Marble, with its opulent allure and timeless charm, has graced everything from ancient sculptures to modern kitchen countertops. But when it comes to affixing this exquisite stone to plywood, choosing the right adhesive becomes absolutely crucial. After all, no one wants their stunning marble masterpiece slipping out of place and shattering their dreams of a truly magnificent environment.

So, what’s the secret adhesive that ensures a flawless bond between marble and plywood? Brace yourself for an enthralling journey as we dig deep into this captivating blog post. Prepare to be amazed by the remarkable chemistry that emerges when these seemingly different materials unite.

Imagine this: you’ve painstakingly handpicked the perfect piece of marble, envisioning it as the centerpiece of your refined interior design. But without understanding the intricacies of adhesive selection, your masterpiece may crumble in the face of time and various environmental factors.

As we embark on this adhesive adventure, we’ll explore the characteristics that make an adhesive worthy of bonding marble and how it interacts harmoniously with plywood. We’ll delve into essential factors like load-bearing capacity, flexibility, and moisture resistance – elements that simply cannot be overlooked when selecting the ideal adhesive.

Moreover, we’ll shed light on the most commonly used adhesives for marrying marble with plywood. Each adhesive brings its unique advantages and limitations to the table. Whether you’re a seasoned contractor or an enthusiastic DIYer, arming yourself with this knowledge will empower you to make informed decisions and achieve astonishing results.

Get ready as we unravel the adhesive secrets that have the power to transform your marble-plywood combination into an architectural match made in heaven. Let’s embark on this bonding journey together.

Types of Adhesive Used for Marble to Plywood

Contents

Marble, with its elegant and timeless beauty, is a sought-after material for various construction and design projects. When it comes to bonding marble to plywood, selecting the right adhesive is crucial for creating a strong and enduring connection.

In this article, we will delve into different types of adhesives commonly used for this purpose, each offering unique properties and advantages.

Epoxy Adhesive:

With its exceptional bond strength and remarkable resistance to moisture and chemicals, epoxy adhesive stands as a top choice for marble to plywood bonding. Picture the fusion of two magical elixirs, blending together to create an adhesive masterpiece. Epoxy’s dual-component composition combines forces, resulting in a powerful bond that can withstand heavy loads and temperature fluctuations. This adhesive ensures a long-lasting union between the marble and plywood surfaces.

Polyurethane Adhesive:

For applications that require flexibility and resilience, polyurethane adhesive is an excellent option. This adhesive boasts good bonding strength while accommodating slight movements or exposure to water. Imagine a superhero capable of adapting to any situation. Polyurethane adhesive forms a robust bond between marble and plywood, offering peace of mind against cracks or breaks.

Acrylic Adhesive:

Lighter marble applications often benefit from acrylic adhesive’s strong bonding capabilities. While not as durable as epoxy or polyurethane adhesives, acrylic serves as a trustworthy friend, doing its utmost to hold things together. Visualize acrylic adhesive as the kind-hearted companion who strives to create a bond that meets less demanding requirements, ensuring a reliable connection between marble and plywood.

Specialized Marble Adhesive:

In some cases, manufacturers offer specialized adhesives explicitly designed for bonding marble to various substrates, including plywood. These adhesives resemble superheroes tailored specifically for marble’s unique needs. They are formulated to provide exceptional bond strength while minimizing any risk of discoloration or staining on the marble surface. Utilizing a specialized marble adhesive guarantees the perfect bond without any unwelcome side effects.

Surface Preparation:

Regardless of the chosen adhesive, proper surface preparation is paramount for achieving a successful bond between marble and plywood. Before applying the adhesive, both surfaces must be pristine – clean, dry, and free from any lingering dust or debris. Imagine an artist preparing their canvas before embarking on a masterpiece; the same care and attention are required to create a clean and smooth surface, allowing the adhesive to work its magic.

Selecting the right adhesive for bonding marble to plywood is an art form in itself. Epoxy, polyurethane, acrylic, and specialized marble adhesives each offer distinct advantages based on specific project requirements.

Polyurethane-Based Adhesive

When it comes to bonding marble to plywood, only one adhesive rises above the rest – polyurethane-based adhesive. In this article, we will delve into the extraordinary properties and advantages of this superhero adhesive, shedding light on why it is the perfect choice for creating a lasting and robust bond between these two materials.

Unmatched Adhesion Abilities:

Polyurethane-based adhesive possesses an uncanny ability to form an unbreakable bond with both porous and non-porous surfaces. Picture a love story between marble’s smooth surface and plywood’s porous nature – this adhesive creates a match made in heaven. Its exceptional adhesion ensures a reliable bond that will stand the test of time.

Flexibility: The Secret Weapon:

Marble may be heavy, but fear not, as polyurethane-based adhesive has your back. Its flexibility allows it to adapt to any situation, absorbing stress or movement like a true superhero. Say goodbye to cracks and detachment – this adhesive ensures a strong and resilient bond that can withstand even the most demanding conditions.

Defying Moisture with Ease:

Bathrooms and kitchens, where marble installations are prevalent, pose challenges in terms of moisture. But worry not. Polyurethane-based adhesive is here to save the day with its impressive moisture resistance. It forms an impenetrable barrier against water, protecting your bond from deterioration even in the most humid environments.

Temperature? No Match:

Extreme temperature changes can wreak havoc on your marble-to-plywood bond, but fear not – polyurethane-based adhesive thrives in such conditions. Whether it’s scorching heat or freezing cold, this adhesive remains unyielding. No matter the weather, your bond will stay intact and durable.

Chemical Resistance? Absolutely:

Cleaning agents and solvents can be a threat to your bond’s longevity, but polyurethane-based adhesive is here to shield it. With its excellent chemical resistance, you can confidently use cleaning products without worrying about damaging the bond. It’s like having a protective shield that keeps your bond safe and sound.

Epoxy Resin

Prepare to be amazed as we unravel the secrets of a dynamic duo that defies the laws of bonding. Epoxy resin, the unsung hero of adhesives, joins forces with marble and plywood to create an unbreakable alliance. In this captivating article, we delve into the advantages of using epoxy resin to bond marble to plywood, revolutionizing the world of construction.

So, brace yourselves for a thrilling journey through the superpowers of this extraordinary adhesive.

Advantage #1: Unrivaled Bonding Strength

Epoxy resin unleashes its unparalleled strength when it comes to bonding. Its ingenious fusion of epoxy resin and hardener initiates a chemical reaction that yields a bond so robust, it would make even the mighty Hulk envious.

This exceptional strength is particularly vital when working with heavy materials like marble, guaranteeing a steadfast connection capable of withstanding immense loads and enduring stress over time.

Advantage #2: Defying Mother Nature’s Challenges

No villain can defeat our marble-plywood duo when safeguarded by epoxy resin. This extraordinary adhesive fends off moisture, chemicals, and temperature variations with unwavering determination.

Whether your project faces the wrath of rain or the scorching fury of the sun, epoxy resin stands as an impenetrable shield, preserving your bond. Picture it as a superhero cape repelling any obstacle life throws its way.

Advantage #3: Perfection in Every Seam

Perfection knows no bounds when epoxy resin takes center stage. Its adhesive properties enable it to flawlessly fill gaps and voids between marble and plywood surfaces. Bid farewell to unsightly cracks or uneven connections. Epoxy resin ensures a seamless bond that elevates your project to pure brilliance, captivating all who behold it.

Mastering the Art: Unleashing the Full Potential of Epoxy Resin

To unlock the full potential of epoxy resin, one must heed the manufacturer’s instructions diligently. Pay close attention to the precise mixing ratio between epoxy resin and hardener, applying it to impeccably clean, dry surfaces, free from any debris or contaminants. Remember, meticulous preparation sets the stage for a triumphant bond.

Step-by-Step Guide on Applying Adhesive

Today, we embark on a quest to uncover the secrets of applying adhesive for marble to plywood. Get ready to witness the birth of a bond so unbreakable that it could withstand the fiery breath of a dragon. So, don your safety gear and prepare for an adventure like no other.

Step 1: Cleanliness is Key

In our epic adhesive odyssey, cleanliness reigns supreme. Begin by purging both the marble and plywood surfaces of any impurities. With a damp cloth or mild detergent solution, wipe away every speck of dirt, dust, and debris. Let us create a canvas so pure that angels themselves would marvel.

Step 2: Shaping Destiny

Now, it’s time to shape destiny itself – well, at least the plywood. With the precision of a master craftsman, measure and cut the plywood to your desired size and shape. Remember, safety first. Don your trusty goggles and gloves to protect yourself from any potential perils.

Step 3: The Glue that Binds

Now comes the moment of truth – choosing the adhesive that will weave these two majestic materials into a harmonious union. Will you opt for the strength of epoxy resin, the versatility of polyurethane adhesive, or the reliability of construction adhesive? Consult the sacred texts – the manufacturer’s instructions – to make a choice that will stand the test of time.

Step 4: Follow the Path

Feel the power surging within as you follow the sacred path outlined in the manufacturer’s instructions. These ancient texts hold the key to unlocking the full potential of your chosen adhesive. Do not underestimate their wisdom – they are your guiding light on this formidable journey.

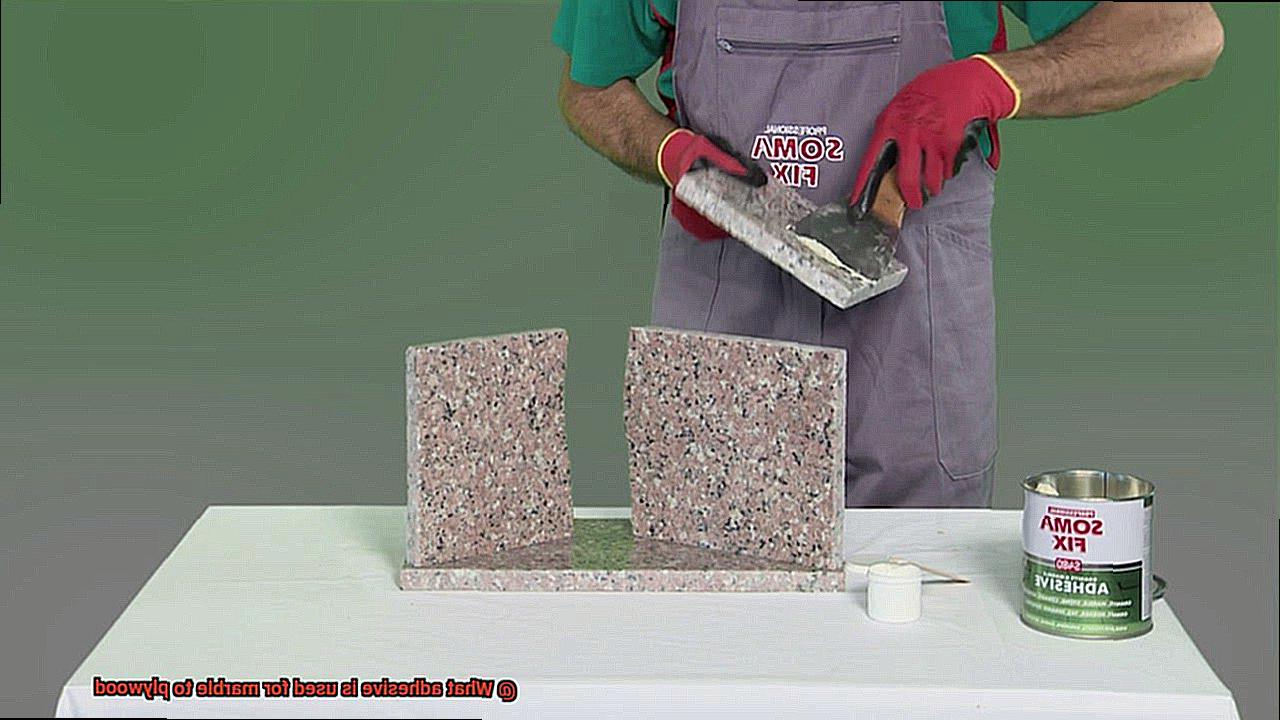

Step 5: Spreading Greatness

With your trusty notched trowel or putty knife in hand, it’s time to spread the adhesive onto the plywood surface. Like an artist wielding a brush, ensure an even application, leaving no crevice untouched. Let the adhesive flow like a river, binding the materials with unwavering precision.

Considerations When Choosing an Adhesive

When it comes to choosing an adhesive for marble to plywood, there are several crucial factors to consider. Let’s explore these considerations in detail:

- Compatibility: Selecting an adhesive specifically designed for bonding marble to plywood is essential. Marble has a smooth surface, while plywood is porous, so finding an adhesive that can adhere well to both surfaces is crucial for a strong and durable bond.

- Strength: Marble is heavy, and when installed on plywood, it exerts significant weight and pressure on the adhesive bond. To ensure a secure installation without worrying cracks or breaks, choose an adhesive with high tensile and shear strength.

- Flexibility: Both marble and plywood can expand and contract with changes in temperature and humidity. To prevent cracks or breaks under these conditions, select an adhesive that offers good flexibility for long-term durability.

- Waterproofing: Since marble is often used in areas like bathrooms and kitchens where water or moisture is present, it is crucial to choose an adhesive with waterproofing properties. This will protect the plywood from damage due to moisture seepage and maintain the integrity of the adhesive bond.

- Setting Time: Consider the setting time of the adhesive based on factors such as the size and weight of the marble pieces and the complexity of the installation process. Choose an adhesive with a setting time that allows sufficient working time to properly position the marble pieces before it sets.

- Ease of Application: For a hassle-free installation, consider the ease of application of the adhesive. Some adhesives come pre-mixed, while others require mixing with a hardener or activator. Choose an adhesive that suits your level of expertise and the specific installation requirements. Also, consider the viscosity of the adhesive to ensure proper spreading and filling of gaps between the marble and plywood surfaces.

Benefits of Using Clamps and Weights

Today, we unravel the secret weapons that elevate our projects from good to extraordinary. Step forward, clamps and weights, the unsung heroes that ensure a flawless connection. Prepare to be amazed as we unleash their incredible benefits and witness the birth of masterpieces.

Forge an Unbreakable Union:

In the realm of marble-to-plywood bonding, uniform pressure distribution reigns supreme. Enter clamps and weights, the dynamic duo that applies unyielding pressure on every inch of the surface. With their unwavering support, weak points and loose ends become a thing of the past.

Vanquish Gaps and Air Pockets:

Picture this: you’ve poured your heart into a marble-to-plywood masterpiece, only to be plagued by unsightly gaps and air pockets. Fear not. Clamps and weights come to your rescue, eliminating these sneaky intruders. They leave you with a breathtaking finish that will make even the most discerning eye dance with delight.

Command Stability:

In the chaotic dance of bonding, stability is key to achieving perfection. Fear not, for clamps are here to hold steadfast. They lock marble and plywood in an unyielding embrace, banishing any movement that threatens the integrity of the bond. Take that well-deserved coffee break without fear of mishaps on your artistic stage.

Embrace Patience:

Rome wasn’t built in a day, and neither is a bond that withstands the test of time. Harness the power of clamps and weights to grant your adhesive the patience it craves. Allow it to set and cure fully, ensuring a connection that holds strong through endless trials.

Shield Plywood from Warping:

As we bind marble to plywood, the very foundation of our creation is at risk of warping and bending. Fear not, for clamps and weights emerge as valiant protectors. With their unwavering grip, they keep your plywood flat and unyielding, ensuring the structural integrity of your masterpiece remains untarnished.

Tips for Working with Marble and Plywood

Marble and plywood are two versatile materials that, when combined, can create stunning surfaces. However, achieving a successful and long-lasting bond between them requires careful attention to detail.

In this article, we will explore expert tips to help you navigate the process of working with marble and plywood, ensuring a secure and durable bond that will stand the test of time.

Choose the Right Adhesive:

The first step in creating a lasting bond between marble and plywood is selecting the appropriate adhesive. Epoxy adhesives are highly recommended for their exceptional strength and durability. Look for an epoxy adhesive specifically designed for bonding stone or marble to ensure optimal results. By choosing the right adhesive, you can have confidence in the longevity of your marble and plywood project.

Prepare the Surfaces:

Proper surface preparation is crucial for a strong bond between marble and plywood. Take the time to thoroughly clean both surfaces, eliminating any dust, dirt, or grease that could hinder adhesion.

Use a mild detergent or specialized stone cleaner to clean the marble surface, while sanding the plywood surface will create a rougher texture that promotes better adhesion. These preparatory steps lay the foundation for a successful bond.

Apply Adhesive Evenly:

To ensure an even and secure bond, it is essential to apply the adhesive evenly on both the marble and plywood surfaces. Utilize a notched trowel or suitable applicator to spread an even layer of adhesive on the plywood surface, ensuring complete coverage in the area where the marble will be installed. An even application guarantees proper contact between the two materials, enhancing adhesion.

Employ the Back Buttering Technique:

For added bond strength and stability, consider using the back buttering technique when working with marble and plywood. Apply a thin layer of adhesive on the backside of the marble tiles before pressing them onto the plywood surface. This technique fills any gaps and imperfections, ensuring a more secure and durable bond. Back buttering is particularly beneficial when working with irregularly shaped or uneven marble tiles.

Allow Sufficient Curing Time:

Patience is key when working with marble and plywood. After installing the marble tiles onto the plywood surface, allow ample time for the adhesive to cure fully. Follow the manufacturer’s instructions regarding curing time, as it may vary depending on the specific adhesive used. Avoid subjecting the bonded area to excessive stress or weight until the adhesive has fully cured. This patience will pay off in a strong and enduring bond.

5jU1uNNj-BI” >

Conclusion

When it comes to bonding marble to plywood, choosing the right adhesive is crucial. One commonly used adhesive for this purpose is epoxy resin. Epoxy resin provides a strong and durable bond that can withstand the weight and stress of the marble. Its high tensile strength and excellent adhesion properties make it an ideal choice for this application.

Another adhesive option for marble to plywood bonding is polyurethane glue. Polyurethane glue offers good flexibility and resistance to moisture, making it suitable for both indoor and outdoor applications. It forms a strong bond that can withstand temperature fluctuations and vibrations.

In addition to epoxy resin and polyurethane glue, there are also specific marble adhesives available in the market. These adhesives are specially formulated to provide a reliable bond between marble and various substrates, including plywood. They offer excellent adhesion properties, ensuring a long-lasting bond that will not deteriorate over time.

When using any adhesive for marble to plywood bonding, it is important to follow the manufacturer’s instructions carefully. Proper surface preparation, such as cleaning and sanding the surfaces, is crucial for achieving a successful bond. Additionally, allowing sufficient curing time as specified by the adhesive manufacturer will ensure optimal strength and durability.

In conclusion, when it comes to bonding marble to plywood, epoxy resin, polyurethane glue, or specific marble adhesives are all viable options. Each adhesive has its own unique properties that make it suitable for different applications.