Picture this: you’re working under the hood of your car, faced with the decision of whether or not to use RTV (room-temperature vulcanizing) sealant on your intake manifold gasket. It’s a debate that has sparked countless discussions among car enthusiasts. Some swear by it, while others question its necessity and cost. In this blog post, we’ll dive into the pros and cons of using RTV sealant on an intake manifold gasket, considering factors like cost, ease of installation, durability, and performance.

Let’s start with cost – a factor that can make or break any automotive decision. RTV sealant won’t break the bank when compared to potential repair costs for a failed intake manifold gasket. Plus, if applied correctly, it can extend the lifespan of the gasket, saving you money in the long run. But beware. Improper application can lead to leaks and other issues that might leave you feeling like you’ve thrown your hard-earned cash down the drain.

Now let’s talk about ease of installation. Applying RTV sealant may require some extra time and effort, but it can provide a more secure seal for your intake manifold gasket. Just remember to carefully follow both the gasket and RTV sealant manufacturer’s instructions – no shortcuts allowed.

Durability is another crucial consideration. RTV sealants are built to withstand high temperatures and fluctuations found in engine compartments. They create a flexible and sturdy seal that can handle internal pressure, heat, vibrations – all those things that could potentially cause leaks.

But here’s what really matters – performance. Using RTV sealant properly can help prevent vacuum leaks, oil leaks, coolant leaks – basically any kind of leak that could compromise your engine’s performance and reliability. And who doesn’t want their car to perform at its best?

Ultimately, the decision to use RTV sealant on an intake manifold gasket is up to you. If you’re willing to put in the time and effort, and consider the potential benefits it offers, RTV sealant can be a game-changer for your intake manifold gasket installation. Just make sure to do your research and follow the recommended guidelines – no cutting corners.

So stick around as we dive deeper into the nitty-gritty of using RTV sealant on intake manifold gaskets. We’ll weigh the pros and cons,

What Is RTV?

Contents

- 1 What Is RTV?

- 2 What Is the Intake Manifold Gasket?

- 3 The Benefits of Using RTV on an Intake Manifold Gasket

- 4 The Drawbacks of Using RTV on an Intake Manifold Gasket

- 5 Inspecting the Mating Surfaces Before Applying RTV

- 6 How to Apply RTV on an Intake Manifold Gasket

- 7 Curing Time for RTV

- 8 Professional Recommendations and Personal Preferences

- 9 Conclusion

RTV, short for Real-Time Video, is a powerful technology that allows for the transmission and viewing of live video footage in real-time. In this comprehensive guide, we will explore the concept of RTV, its applications, advantages, and disadvantages. Whether you’re a tech enthusiast or simply curious about the world of video streaming, this article will provide you with all the essential details.

Definition and Functionality of RTV:

RTV is a technology that enables the transmission of live video footage over various digital platforms and networks. It allows users to capture and stream videos instantaneously, providing real-time viewing experiences to audiences around the world. This makes it an invaluable tool in various industries such as entertainment, sports, news broadcasting, security surveillance, and video conferencing.

Applications of RTV:

RTV has revolutionized the way we consume and interact with video content. Its applications are vast and varied:

- Entertainment: RTV allows for live streaming of concerts, sporting events, and other performances, bringing the action directly to viewers’ screens.

- News Broadcasting: Journalists can utilize RTV to report breaking news stories as they unfold, providing viewers with up-to-the-minute information.

- Security Surveillance: RTV enables real-time monitoring of premises, allowing for immediate responses to potential threats or incidents.

- Video Conferencing: Businesses can conduct virtual meetings and conferences with participants located in different parts of the world through RTV.

Advantages of RTV:

RTV offers numerous advantages over traditional video recording and playback methods:

- Real-Time Interaction: Viewers can engage with the content in real-time through comments, likes, and shares, fostering a sense of community and interactivity.

- Instantaneous Delivery: RTV eliminates the need for post-production editing and allows for immediate distribution of video content, ensuring viewers receive the latest information without delay.

- Cost-Effective: RTV reduces the need for expensive equipment and infrastructure, making it a more affordable option for content creators and businesses.

- Global Reach: With RTV, content can be accessed by audiences worldwide, breaking down geographical barriers and reaching a broader audience.

Disadvantages of RTV:

While RTV offers numerous benefits, there are some drawbacks to consider:

- Bandwidth Requirements: Real-time video transmission requires high bandwidth capabilities, which may pose challenges in areas with limited internet connectivity or slower network speeds.

- Technical Challenges: The complexity of RTV systems and the need for reliable equipment and software can present technical hurdles for users.

- Quality Control: Maintaining consistent video quality during live streaming can be challenging, as factors such as network congestion or equipment malfunctions can impact the viewing experience.

What Is the Intake Manifold Gasket?

The intake manifold gasket, though often overlooked, is a crucial component of an internal combustion engine. Nestled between the engine block and the intake manifold, this unassuming gasket plays a vital role in sealing the gap between these two parts. But why is this seal so important, you may ask?

First and foremost, the intake manifold gasket ensures a proper seal between the intake manifold and the engine block. This seal is essential for maintaining the correct air-fuel mixture inside the engine’s combustion chambers. Without it, the engine would struggle to perform efficiently and effectively.

But sealing isn’t the only task on the intake manifold gasket’s to-do list. It also acts as a gatekeeper, regulating the flow of air and fuel mixture into the engine. With channels and passages strategically designed within its structure, this gasket directs the mixture to each individual cylinder, ensuring an even distribution for optimal performance.

To withstand the harsh environment of an engine’s intake system — with its high temperatures and pressures — intake manifold gaskets are typically crafted from durable rubber or composite materials. These materials are carefully selected for their heat and chemical resistance, ensuring that the gasket can handle whatever challenges come its way.

Unfortunately, over time, even these resilient materials can deteriorate or develop leaks due to heat cycles and exposure to various chemicals. When this happens, it is crucial to replace the gasket promptly to prevent further engine damage and ensure optimal performance.

Installing a new intake manifold gasket requires attention to detail. Thoroughly cleaning both mating surfaces before installation is essential to achieve a proper seal. Additionally, following the manufacturer’s torque specifications for tightening the bolts is crucial to prevent over-tightening or under-tightening, both of which can lead to issues down the road.

The Benefits of Using RTV on an Intake Manifold Gasket

In the world of engine maintenance, even the smallest components can have a significant impact on performance and reliability. One such component is the intake manifold gasket, which plays a crucial role in sealing the connection between the intake manifold and the engine block. This article will explore the various benefits of using RTV (room temperature vulcanizing) sealant on an intake manifold gasket, including improved sealing performance, corrosion resistance, and ease of installation.

Enhanced Sealing Performance:

RTV sealant offers an additional layer of protection against leaks by establishing a more secure seal between the intake manifold and engine block. Over time, heat cycles and engine vibrations can cause gaskets to wear out or develop gaps. By applying a thin layer of RTV on both sides of the gasket, you can ensure a tighter and more reliable seal, effectively preventing any potential leaks.

Resistant to Corrosion:

Not only does RTV sealant withstand high temperatures, but it also exhibits resistance to various automotive fluids such as oil, coolant, and fuel. These fluids can come into contact with the gasket and potentially degrade its material over time. By utilizing RTV, you create a protective barrier that helps prevent fluid penetration and extends the lifespan of the gasket.

Simplified Installation:

One of the key advantages of using RTV sealant is its ability to compensate for minor imperfections in the mating surfaces of the intake manifold and engine block. Despite careful machining and installation, slight irregularities or imperfections may still be present. By employing RTV, you can fill in these gaps and create a more even surface for the gasket to seal against. This not only simplifies the installation process but also ensures a tighter and more effective seal.

Realizing Benefits in Automotive Applications:

The advantages of using RTV on an intake manifold gasket can be experienced in a wide range of automotive applications. Whether you are driving a daily commuter, a high-performance vehicle, or undertaking a classic car restoration project, RTV sealant can significantly improve sealing performance, protect against corrosion, and simplify the installation process. It provides an additional layer of security and peace of mind, ensuring that your engine’s air-fuel mixture remains optimal and your vehicle performs at its best.

The Drawbacks of Using RTV on an Intake Manifold Gasket

The use of RTV (room temperature vulcanizing) on an intake manifold gasket may seem like a convenient solution, but it is not without its drawbacks. These drawbacks can have serious consequences for your engine and the overall performance of your vehicle.

Firstly, excessive application of RTV can lead to disaster. If too much RTV is applied and it squeezes out, it can find its way into the engine’s intake ports or combustion chambers. This can result in serious engine damage, which is not something any car enthusiast wants to deal with.

Additionally, removing an intake manifold gasket that has been sealed with RTV can be a real challenge. Over time, RTV can harden, making it difficult to remove the gasket without damaging the mating surfaces. It’s like trying to open a jar of pickles with slippery hands – frustrating and potentially damaging.

Furthermore, using RTV as a long-term solution is not advisable. While it may temporarily fix the problem, it is not going to hold up in the long run. It is always best to replace the gasket with a new one to ensure proper sealing and prevent any potential issues down the road.

Another drawback of using RTV is that it can interfere with the proper torqueing of the intake manifold bolts. The excess thickness of the sealant can disrupt the clamping force applied to the manifold, resulting in uneven pressure distribution and possible leaks. This can lead to loss of horsepower and decreased performance.

Compatibility concerns are also a major drawback of using RTV on an intake manifold gasket. Not all intake manifold materials play well with RTV. It is crucial to check the manufacturer’s recommendations before applying RTV, as using it on incompatible materials can cause further damage or even complete failure.

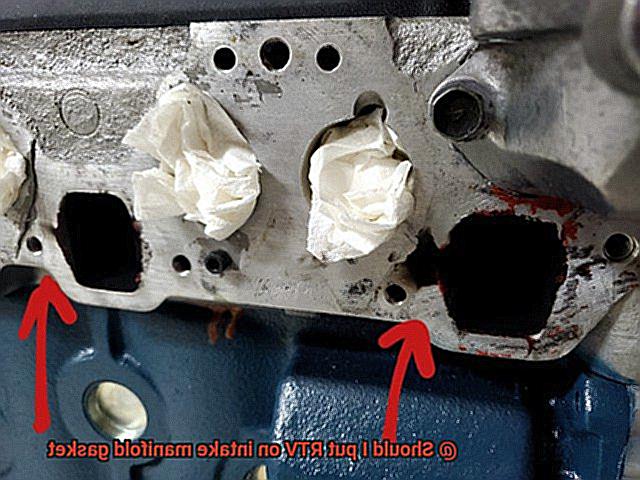

Inspecting the Mating Surfaces Before Applying RTV

Inspecting the mating surfaces before applying RTV (Room Temperature Vulcanizing) is an essential and often overlooked step that can make all the difference in achieving a proper seal between the intake manifold gasket and the engine block. This seemingly small task can have a huge impact on the performance and longevity of your engine.

So, why is inspecting the mating surfaces so important? Well, let me paint you a vivid picture. Imagine your engine as a finely-tuned orchestra, with each component playing its part harmoniously. The intake manifold gasket acts as a conductor, ensuring that all the notes are in perfect sync. However, if there are any imperfections or damage on the mating surfaces, it’s like having a musician play out of tune. The result? A cacophony of leaks and decreased performance.

To properly inspect the mating surfaces, you need to be thorough and meticulous. Start by giving both the intake manifold and engine block a thorough cleaning. Think of it as preparing a canvas for a masterpiece. Use a suitable solvent to remove any dirt, oil, or remnants of old gasket material that may be lurking around. A clean surface is not only visually appealing but also essential for accurate examination and proper adhesion of the RTV.

Once the surfaces are squeaky clean, it’s time to put on your detective hat and examine them closely. Grab a good source of lighting and take a close look for any visible signs of damage or irregularities. Look for cracks that can occur due to excessive heat or stress, warping that may result from improper torque during installation or engine overheating, and pitting caused by corrosion or wear over time.

But don’t stop there. To truly ensure flatness and perfection, grab a straight edge tool and perform the ultimate test. Place that straight edge across different areas of the mating surfaces and observe if there are any gaps or light passing through. If you see significant gaps or uneven contact between the straight edge and surface, it’s a clear sign that your surfaces are not as flat as they should be.

Now, let’s say you do find some imperfections during your inspection. Don’t panic just yet. There are several ways to address these issues and bring back harmony to your engine. One option is resurfacing, which involves machining or sanding down the mating surfaces to remove any imperfections and restore flatness. However, this delicate task should be entrusted to professionals or experienced technicians who have the skills and precision required for this job.

In some cases, the damage may be too extensive or cannot be repaired effectively through resurfacing alone. In such situations, it may be necessary to replace either the intake manifold or engine block. But beware. Don’t settle for cheap imitations. It’s crucial to use OEM parts or high-quality aftermarket replacements to ensure proper fitment and optimal performance.

If the damage is localized or there are cracks that need attention, specialized repair techniques like epoxy filling or metal stitching may be viable options. However, it’s important to seek professional advice before proceeding with these methods to ensure they don’t compromise the integrity of the mating surfaces.

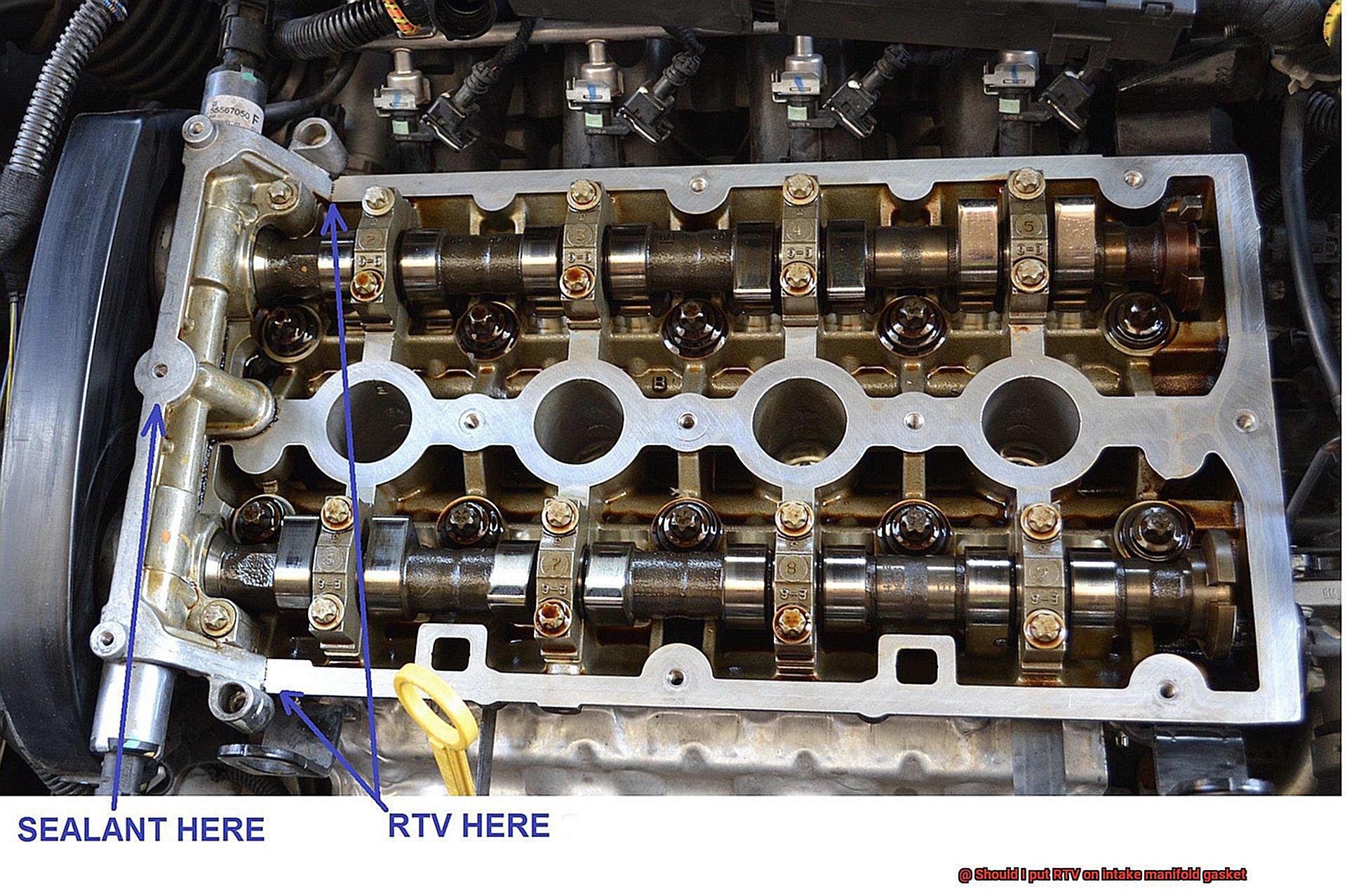

Once you’ve inspected and addressed any necessary repairs or replacements, it’s finally time for the grand finale – applying the RTV. Think of it as the final brushstroke on a masterpiece. The RTV acts as a sealant, filling in any remaining small imperfections on the mating surfaces and providing an additional layer of protection against leaks. It’s like adding that extra touch of perfection to ensure a flawless performance from your engine.

How to Apply RTV on an Intake Manifold Gasket

In this comprehensive guide, we will take you through the step-by-step process of applying RTV on an intake manifold gasket. Whether you’re a car enthusiast or simply want to learn something new, this guide is perfect for you.

Step 1: Thoroughly Clean the Surfaces

Before applying RTV, it is crucial to clean both the intake manifold and cylinder head surfaces thoroughly. Use a specialized cleaner to remove any oil, grease, or dirt that might hinder the adhesion of the RTV. The cleaner ensures a clean and smooth surface for the RTV to bond with, creating a reliable seal.

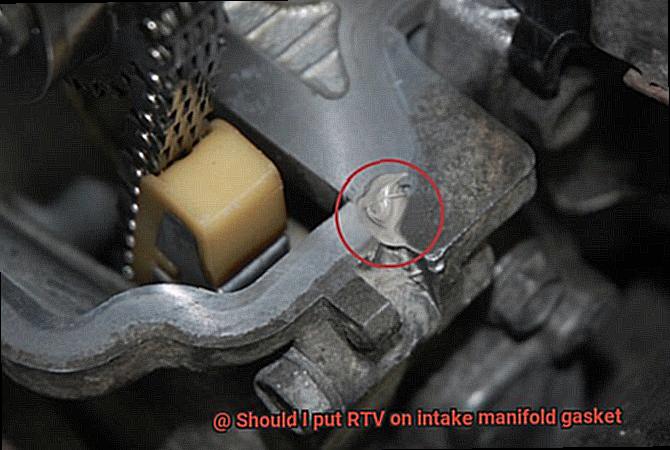

Step 2: Apply a Thin and Even Layer of RTV

With a steady hand, squeeze a small bead of RTV along the entire length of the intake manifold gasket. It is essential to apply a thin and even layer to prevent excess RTV from squeezing out when tightening the bolts. The thin layer ensures proper sealing without causing any issues during assembly.

Step 3: Smooth Out the RTV

After applying the RTV, use your finger or a brush to smooth out the bead. This step is crucial as it helps eliminate any gaps or air pockets between the gasket and the surfaces it seals against. By smoothing out the RTV, you ensure maximum contact between the gasket and the surfaces, enhancing its sealing capabilities.

Step 4: Install the Gasket

Carefully place the intake manifold gasket onto the RTV, aligning it with the bolt holes on both the intake manifold and cylinder head. Ensure that it sits flat and is not twisted or misaligned. Proper alignment guarantees a secure fit and prevents any leaks from occurring.

Step 5: Gradually Tighten the Bolts

Start tightening the intake manifold bolts gradually and in a crisscross pattern. This method distributes pressure evenly, minimizing the risk of damaging the manifold or cylinder head. Refer to your vehicle’s service manual for specific torque specifications to ensure proper tightening.

Step 6: Clean Up Excess RTV

Remove any excess RTV that may have squeezed out between the gasket and surfaces. Use a clean rag or paper towel dampened with a solvent recommended by the RTV manufacturer. Cleaning up excess RTV ensures a neat and tidy finish, preventing any interference with other engine components.

Curing Time for RTV

Today, we embark on a journey to uncover the secrets behind achieving flawless seals by exploring the factors that influence their curing time. Brace yourselves, as we delve into the art and science of RTV sealants.

Temperature: The King of Curing Time

Humidity: A Moisture Tango

The dance between humidity levels and curing time is quite the spectacle. Higher humidity slows down the process, while lower humidity quickens it. Maintaining control over humidity during application is crucial for proper curing. Consider utilizing a controlled environment or adjusting application time when faced with extreme humidity levels.

Thickness: Thin is In.

When it comes to RTV sealants, less is more. Thin layers cure faster compared to their thicker counterparts. Adhering to the manufacturer’s recommended thickness is paramount for achieving optimal results. Remember, don’t go overboard with your application – a little goes a long way.

Curing Time: Patience is a Virtue

Now that you’ve skillfully applied your chosen RTV sealant, it’s time to embrace patience. Rushing the curing process can lead to weak bonds and potential leaks. Allow your sealant at least 24 hours before subjecting it to stress or pressure. Trust us, patience pays off when striving for a strong and effective seal.

You now possess the knowledge to conquer the world of RTV sealants and create impeccable seals like a true adhesive aficionado. Remember, temperature, humidity, thickness, and patience are the key elements shaping curing time. By mastering these factors, you’ll ensure reliable performance, prevent leaks, and become the glue guru you were destined to be.

Professional Recommendations and Personal Preferences

When it comes to using RTV (Room Temperature Vulcanizing) on an intake manifold gasket, professionals and individuals have varying opinions. In this blog post, we will explore the differences between professional recommendations and personal preferences, providing a comprehensive overview of the subject.

Professional Recommendations:

- Addressing imperfections: Professionals strongly recommend using RTV to fill gaps and inconsistencies in the mating surfaces of the intake manifold gasket. This ensures a secure seal and prevents leaks.

- Extra safeguard: The engine’s vibrations and heat can cause the intake manifold to expand and contract, potentially loosening fasteners. RTV acts as an additional layer of security to prevent leaks caused by these movements.

Personal Preferences:

- Positive experiences: Some individuals have had positive experiences with using RTV on intake manifold gaskets. They find it adds protection and peace of mind.

- Trusting the gasket alone: Others prefer relying solely on the gasket’s design and material properties to create a secure seal. They believe a properly installed gasket should be sufficient without additional sealants.

Manufacturer Guidelines:

Consulting manufacturer guidelines is crucial for specific recommendations on using RTV on intake manifold gaskets. They provide valuable insights into appropriate RTV type and amount for your application.

IlOxvazpSuU” >

Conclusion

When it comes to the question of whether or not to put RTV on an intake manifold gasket, there are a few key factors to consider. First and foremost, it’s important to understand what RTV is and how it works. RTV stands for Room Temperature Vulcanizing, and it is a type of sealant commonly used in automotive applications. Its purpose is to create a tight and durable seal between two mating surfaces.

Now, let’s talk about the intake manifold gasket itself. This gasket is responsible for sealing the gap between the intake manifold and the engine block. It plays a crucial role in ensuring that air and fuel are properly delivered to the engine cylinders for combustion. Any leaks or gaps in this area can lead to a variety of issues, including decreased engine performance and fuel efficiency.

So, should you use RTV on your intake manifold gasket? The answer depends on several factors. In some cases, using RTV can be beneficial as it provides an extra layer of protection against potential leaks. However, it’s important to note that not all intake manifold gaskets require RTV. Some gaskets come with built-in seals or coatings that eliminate the need for additional sealants.

If you do decide to use RTV on your intake manifold gasket, there are a few key steps you should follow. First, ensure that both surfaces are clean and free from any debris or old sealant residue. Apply a thin bead of RTV along the entire length of the gasket surface, making sure to cover any potential leak points.

However, it’s crucial not to overdo it with the RTV. Applying too much sealant can actually hinder its effectiveness and may cause excess material to enter into the engine cylinders during installation.

In conclusion, while using RTV on an intake manifold gasket can provide added protection against leaks, it’s essential to assess whether your specific gasket requires this additional step.