Welcome to our blog post all about the burning question: is dry super glue heat resistant?

We’ve all been in those sticky situations where only super glue can save the day. It’s like a superhero for fixing ceramics, jewelry, and unleashing your inner artist.

But when things start to heat up, can this wonder adhesive handle the pressure? That’s what we’re here to find out.

So grab a cup of joe, kick back, and let’s dive into the wild world of dry super glue and its ability to withstand scorching temperatures.

Heat Resistance of Dry Super Glue

Contents

- 1 Heat Resistance of Dry Super Glue

- 2 Types of Super Glue and Their Heat Resistance

- 3 Household vs Specialized Heat-Resistant Super Glues

- 4 Temperature Thresholds for Different Types of Super Glues

- 5 Benefits of Using Heat-Resistant Super Glues

- 6 Preparing Surfaces Before Applying the Glue

- 7 Factors to Consider When Choosing a Heat-Resistant Super Glue

- 8 Conclusion

Dry super glue, the go-to adhesive for quick fixes and DIY projects, is renowned for its fast-acting properties and strong bonding capabilities. However, when it comes to heat resistance, its performance becomes a subject of debate. In this article, we embark on a journey into the world of dry super glue to unravel its true potential under different temperature conditions.

Understanding Dry Super Glue:

Scientifically known as cyanoacrylate adhesive, dry super glue is formulated to create an instant bond upon contact with moisture. As it dries, this liquid adhesive transforms into a rigid and durable bond, making it ideal for a variety of applications, from repairing ceramics to bonding metal components.

The Heat Resistance Debate:

The heat resistance of dry super glue has sparked discussions among users. While it does possess some degree of heat resistance, prolonged exposure to high temperatures can impact its performance. The formulation of the adhesive plays a crucial role in determining its ability to withstand heat.

Factors Influencing Heat Resistance:

Let’s explore the factors that influence the heat resistance of dry super glue:

- Temperature Range: Generally, super glue can endure temperatures ranging from -40°F (-40°C) to 180°F (82°C) without significant loss of strength. However, beyond this range, the bond may weaken or even fail altogether.

- Material Compatibility: Different materials have distinct coefficients of thermal expansion, causing them to expand and contract at varying rates when exposed to heat. This difference in expansion rates can strain the bond line and compromise adhesive strength.

- Exposure Duration: The duration of heat exposure also impacts dry super glue’s performance. Prolonged exposure to high temperatures can render the adhesive brittle and less flexible, making it susceptible to failure.

Choosing the Right Super Glue:

For applications requiring high heat resistance, specialized high-temperature formulations are advisable. These glues often incorporate additives that enhance their ability to endure elevated temperatures without sacrificing strength. Always refer to the manufacturer’s instructions and guidelines for optimal performance.

Types of Super Glue and Their Heat Resistance

Super glue is a magical adhesive that can bond materials in an instant. However, not all super glues possess the same heat resistance capabilities. In this article, we will explore the different types of super glue and delve into their unique heat resistance properties. By understanding these distinctions, you’ll be equipped to choose the perfect super glue for your heat-resistant projects.

Standard Super Glue:

Standard super glue is like a superhero, strong and speedy. However, when it comes to heat resistance, it may falter like an ice cream melting under the blazing sun. As temperatures rise, standard super glue can lose its strength and jeopardize your project’s integrity. So, if you’re working on something that involves exposure to high temperatures, it’s best to consider other options.

Gel Super Glue:

Imagine a thick, gooey substance that adheres like magic. That’s gel super glue. It’s perfect for intricate projects where precision is paramount. While gel super glue exhibits better heat resistance than its standard counterpart, it still might not withstand extreme temperatures. So, if your project requires battling infernal heat, you’ll need a different hero.

High-Temperature Resistant Super Glue:

When you find yourself in a fiery predicament, high-temperature resistant super glue will be your ultimate ally. This specialized adhesive is designed to endure scorching temperatures with unwavering strength. Like a fearless knight facing a fire-breathing dragon, this super glue won’t buckle under pressure. From repairing car engines to bonding metal objects, high-temperature resistant super glue will stand firm.

Epoxy Resin:

If you’re searching for an adhesive with superpowers against heat, epoxy resin is here to save the day. With exceptional heat resistance, epoxy resin can endure temperatures up to several hundred degrees Fahrenheit. Like a brave knight facing a dragon’s fiery breath, epoxy resin forms an incredibly strong bond. It’s perfect for bonding metal, glass, and ceramics, making it the ideal choice for those high-temperature projects.

Silicone Adhesive:

Flexibility is key when it comes to heat resistance, and silicone adhesive is a master at it. This superhero of adhesives can handle temperatures ranging from freezing cold to scorching hot. Like a superhero who adapts to any situation, silicone adhesive is versatile and dependable. From sealing windows to fixing electronics, this adhesive has got you covered in the face of extreme temperatures.

Household vs Specialized Heat-Resistant Super Glues

Super glue is a popular adhesive for household repairs and craft projects due to its quick-drying properties and strong bond. However, when it comes to projects involving high temperatures, specialized heat-resistant super glues may be the better choice. The key difference between household super glue and specialized heat-resistant super glues lies in their ability to withstand heat.

Household super glue tends to lose its adhesive strength when exposed to high temperatures, which can be problematic for certain projects. On the other hand, specialized heat-resistant super glues are specifically formulated to maintain their bond even under extreme heat conditions.

One of the main advantages of specialized heat-resistant super glues is their ability to withstand higher temperatures. While household super glue typically has a heat resistance threshold of around 180°F to 220°F, specialized heat-resistant glues can handle temperatures up to 500°F or even higher. This makes them ideal for applications where exposure to extreme heat is a concern.

In addition, specialized heat-resistant super glues have a different chemical composition compared to household super glue. They often include additives and modifiers that enhance their heat resistance properties. These additional components ensure that the glue maintains its strength and integrity even under high-temperature conditions.

However, it is important to note that specialized heat-resistant super glues may require specific application techniques or surface preparations for optimal results. Some may require a clean and dry surface, while others may work better on roughened or primed surfaces. Following the manufacturer’s instructions is crucial to ensure proper bonding and heat resistance.

Temperature Thresholds for Different Types of Super Glues

Today, we embark on a journey into the realm of adhesive enchantment to uncover the secrets behind different types of super glues and their ability to withstand high temperatures. Join us as we explore how to maximize their heat-resistant powers and create unbreakable bonds.

The Hot and Not-So-Hot Types:

Not all super glues are created equal when it comes to heat resistance. The widely-used cyanoacrylate-based super glues, like the renowned “Krazy Glue,” boast quick-drying properties and formidable strength. However, they begin to weaken at temperatures above 180 degrees Fahrenheit (82 degrees Celsius). But fear not, for there are specialized high-temperature super glues that come to the rescue in fiery situations.

High-Temperature Heroes:

These super glues can be likened to the mighty superheroes of the adhesive world. Crafted specifically to withstand scorching temperatures, they maintain their bond strength even in the face of extreme heat. From automotive repairs to industrial applications, high-temperature super glues can handle temperatures up to a sizzling 500 degrees Fahrenheit (260 degrees Celsius) or even higher. These remarkable adhesives ensure that your projects stay intact in the most demanding environments.

Factors at Play:

However, there is more than meets the eye when it comes to temperature thresholds for heat resistance in super glues. Various factors influence a glue’s performance under heat. The duration of exposure to high temperatures and the materials being bonded both play significant roles in determining the glue’s efficacy. Certain materials, such as plastics or metals, may require a higher temperature threshold for the glue to maintain its strength.

Read Those Instructions:

To become a true maestro of adhesion, always carefully peruse the manufacturer’s instructions. These invaluable guides provide essential information about temperature limits and recommended materials for each type of super glue. Remember, knowledge is power, especially when it comes to navigating sticky situations.

When in Doubt, Go High-Tech:

If uncertainty surrounds the heat resistance of a particular super glue, it is best to err on the side of caution. Opt for specialized high-temperature super glues when embarking on projects involving heat exposure. It is better to be safe than sorry, wouldn’t you agree? By choosing the right adhesive, you can confidently conquer any challenge that arises.

Benefits of Using Heat-Resistant Super Glues

Heat-resistant super glues are here to save the day. These specially formulated adhesives are designed to withstand high temperatures, making them an excellent choice for a wide range of applications.

One of the biggest advantages of heat-resistant super glues is their ability to provide a durable and reliable bond even in the harshest heat. Whether it’s in automotive engines, industrial machinery, or electronic components, these glues won’t back down when things get hot. They can handle thermal expansion and contraction like a pro, ensuring that your glued parts stay securely attached, no matter the temperature fluctuations.

But it’s not just their ability to withstand high temperatures that sets them apart. Heat-resistant super glues also offer excellent resistance to heat-related stress. This means that even under extreme heat, the bond won’t weaken or break, keeping your materials firmly together. Talk about strength under pressure.

And let’s not forget about their incredible versatility. These glues can bond a wide range of materials, including metal, plastic, rubber, ceramics, and glass. So whether you’re working on a metal sculpture or fixing a cracked glass surface, heat-resistant super glue has got your back.

But the benefits don’t stop there. Heat-resistant super glues also have a fast curing time, allowing for efficient bonding in manufacturing processes where time is of the essence. Say goodbye to long waiting times and hello to increased productivity.

Not only will using heat-resistant super glues save you time, but they can also save you money. Their reliability and durability mean fewer repairs and replacements, reducing costs in the long run. Plus, their excellent aging properties ensure that the bond remains strong over time – no need to worry about things falling apart down the line.

The best part? Heat-resistant super glues are widely available in the market. So whether you’re a professional in the automotive industry or a DIY enthusiast, you can easily get your hands on these super glues and experience their incredible benefits for yourself.

Preparing Surfaces Before Applying the Glue

Today, we are delving into the art of preparing surfaces before applying glue. So, gear up and let’s embark on this exciting journey.

First things first, cleanliness is key. Before you even think about reaching for that trusty tube of glue, you must ensure that the surfaces you’re bonding are spotlessly clean. The tiniest speck of dirt, dust, or grease can wreak havoc on the adhesive properties of the glue. Arm yourself with a gentle detergent or an alcohol-based cleaner and scrub away any impurities. Rinse the surfaces thoroughly and make sure they are bone dry before moving forward.

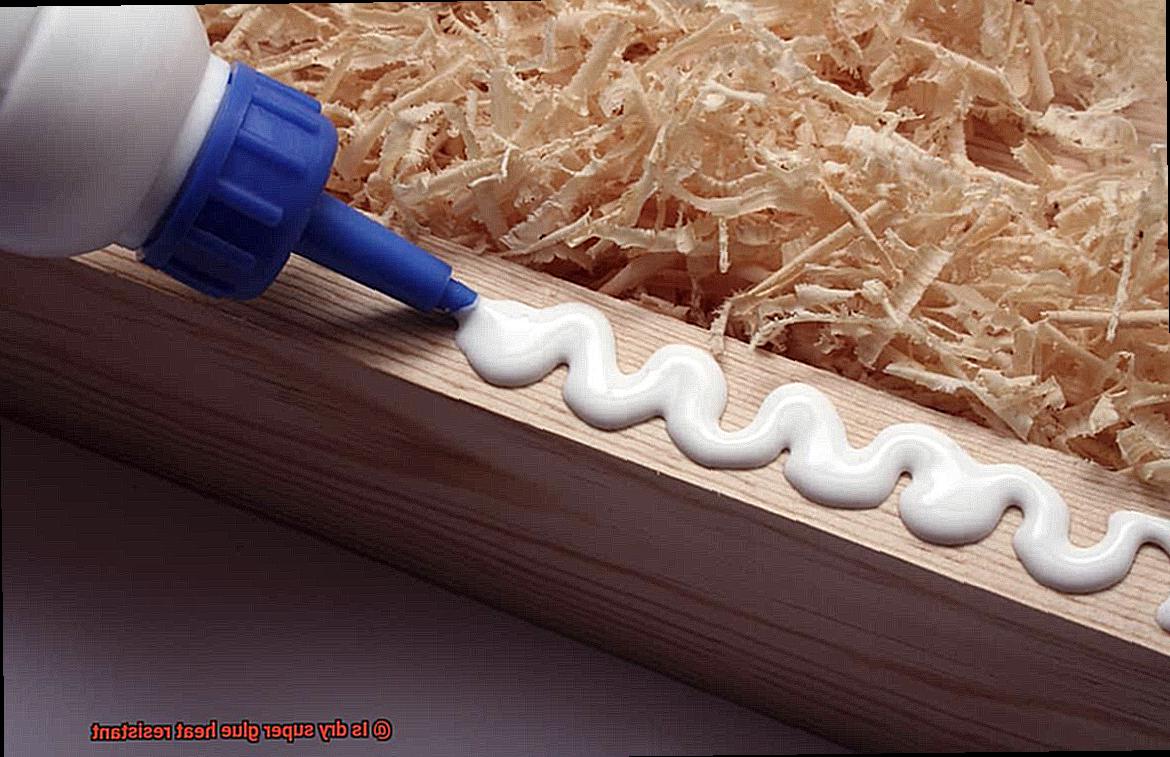

Now, here comes the fun part – roughening things up. Grab some fine-grit sandpaper and gently create a textured surface on the materials you are bonding. We are not talking about major sanding here, just enough to provide a better grip for the glue. This step is particularly crucial when dealing with non-porous materials like metal or plastic.

Sometimes, even the most meticulously cleaned and roughened surfaces need a little extra help. This is where primers or adhesion promoters come into play. These magical products work wonders by promoting adhesion between the surfaces and the glue. Simply brush or spray them onto the prepared surfaces and allow them to dry completely before applying the glue. Don’t forget to carefully follow the instructions on the bottle.

Now that your surfaces are cleaned, roughened, and primed if necessary, it’s time to double-check their dryness. Moisture can play havoc with the curing process of glue, so grab a clean cloth or paper towel and ensure that every nook and cranny is thoroughly dried.

Oh, but wait. We cannot forget about temperature and humidity. Extreme conditions can have a significant impact on the adhesive properties of glue. Therefore, it’s best to work in an environment with moderate levels of temperature and humidity to achieve optimal results.

Last but not least, treat those prepped surfaces with the utmost care. Avoid touching them with bare hands, as the oils from your skin can interfere with the bond. Instead, use gloves or clean tools to handle them, minimizing any potential contamination.

By meticulously following these steps and properly preparing your surfaces, you can ensure a bond that is as strong as a superhero. Just remember to read and adhere to the instructions provided by the manufacturer for the best possible outcome.

Factors to Consider When Choosing a Heat-Resistant Super Glue

When choosing a heat-resistant super glue, there are several factors to consider. These factors include the temperature range, adhesive strength, application method, material compatibility, curing time, and safety precautions.

- Temperature Range: Different glues have different heat resistance levels. It is crucial to choose a glue that can withstand the specific temperatures you will be exposing it to. Some glues are designed for low-temperature applications, while others can endure extreme temperatures up to several hundred degrees Fahrenheit.

- Adhesive Strength: Along with heat resistance, it is essential to ensure that the glue provides a strong bond. Look for a glue with a high tensile strength, which measures the maximum force the glue can withstand before breaking. A secure and long-lasting bond is paramount.

- Application Method: Consider how the glue is applied. Some glues come in liquid form, while others are available as gels or pastes. The application method can affect how well the glue adheres to different materials and its overall heat resistance. Gel or paste glues may be better suited for vertical applications or bonding porous materials.

- Material Compatibility: Make sure the glue you choose is suitable for the materials you will be working with, such as metal, plastic, ceramic, or wood. Optimal bonding performance and heat resistance can only be achieved when using a glue that is compatible with your chosen materials.

- Curing Time: Consider the curing time of the glue. Some glues require longer curing times to achieve full bond strength, while others offer quick-drying capabilities. Depending on your project requirements, you may need a glue that cures rapidly or allows for more time for adjustments before setting.

- Safety Precautions: Always follow the manufacturer’s instructions and safety guidelines when using any adhesive product. Some glues may emit fumes during the curing process, so proper ventilation is recommended. Protective gloves or goggles may also be necessary to prevent skin or eye irritation.

- Also Read: What Temperature Does Super Glue Melt?

Conclusion

In conclusion, the debate surrounding the heat resistance of dry super glue is ongoing. Although it does possess a certain level of heat resistance, prolonged exposure to high temperatures can have an impact on its performance. The formulation of the adhesive is a key factor in determining its ability to withstand heat.

Temperature range, material compatibility, and duration of exposure are all factors that influence the heat resistance of dry super glue. Generally, super glue can handle temperatures ranging from -40°F (-40°C) to 180°F (82°C) without experiencing significant loss of strength. However, if you venture beyond this range, there is a risk that the bond may weaken or even fail completely.

To ensure optimal heat resistance, it is advisable to opt for specialized high-temperature formulations when dealing with applications that require withstanding extreme temperatures. These types of glues often incorporate additives that enhance their ability to endure elevated temperatures while still maintaining their strength.

It’s important to note that not all super glues possess the same level of heat resistance capabilities. Standard super glue and gel super glue may struggle under extreme temperatures and are not suitable for projects involving high levels of heat. On the other hand, high-temperature resistant super glue, epoxy resin, and silicone adhesive offer superior heat resistance properties and are ideal for projects requiring withstanding scorching temperatures.

When working with any adhesive product, it is crucial to adhere to the manufacturer’s instructions and safety guidelines for optimal bonding and heat resistance. Proper surface preparation, including thorough cleaning and roughening surfaces if necessary, is also essential in ensuring a strong bond.

To summarize, while dry super glue does offer some level of heat resistance, it is recommended to select specialized high-temperature formulations for projects involving extreme temperatures.