Thinking about using Liquid Nails for your MDF project?

Not sure if it’s the right move? Well, fear not my friend.

I’m here to share my wisdom as a DIY and woodworking guru and give you the lowdown on whether Liquid Nails is the right adhesive for your MDF masterpiece. Whether you’re sprucing up your space with a small home improvement project or tackling a big carpentry challenge, choosing the right glue can be a game-changer.

So, let’s jump in and discover the magic of Liquid Nails and its compatibility with MDF.

What is Liquid Nails?

Contents

- 1 What is Liquid Nails?

- 2 What is MDF?

- 3 Is Liquid Nails Suitable for Bonding MDF?

- 4 Factors to Consider When Selecting Liquid Nails for Bonding MDF

- 5 Preparing the Surfaces for Bonding with Liquid Nails

- 6 Applying Liquid Nails to MDF

- 7 Securing the Bond with Pressure and Drying Time

- 8 Alternatives to Using Liquid Nails on MDF

- 9 Conclusion

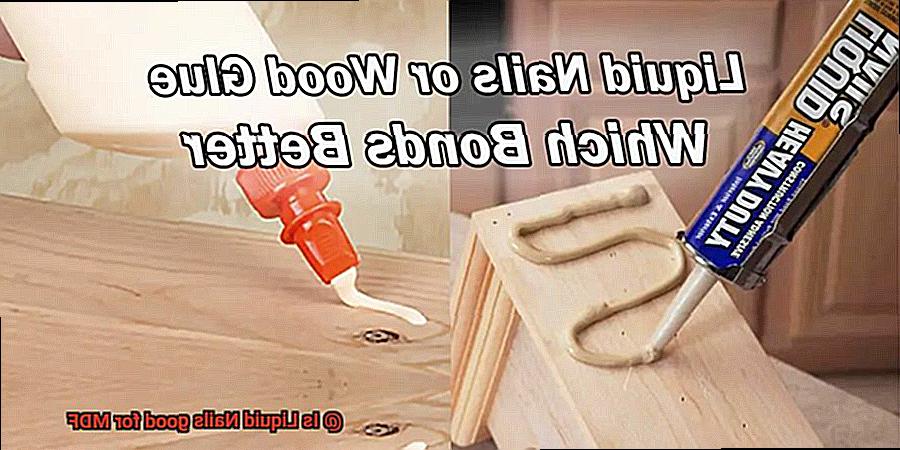

When it comes to construction and home improvement projects, finding the perfect adhesive is crucial. One brand that has gained a reputation for its strength and versatility is Liquid Nails. In this blog post, we will explore everything you need to know about Liquid Nails, from its powerful formulation to its wide range of applications. Get ready to discover why Liquid Nails is the go-to adhesive for your next project.

Liquid Nails: A Powerful Bonding Solution

Liquid Nails is a specially formulated construction adhesive designed to bond an array of materials together. With its superior bonding strength, it can securely unite wood, concrete, metal, and even MDF (medium-density fiberboard). Whether you’re building furniture or tackling a large-scale construction project, Liquid Nails delivers a durable and long-lasting bond that stands the test of time.

Formulations to Suit Every Need

Liquid Nails offers a variety of formulations, each tailored for specific applications. The general-purpose version is the most common type, suitable for numerous materials and surfaces. However, it’s crucial to select the right formulation based on your project’s requirements.

For instance, if you’re working with porous surfaces like wood or MDF, opt for an adhesive designed specifically for these materials.

Bonding MDF with Liquid Nails:

MDF is a popular material in woodworking due to its affordability and versatility. When bonding MDF, it’s essential to choose an adhesive that can effectively adhere to porous surfaces. Liquid Nails proves to be an excellent choice, but proper surface preparation and application techniques are vital for optimal results.

Surface Preparation:

Before applying Liquid Nails to MDF, ensure both surfaces are clean, dry, and free from dust or debris. To enhance the adhesive’s grip, lightly sand the MDF surface to create a rougher texture.

Application Techniques:

Achieving an even and adequate application of Liquid Nails on MDF is key. Apply the adhesive in a zigzag pattern or small dots along the surface. This technique ensures the adhesive is distributed evenly, preventing excessive squeeze-out during bonding.

Pressing and Curing:

After applying Liquid Nails, firmly press the surfaces together using clamps or weights to ensure proper contact. Follow the manufacturer’s instructions regarding drying time and any additional steps, such as applying pressure or allowing for curing.

Considerations and Alternatives:

While Liquid Nails provides a strong bond for MDF, it may not always be the optimal choice for every application. Depending on your project’s specific requirements, alternatives like PVA glue or epoxy might offer better performance and durability. It’s advisable to test the adhesive on a small area of the MDF before proceeding with the full application.

What is MDF?

Medium-Density Fiberboard (MDF) is a remarkable engineered wood product that has revolutionized the construction and furniture manufacturing industries. By breaking down hardwood or softwood residuals into wood fibers and combining them with wax and a resin binder, MDF is created. This mixture is then subjected to high pressure and heat, resulting in a dense and uniform board that possesses numerous benefits.

One of the standout features of MDF is its consistency and smoothness. Unlike natural wood, MDF lacks knots or grain patterns, making it a dream to paint, laminate, or veneer. Its uniformity also allows for precise cuts and shaping, making it a popular choice for intricate designs or detailed woodworking projects.

The affordability and versatility of MDF have contributed to its widespread use. As a cost-effective substitute for solid wood, MDF has become a staple material for furniture manufacturers, cabinet makers, and carpenters. Its ability to be easily customized and finished allows for endless design possibilities.

However, it is important to be aware of the limitations of MDF. Moisture vulnerability is one concern as MDF can swell and warp when exposed to moisture. Therefore, caution must be exercised when using MDF in environments with high humidity or moisture levels.

Another consideration is the formaldehyde content in MDF. While formaldehyde is used as a binding agent in the manufacturing process, prolonged exposure to this chemical compound can have adverse health effects. To ensure safety, it is crucial to choose MDF products that meet national or international standards for formaldehyde emissions.

Is Liquid Nails Suitable for Bonding MDF?

This incredible brand of construction adhesive is renowned for its unrivaled ability to bond an array of materials, including wood, metal, and plastic. But the question remains: Is it suitable for bonding MDF? Let’s dive deeper into the details and unveil the truth.

Liquid Nails comes highly recommended for bonding MDF, thanks to its exceptional adhesive properties and remarkable versatility. Crafted to deliver a bond that can withstand the weight and stress placed on the bonded surfaces, Liquid Nails guarantees durability and excellence. Whether you’re pouring your passion into crafting furniture, assembling cabinets, or undertaking any other interior application, rest assured that Liquid Nails has your back.

However, there are a few crucial points to bear in mind when using Liquid Nails on MDF. First and foremost, surface preparation is paramount when it comes to achieving a successful bond. Before applying this adhesive masterpiece, ensure that the surface of the MDF is meticulously cleansed of any pesky dust, dirt, or grease that could potentially interfere with the bonding process. Trust me when I say that a pristine surface is key to unlocking optimum adhesion.

To take your adhesive game up a notch and further enhance Liquid Nails’ performance, consider giving the surface of your MDF a gentle sanding with some trusty sandpaper. This seemingly simple step will revolutionize the adhesive’s ability to grip onto the material with unwavering strength, forging an unbreakable bond that will stand the test of time.

When it finally comes time to apply Liquid Nails, remember that an even distribution across the surface is crucial. Don’t be shy about using enough adhesive to ensure proper adhesion. Follow the manufacturer’s instructions religiously for application and drying times in order to achieve nothing short of perfection.

Factors to Consider When Selecting Liquid Nails for Bonding MDF

When choosing a liquid nails adhesive for bonding Medium Density Fiberboard (MDF), several factors should be taken into consideration. These factors include adhesion strength, drying time, water resistance, flexibility, VOC content, application method, and longevity.

Adhesion strength is crucial when selecting an adhesive for MDF. Due to its smooth surface, MDF can be challenging to bond effectively. Therefore, it is important to choose an adhesive specifically designed for bonding MDF that offers strong adhesion properties.

Drying time is another factor to consider. Different liquid nails adhesives have varying drying times. It is essential to select an adhesive that provides enough working time to align and adjust the MDF pieces before it sets. Additionally, considering the project timeline, it is beneficial to choose an adhesive that dries within a reasonable timeframe, allowing for efficient completion of the project.

Water resistance is crucial when bonding MDF, as it is susceptible to moisture and water damage. Opting for a water-resistant or waterproof adhesive can provide added protection against moisture infiltration, ensuring the longevity of the bond and preventing any potential damage caused by exposure to water.

Flexibility is also important because MDF tends to expand and contract due to changes in temperature and humidity levels. Choosing a flexible adhesive allows for dimensional changes without compromising the bond between the MDF pieces. This flexibility helps prevent cracking or weakening of the bond over time.

Considering VOC content is essential for indoor applications. High VOC content in adhesives can contribute to poor indoor air quality and pose health risks. Selecting an adhesive with low VOC content or one that is labeled as VOC-free ensures a safer and healthier environment.

The application method should also be taken into account. Different liquid nails adhesives may require different application methods such as squeeze tubes or caulk guns. It is important to choose an adhesive that can be easily applied and spread evenly on the MDF surface.

Lastly, evaluating the longevity of the adhesive is crucial. Depending on the intended use and durability requirements of the bonded MDF pieces, it is important to select an adhesive that offers long-lasting strength. The adhesive should be able to withstand regular use, potential stress, and load-bearing conditions without compromising the bond.

Preparing the Surfaces for Bonding with Liquid Nails

When it comes to gluing surfaces together, you need an adhesive that will hold tight, just like your morning coffee. Enter Liquid Nails – a reliable adhesive that can make your projects stick like never before. However, before you embark on the gluing process, it’s crucial to properly prepare your surfaces. In this comprehensive guide, we’ll walk you through the steps to ensure an unbreakable bond between Liquid Nails and Medium-Density Fiberboard (MDF).

Step 1: Cleanliness is Key

Just as you wouldn’t want to stick something on a grimy window, starting with clean surfaces is essential. Grab a cloth or sponge and saturate it with a mild detergent or household cleaner. Give both the MDF and bonding surface a thorough scrub to eliminate any dirt, dust, grease, or other contaminants. Rinse away any residue and ensure that the surfaces are completely dry before proceeding.

Step 2: Sanding for Superior Grip

To give your bond some extra oomph, it’s time to rough things up a bit. Gently sand both the MDF and bonding surface using fine-grit sandpaper (around 120-150 grit). Follow the wood grain direction to create a rougher surface that allows the adhesive to grip firmly. Remember to wipe away the resulting dust to maintain cleanliness.

Step 3: Smooth Out Jagged Edges

Nobody wants rough edges when it comes to bonding – they can weaken the bond. Take a close look at the edges of your MDF and smooth out any sharp or jagged areas using sandpaper or a file. This step guarantees an even bond without any weak spots.

Step 4: Primer for Extra Adhesion (Optional)

If you want to go above and beyond for an unshakeable bond, consider applying a primer. While Liquid Nails is designed to bond well to various surfaces, a primer can further enhance adhesion. Choose a primer compatible with both MDF and Liquid Nails, and meticulously follow the manufacturer’s instructions for application.

Step 5: Test Fit for Perfect Alignment

Before you dive into gluing, it’s always wise to do a test fit. This allows you to ensure proper alignment and fit between the MDF and bonding surface before applying the adhesive. It’s like trying on clothes before making a purchase – you want everything to fit just right.

Step 6: Applying Liquid Nails – The Moment of Truth

Applying Liquid Nails to MDF

Applying Liquid Nails to MDF requires attention to detail and a little bit of finesse. This adhesive, known for its strength and versatility, can be a game-changer for your woodworking projects. But before you dive in, let’s go through the process step by step to ensure success.

First and foremost, it’s crucial to choose the right type of Liquid Nails for your MDF project. With different formulations available, make sure to read the label or consult with a professional at your local hardware store. You want an adhesive that is specifically designed for MDF and compatible with the task at hand.

Once you have your Liquid Nails in hand, it’s time to prep your surfaces. MDF can be a little picky, so show it some love before applying any adhesive. Give the surface a thorough cleaning, making sure it’s dry and free from any dust or grease that could interfere with adhesion. And here’s a secret weapon – lightly sanding the surface with fine-grit sandpaper will create a better bond between the adhesive and the MDF. It’s like magic.

Now it’s showtime – time to apply the Liquid Nails. Grab your trusty adhesive and squeeze a generous amount onto the backside of the material you’re attaching to the MDF. Don’t be shy. To ensure full coverage, use a zigzag pattern or vertical lines. But remember, too much adhesive can cause squeeze-out when pressure is applied, so go easy on it.

Once you’ve applied the glue, press the material firmly against the MDF surface and hold it in place for a few minutes. If you’re aiming for a bond that’s as solid as a rock, add some extra weight or use clamps to keep everything in place. Trust me, this adhesive is stronger than your morning coffee addiction.

But here comes the hard part – patience. Let the Liquid Nails dry and cure according to the manufacturer’s instructions. The exact time will depend on factors like temperature and humidity, so resist the temptation to rush it. Good things come to those who wait.

Once the adhesive is fully cured, you’ll have a bond that can withstand the test of time. However, to be on the safe side, give it a little test before putting any heavy stress or load on your project. This way, you can enjoy the satisfaction of knowing your hard work will stand strong.

Securing the Bond with Pressure and Drying Time

When it comes to bonding Liquid Nails with MDF, the steps of applying pressure and allowing sufficient drying time are vital. These measures ensure a robust and durable bond, especially considering the unique properties of MDF.

In this blog post, we will delve into the importance of these steps, exploring the types of pressure required, the optimum drying time needed, and other factors that can affect the strength of the bond.

So, let’s jump right in and discover how to create a bond that stands the test of time.

Applying the Right Pressure:

Pressing the bonded surfaces together is crucial in creating a successful adhesive connection. By doing so, you enhance contact between the Liquid Nails and MDF, eliminating any gaps or air pockets that could weaken the bond.

However, finding the right balance is key – excessive pressure can deform or damage the delicate MDF. To ensure an even distribution of pressure across the bonded area, refer to the product instructions for recommended guidelines.

Drying Time: Patience is Key:

Achieving a strong bond requires sufficient drying time. This refers to the period needed for the adhesive to fully cure and develop its maximum strength. Various factors such as temperature, humidity, and specific product variations can influence drying time. To avoid compromising the integrity of the bond, it is essential to strictly adhere to the manufacturer’s instructions.

Avoid Disturbance for Optimal Results:

During the drying process, it is crucial not to disturb or manipulate the bonded surfaces. Premature handling or movement can weaken or break the bond before it has fully cured. For optimal results, exercise patience and wait until the adhesive has completely dried and reached its maximum strength before subjecting it to any stress or load-bearing activities.

Ventilation: Aiding the Curing Process:

Proper ventilation plays a vital role in expediting the curing process and optimizing bond strength. Adequate airflow helps disperse any volatile components in the adhesive and promotes faster curing. Ensure a well-ventilated workspace or utilize fans to stimulate air circulation, ensuring a strong and durable bond.

Alternatives to Using Liquid Nails on MDF

Well, if you’re working with MDF and looking for alternatives to using Liquid Nails, you’ve come to the right place. Liquid Nails may be a popular adhesive, but it’s not always the best choice for every project. So, let’s explore some alternative options that might just be the perfect fit.

First on our list is wood glue. This stuff is specifically designed for bonding MDF and provides a strong hold. Look for high-quality wood glue that’s formulated for MDF to ensure a proper bond. It’s easy to work with and gets the job done like a boss.

Next up, we have screws or nails. This method involves drilling pilot holes into the MDF and securely fastening it with screws or nails. It’s sturdy, reliable, and can handle the toughest projects. Just keep in mind that it may leave visible holes in the MDF, so consider that for your design.

Looking for a quick and hassle-free option? Double-sided adhesive tape is here to save the day. Simply apply the tape to both the MDF and the surface it will be attached to. While it may not be as strong as other methods, it’s perfect for lighter projects and gives you the advantage of no clamps or drying time. Talk about convenience.

But hey, why settle for just one method when you can have the best of both worlds? For those extra demanding projects, consider using a combination of methods. Use wood glue along with screws or nails to achieve an even stronger bond. The wood glue holds everything in place while it dries, ensuring added stability and peace of mind.

Remember, no matter which alternative you choose, preparation is key. Make sure to sand the edges of the MDF to create a rough surface for better adhesion. Also, ensure that both surfaces are clean and free from any dust or debris. This way, you’ll ensure a solid bond that will stand the test of time.

In the end, the choice of alternative will depend on your specific project requirements and personal preference. Consider factors like the strength of the bond needed, the type of surface you’re working with, and the overall aesthetic you want to achieve.

hukFoQ4GIk8″ >

Conclusion

Liquid Nails is a versatile adhesive that can be used for various applications, including bonding MDF (Medium Density Fiberboard). When it comes to MDF, Liquid Nails proves to be a reliable choice. Its strong bond and fast-drying formula make it ideal for securely attaching MDF pieces together.

One of the key advantages of using Liquid Nails with MDF is its ability to create a durable bond. MDF is a dense and heavy material, and it requires an adhesive that can withstand its weight and pressure. Liquid Nails excels in this aspect, providing a strong and long-lasting bond that ensures your MDF projects stay intact.

Furthermore, Liquid Nails’ fast-drying formula is particularly beneficial when working with MDF. Unlike other adhesives that may take hours or even days to fully cure, Liquid Nails sets quickly, allowing you to proceed with your project without unnecessary delays. This feature is especially advantageous when you have tight deadlines or time-sensitive tasks.

In addition to its practical benefits, Liquid Nails offers ease of use. Its user-friendly application process makes it convenient for both professionals and DIY enthusiasts alike. Simply apply the adhesive onto the surface of the MDF, press the pieces together firmly, and let it dry. The straightforward process saves you time and effort while ensuring a secure bond.

It’s worth noting that proper surface preparation is essential when using Liquid Nails with MDF. Ensure that the surfaces are clean, dry, and free from any dust or debris before applying the adhesive. This will enhance the overall effectiveness of the bond and promote better adhesion between the materials.

In conclusion, Liquid Nails is indeed good for MDF. Its strong bond, fast-drying formula, ease of use, and durability make it an excellent choice for bonding MDF pieces together.