In our ever-changing world, we’re constantly on the lookout for materials that push the boundaries of what’s possible. And now, a captivating question has emerged: Can epoxy, that go-to adhesive superstar, also conduct electricity? Traditionally known for its strength and insulating properties, epoxy has recently caught the eye of scientists and engineers who wonder if it could be a game-changer in electrical conduction.

Epoxy is hailed as an adhesive superhero, capable of forming unbreakable bonds. But what if it could do more? What if it could carry electrical current with ease? Imagine the possibilities. From electronics to telecommunications to renewable energy, industries could be transformed by this newfound electric potential.

Is there an epoxy that conducts electricity?

Contents

- 1 Is there an epoxy that conducts electricity?

- 2 What is Epoxy?

- 3 Types of Epoxy

- 3.1 Metallic Fillers: Sparking Innovation

- 3.2 Non-Metallic Fillers: The Carbon Connection

- 3.3 Balancing Electrical and Mechanical Properties

- 3.4 Conductive epoxies find their place in a wide range of applications, including bonding electrical components on circuit boards, repairing damaged traces, and creating electromagnetic shielding materials. Their excellent adhesion properties and ability to provide mechanical strength make them invaluable in industries where reliability and performance are paramount.

- 4 Traditional Epoxy Formulations

- 5 Development of Conductive Epoxies

- 6 How Does Conductive Epoxy Work?

- 7 Applications of Conductive Epoxy

- 8 Advantages of Using Conductive Epoxy

- 9 Considerations for Choosing the Right Conductive Epoxy

- 10 Conclusion

Advantages and Disadvantages:

The advantages of using epoxy as a conductor are thrilling. Picture this: smaller, lighter electronic devices that pack a punch. With epoxy-based conductors taking up less space than their traditional counterparts, we’d have sleeker gadgets that don’t skimp on performance. Plus, thanks to epoxy’s knack for sticking to complex surfaces like nobody’s business, it would ensure efficient current flow even in tricky situations.

But let’s not forget about potential drawbacks. Epoxy might not conduct electricity as well as metals or other conductive materials due to its inherent insulation properties. And when things heat up—literally—epoxy might struggle to keep its cool. High temperatures could pose a challenge for this versatile substance when used in heat-intensive electronic systems.

The Verdict:

While there have been exciting breakthroughs in the world of conductive epoxy, cautious optimism is key. Combining epoxy’s adhesive strength with newfound conductivity holds immense promise for innovation. However, further research and development are needed to overcome limitations and determine the exact conditions under which epoxy can truly shine as an electrical conductor.

Join us on this thrilling journey as we dive deep into the realm of conductive epoxy. We’ll explore the latest advancements, unravel the possibilities, and confront the challenges that lie ahead. With a dash of ingenuity, we might just witness epoxy stepping up to revolutionize electrical conduction and reshape the technology we rely on every day.

What is Epoxy?

Epoxy is more than just a strong adhesive; it is a versatile material with a multitude of uses across industries. While traditional epoxy formulations are known for their non-conductive properties, recent advancements have led to the development of conductive epoxies that combine the adhesive strength with enhanced electrical conductivity. In this article, we will dive into the fascinating world of conductive epoxy, exploring its applications, properties, and the factors that affect its conductivity.

What is Conductive Epoxy?

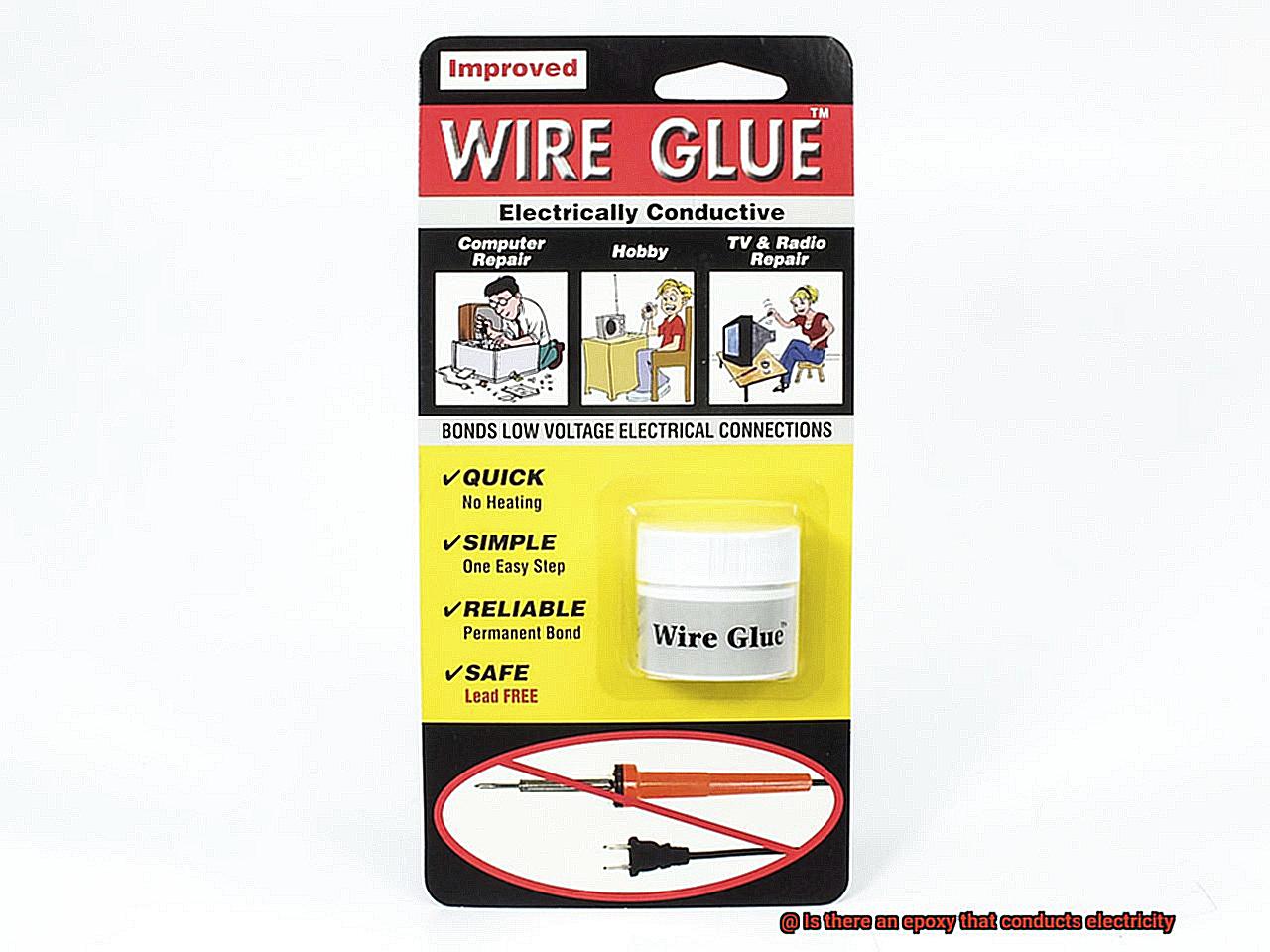

Conductive epoxy is a specialized formulation that merges the adhesive capabilities of epoxy with improved electrical conduction. This unique material contains additives or fillers that allow the flow of electrical current through the epoxy matrix. Metallic particles like silver or copper are commonly used as fillers due to their high electrical conductivity. Carbon-based fillers such as carbon nanotubes or graphene can also be incorporated to achieve conductivity.

Applications of Conductive Epoxy:

The applications for conductive epoxy abound, particularly in the electronics industry. It is used for bonding components, creating electrical connections, repairing circuit boards, and producing sensors, antennas, and electromagnetic shielding materials. Beyond electronics, conductive epoxy finds utility in the aerospace, automotive, and renewable energy sectors. Its ability to provide both mechanical strength and electrical conductivity makes it a valuable material in these demanding applications.

Factors Affecting Conductivity:

The electrical conductivity of conductive epoxy varies based on factors such as filler content, particle size, and distribution within the epoxy matrix. The choice of filler material plays a crucial role in achieving the desired level of conductivity. Metallic fillers offer high conductivity while carbon-based fillers provide a balance between conductivity and other desirable properties like flexibility and chemical resistance.

Electrical Resistance Measurements:

The electrical resistance of conductive epoxy is typically measured in terms of surface resistivity or volume resistivity. Surface resistivity refers to the resistance between two points on the material’s surface, while volume resistivity measures the resistance through the bulk material. These measurements help determine the suitability of a conductive epoxy for specific applications where specific levels of electrical resistance are required.

Considerations and Limitations:

When considering the use of conductive epoxy, it is essential to evaluate its electrical and mechanical properties to ensure compatibility with the intended application. The presence of conductive fillers may impact adhesive strength, so striking a balance between conductivity and bonding performance is crucial.

Additionally, the availability of conductive epoxy may depend on geographical location and industry-specific requirements.

Types of Epoxy

Today, we dive into the fascinating realm of epoxy adhesives, specifically focusing on the types that conduct electricity. Whether you’re a DIYer or a professional in the electronics industry, understanding the different types of conductive epoxy and their applications can help you choose the right adhesive for your projects. So, let’s jump right in.

Metallic Fillers: Sparking Innovation

To enhance electrical conductivity, metallic fillers like silver or copper particles are commonly used in conductive epoxies. These tiny conductors form a network within the epoxy matrix, allowing the flow of electrical current. With their impressive conductivity capabilities, metallic-filled epoxies are preferred for applications requiring high levels of electrical performance.

One key advantage of metallic fillers is their ability to provide excellent electrical conductivity even at low concentrations. This makes them cost-effective options for applications where budget constraints come into play. Metallic-filled conductive epoxies are widely used in various industries, including electronics, aerospace, and automotive.

They are commonly employed in bonding electronic components onto circuit boards, creating electrical connections between different parts, or repairing damaged electrical traces on PCBs.

Non-Metallic Fillers: The Carbon Connection

Carbon-based materials, such as graphite or carbon nanotubes, offer an alternative solution for achieving electrical conductivity in epoxy. These non-metallic fillers create conductive pathways within the epoxy matrix and are often used when cost considerations or specific application requirements come into play.

Non-metallic fillers provide advantages such as improved flexibility and resistance to thermal expansion compared to metallic fillers. This makes them suitable for applications where mechanical stress or temperature fluctuations may occur.

Carbon-filled conductive epoxies find their applications in industries such as electronics and telecommunications, where they are used for bonding electronic components, creating electromagnetic shielding materials, or manufacturing flexible circuits.

Balancing Electrical and Mechanical Properties

While conductive epoxies excel in electrical conductivity, they may not match the mechanical strength or adhesion properties of their non-conductive counterparts. Therefore, it is crucial to consider both electrical and mechanical requirements when choosing the right epoxy for your project.

For applications demanding both strong bonding and electrical connectivity, high-performance conductive epoxies are available.

High-performance conductive epoxies are designed to provide a balance between electrical conductivity and mechanical strength. These specialized formulations often incorporate a combination of metallic and non-metallic fillers to achieve the desired properties.

They are commonly used in industries such as aerospace and defense, where reliability and performance are paramount. High-performance conductive epoxies find their applications in bonding critical electronic components, creating conductive gaskets or seals, or manufacturing specialized electronic devices.

From Electronics to Aerospace: The Versatility of Conductive Epoxies

Conductive epoxies find their place in a wide range of applications, including bonding electrical components on circuit boards, repairing damaged traces, and creating electromagnetic shielding materials. Their excellent adhesion properties and ability to provide mechanical strength make them invaluable in industries where reliability and performance are paramount.

In the electronics industry, conductive epoxies are used for various applications such as die attach, wire bonding encapsulation, or flip-chip underfill. These adhesives ensure reliable electrical connections while providing protection against environmental factors such as moisture or temperature fluctuations.

In the aerospace industry, conductive epoxies play a crucial role in manufacturing electronic systems for aircraft. They are used for bonding connectors, sensors, or antennas onto composite structures, ensuring both electrical connectivity and structural integrity.

Traditional Epoxy Formulations

Traditional epoxy formulations are a fascinating world of adhesive wonders. Composed of two main components – a resin and a hardener – these adhesives create a chemical reaction when combined in the right ratio, resulting in a strong and durable bond.

The resin component of traditional epoxy formulations is typically an organic compound with multiple epoxide functional groups. These groups give the epoxy its adhesive properties, allowing it to bond with various materials. On the other hand, the hardener component is usually an amine-based compound. When mixed with the resin, the amine groups react with the epoxide groups, forming a three-dimensional network called a thermosetting polymer.

This cross-linked structure gives traditional epoxy adhesives exceptional mechanical properties, including high strength, toughness, and resistance to chemicals and heat. Additionally, they are electrically insulating materials due to the presence of the cross-linked polymer network, meaning they do not conduct electricity.

Traditional epoxy formulations have found their place in applications where electrical insulation is required. They are commonly used in electronic circuit boards, electrical insulation coatings, and encapsulation of electronic components.

However, advancements in epoxy technology have led to the development of conductive epoxies. These formulations contain additives or modifications that enhance their electrical conductivity while maintaining their adhesive properties. One common approach is to incorporate conductive fillers or particles into the epoxy formulation.

Conductive fillers can be metallic or non-metallic materials with high electrical conductivity, such as carbon nanotubes, graphene, silver flakes, or copper particles. These fillers create pathways throughout the epoxy, enabling the flow of electrons and making it electrically conductive.

Conductive epoxies have opened up a whole new world of applications. They are used in electronic packaging, electromagnetic shielding, and electrostatic discharge protection. These adhesives offer both adhesion and electrical conductivity, making them highly versatile for bonding and grounding applications.

Development of Conductive Epoxies

Picture a world where adhesive materials not only possess unparalleled bonding strength but also conduct electricity. This seemingly fantastical concept has become a reality through the development of conductive epoxies. In this article, we will embark on an exploration into the captivating realm of conductive epoxies and discover their remarkable applications across diverse industries.

Unleashing the Power:

Conductive epoxies are a groundbreaking type of adhesive material that possesses the ability to conduct electricity. These ingenious creations address the demand for materials that can deliver both robust bonding properties and efficient electrical conductivity. Unlike traditional epoxy adhesives, which excel in bonding but lack electrical conduction capabilities, conductive epoxies have undergone a transformative metamorphosis by incorporating conductive fillers or additives.

The Incredible Fillers:

A pivotal aspect of developing conductive epoxies lies in selecting and optimizing the filler material. Metallic particles, such as silver or copper, reign supreme due to their exceptional electrical conductivity. These particles are cleverly dispersed within the epoxy matrix, forging a pathway for electrons to flow effortlessly. Carbon nanotubes and graphene, with their awe-inspiring conductivity and low resistance, present themselves as alluring alternatives.

Whether incorporated individually or in sheets, these materials create an intricate network that facilitates seamless electron transfer. Moreover, conductive polymers—flexible yet electrically conductive—emerge as an ideal choice for applications where flexibility is paramount.

Applications Across Industries:

Conductive epoxies have made their indelible mark across various industries, revolutionizing electronics, automotive engineering, aerospace technology, and telecommunications.

- Electronics: With their ability to bond and seal electronic components like printed circuit boards (PCBs), sensors, and connectors, conductive epoxies ensure both unwavering mechanical bonds and efficient electrical connections.

- Automotive Engineering: In the automotive industry, conductive epoxies play an indispensable role in bonding dissimilar materials, electromagnetic shielding, and grounding. They establish reliable electrical connections while enhancing structural integrity.

- Aerospace Technology: Conductive epoxies have become vital for aerospace applications, providing electromagnetic shielding, grounding, and bonding of critical components. These epoxies guarantee efficient electrical transfer and safeguard against interference.

- Telecommunications: The telecommunications sector benefits from the use of conductive epoxies for bonding and sealing delicate components. These epoxies ensure dependable electrical connections while shielding against electrostatic discharge.

How Does Conductive Epoxy Work?

In the fascinating world of adhesive materials, there exists a remarkable substance that possesses the ability to bond with tremendous strength while simultaneously conducting electricity. Welcome to the realm of conductive epoxy, where the possibilities are endless and industries like electronics, automotive engineering, aerospace technology, and telecommunications are forever transformed.

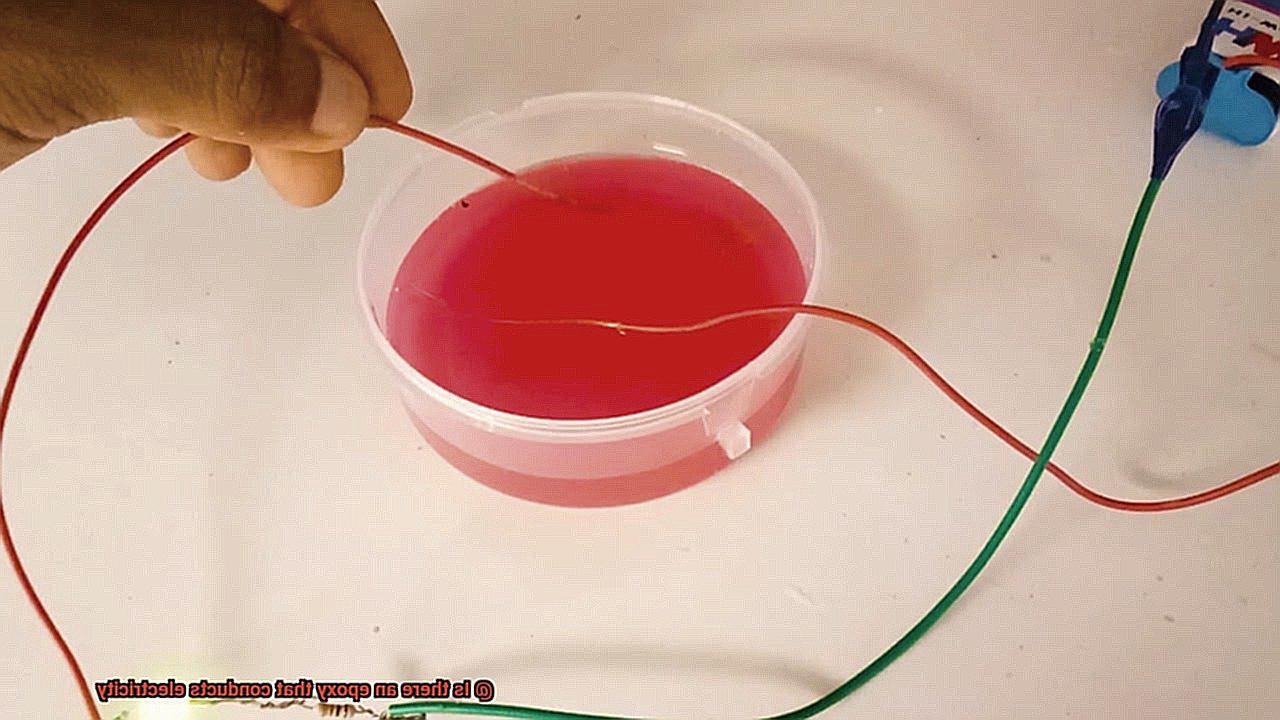

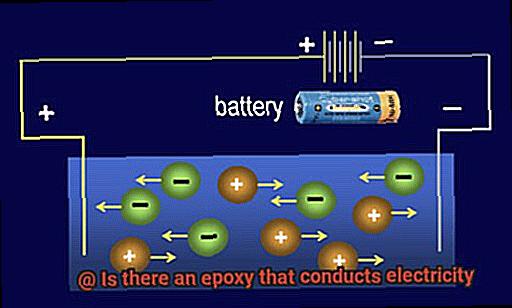

At the heart of conductive epoxy lies a secret ingredient – conductive fillers. These microscopic particles, such as metal particles or carbon nanotubes, are evenly dispersed within the epoxy matrix. Just like a network of wires, they create a continuous pathway for electrons to flow, allowing electrical current to pass through.

The choice of filler material depends on the specific requirements of each application. Metals like silver or copper are preferred for their excellent electrical conductivity. On the other hand, carbon-based materials such as carbon black or carbon nanotubes offer high aspect ratios and desirable electrical properties. Engineers carefully select the filler material that best suits their needs to achieve optimal conductivity.

To transform conductive epoxy from a liquid to a solid state, it undergoes a curing process initiated by heat or ultraviolet (UV) light exposure. As the epoxy cures, the conductive fillers become embedded within the solid matrix, forming a three-dimensional network of conductive pathways. This ensures long-term stability and durability.

Several factors influence the conductivity of conductive epoxy. The concentration and distribution of the conductive fillers play a crucial role in determining its electrical properties. Higher filler concentrations generally result in higher conductivity, but there is often an optimal loading level that balances conductivity and mechanical strength.

The electrical resistance of conductive epoxy is measured using a technique called four-point probe testing. By passing a known current through two outer probes and measuring the voltage drop across two inner probes, the resistance can be calculated using Ohm’s law. This provides a reliable method for determining the conductivity of the epoxy.

Conductive epoxy finds its way into a wide range of industries due to its unique properties. In electronics, it bonds electrical components, repairs circuit boards, and creates electrical connections in sensitive devices. In the automotive industry, it is used to bond dissimilar materials and provide electromagnetic shielding. Aerospace technology relies on conductive epoxy for protecting against interference and grounding critical components. Telecommunications benefit from its ability to establish dependable electrical connections while shielding against electrostatic discharge.

Applications of Conductive Epoxy

Conductive epoxy, with its remarkable properties, has become an indispensable material in a wide range of industries. From electronics to aerospace, automotive to medical devices, conductive epoxy finds applications that enhance performance, reliability, and functionality.

In the realm of electronics and electrical engineering, conductive epoxy takes center stage as the adhesive of choice for bonding components onto circuit boards. Integrated circuits, transistors, and other delicate parts require a steadfast electrical connection to function optimally. Conductive epoxy delivers just that, creating a durable bond that enables efficient transmission of electrical signals.

But its versatility stretches far beyond electronics. Conductive epoxy is also crucial in manufacturing sensors and actuators. These components rely on a conductive material to accurately sense or convert electrical energy into mechanical motion. With conductive epoxy, these devices operate with precision and stability.

Imagine a world free from electromagnetic interference (EMI) wreaking havoc on sensitive electronic devices. Conductive epoxy makes this possible by providing electromagnetic shielding. A simple layer of conductive epoxy shields surfaces from EMI, redirecting electromagnetic waves away from the delicate electronics.

The aerospace industry reaps significant benefits from conductive epoxy’s prowess. Bonding antennas, connectors, and sensors onto spacecraft and aircraft structures demands a material that can withstand extreme temperatures and vibrations. Conductive epoxy delivers the necessary conductivity even in these demanding environments.

The automotive industry also relies on conductive epoxy for reliable electrical connections in critical electronic systems like engine control modules and sensor assemblies. By ensuring a stable bond, conductive epoxy enables flawless operation of these systems, contributing to overall vehicle performance.

But the applications do not stop there. Conductive epoxy has found its way into medical devices where precision and consistency are paramount. It bonds electrodes onto medical sensors, guaranteeing accurate measurements. It also connects wires and cables within medical devices, creating dependable electrical pathways.

Conductive epoxy’s reach extends further still. It is used in solar cell manufacturing to interconnect individual cells and create efficient modules. Furthermore, it is employed in the field of flexible electronics, bonding conductive traces onto flexible substrates.

Advantages of Using Conductive Epoxy

Conductive epoxy, the unsung hero of the glue world, has emerged as a game-changer in various industries. With its exceptional electrical conductivity, unwavering reliability, and unmatched versatility, this superhero adhesive is revolutionizing the way we approach bonding. Whether you’re in electronics, automotive, aerospace, or even medicine, conductive epoxy brings precision, stability, and cost-effectiveness to your projects. Let’s explore the captivating advantages of harnessing the power of this extraordinary adhesive.

Enhanced Electrical Conductivity:

Unlike ordinary epoxy adhesives that insulate electrical connections, conductive epoxy contains particles like silver, copper, or graphite that create a dynamic pathway for electricity. This upgraded electrical conductivity makes it the perfect adhesive for applications that demand flawless electrical connections or grounding. Bid farewell to unreliable connections and welcome efficient current transfer with open arms.

Unwavering Reliability:

Conductive epoxy surpasses traditional methods like soldering or mechanical fastening in terms of reliability. Soldering poses a constant risk of joint failure due to thermal expansion and contraction. In striking contrast, conductive epoxy forms an unbreakable bond with the surfaces it graces, ensuring a durable and long-lasting electrical connection. Say goodbye to cracks or breaks caused by vibrations or thermal cycling—reliability has found its superhero.

Unmatched Versatility:

From metals to plastics, ceramics to composites—conductive epoxy flexes its muscles on a wide range of substrates. This extraordinary versatility makes it a staple across industries like electronics, automotive, aerospace, and telecommunications. Whether you need to bond components together, repair circuit boards with finesse, seal electrical connections securely, or create impenetrable EMI/RFI shielding, conductive epoxy has got your back.

Cost-Effectiveness at its Finest:

Conductive epoxy not only delivers exceptional performance but also saves you substantial costs compared to other methods. It can seamlessly replace expensive soldering techniques in select electronic assembly processes, all while providing reliable electrical connections. Say goodbye to additional equipment and labor costs associated with soldering. Conductive epoxy simplifies and streamlines the assembly process, saving you precious time and money.

Environmental Responsibility:

When it comes to sustainability, conductive epoxy shines like a beacon of hope. Unlike soldering, which involves lead-containing solder alloys, conductive epoxy poses no risks to human health or the environment. It’s typically solvent-free, reducing the emission of volatile organic compounds (VOCs) during application. If you prioritize environmental responsibility, conductive epoxy is your go-to adhesive.

Considerations for Choosing the Right Conductive Epoxy

This remarkable adhesive is a game-changer in industries like electronics, automotive, aerospace, and medical devices. With numerous options available, how do you choose the right conductive epoxy for your needs? Let’s delve into the key considerations.

First and foremost, let’s think about electrical conductivity. Conductive epoxies come with different resistivity levels, where lower resistivity signifies higher conductivity. The required level of conductivity will depend on factors such as the intended use and the materials being bonded. For applications demanding high conductivity like electrical connections or grounding, opt for an epoxy with very low resistivity.

Next up is compatibility. Ensure that the conductive epoxy you choose is compatible with the materials you’ll be bonding. Common substrates for these adhesives include metals, ceramics, and other conductive materials. You want an epoxy that forms a strong bond with these materials while providing reliable electrical conduction.

Consider curing time and temperature as well. Different conductive epoxies have varying curing requirements, so choose one that aligns with your application and process. Some may need elevated temperatures or longer curing times for optimal electrical conductivity.

Viscosity or flow characteristics also play a role. Low-viscosity epoxies are easier to work with and can effectively fill small gaps. High-viscosity options offer better structural support but may be more challenging to apply in certain situations.

Don’t forget about shelf life and storage requirements. Some conductive epoxies have limited shelf lives and specific storage conditions like refrigeration or protection from extreme temperatures. Understanding these requirements ensures the epoxy remains in good condition and retains its electrical conductivity.

Lastly, cost matters, especially for large-scale or commercial applications. Balance the desired level of electrical conductivity with your project’s budget.

dMyJEpiL6TI” >

Conclusion

There are indeed epoxy materials available that have the ability to conduct electricity.

These specialized formulations contain conductive fillers such as metallic particles or carbon nanotubes, which allow for the flow of electrical current. This unique property opens up a world of possibilities in various industries, from electronics to aerospace.

With their exceptional conductivity and adhesive properties, they offer both functionality and durability.