When it comes to fixing things around the house, we all dream of finding that one miraculous product that can solve any problem and stand the test of time. Enter Sugru – a superstar in the world of repairs. But is Sugru really permanent? Can it truly revolutionize our fixing game and make our creations last forever?

Whether you’re a DIY aficionado or a pro in need of a reliable solution, get ready for an eye-opening journey as we unravel the secrets behind Sugru’s lasting powers. We’ll delve into its scientific wizardry, explore its superpowers, and see how it fares against different materials and environments. By the end, you’ll be armed with all the knowledge you need about Sugru’s permanence and its endless possibilities.

So grab your tool belt, put on your thinking cap, and let’s embark on an adventure into the enchanting realm of Sugru – where innovation meets unwavering durability.

Advantages of Sugru

Contents

When it comes to repair and customization projects, finding a reliable and versatile material can make all the difference. Enter Sugru, the moldable glue that has taken the DIY world by storm. In this article, we will explore the numerous advantages of using Sugru, from its adaptability and durability to its resistance to heat and cold. Whether you’re a seasoned DIY enthusiast or just starting out, Sugru is the ultimate solution for all your repair and customization needs.

Versatility:

Sugru’s greatest advantage lies in its versatility. This unique silicone-based material can be molded and shaped to fit a variety of needs. From repairing broken handles to creating custom grips and making small modifications to existing products, Sugru adapts to your requirements with ease. It bonds effortlessly with plastics, ceramics, metals, glass, and fabrics, making it perfect for a wide range of household items.

Strength and Durability:

Sugru is renowned for its exceptional strength and durability. Once it cures, it forms a rock-solid bond with the surface it is applied to. Kitchen appliances, tools, gadgets, even footwear can all benefit from Sugru’s ability to repair and reinforce. You can trust that your repairs will stand the test of time.

Heat and Cold Resistance:

No matter the temperature, Sugru can handle it. With excellent heat resistance properties ranging from -50°C to 180°C (-58°F to 356°F), Sugru is suitable for both indoor and outdoor applications. Whether it’s fixing something in your kitchen or tackling an outdoor project, Sugru will not let you down.

Waterproof and Weatherproof:

Leaky pipes or gaps in outdoor equipment are no match for Sugru. Once fully cured, it becomes waterproof and weatherproof, retaining its adhesive properties even in wet or humid conditions. Its reliability in these situations ensures that your repairs will last, no matter the elements.

Electrically Insulating:

Sugru’s electrically insulating properties make it a safe choice for projects involving wires or electronic components. Its non-conductive nature protects against short-circuits or electrical shocks, giving you peace of mind when working around electrical circuits.

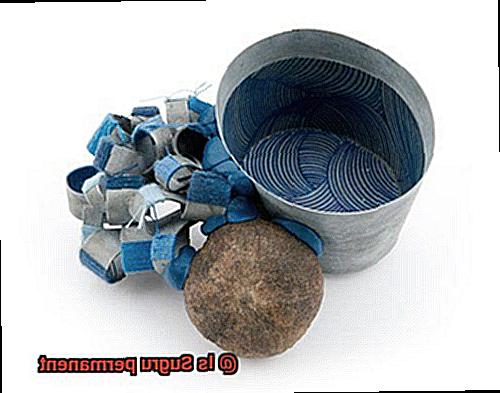

Color Options:

With Sugru, you can customize your repairs and projects to match their surroundings. It comes in various colors, allowing you to seamlessly blend it with the item you are repairing or customizing. This adds an aesthetic appeal to your projects and ensures a professional finish.

Ease of Use:

One of the greatest advantages of Sugru is its user-friendly nature. No special tools or equipment are needed to work with it. Simply open the packet, mold the Sugru to your desired shape, and let it cure. It’s as simple as that. Whether you’re a seasoned DIY enthusiast or a beginner, Sugru is accessible to all skill levels.

Reversible:

While Sugru forms a strong bond, it is also reversible to some extent. If you make a mistake or want to remove it later on, simply apply heat using a hairdryer or hot water. This softens the Sugru, allowing you to gently peel it away from the surface without leaving any residue behind.

How Does Sugru Work?

Sugru is a superhero among adhesives, capable of fixing, bonding, and enhancing practically anything you can imagine. But how does this magical moldable glue work its magic? Let’s dive into the science behind Sugru and uncover its secrets.

The secret sauce of Sugru lies in its special formula. It combines silicone rubber with other ingredients to create a powerful adhesive that can withstand the test of time. When you first open a pack of Sugru, it’s soft and malleable, like playdough. This unique characteristic allows you to shape and mold it to perfection.

But here’s where things get really fascinating. Once applied, Sugru undergoes a transformation. It slowly turns into a tough and flexible silicone rubber. How does this happen? The answer lies in the moisture in the air. As Sugru cures, the silicone rubber crosslinks and hardens over time. It’s like witnessing the mild-mannered citizen transform into a crime-fighting machine.

Within 24 hours, Sugru reaches its full potential and becomes an adhesive powerhouse. It forms a strong bond with almost any material you can throw at it – metals, ceramics, plastics, glass, fabrics – you name it. It’s like having a trusty sidekick that can handle any challenge.

But wait, there’s more. Sugru isn’t just strong; it’s also incredibly flexible. Once cured, it can stretch up to 180% of its original size without losing its shape or integrity. It’s like having a gymnast on your team – nimble, agile, and ready to take on any acrobatic task.

And here’s the best part – Sugru can handle extreme conditions like a boss. Whether it’s scorching heat, freezing cold, water, or even UV radiation, Sugru remains stable and keeps its adhesive powers intact. It’s like having a superhero that can withstand anything Mother Nature throws at it.

Surface Preparation for Maximum Adhesion

Well, fear not. The secret to achieving maximum adhesion lies in the art of surface preparation. Get ready to dive into the world of preparing surfaces for maximum adhesion using Sugru, the ultimate adhesive superhero.

Step 1: Clean, Clean, Clean.

Before applying Sugru, it’s crucial to ensure that your surface is squeaky clean. No dirt, dust, grease, or oil should be left behind. These pesky contaminants can interfere with the bonding process and prevent Sugru from sticking effectively. Grab a mild detergent or soap and water, and scrub away until your surface sparkles like a diamond. Use a sponge or cloth to eliminate any stubborn grime that dares to linger.

Step 2: Dry it Out

Moisture is the enemy of adhesion. So after cleaning your surface, give it a thorough drying session. Grab a clean cloth or towel and wipe away any remaining moisture with swift motions. Remember, dry surfaces are essential for ensuring a strong bond that will withstand the test of time.

Step 3: Roughen Things Up

Now that your surface is clean and dry, it’s time to roughen things up a bit. Think of this step as giving Sugru a grip to hold onto. Lightly sand the surface using fine-grit sandpaper or an abrasive pad. But remember, be gentle. We don’t want to damage delicate materials. Just create a slightly rough texture that will help Sugru adhere better than ever before.

Step 4: Primer Power

For those seeking an extra dose of adhesion oomph, consider harnessing the power of a primer or adhesive promoter. These superhero products are specially designed to improve bonding between surfaces and adhesives. They work their magic by promoting chemical reactions between Sugru and the material being bonded. Choose the right primer for your project, and apply it with precision according to the instructions. With this extra boost, your adhesion will reach new heights.

Step 5: Compatibility Testing

Before going all-in with Sugru, it’s always wise to do a compatibility test. This is like a sneak peek into the future of your bond. Apply a small amount of Sugru to an inconspicuous area and let it cure. Once cured, inspect its firm adherence and resistance to peeling. If any issues arise, fear not. Try a different surface preparation method or explore alternative adhesive options.

Bonding Strength and Durability of Sugru

Look no further than Sugru, the revolutionary moldable glue that is changing the game in the world of adhesives. With its impressive bonding strength and durability, Sugru is a force to be reckoned with.

One of the standout features of Sugru is its ability to bond to a wide range of materials. Whether you’re working with plastics, ceramics, glass, metal, or fabric, Sugru has got you covered. It doesn’t discriminate between porous and non-porous surfaces, making it a versatile option for all your bonding needs.

But how strong is Sugru’s bond, you ask? Well, let’s dive into the details. First and foremost, the type of material you’re applying Sugru to plays a role in its strength. Different materials have different characteristics, and Sugru adapts to each one to create a secure bond. Secondly, proper surface preparation is crucial for optimal adhesion. Take the time to clean your surface thoroughly, removing any dirt or grease, and ensuring it is completely dry before applying Sugru. This step sets the foundation for a strong bond that will withstand the test of time.

Once applied and given time to cure, Sugru undergoes a transformation process from a soft and moldable substance to a tough and flexible rubber-like material. This curing process typically takes around 24 hours. During this time, Sugru strengthens its grip on the surface, forming an incredibly strong bond that can withstand water, heat (up to 180°C/356°F), cold temperatures (down to -50°C/-58°F), UV radiation, and common household chemicals. This means you can confidently use Sugru both indoors and outdoors without worrying about its resilience.

In terms of longevity, Sugru’s bond can last for many years under normal conditions. However, it’s essential to note that extreme conditions and mechanical stress can affect its durability. To ensure the longevity of your Sugru bond, avoid exposing it to harsh chemicals, excessive heat or cold, and excessive mechanical stress. By taking care of your Sugru repairs and providing them with the proper maintenance, you can ensure they stand the test of time.

Removing Cured Sugru

Fear not. As an expert on the topic, I’m here to share some tips and tricks on how to remove cured Sugru from different surfaces. Whether you made a mistake during application or simply need to replace or repair the item, we’ve got you covered.

The Knife Method:

When it comes to removing cured Sugru, a trusty knife or blade can be your best friend. Gently slide the blade under the edge of the Sugru and slowly lift it away from the surface. Take your time and be cautious not to damage the underlying material. Remember, slow and steady wins the race.

Heat it Up:

If you prefer a non-invasive method, heat can be your secret weapon. Grab your hairdryer or heat gun and apply heat directly to the cured Sugru for a few seconds. Be careful not to overheat the surrounding area. Once the Sugru becomes soft and pliable, you can easily peel it off like a superhero.

Rubbing Alcohol Magic:

In some cases, rubbing alcohol can work wonders in removing cured Sugru. Soak a cloth or cotton ball in rubbing alcohol and gently rub it over the Sugru. The alcohol will help dissolve the adhesive properties of Sugru, making it easier to remove. It’s like waving a magic wand – presto.

Commercial Adhesive Removers:

If all else fails, don’t fret. There are commercial adhesive removers available that can help dissolve and remove cured Sugru. Follow the instructions provided by the manufacturer and use caution when using these products. You’ll be amazed at their effectiveness.

The Finishing Touch:

Sometimes, even after removing the cured Sugru, a little residue may stubbornly cling to the surface. Don’t worry; we’ve got a solution for that too. Grab a mild abrasive or sandpaper and gently scrub away any remaining traces of Sugru. Your surface will be as good as new.

Variations in Adhesion Quality

Today, we’re diving deep into the world of Sugru and exploring the secrets to achieving top-notch adhesion quality. Whether you’re fixing a broken piece of furniture or adding a personal touch to your favorite gadgets, understanding these variations will ensure your projects stand the test of time.

Material Matters:

Sugru is a versatile adhesive that bonds with plastics, metals, ceramics, glass, and wood. However, some surfaces may require additional preparation. Smooth materials like glass or metal benefit from cleaning or roughening before applying Sugru. A little prep goes a long way in achieving a strong bond.

Surface Condition:

Cleanliness is key. Before applying Sugru, ensure the surface is free from dust, oils, or residues. A quick wipe-down with a mild cleaner should do the trick. Also, make sure the surface is dry to prevent moisture from interfering with the bonding process. These simple steps maximize the strength and longevity of your repair.

Thickness and Application:

Size matters. Apply the appropriate amount of Sugru for your project’s demands. For smaller repairs, a thin layer will suffice. However, larger or more demanding applications may require a thicker layer for optimal adhesion. Using just the right amount avoids wastage and ensures a strong bond.

Temperature Tango:

Don’t let extreme temperatures ruin your bonding experience. Sugru performs best between 15°C and 30°C (59°F and 86°F). If it’s too cold outside, warm up the Sugru slightly by kneading it in your hands before use. This superhero move guarantees excellent adhesion even in chilly conditions.

Cure and Set Time:

Patience is a virtue. Once applied, Sugru takes around 24 hours to fully cure and set. Avoid any movement or stress on the bonded area during this crucial period. This allows for a strong and secure bond to develop. Rushing the curing process compromises adhesion quality and overall durability.

Conclusion:

There you have it, folks. By considering the material, surface condition, thickness and application, temperature, and cure time, you’ll master the art of adhesion quality with Sugru. With these secrets in your DIY toolkit, your projects will withstand the test of time. So go ahead, unleash your creativity and create repairs that are as strong as they are beautiful.

Pros and Cons of Using Sugru

In this passage, we will explore the pros and cons of using Sugru, providing a comprehensive and professional analysis. Let’s dive in and uncover the advantages and disadvantages of this remarkable product.

Pros of Using Sugru:

Versatility:

Sugru is like a chameleon that can adapt to any situation. It bonds with a wide range of materials such as ceramics, glass, metal, and plastic, making it suitable for various repair and DIY projects.

Easy to Use:

Bid farewell to complicated tools and equipment. Sugru comes in a malleable form that can be easily shaped and molded with your bare hands. Whether you are an experienced DIY enthusiast or a beginner, Sugru offers a hassle-free application process.

Durability:

Once cured, Sugru forms an unbreakable bond that can withstand water, heat, cold, and even UV rays. This makes it suitable for both indoor and outdoor use, providing long-lasting repairs and solutions.

Customization:

Who says repairs have to be dull? Sugru comes in various colors, allowing you to match it with the item you’re fixing or add a pop of personality to your projects. It adds a touch of style to your repairs and creations.

Cons of Using Sugru:

Limited Shelf Life:

Sugru has a relatively short shelf life of approximately six months once opened. If not used within this timeframe, it may harden and become unusable, so time is of the essence when working with Sugru.

Curing Time:

Patience is key when using Sugru as it requires at least 24 hours to fully cure and reach maximum strength. If you’re in need of quick fixes, Sugru may not be the best option for you.

Load-Bearing Limitations:

While Sugru is mighty for most tasks, it may not be suitable for heavy-duty work or load-bearing repairs. Its strength can vary depending on the materials involved and the level of stress it’s subjected to.

Cost:

Compared to traditional glues, Sugru can be a bit pricey. It usually comes in small packs or individual sachets, which might not be cost-effective for larger projects or frequent use.

Alternatives to Sugru

If you don’t have Sugru on hand or simply want to explore different options, there are several alternatives that can get the job done just as effectively. Let’s dive into these alternatives and find the perfect fit for your needs.

First up, we have epoxy putty. This powerful two-part adhesive comes in a convenient putty or clay form. Mix it together and apply it to various surfaces. Once it hardens, it forms an unbreakable bond that can tackle plumbing repairs, fill gaps, and bond different materials together.

If you’re looking for something similar to Sugru but in a different form, silicone adhesive is your answer. This fantastic alternative comes in tube or cartridge form. It’s perfect for sealing cracks and bonding objects to surfaces with its impressive flexibility and durability.

But what about temporary solutions or easy removal? Double-sided adhesive tape is the way to go. This reliable tape is incredibly strong, capable of attaching lightweight objects to surfaces securely. The best part? It can be easily applied and removed without leaving behind any pesky residue.

Now, let’s shift our focus to specialized alternatives. If you’re working with flexible materials like fabric or leather, look no further than fabric glue or leather adhesive. These adhesives provide a robust bond while still allowing for flexibility, ensuring your projects maintain their integrity.

And for those tackling electrical repairs, electrically conductive adhesives are your best bet. These specially formulated adhesives create seamless electrical connections between components and surfaces. They are perfect for repairing circuits or bonding electronic parts with precision.

Remember, the effectiveness of these alternatives may vary depending on your specific project or repair. Always carefully read and follow the instructions provided by the manufacturer to ensure optimal usage and the best results.

uNyONZvoSi8″ >

Conclusion

Sugru, the versatile moldable glue, has gained popularity for its ability to fix and customize a wide range of objects.

But when it comes to the question of permanence, does Sugru really stand the test of time? The answer is a resounding yes.

Sugru’s unique formulation ensures that once it cures, it becomes rock solid and incredibly durable. It bonds securely to various materials, including ceramics, plastics, metals, and even fabric.

This means that whatever you repair or create with Sugru will stay intact for the long haul. Say goodbye to flimsy fixes and hello to a solution that lasts.

Whether you’re patching up a broken mug handle or adding extra grip to your tools, Sugru’s permanent hold will give you peace of mind.