Ever wondered how glue manages to hold our world together? From simple arts and crafts to heavy-duty industrial applications, glue plays a crucial role in bonding materials. But have you ever pondered over the mystical concoction of substances that come together to give us this adhesive wonder? Today, get ready to peel back the veil of mystery and dive into the fascinating world of glue-making.

Imagine a world without glue – no more carefully crafted school projects, no more sturdy furniture joints, and no more fixing broken treasures. As we find ourselves caught in a sticky web of curiosity, let’s uncover the four indispensable ingredients that bring this magical adhesive to life.

- Polymers: The backbone of glue, polymers are long chains of molecules that provide flexibility and adhesive strength. Think of them as the superheroes that hold everything together. Common polymers like polyvinyl acetate (PVA) and ethylene-vinyl acetate (EVA) step up to save the day.

- Solvents: Solvents serve two crucial purposes in glue-making. They swoop in to dissolve the polymers, making them easier to work with, and then vanish into thin air when the glue dries, leaving behind a solid bond. Acetone, ethanol, and water take on these superhero roles.

- Fillers: To give glue its unique properties, fillers join forces with polymers. These sidekicks enhance certain characteristics like strength, durability, and performance. Talc, chalk, or cellulose lend their powers to make glues even mightier.

- Additives: Like secret spices in a recipe, additives are employed to impart specific traits to the glue – think faster drying time or increased resistance to moisture. Drying agents speed things up while plasticizers add some extra flex appeal. And don’t forget the preservatives that keep the glue fresh and ready for action.

With these four key ingredients at play, glue manufacturers become master chefs, meticulously balancing each component to produce adhesives suitable for a range of applications – from lightweight stationery bonding to heavy-duty construction needs.

So, the next time you uncork a bottle of glue or peel away a sticky adhesive strip, take a moment to appreciate the chemistry and craftsmanship behind the scenes. The remarkable synergy of polymers, solvents, fillers, and additives come together to unite materials, bond creations, and

What is Glue?

Contents

Glue, the unsung hero of adhesives, has been captivating minds and joining materials for centuries. From ancient civilizations to the modern world, glue has revolutionized industries and transformed everyday life. In this captivating guide, we embark on a journey into the mystical realm of glue, unraveling its composition and discovering the endless wonders it holds.

The Mighty Bonding Agent:

At the heart of every glue lies its binding agent, the secret ingredient that creates the magical connection between two materials. This adhesive powerhouse can take on various forms – natural or synthetic. Nature’s offerings include glues derived from the bones, hides, and cartilage of animals, as well as plant-based glues like starch or vegetable glue. Meanwhile, the synthetic realm boasts powerhouses such as polyvinyl acetate (PVA) or cyanoacrylate, renowned for their unparalleled strength and versatility.

Solvent Sorcery:

Enter the realm of solvents – enchanting components that effortlessly dissolve the binding agent and bestow upon it the power to adhere flawlessly. Water, a ubiquitous solvent in many household glues, dances harmoniously with natural substances. Meanwhile, organic solvents like acetone or ethanol hold hands with industrial-grade adhesives, evaporating swiftly to leave behind a bond that defies gravity.

Fillers: Building Blocks of Strength:

In the realm of glue, fillers reign supreme, imbuing it with strength and consistency while stretching its prowess to new heights. These magical additives not only enhance bonding properties but also ensure cost-effectiveness by expanding the volume of glue without compromising its effectiveness. Witness the marvels of fillers like calcium carbonate or talc powder as they weave their magic to thicken glue and fortify bonds.

Preservation Enchantment:

Preservation is key to prolonging the life of glue and shielding it from the clutches of microbial invaders. In the realm of water-based glues, where bacterial and fungal intruders lurk, preservatives stand tall as guardians of quality and longevity. Behold the power of formaldehyde and phenols as they repel the forces that seek to undermine the adhesive’s integrity.

The Four Essential Ingredients of Glue

In our previous section, we delved into the boundless possibilities and enchanting powers of this magical adhesive. Today, we’ll explore the inner workings of glue and uncover the four essential ingredients that make it all possible. So, grab your lab coats and let’s dive right in.

The Polymer – The Glue’s Superstar:

Our first essential ingredient is none other than the polymer, the glue’s main component responsible for its adhesive properties. Picture this as the superstar of our glue ensemble. Polymers form a strong bond between two surfaces when they dry, creating that magical connection we all rely on.

- Polyvinyl acetate (PVA): This versatile polymer is commonly found in wood glues and craft adhesives. It forms a durable bond that withstands stresses without yellowing over time.

- Cyanoacrylate: Known for its quick-drying properties, cyanoacrylate glues (also called super glues) create incredibly strong bonds with various materials, including plastic, metal, and rubber.

- Epoxy resins: Often used in heavy-duty applications, epoxy resins offer exceptional strength and durability. They’re ideal for bonding metals, ceramics, and even concrete.

The Solvent – The Glue’s Magical Carrier:

Next up is the solvent, the glue’s magical carrier that keeps it in a liquid form until it’s applied. Think of it as the enchanting elixir that allows our glue to spread evenly and penetrate the surfaces being bonded.

- Water: The most common solvent used in glues like PVA-based products. It’s safe, easy to use, and readily available.

- Ethanol: Often used in industrial glues for its evaporation properties that enable quick drying.

- Acetone: Commonly found in nail polish removers, acetone is a fast-evaporating solvent that’s suitable for specific gluing applications.

The Filler – Strength and Flexibility Reinforcements:

Our glue ensemble wouldn’t be complete without the filler, our strength and flexibility reinforcements. This optional ingredient can enhance the glue’s properties, fill gaps, or provide additional features like heat or UV resistance.

Silica: A fine powder filler that improves the strength and durability of glues used in construction or automotive applications.

Binding Agents

These extraordinary substances have the ability to adhere to various surfaces, forming strong and durable connections that can withstand any challenge. So, let’s embark on a journey to unravel the secrets of binding agents and explore some fascinating examples used in glue making.

Unveiling the Magic of Binding Agents:

Binding agents, also known as adhesive resins, are the unsung heroes of the glue-making realm. Like skilled magicians, they work their enchantment by forming chemical or physical bonds between materials, ensuring their union remains steadfast over time.

Marvelous Examples of Binding Agents:

Now, let’s delve into the realm of binding agents and discover their incredible powers. Brace yourself for a spellbinding experience.

Polyvinyl Acetate (PVA) – The Versatile Wizard:

First in our magical lineup is polyvinyl acetate (PVA), a true wizard among binding agents. This thermoplastic polymer possesses the ability to transform from a non-sticky state when cool to a sticky state when heated. Once cooled again, it solidifies into a bond that’s virtually unbreakable. PVA works its sorcery best on porous surfaces like wood, paper, and fabric, making it an indispensable tool for crafters and woodworking enthusiasts alike.

Cyanoacrylate – The Super Glue Extraordinaire:

Behold the legendary cyanoacrylate, known far and wide as super glue. This acrylic resin possesses phenomenal powers of rapid curing when exposed to moisture. Its lightning-fast drying nature makes it the superhero of adhesives, capable of bonding diverse materials such as metal, plastic, rubber, and ceramics with ease. When you need an instant fix or repair, super glue is your trusted ally, providing unmatched adhesion capabilities.

Solvents

In our previous adventure, we explored the mesmerizing world of glue making, where binding agents worked their magic to create unbreakable bonds. Today, we embark on a captivating journey to uncover the secrets of solvents in this enchanting process.

So, grab your safety goggles and join us as we delve into the role of solvents and discover the various types that bring glue to life.

The Role of Solvents:

Solvents, the unsung heroes of glue making, play a crucial role in creating that liquid or semi-liquid adhesive substance we all know and love. They work their magic by dissolving other ingredients like polymers or resins, providing the necessary consistency and workability to the glue. Think of them as the enchanters behind the scenes, preparing the stage for a show-stopping performance.

Water: The Gentle Giant:

Enter the gentle giant of solvents – water. It’s not just for quenching thirst; it’s a powerhouse in glue making. Water-based glues, also known as emulsion adhesives, are favored for their non-toxic nature and ease of use.

Acting as a solvent, water dissolves components like polymers, resins, and additives to create a milky white adhesive. Once dry, this glue forms a strong bond that can withstand even the most demanding challenges.

Alcohol: The Speedy Sorcerer:

When time is of the essence, alcohol takes center stage as a solvent in glue making. Ethanol or isopropanol are often chosen for their ability to evaporate quickly, resulting in rapid bonding. Craft projects or woodworking endeavors can’t afford to wait around, which is why alcohol-based glues are perfect for such applications. These glues leave behind a robust adhesive bond that won’t keep you waiting.

Industrial-Grade Magic:

For heavy-duty applications that require Herculean strength, solvents like acetone or toluene step onto the scene. These industrial-grade glues break down a wide range of polymers and resins, making them ideal for bonding metals, plastics, or composites. With their exceptional dissolving properties, these solvents create adhesives that can withstand the toughest challenges.

Fillers

These unsung heroes may not steal the spotlight like solvents, but they play a crucial role in creating top-notch and long-lasting glues.

First up is calcium carbonate, derived from limestone. This unassuming substance works wonders as a thickening agent, increasing the viscosity of glue for easier application and control. But that’s not all – calcium carbonate also enhances adhesive properties, resulting in stronger and more durable bonds. Talk about a double whammy.

Next on our filler adventure is cellulose, derived from plant fibers. This powerhouse filler flexes its muscles by reinforcing the adhesive properties of glue, making it perfect for a wide range of applications. But wait, there’s more. Cellulose adds flexibility to the dried glue film, ensuring it doesn’t become brittle over time. It’s like giving your glue a yoga session to keep it flexible and ready for action.

Now let’s dive into silica – the secret ingredient found in sand. Don’t be fooled by its unassuming appearance; silica brings some serious strength to the table. Acting as a reinforcing agent, it boosts the overall strength and durability of the adhesive. No more worrying about weak bonds or flimsy repairs. Silica also saves the day during the drying process by preventing shrinkage and cracking. It’s like having a personal bodyguard for your glue.

Lastly, talc makes its grand entrance. This soft mineral may remind you of baby powder, but it has some tricks up its sleeve in glue production. Talc improves spreadability and adhesion, making it a breeze to work with your chosen glue. But here’s the best part – talc also acts as a bulking agent. Manufacturers can produce larger quantities of glue without compromising quality or performance. More glue for everyone.

Preservatives

In our previous blog post, we explored the fascinating world of glue production and the essential ingredients that make adhesives strong and flexible. Today, we will shine a spotlight on another vital component of glue manufacturing: preservatives. These mighty additives are the unsung heroes that ensure glue remains effective and reliable even after prolonged storage. Join us as we dive into the captivating world of preservatives in glue production.

Formaldehyde – The Microbial Guardian:

Imagine a superhero capable of thwarting the growth of bacteria, fungi, and other microorganisms. Well, formaldehyde is that superhero in the realm of glue. With its robust antimicrobial properties, formaldehyde acts as a disinfectant, preventing degradation caused by microbial activity. This powerful preservative keeps glue fresh, mold-free, and potent for extended periods.

Sodium Benzoate – The Microbial Warrior:

Enter sodium benzoate, another formidable preservative found in glue. You may recognize this ingredient from your favorite food products, as it is widely used in the food industry for its antimicrobial properties. In glue production, sodium benzoate expertly inhibits bacterial and yeast growth, preserving the adhesive’s integrity and preventing any undesired changes in its composition. Consider sodium benzoate as the warrior guarding your glue against microbial contamination.

Propylene Glycol – The Moisture Master:

Moisture can be an adhesive’s worst enemy, causing it to dry out and lose effectiveness over time. But fear not. Propylene glycol comes to the rescue as an exceptional moisture-retaining preservative. Not only does it prevent glue from drying out, but it also acts as an antimicrobial agent, keeping microorganisms at bay. With propylene glycol, your glue will remain moist, easy to apply, and as adhesive as ever, even after months on the shelf.

Phenoxyethanol – The Versatile Protector:

Our final preservative hero in the glue production process is phenoxyethanol. This compound boasts broad-spectrum antimicrobial activity, ensuring that various microorganisms do not contaminate and degrade the adhesive. Phenoxyethanol is renowned for its stability and compatibility with different glue formulations, making it a reliable choice for preserving the glue’s quality. Count on phenoxyethanol as the versatile protector of your glue.

Different Types of Glue and Their Ingredients

Have you ever wondered about the magical properties of glue that allow it to stick things together? Glue is an incredible adhesive that comes in various types, each with its own special ingredients. In this blog post, we will take a deep dive into the captivating world of glue and uncover the secrets behind its stickiness. So put on your lab coat and let’s embark on this adhesive adventure.

White Glue: The Craft Enthusiast’s Best Friend

One of the most common types of glue is white glue, also known as PVA glue or school glue. Its main ingredient, polyvinyl acetate (PVA), is a synthetic polymer that works wonders for craft projects, paper, and woodwork. What sets white glue apart is its non-toxic nature and its ability to dry clear, making it perfect for projects where visibility is key. When combined with water, PVA creates a smooth and spreadable adhesive. To ensure optimal performance and longevity, white glue may contain additives like plasticizers and stabilizers.

Super Glue: The Speedy Fixer-Upper

In need of a quick fix? Look no further than super glue, also known as cyanoacrylate adhesive. This powerful adhesive contains cyanoacrylate, an acrylic resin that forms an incredibly strong bond when exposed to moisture. What makes super glue so popular is its ability to dry rapidly, creating a near-instantaneous bond. To enhance its usability and durability, super glue may be blended with stabilizers and thickeners that contribute to its fast-drying properties.

Epoxy Glue: The Mighty Bond Builder

When it comes to heavy-duty bonding, epoxy glue is the ultimate choice. This versatile adhesive consists of two components: resin and hardener. When these components are mixed in equal amounts, a chemical reaction occurs, resulting in a durable and robust bond.

Epoxy glue is renowned for its strength and resistance to extreme conditions. Manufacturers can customize epoxy glue with various additives, such as modifiers for flexibility, accelerators for faster curing, and fillers for enhanced performance on different materials.

Hot Glue: The Crafters’ Secret Weapon

Crafters rejoice. Hot glue is here to save the day. Composed of thermoplastic polymers, hot glue melts when heated and solidifies upon cooling. The beauty of hot glue lies in its versatility and ease of use. With a hot glue gun in hand, you can apply the melted adhesive to any surface with precision and watch it harden within seconds. This makes hot glue perfect for a wide range of craft projects, DIY endeavors, and temporary fixes.

Benefits of Using the Right Ingredients in Glue Production

In our previous adventure, we uncovered the enchanting world of glues. Now, let’s embark on a thrilling journey through the benefits of using the right ingredients in glue production. Brace yourselves for a captivating expedition into improved adhesion, enhanced durability, faster drying time, and environmental friendliness.

Improved Adhesion:

Imagine this: you’re creating a masterpiece or mending a cherished item, but your glue fails to hold it together. Frustrating, isn’t it? Fear not, my friends. The secret lies in using the perfect ingredients during glue production.

By incorporating high-quality components, manufacturers create glues that form unbreakable bonds with different surfaces. Say goodbye to worries about your creations falling apart.

Enhanced Durability:

Glues with unwavering durability are the superheroes of your projects. By carefully selecting the right ingredients, manufacturers unleash the power of glues that can withstand even the most challenging conditions.

Temperature fluctuations? No match for these glues. Moisture? They laugh in its face. Physical stress? Just a trivial obstacle. With these glues by your side, your bonds will stand the test of time.

Faster Drying Time:

Time is precious, especially in fast-paced industrial applications. That’s where the magic of perfect ingredients truly shines. Certain components in glue formulations accelerate drying time, allowing for lightning-fast bonding.

No more waiting around for hours before moving forward. These glues save time without compromising on bond strength, ensuring maximum efficiency.

Environmental Friendliness:

Our beloved Mother Nature deserves our utmost care and consideration. The right ingredients in glue production can make a significant impact on our planet. Traditional glues often contain harmful substances that endanger our health and pollute the environment. But fret not, eco-warriors. By harnessing eco-friendly ingredients, manufacturers can produce glues free from volatile organic compounds (VOCs) and toxic chemicals. This guarantees a safer experience for users and minimizes our environmental footprint.

B2RxoF3uzzQ” >

Conclusion

In conclusion, when it comes to making glue, there are four key ingredients that you need.

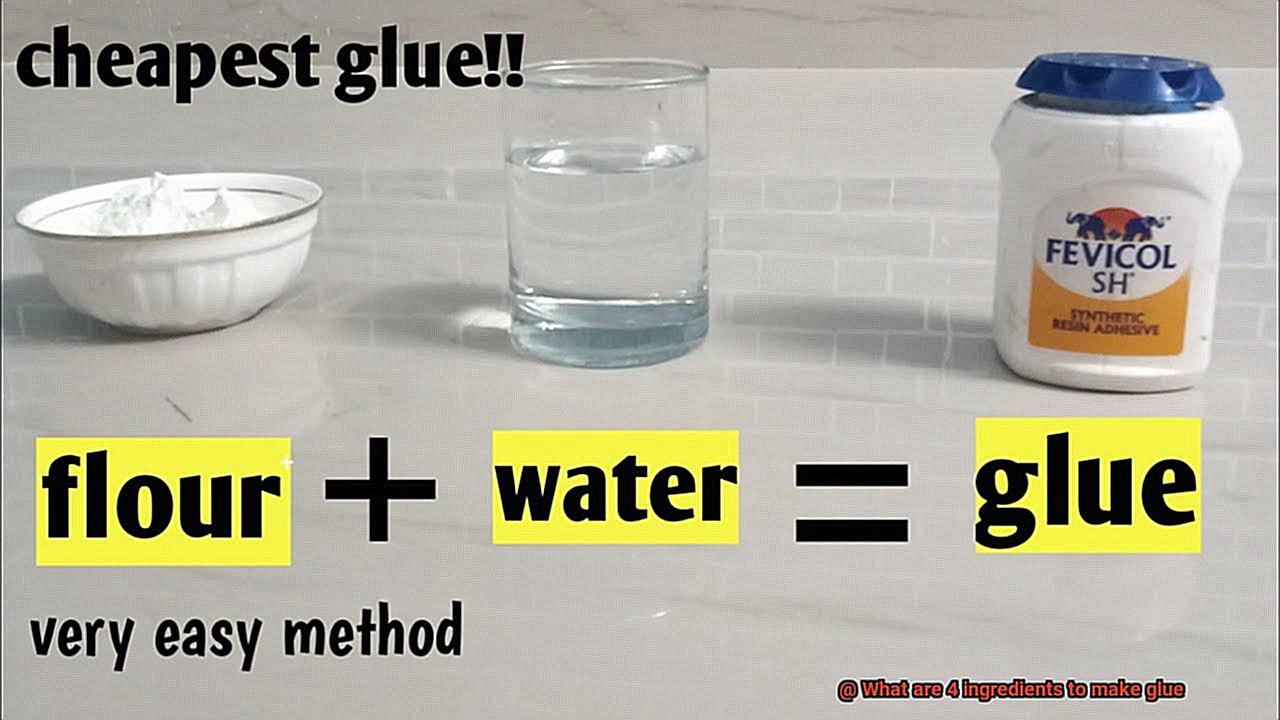

These ingredients include water, a type of adhesive substance like resin or gum, a thickening agent such as flour or cornstarch, and a preservative to prevent the glue from spoiling. By combining these four ingredients in the right proportions and following the appropriate steps, you can create your own homemade glue.

So whether you’re looking for an arts and crafts project or simply need a quick fix around the house, knowing these four ingredients will come in handy.