Have you ever wondered if there’s a glue out there that can conduct electricity? Well, hold onto your hats because we’re about to dive into the mind-boggling world of conductive glue.

Picture this: a sticky substance that not only bonds things together but also allows electricity to flow through it. It’s like having a superhero sidekick for all your electronic devices, making repairs and building gadgets a breeze.

Today, we’re going to take a closer look at this electrifying innovation and discover if such a miraculous adhesive truly exists.

So, get ready for an adventure that will leave you buzzing with excitement as we explore the captivating realm of electricity-conducting glues.

What is Conductivity?

Contents

- 1 What is Conductivity?

- 2 Traditional Glues vs. Conductive Glues

- 3 Applications of Conductive Glue

- 3.1 Electronics – A Bonding Revolution:

- 3.2 Flexible Electronics – Embracing Freedom:

- 3.3 Automotive Industry – Driving Connections:

- 3.4 Medical Marvels – Bonding with Care:

- 3.5 Renewable Energy – Harnessing the Power of the Sun:

- 3.6 Aerospace – Taking Flight with Reliability:

- 3.7 Emerging Applications – 3D Printing Electronics:

- 4 Types of Conductive Glue

- 5 Surface Preparation for Using Conductive Glue

- 6 Repairing Electronic Circuits with Conductive Glue

- 7 Limitations of Conductive Glue

- 8 Advantages of Using Conductive Glue

- 9 Conclusion

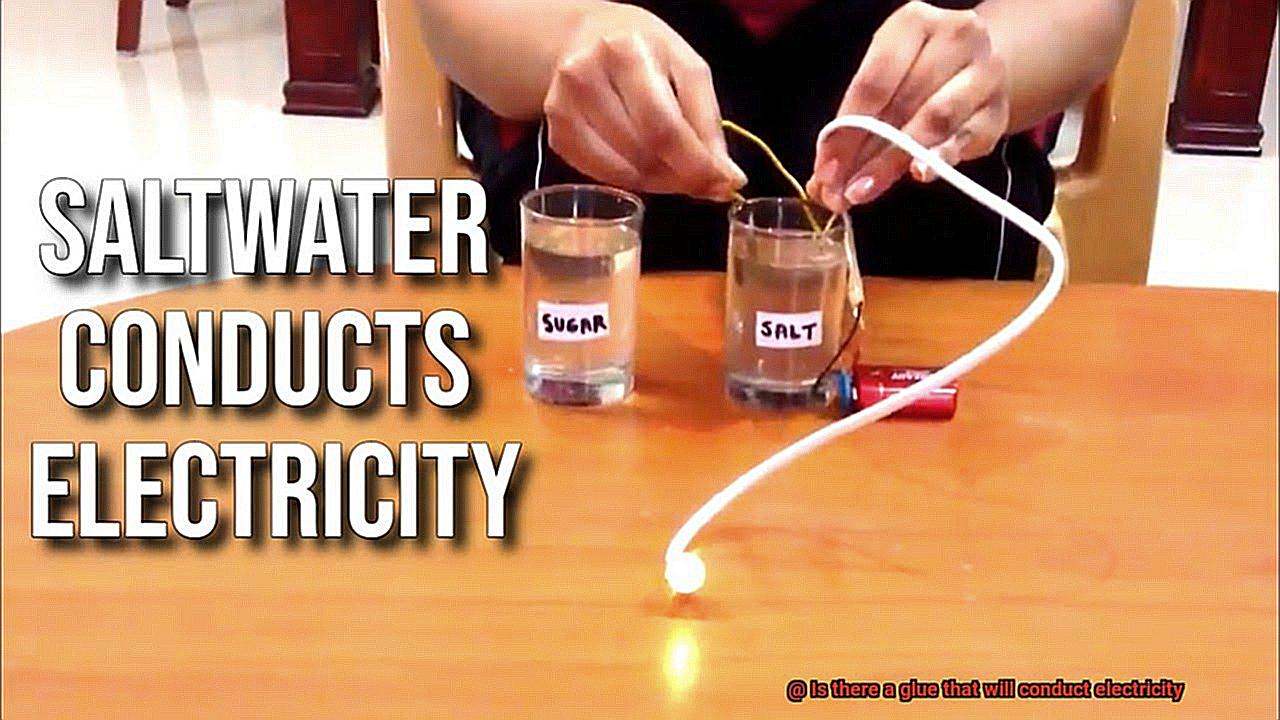

It powers our world, illuminates our nights, and propels our technology forward. But have you ever wondered how it travels through different materials? The answer lies in conductivity.

Conductivity is the magical property that allows materials to conduct electric current. It is the ability of a substance to let electrons flow freely, like a river rushing downstream. This flow is influenced by the arrangement and behavior of atoms or molecules within the material.

Metals are the superheroes of conductivity. They boast high conductivity because they have free electrons that can easily move through their atomic structure. Copper and aluminum, for example, are the go-to choices for electrical wiring and circuits due to their exceptional conductivity.

On the other end of the spectrum, we have insulators. These materials have low conductivity as they tightly hold onto their electrons, preventing them from venturing out into the world. Rubber, plastic, and wood fall into this category. Insulators act as barriers, keeping electricity contained and controlled.

But what about those materials that fall somewhere in between? Welcome to the world of semi-conductors. These materials possess unique properties that allow them to conduct electricity under certain conditions, although not as efficiently as metals. Semiconductor elements like silicon and germanium play a crucial role in the electronic industry, acting as the building blocks for transistors and microchips.

We quantify conductivity using units such as Siemens per meter (S/m) or ohm-meter (Ω∙m). High conductivity means low resistance, enabling electric current to flow with ease. Low conductivity means high resistance, impeding the flow of electric current.

Now, let’s talk about glues. Glue is a remarkable substance that joins different materials together, but can it conduct electricity? Most traditional glues, such as white glue or super glue, are insulators. They lack free-moving charged particles that can carry an electric current. These glues are designed for adhesion, not electrical conductivity.

However, fear not. There are specialized conductive glues available that can conduct electricity with finesse. These glues contain additives or fillers like silver or graphite particles, which allow the electric current to flow effortlessly.

Conductive glues are the unsung heroes of the electronics and electrical world. They offer a convenient solution for creating electrical connections without the need for soldering. Here are some key points to consider:

- Conductivity: Conductive glues possess a certain level of electrical conductivity, capable of transmitting electric current. However, the actual conductivity may vary depending on factors like particle concentration and size.

- Applications: Conductive glues find their purpose in electronics, bonding wires, attaching components to circuit boards, and repairing electronic circuits. They offer a versatile alternative when traditional soldering is not feasible or desired.

- Surface Preparation: Proper surface preparation is critical when using conductive glues to ensure optimal electrical contact. The surfaces must be clean and free from any contaminants that could hinder conductivity.

- Limitations: While conductive glues can provide electrical conductivity, they do have limitations. High-current applications or those requiring precise control of electrical properties may not be suitable for these glues.

In conclusion, most glues are insulating materials that cannot conduct electricity. However, specialized conductive glues exist, designed to bridge the gap between adhesive power and electrical prowess. These glues offer a unique combination of properties, making them indispensable in various electronics and electrical bonding applications. Remember to choose the right type of conductive glue based on your specific requirements and ensure proper surface preparation for optimal electrical contact.

Traditional Glues vs. Conductive Glues

When it comes to glues, there are two distinct categories that hold vastly different properties and capabilities. On one hand, we have traditional glues, which are made of organic materials such as polymers, resins, or adhesives. These glues are widely used for bonding various materials together but lack the ability to conduct electricity.

On the other hand, we have conductive glues, which are specifically formulated to possess electrical conductivity. These glues are created by incorporating conductive particles or fillers into the adhesive matrix.

The addition of conductive particles is what sets conductive glues apart from their traditional counterparts. These particles can be metals like silver, copper, or gold, or they can be carbon-based materials such as graphite or carbon nanotubes. The presence of these conductive additives allows the glue to create a path for electrical current to flow through.

One of the key advantages of conductive glues is their ability to bond dissimilar materials that may not be easily soldered together. Soldering requires compatible melting temperatures, making it challenging to join materials with different melting points. Conductive glue, on the other hand, overcomes this limitation and enables electrical connections between materials that would otherwise be incompatible.

Conductive glues also offer flexibility and conformability, making them ideal for applications where traditional glues fall short. They excel at bonding irregularly shaped surfaces or flexible substrates, opening up a whole new world of possibilities for designers and engineers. Imagine being able to create electrical connections on curved surfaces or flexible electronics – the potential for innovation is boundless.

However, it’s important to note that conductive glues may not possess the same strength and durability as traditional glues. The inclusion of conductive particles within the glue can reduce its overall adhesive strength and may impact its long-term stability and reliability. Additionally, the electrical conductivity of conductive glues can vary depending on factors such as the type and concentration of the conductive particles used.

Choosing the right conductive glue for a specific application is crucial to ensure optimal performance and reliability. Different conductive glues have varying properties and are designed for specific purposes. It’s important to consider factors such as electrical conductivity, adhesive strength, and long-term stability when selecting a conductive glue.

Applications of Conductive Glue

Today, we will delve into the mesmerizing applications of conductive glue across different industries, from electronics to aerospace and even renewable energy. So, don your lab coat and let’s explore the enchanting world of conductive glue.

Electronics – A Bonding Revolution:

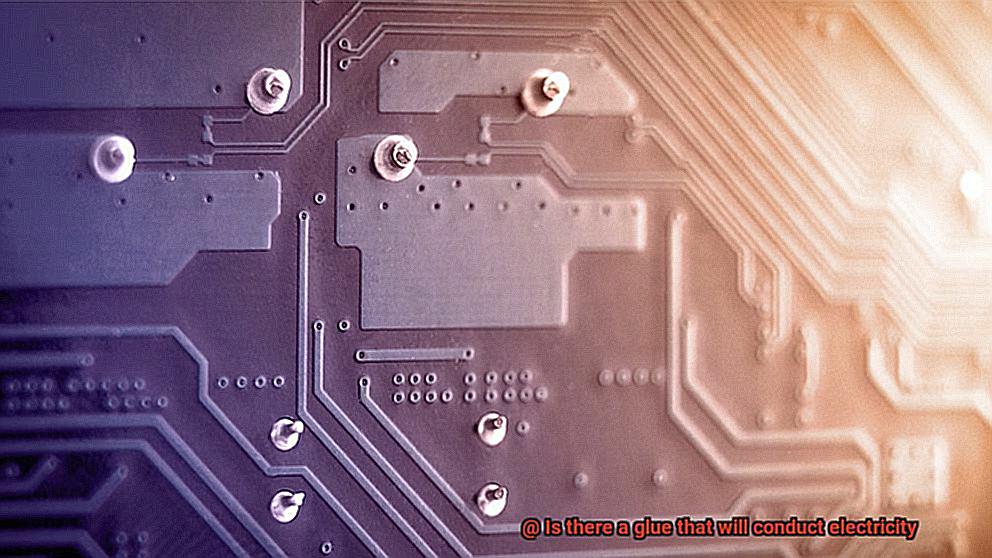

Conductive glue has revolutionized the electronics industry by providing an alternative to soldering. It enables reliable and cost-effective bonding of components like resistors, capacitors, and integrated circuits to circuit boards. With lower manufacturing costs and reduced heat stress on sensitive components, conductive glue is a game-changer in electronic assembly.

Flexible Electronics – Embracing Freedom:

Imagine a world where electronics can bend and flex like rubber. Conductive glue makes this dream a reality by enabling the creation of wearable devices, flexible displays, and more. By bonding flexible circuits and components together, conductive glue unlocks endless possibilities for innovation.

Automotive Industry – Driving Connections:

In the fast-paced world of automotive technology, secure electrical connections are crucial. Conductive glue plays a pivotal role by bonding sensors, connectors, and other electrical components within vehicles. Its adhesive properties ensure durability even in harsh conditions, keeping your car running smoothly.

Medical Marvels – Bonding with Care:

Conductive glue finds its way into medical devices and equipment by bonding electrodes or sensors to the human body. With non-toxic properties suitable for direct skin contact, it offers a safe and reliable solution for diagnostic or therapeutic purposes.

Renewable Energy – Harnessing the Power of the Sun:

Solar panels have become a symbol of sustainability, and conductive glue plays a vital role in their assembly. By connecting individual solar cells, conductive glue enhances flexibility, reduces weight, and improves resistance to thermal stress, making solar energy more accessible.

Aerospace – Taking Flight with Reliability:

In the aerospace industry, reliable electrical connections are essential for avionics systems in high-vibration and high-temperature environments. Conductive glue provides a strong bond, ensuring secure electrical connections that can withstand the rigors of flight.

Emerging Applications – 3D Printing Electronics:

The future is here. Researchers are exploring the use of conductive adhesive materials in 3D printing electronics. Imagine printing custom electronic circuits directly onto substrates, opening up a whole new world of possibilities in personalized electronics.

Types of Conductive Glue

In this electrifying adventure, we will explore the different types of conductive glue, their unique properties, and how they are used. Prepare to be amazed as we uncover the secret behind these remarkable adhesives that not only bond but also conduct electricity.

Epoxy-based Conductive Glue – The Reliable Connector:

Imagine a broken circuit board in need of urgent repair. Enter epoxy-based conductive glue, your reliable ally in such situations. This type of glue is created by blending graphite or carbon black fillers with an epoxy resin. Its exceptional adhesion and conductivity make it perfect for joining electrical components or repairing damaged tracks on circuit boards. With the power to bond and conduct electricity simultaneously, epoxy-based conductive glue is truly a superhero in the adhesive world.

Silver-based Conductive Glue – The High-Speed Hero:

In scenarios where lightning-fast connections are required, like high-frequency circuits or sensitive component bonding, have no fear—silver-based conductive glue is here to save the day. This adhesive contains tiny silver particles suspended in a polymer matrix. As we all know, silver is an incredible conductor of electricity, making this glue the epitome of high conductivity. It is ideal for applications where low resistance is crucial for optimal performance.

Copper-based Conductive Glue – The Cost-Effective Champion:

In some cases, saving money is as important as conducting electricity. That’s where copper-based conductive glue shines. It contains copper particles that offer good electrical conductivity at a lower cost compared to silver. So, if you’re searching for an affordable solution without compromising too much on performance, copper-based conductive glue is your go-to option.

Specialty Conductive Glue – The Flexible Friend:

Imagine a world where even glue can stretch and bend without losing its conductivity. Well, that world exists. Specialty conductive glues are designed to withstand all sorts of twists and turns, making them perfect for wearable electronics or flexible circuits. With their flexibility and durability, these glues bring a new level of versatility to the world of conductive bonding.

Choosing the Perfect Glue – The Quest for Compatibility:

Now that we’ve explored the different types of conductive glue, how do you choose the perfect one for your needs? It’s essential to consider factors such as required conductivity, substrate material, application method, and curing time. Don’t forget to follow the manufacturer’s instructions and conduct tests to ensure compatibility and achieve desired performance. Choose wisely, my friends.

Surface Preparation for Using Conductive Glue

Today, we shall unravel the secrets of surface preparation, an essential ritual before harnessing the power of this enchanting adhesive. Prepare yourself, for this is the key to forging unbreakable connections that shall endure the test of time.

First and foremost, cleanliness reigns supreme. You must ensure that the surface is devoid of any impurities that could hinder adhesion – no dirt, oils, or contaminants allowed. Arm yourself with a mild detergent or isopropyl alcohol and scrub away. But beware, my friends, for harsh chemicals can wreak havoc upon your materials; we crave strength, not destruction.

Now, let us delve into the art of roughening the surface. This step holds particular significance when bonding non-conductive materials like plastics or ceramics. Seize sandpaper or abrasive pads and create a textured landscape for your adhesive to cling onto. Trust me, this multitude of contact points will grant your conductive glue an unyielding grip.

Ah, but those treacherous oxide layers that plague certain metal surfaces must not be forgotten. They must be banished before your conductive glue can work its magic. Employ a fine-grit sandpaper or a specialized oxide-removing solvent to obliterate these foes and pave the way for seamless conductivity.

Next, we shall activate the surface. Certain materials – glass and specific plastics, to be precise – yearn for an extra dose of affection to bolster their adhesion. Unleash plasma treatment or coat them with a primer designed to enhance their bondability. Consider this as a gentle nudge to propel your surface towards an extraordinary union.

Alas, we must ensure that our canvas is void of moisture before applying the conductive glue. Moisture, like a wicked sorceress, can vanquish both adhesion and conductivity in a single blow. Allow the surface ample time to air dry or hasten the process with a clean, lint-free cloth.

Ah, one final note of caution – handle the prepped surface with pristine gloves or tools. We mustn’t allow fingerprints, oils, or dust particles to mar our adhesive extravaganza.

By following these sacred rituals, you shall unlock the full potential of conductive glue for your electrical connections. However, do remember that each glue and material may possess its own unique requirements. Consult the instructions bestowed upon you by the manufacturers to ensure an outcome befitting your desires.

Repairing Electronic Circuits with Conductive Glue

In this article, we will explore the benefits, applications, and essential tips for using this innovative adhesive. Whether you’re a tech enthusiast or a DIY electronics repair enthusiast, this guide aims to equip you with the knowledge needed to embark on a successful circuit repair journey.

Understanding Conductive Glue:

- Definition: Conductive glue, also known as electrically conductive adhesive (ECA), is a unique adhesive that contains conductive particles, enabling it to create an electrical path between electronic components.

- Advantages over traditional soldering: Conductive glue offers an alternative to soldering, eliminating the need for high heat and reducing the risk of damaging delicate components.

- Versatile applications: It can fix broken traces on circuit boards, connect wire leads to components, repair flexible circuits, and create electrical connections on unconventional substrates like plastics or glass.

Surface Preparation:

- Essential step: Proper surface preparation is crucial for successful bonding and conductivity.

- Pristine cleanliness: Ensure surfaces are free from contaminants that hinder conductivity.

- Activators and primers: Some conductive glues require activators or primers to enhance adhesion and conductivity.

Application and Curing:

- Convenient forms: Conductive glue comes in syringes for precise application or pre-cut adhesive tapes for easy handling.

- Curing process: Most conductive glues cure at room temperature, but some may require elevated temperatures for faster curing.

- Unyielding bond: Once cured, conductive glue forms a robust bond that withstands vibrations and thermal cycles.

Considerations and Limitations:

- High-current applications: Traditional soldering or specialized electrical connections may be more suitable for high-current applications.

- Electrical precision: Alternative methods should be considered when precise electrical characteristics are crucial.

Safety and Availability:

- Safety precautions: Follow manufacturer’s instructions and safety guidelines, as some formulations may contain volatile chemicals or pose health hazards if mishandled.

- Easy availability: Conductive glue can be purchased from electronics suppliers or online retailers.

Limitations of Conductive Glue

This innovative adhesive has revolutionized the electronics industry, providing an alternative to traditional methods like soldering and wire bonding. However, it’s important to be aware of the limitations of conductive glue before diving in.

In this article, we will explore the drawbacks of this adhesive, allowing you to make informed decisions for your projects.

Lower Conductivity:

Conductive glue falls short in terms of conductivity when compared to metal conductors, soldering, or wire bonding.

Its lower conductivity leads to higher resistance and decreased performance in certain applications, especially those that demand optimal conductivity.

Environmental Stability:

Conductive glue may not be suitable for high-temperature applications or environments with high humidity levels. Over time, the adhesive properties can deteriorate, compromising the integrity of your electrical connections.

If your project is exposed to extreme temperatures or moisture, consider alternative bonding methods.

Mechanical Strength and Durability:

While conductive glue provides sufficient bonding for many applications, it may not be as strong or durable as soldering or welding. Heavy mechanical stress, frequent vibrations, or impacts can weaken the adhesive over time. For more robust connections, explore alternative methods that offer superior mechanical strength.

Curing Time:

Conductive glue may require longer curing times compared to other bonding methods. This can slow down assembly processes and delay project completion. Plan accordingly and allocate sufficient time for the adhesive to cure.

Material Compatibility:

Not all materials are compatible with conductive glue. Some substrates or components may have compatibility issues, limiting its use in specific applications. Always ensure that conductive glue is compatible with the materials involved to avoid any unwanted surprises.

Advantages of Using Conductive Glue

Conductive glue is revolutionizing the way electrical connections are made in various industries.

Its unique properties and benefits make it a superior choice over traditional methods like soldering or welding.

Here are the advantages of using conductive glue:

- Versatility: Conductive glue offers versatility in bonding different materials together. It can be used on metals, plastics, ceramics, fabrics, and more. This makes it ideal for applications where traditional methods may not be feasible.

- Ease of Use: Conductive glue is easy to use, even for beginners. It is typically available in a syringe or tube, allowing for precise application. It eliminates the need for complex soldering techniques and specialized equipment, making it suitable for DIY projects and small-scale repairs.

- Cost-Effective: Conductive glue is a cost-effective option compared to soldering. The additional materials required for soldering, such as solder wire, flux, and a soldering iron, can be expensive. Conductive glue comes in affordable packaging sizes and requires minimal additional tools, making it an economical choice for both commercial applications and personal projects.

- Flexibility: Conductive glue offers flexibility in both application and design possibilities. It can conform to irregular shapes and contours, allowing for more creative design options in electronic devices or circuitry. Additionally, it can be used to repair broken circuit traces or damaged electronic components without complex rework procedures.

- Non-Destructive: Unlike soldering or welding, which involve high temperatures that can damage sensitive electronic components, conductive glue provides a non-destructive method of electrical connection. It eliminates the risk of heat-induced damage and allows for bonding heat-sensitive materials or components.

- Enhanced Durability: Conductive glue forms a strong and durable bond between materials, ensuring reliability and longevity. It can withstand various environmental conditions like temperature changes, vibrations, and moisture. This makes it suitable for applications in automotive electronics or aerospace industries.

- Reversible Connections: Conductive glue allows for temporary or removable connections, which can be advantageous during prototyping or testing phases. It enables easy disassembly and rework without causing permanent damage to the components or materials involved.

hFK0CIpTqsE” >

Also Read: Can You Super Glue Electrical Wires?

Conclusion

In conclusion, the quest for a glue that can conduct electricity continues to be an ongoing pursuit.

While there are conductive adhesives available in the market, they often fall short when it comes to providing reliable and efficient electrical conductivity. Researchers and scientists are constantly exploring new materials and techniques to bridge this gap.

With advancements in nanotechnology and the development of innovative composite materials, there is hope on the horizon. The day may not be far when we see a glue that not only bonds surfaces but also conducts electricity seamlessly, revolutionizing various industries such as electronics, automotive, and renewable energy.

So, while we may not have a definitive answer yet, the future looks promising for an electrically conductive adhesive that will spark a whole new era of possibilities.