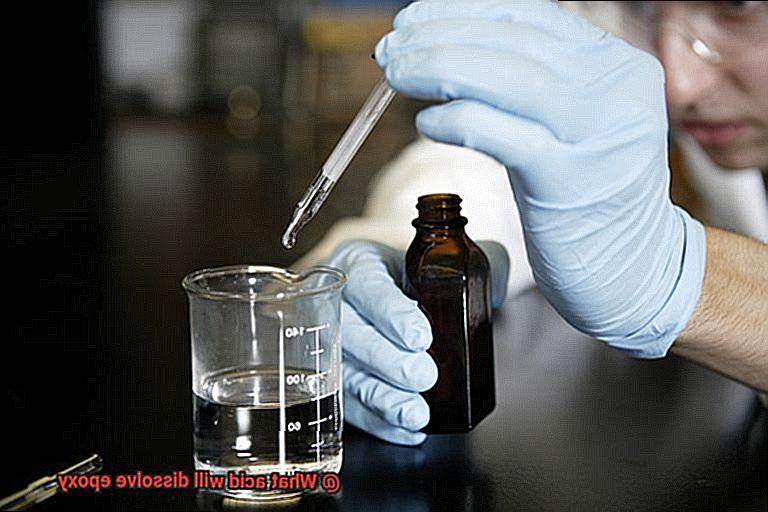

Before you proceed with the task, it’s essential to understand the safety precautions necessary to avoid any health hazards. Acids can be highly corrosive and dangerous if not handled properly. As an expert in this field, I’ve put together some safety precautions you should follow when using acids to dissolve epoxy.

Firstly, always wear protective clothing such as gloves, goggles, and a lab coat. These safety measures will protect your skin and eyes from any acid splashes, which can cause severe burns and injuries. Secondly, ensure that your workspace is well-ventilated to prevent inhaling any fumes from the acid. Proper ventilation will also help keep the air clear of any vapors from the chemical reaction.

Additionally, it’s crucial to use the correct concentration of acid for the type of epoxy you are dissolving. Using a higher concentration than necessary can be dangerous and potentially damage surrounding materials. Diluting the acid with water according to the manufacturer’s instructions before use is also imperative. This will ensure that you have a safe and effective solution for dissolving your epoxy.

When handling acids, you must do so with great care to avoid spills or splashes that can cause serious injuries or damage to your workspace. Also, ensure that you dispose of the acid after use according to local regulations. Pouring it down the drain or disposing of it in regular trash is not advisable.

In summary, safety should always be your top priority when working with acids to dissolve epoxy. Here is a list of safety precautions to keep in mind:

- Wear protective clothing such as gloves, goggles, and a lab coat.

- Work in a well-ventilated area.

- Use the appropriate concentration of acid.

- Dilute the acid properly according to manufacturer instructions.

- Handle the acid with care.

- Dispose of the acid correctly according to local regulations.

Pros and Cons of Using Acids to Dissolve Epoxy

We have a solution – using acids. However, before you jump into this method, it’s crucial to weigh the pros and cons of using acids to dissolve epoxy.

Let’s start with the pros:

- Effectiveness: Acids are a potent solution that can break down the chemical bonds in cured epoxy, making it easier to remove. With this method, you can say goodbye to that pesky epoxy in no time.

- Speed: Time is of the essence, and acids work quickly, making the process of removing epoxy faster than other methods. You won’t have to spend hours or even days trying to remove the epoxy.

- Cost: Acids are relatively cheap and readily available at hardware stores and online shops. You won’t have to break the bank to purchase these chemicals.

However, there are also cons to using acids:

- Safety concerns: Acids are hazardous chemicals that can cause serious harm if not handled properly. They can burn skin, damage eyesight, and cause respiratory problems when inhaled. Always prioritize safety first by wearing protective gear and working in a well-ventilated area when handling acids.

- Material damage: While acids are effective in dissolving epoxy, they can also damage the surface beneath the epoxy if not used correctly. For instance, using hydrochloric acid on metal surfaces can cause corrosion. It’s crucial to be cautious and use the appropriate acid for your surface.

- Environmental concerns: Improper disposal of acids can be harmful to the environment and wildlife. Always dispose of them correctly according to local regulations.

In conclusion, using acids to dissolve epoxy is an effective method but comes with its share of safety precautions and potential material damage and environmental harm. If you’re unsure about using acids safely or don’t want to risk damaging your surface, it’s best to seek professional help or use alternative methods.

v6LuNGv4IKo” >

Conclusion

In conclusion, epoxy adhesive is an exceptional bonding agent that can withstand harsh conditions in various industries. However, removing cured epoxy can be a daunting task. Luckily, acids have proven to be effective in dissolving epoxy.

Acids are chemical compounds that can donate hydrogen ions during a chemical reaction. But not all acids are equally effective for this purpose. Hydrochloric acid, sulfuric acid, phosphoric acid, acetic acid (vinegar), formic acid, and nitric acid are commonly used to dissolve epoxy adhesive. It’s important to handle acids with care as they can be hazardous if not handled properly.

Wearing protective gear such as gloves and goggles and working in a well-ventilated area is crucial when handling acids. Additionally, choosing the appropriate concentration of acid for the type of epoxy being dissolved and disposing of the acid correctly according to local regulations is essential.

While using acids to dissolve epoxy is an effective method, it also comes with safety precautions and potential material damage and environmental harm. Seeking professional help or using alternative methods may be best if unsure about using acids safely or don’t want to risk damaging your surface.