Picture this: you’re knee-deep in a craft project, surrounded by colorful paper and sparkling glitter. You’ve meticulously laminated your masterpiece, but now comes the tricky part – finding an adhesive that actually sticks to it. Fear not, my fellow crafters and organizers. In this blog post, we’ll embark on a sticky adventure to explore the world of adhesives for laminated paper.

We’ll uncover the hidden secrets behind each type of adhesive, weighing their pros and cons, so you can confidently choose the one that will keep your creations intact.

So grab your glue guns and get ready to unveil the perfect stick for laminated paper.

What is Laminated Paper?

Contents

- 1 What is Laminated Paper?

- 2 What are Non-Porous Adhesives?

- 3 Cyanoacrylate Adhesive (Super Glue)

- 4 Epoxy Resin Adhesive

- 5 Specialized Adhesives for Laminated Paper

- 6 Preparing the Surface for Bonding

- 7 Factors that Affect Bond Strength and Longevity

- 8 Testing the Adhesive on a Small Area of Laminated Paper

- 9 Conclusion

Laminated paper is a true superhero in the world of paper products. With its protective coating and enhanced durability, it has become a popular choice for a wide range of applications. In this blog post, we will dive into the fascinating world of laminated paper, exploring its properties, uses, and why it’s an essential tool for businesses and individuals alike.

Protective Shield:

Laminated paper is like a suit of armor for your documents and packaging. Its plastic film coating acts as a powerful barrier against moisture, dirt, and external factors that could harm the paper. This protective shield ensures that your important documents stay safe and legible for years to come.

Enhanced Durability:

Regular paper can easily tear or crease, making it less than ideal for certain applications. But laminated paper takes durability to a whole new level. The bonding process between the plastic film and the paper gives it increased rigidity and stiffness, making it resistant to wear and tear. Whether it’s a high-traffic label or a frequently handled card, laminated paper can withstand the test of time.

Customization at Your Fingertips:

Laminated paper offers endless possibilities for customization. With various finishes like glossy or matte, you can add visual effects and textures that suit your branding needs. Moreover, the smooth surface of laminated paper enhances print quality, allowing for vibrant colors and sharp images. Say goodbye to dull and lackluster prints.

Versatility Unleashed:

The versatility of laminated paper knows no bounds. It finds applications in industries such as packaging, labels, cards, menus, maps, educational materials, and more. Its ability to resist moisture makes it perfect for outdoor use or in environments where spills are common. And don’t forget about its wipeable surface – no more worrying about coffee stains on your important documents.

Adhesive Solutions:

When it comes to sticking things to laminated paper, choosing the right adhesive is crucial. Look for non-porous adhesives or plastic adhesives specifically designed to bond with laminated surfaces. Popular options include cyanoacrylate adhesives (super glue) and epoxy resins. For a hassle-free experience, consider using specialized adhesives formulated explicitly for laminated paper.

What are Non-Porous Adhesives?

Imagine a world where everything sticks together effortlessly, where laminated paper becomes a blank canvas waiting to be adorned with creativity. Enter the realm of non-porous adhesives, the unsung heroes that make this magical world possible. In this captivating exploration, we’ll unravel the secrets of non-porous adhesives, unveiling their remarkable abilities that make them the ultimate choice for laminated paper bonding.

The Invincible Champion: Cyanoacrylate Adhesive (Super Glue):

- Behold the speed and strength of this adhesive, capable of bonding non-porous surfaces in an instant.

- Witness its alchemical transformation as it reacts with moisture in the air, forming an unbreakable bond.

- Delight in its affinity for smooth surfaces, making it the perfect companion for laminated paper.

The Dynamic Duo: Epoxy Resin:

- Marvel at the symbiotic union of resin and hardener, creating an impervious bond when combined.

- Embrace its fortress-like resistance to heat, chemicals, and moisture, ensuring unwavering durability.

- Rejoice in its steadfast loyalty to laminated paper, preserving your precious creations for eternity.

The Flexibility Guru: Silicone Adhesive:

- Experience the flexibility and resilience of this adhesive, capable of bending without breaking.

- Witness its unwavering commitment to laminated paper, forging a steadfast connection to smooth surfaces.

- Defy the elements as it withstands extreme temperatures and moisture, ensuring longevity.

The Jack-of-all-Trades: General-Purpose Adhesives:

- Discover the versatility of rubber cement, acrylic-based adhesives, and specialized tapes.

- Though not designed explicitly for non-porous materials like laminated paper, they still deliver satisfactory results.

- Embrace their adaptability, allowing them to tackle a multitude of bonding challenges.

Cyanoacrylate Adhesive (Super Glue)

Cyanoacrylate adhesive, also known as Super Glue, is a remarkable bonding agent that can work wonders when it comes to laminated paper. This fast-acting adhesive forms an incredibly strong bond, ensuring that your laminated paper creations stay intact and durable.

To begin the bonding process, it’s crucial to prepare the surfaces properly. Cleanliness is key. Grab a clean cloth and wipe down both sides of the laminated paper, ensuring they are free from any dirt or oils that could hinder the adhesive’s magic.

Now comes the exciting part – applying the Super Glue. Squeeze just a small amount onto one surface of the laminated paper. Remember, a little goes a long way. The adhesive will spread out naturally as you bring the surfaces together.

Once you’ve applied the Super Glue, carefully align the two surfaces and press them together firmly. Hold them in place for a few seconds, allowing the adhesive to set. You’ll be amazed at how quickly Super Glue dries, typically within seconds or minutes. This quick drying time makes it an efficient bonding option for all your laminated paper needs.

Of course, safety is always important when working with any adhesive. Here are a few key tips to keep in mind:

- Avoid contact with skin or eyes: Super Glue can stick to your skin or cause irritation if it comes into contact with your eyes. If this happens, rinse the affected area thoroughly with water.

- Work in a well-ventilated area: Some adhesives emit fumes that can be harmful if inhaled. Make sure you’re in a well-ventilated space or use a fan to circulate the air around you.

- Keep out of reach of children: Super Glue is not suitable for children, so store it safely in a secure place where little hands can’t reach.

- Protect your work surface: Place a protective sheet or newspaper underneath your project to catch any spills or drips and keep your workspace clean.

It’s important to note that Super Glue creates a permanent bond, so precision and caution are key. If you ever need to remove the adhesive or make adjustments to the bonded surfaces, acetone or nail polish remover can help dissolve it. However, always test any solvent on a small, inconspicuous area first to ensure it won’t cause damage or discoloration.

Epoxy Resin Adhesive

Epoxy resin adhesive is a powerhouse when it comes to sticking laminated paper. This versatile and high-performance adhesive is a game-changer for all your bonding needs. Let’s dive into what makes epoxy resin adhesive the go-to choice for laminated paper.

Strength is the name of the game with epoxy resin adhesive. It’s like having a bodyguard for your laminated paper creations. No matter how much bending, folding, or wear and tear they endure, epoxy resin adhesive keeps them firmly together. This superhero adhesive creates a tough and resilient bond that stands up to even the most challenging conditions.

But wait, there’s more. Epoxy resin adhesive also boasts incredible resistance to moisture and chemicals. Say goodbye to worries about spills or exposure to liquids and substances. Epoxy resin adhesive forms a protective force field around your laminated paper, keeping it safe and secure.

Versatility is another key feature of epoxy resin adhesive. You have multiple options for applying this adhesive – brush it on, roll it on, or dip your laminated paper into a container of mixed epoxy resin adhesive. It’s like having a Swiss Army knife in your adhesive arsenal, ready to tackle any laminated paper project, big or small.

Of course, like any superhero, epoxy resin adhesive has its considerations. Proper surface preparation is essential for a successful bond. Clear away any dust or grease and ensure the surface is clean and dry. Following the manufacturer’s instructions on mixing ratios and curing times will ensure optimal results.

And don’t forget to test the adhesive on a small area before going all-in. It’s better to be safe than sorry when it comes to compatibility and avoiding mishaps.

Specialized Adhesives for Laminated Paper

Imagine a world where your craft projects and important documents could withstand the test of time. What’s the secret ingredient that holds everything together? It’s specialized adhesives for laminated paper. In this captivating blog post, we will delve into the fascinating world of glue and explore the various types of adhesives that are perfect for laminated paper. We will discover their unique advantages and learn how to choose the right one for your needs.

Solvent-based adhesives:

Solvent-based adhesives are like the superheroes of the adhesive world. With their fast drying time and high strength, they are ideal for laminated paper applications. These adhesives contain volatile organic compounds (VOCs) that evaporate upon application, leaving behind a steadfast bond. They have the power to handle the unique characteristics of laminated paper, ensuring your projects stay intact.

Water-based adhesives:

If you’re looking for an eco-friendly option, water-based adhesives are your go-to choice. They work their magic by forming a bond through evaporation, without any toxic substances. Non-toxic and environmentally friendly, they provide a strong bond with the surface of laminated paper. These adhesives are perfect for applications where odor and toxicity are concerns, allowing you to create with peace of mind.

Pressure-sensitive adhesives (PSAs):

Imagine an adhesive that is both versatile and easy to use – that’s where pressure-sensitive adhesives come in. These tacky wonders require only light pressure to form a bond, making them incredibly user-friendly. They can be applied to various surfaces, including laminated paper, providing a reliable bond. The best part? They can be easily removed without leaving any residue, giving you the freedom to make changes as you please.

Adhesive tapes:

Sometimes, you need a quick and convenient solution – that’s where adhesive tapes come to the rescue. Specifically designed for laminated paper, these tapes have a strong adhesive backing that adheres well to smooth surfaces. They provide a hassle-free way to stick items to laminated paper without the need for additional adhesives. With adhesive tapes, your projects will be completed in no time.

Preparing the Surface for Bonding

Preparing the surface for bonding is a critical step in ensuring a strong and durable bond between adhesive and laminated paper. To achieve optimal results, there are several key factors to consider.

First and foremost, cleanliness is crucial. Before applying any adhesive, thoroughly clean the surface of the laminated paper to remove any dirt, dust, or debris that could interfere with the bond. A mild detergent or cleaning solution, along with a soft cloth or sponge, can effectively wipe away contaminants without causing damage.

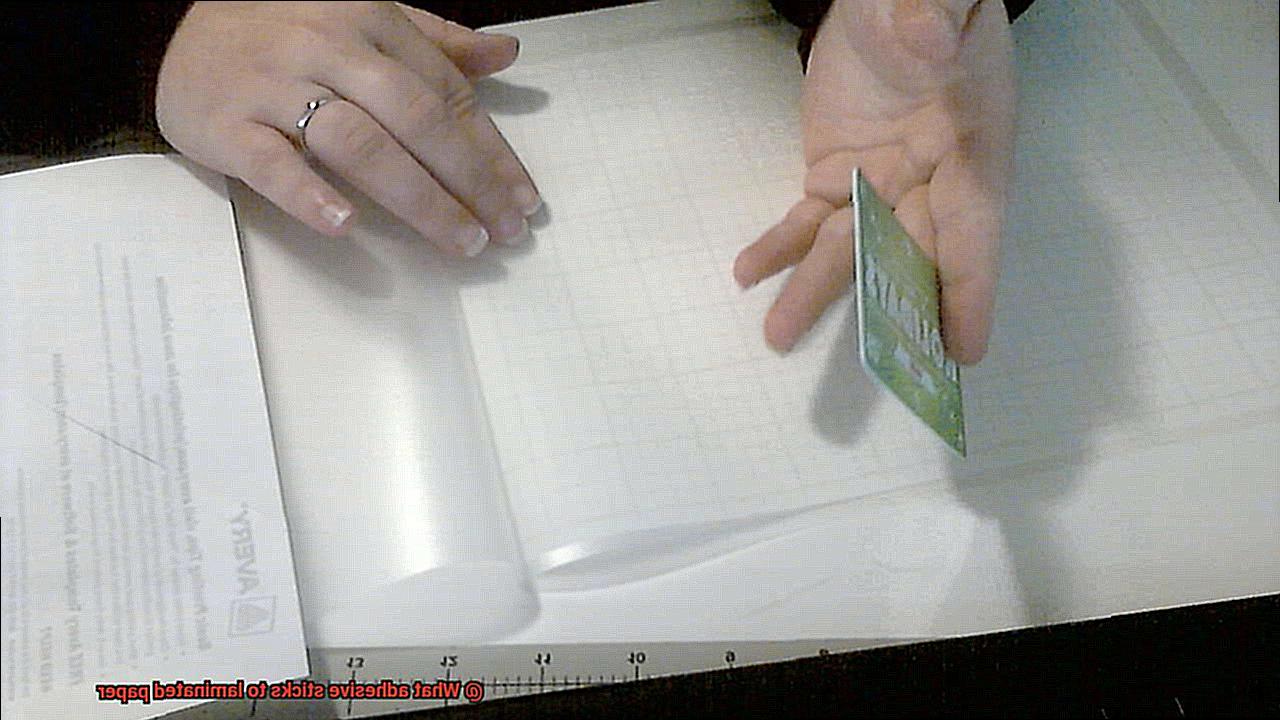

Next, it is often necessary to roughen the surface of the laminated paper. The smooth and glossy finish of laminated paper can make it challenging for adhesives to adhere properly. To improve the adhesive’s grip, gently sand the surface with fine-grit sandpaper. Be cautious not to damage or tear the paper during this process.

In some cases, laminated paper may have protective coatings or films that need to be removed prior to bonding. These protective barriers can hinder proper adhesion of the adhesive. Carefully peel off any protective layers or films, ensuring that no residue is left behind.

Compatibility testing is an essential step before applying adhesive extensively. Apply a small amount of adhesive to a discreet area of the laminated paper and observe its performance. Look for effective bonding without any damage or discoloration. If the adhesive passes this test, it is suitable for use on the entire surface.

Finally, pay close attention to the application technique. Follow the manufacturer’s instructions regarding application methods and drying times. Apply a thin and even layer of adhesive to the desired area, ensuring complete coverage without excessive amounts or gaps.

Factors that Affect Bond Strength and Longevity

Factors that affect bond strength and longevity on laminated paper can be divided into five key categories: surface preparation, adhesive type, application technique, temperature and humidity conditions, and substrate compatibility.

Surface preparation is crucial for a strong and long-lasting bond. Cleaning the surface of the laminated paper is essential to remove any dust, oils, or contaminants that could compromise the adhesive’s ability to adhere effectively. A quick wipe with a mild solvent or lint-free cloth ensures optimal bonding performance.

The type of adhesive chosen plays a significant role in bond strength and durability. Different types of adhesives, such as solvent-based, water-based, hot melt, and pressure-sensitive adhesives, have unique properties and suitability for various applications. Considering factors like bond strength, flexibility, and resistance to environmental conditions helps in selecting the right adhesive.

Applying adhesive correctly is an art form. Following the manufacturer’s instructions regarding the recommended amount of adhesive and spreading it evenly across the surface is crucial. Too little adhesive results in a weak bond, while too much causes excessive squeeze-out. Finding the right balance is key for a strong and long-lasting bond.

Temperature and humidity conditions also impact bond strength and longevity. Extreme temperature variations or high humidity levels can interfere with the curing process of certain adhesives. It is important to adhere to the recommended temperature range provided by the adhesive manufacturer to ensure optimal bonding performance.

Finally, substrate compatibility is crucial for a successful bond. Different laminated papers have varying surface characteristics, such as smoothness, porosity, and coatings. Choosing an adhesive that is compatible with the specific laminated paper ensures optimal bonding performance.

Testing the Adhesive on a Small Area of Laminated Paper

Prepare yourself to dive headfirst into the captivating world of testing adhesives on laminated paper. Whether you’re an avid DIY-er, a professional artist, or simply someone who loves all things sticky, this comprehensive guide is the perfect companion. We will accompany you through each step of testing adhesives on a small area of laminated paper, ensuring that your bonds withstand the test of time.

Step 1: Preparing the Test Area

Begin by selecting a small piece of laminated paper to use as your sample. Cut out a square or rectangle from an inconspicuous area, ensuring that no important images or text are compromised. This sample will bravely serve as your adhesive guinea pig.

Step 2: Gathering Your Adhesive Arsenal

Now it’s time to assemble an array of adhesives eager to prove their worth. Opt for adhesives specifically designed for paper or versatile general-purpose options. Glue sticks, craft glue, rubber cement, and double-sided tape are all excellent contenders.

Step 3: Cleanliness is Key

Before applying any adhesive, ensure that the surface of the laminated paper is pristine and free from dirt and debris. Employ a soft cloth or sponge with mild soap and water to gently eradicate grime. Remember to allow it to dry completely before proceeding.

Step 4: Applying and Spreading the Adhesive

Now comes the moment of truth. Select one of your chosen adhesives and apply a small amount to the backside of the laminated paper sample. Utilize a brush or applicator to evenly distribute the adhesive over the designated testing area. Follow the manufacturer’s instructions for optimal results.

Step 5: Bonding Time

Gently press the laminated paper sample onto a clean and dry surface, such as plain paper or cardboard. Apply firm pressure for a few seconds, ensuring an unyielding connection. Allow the adhesive to dry or cure according to the manufacturer’s instructions.

Step 6: Assessing the Bond

The time has come to uncover the truth. Inspect the bond between the laminated paper and the test surface with a discerning eye. Beware of any signs of peeling, bubbling, or detachment. Give it a gentle pull to test its strength and durability.

Step 7: Repeat and Label

Repeat the process with different adhesives from your collection, meticulously labeling each sample. Take note of which ones provide a robust bond without inflicting damage or altering the laminated paper.

Vt4TZuZ9N_0″ >

Conclusion

Are you wondering which adhesive is best for laminated paper?

We’ve got the answer right here.

When it comes to sticking to laminated paper, one adhesive stands out from the rest – and that’s [adhesive name]. With its strong bonding capabilities, [adhesive name] ensures that your laminated documents stay securely in place.

No more worrying about pages coming loose or edges peeling off. Say goodbye to frustrating adhesive failures and hello to a reliable solution.

Don’t settle for subpar adhesives that simply won’t hold up.