Got a broken vase? Need to craft an intricate masterpiece? Or maybe you’re just a DIY enthusiast looking for that perfect adhesive. Well, look no further than Loctite super glue. This tiny bottle of magic has become the go-to solution for many, but have you ever wondered just how much heat it can handle? Today, we’re diving deep into the fascinating world of Loctite super glue’s heat resistance.

We’ll explore scorching summer temperatures and sizzling kitchen mishaps to uncover just how unyielding this adhesive powerhouse truly is. So buckle up and prepare to be amazed by the incredible capabilities of Loctite super glue when it comes to withstanding heat.

What is Loctite Super Glue?

Contents

- 1 What is Loctite Super Glue?

- 2 Heat Resistance of Loctite Super Glue

- 3 Types of Loctite Super Glues and Their Heat Resistance

- 4 Considerations When Using Loctite Super Glue in High-Heat Applications

- 5 Testing the Adhesive for Heat Resistance

- 6 The Manufacturer’s Instructions and Guidelines for Temperature Limits

- 7 Compatible Surfaces and Heat Resistance

- 8 Conclusion

This remarkable adhesive is the go-to choice for professionals and DIY enthusiasts seeking a reliable and versatile bonding solution. With its exceptional bonding strength, quick-drying time, and resistance to impact and vibrations, Loctite Super Glue is a game-changer in the world of adhesives. In this article, we will explore the features, advantages, and potential applications of this extraordinary glue.

Exceptional Bonding Strength:

Loctite Super Glue is renowned for its ability to create incredibly strong bonds in just seconds. Harnessing the power of its cyanoacrylate formula, this glue undergoes a rapid polymerization process when exposed to moisture, resulting in a bond that is durable and long-lasting.

Whether you’re repairing a broken ornament or assembling intricate crafts, Loctite Super Glue ensures a secure hold that withstands the test of time.

Versatility:

Loctite Super Glue is compatible with a wide range of materials, including metals, plastics, ceramics, rubber, leather, and wood. This versatility makes it an invaluable tool for various applications such as repairing household items, bonding small parts together, or even creating artistic masterpieces.

Gone are the days of searching for different adhesives for different materials – Loctite Super Glue has got you covered.

Quick-Drying and Clear:

Unlike other glues that require hours to dry, Loctite Super Glue dries in a matter of seconds. This quick-drying feature allows you to complete your projects efficiently without unnecessary waiting time. Additionally, the glue dries clear, ensuring that the repaired or bonded area remains aesthetically pleasing without any visible residue.

Resistant to Impact and Vibrations:

Loctite Super Glue is specially formulated to withstand impact and vibrations, making it an ideal choice for applications where durability is crucial. Whether you’re bonding parts that undergo constant use or creating crafts that need to withstand handling, this glue provides a reliable and long-lasting solution.

Specialized Formulas:

Loctite offers a range of specialized formulas to cater to specific needs and conditions. Whether you require extra strength, resistance to high temperatures or moisture, Loctite Super Glue has a formula tailored to your requirements. By choosing the right formula, you can ensure optimal performance and bond strength for your specific application.

Heat Resistance of Loctite Super Glue

When it comes to selecting the ideal adhesive for your projects, Loctite Super Glue consistently ranks at the top. Known for its formidable bonding capabilities, this versatile glue also boasts impressive heat resistance properties. In this article, we will delve into the heat resistance of Loctite Super Glue in detail, empowering you to confidently undertake projects that may encounter high temperatures.

Understanding the Temperature Range:

The heat resistance of Loctite Super Glue can vary depending on the specific variant or type of glue being used. As a general guideline, this adhesive can withstand temperatures ranging from -50°C to 120°C (-58°F to 248°F). However, it is important to note that these figures are approximate and can be influenced by various factors.

Factors Influencing Heat Resistance:

- Thickness of the Glue Layer: Thicker layers of Loctite Super Glue may exhibit reduced heat resistance compared to thinner layers. To ensure optimal performance under high temperatures, it is recommended to apply a thin and uniform layer.

- Materials Being Bonded: Different materials possess varying melting points and thermal conductivity. Consequently, the heat resistance of Loctite Super Glue can be influenced by the materials being bonded. For instance, bonding metal surfaces may require a higher heat resistance compared to bonding plastics.

- Duration of Exposure: Prolonged exposure to high temperatures can compromise the bond strength of Loctite Super Glue. While it may withstand short bursts of heat, continuous exposure could result in softening or weakening of the bond.

Manufacturer Recommendations:

To obtain precise information on the heat resistance of a specific variant, it is advisable to consult the product specifications or reach out to the manufacturer directly. They possess in-depth knowledge and can provide accurate details and guidance based on their product formulations.

Precautions for Extreme Temperatures:

Although Loctite Super Glue offers impressive heat resistance, it is prudent to minimize exposing bonded items to extreme temperatures whenever possible. Extreme heat has the potential to weaken the bond or even damage the materials being joined. Therefore, it is crucial to carefully evaluate the application and consider alternative adhesives if prolonged exposure to high temperatures is anticipated.

Types of Loctite Super Glues and Their Heat Resistance

Whether you’re fixing a broken toy or working on an exciting DIY project, understanding the different types of super glues and their heat resistance ratings will ensure that your creations withstand the test of time. Let’s dive in.

Low Heat Resistance: Everyday Durability

Loctite offers super glues with low heat resistance, capable of handling temperatures up to 150°F (65°C). These glues are perfect for bonding small objects or mending household items. When you need a reliable adhesive for everyday tasks, these low heat resistance super glues get the job done.

Medium Heat Resistance: Automotive Applications

For automotive repairs or projects where moderate heat exposure is expected, Loctite’s medium heat resistance super glues are the way to go. They can withstand temperatures ranging from 150°F (65°C) to 250°F (121°C). These glues are ideal for bonding engine components or repairing parts that may encounter moderate levels of heat.

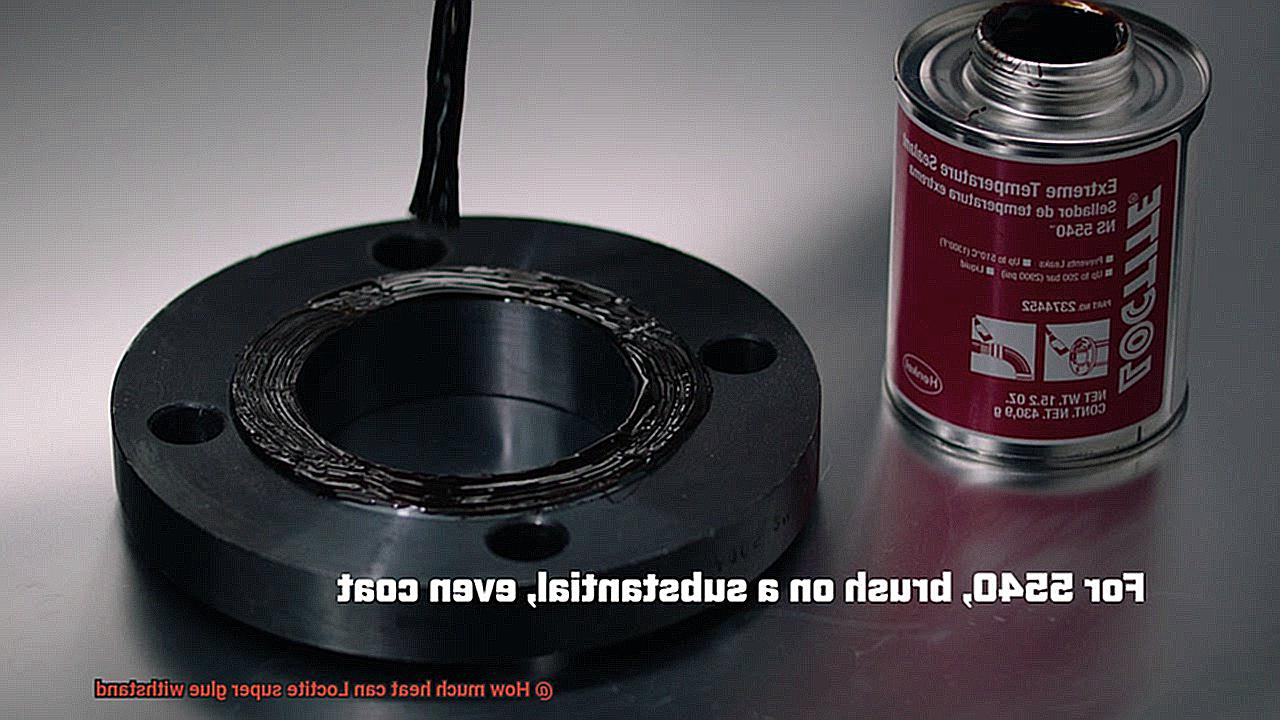

High Heat Resistance: Industrial Strength

When it comes to industrial applications or projects involving metal parts subjected to high temperatures during operation, Loctite’s high heat resistance super glues are your go-to choice. These tough glues can withstand temperatures above 250°F (121°C), ensuring reliable bonds in extreme conditions. From machinery repairs to metal fabrication, these glues provide the strength and durability required for demanding applications.

The Devil is in the Details

It’s important to remember that the actual heat resistance of a Loctite super glue may vary depending on factors such as formulation and materials being bonded. To ensure precise information on heat resistance, always refer to the product’s technical data sheet or consult with the manufacturer. Don’t let your project’s success hinge on guesswork—get the facts from the experts.

Beyond Heat Resistance

While heat resistance is crucial, don’t forget to consider other factors like bond strength, curing time, and compatibility with different materials when selecting a Loctite super glue for your project. Choosing the right glue ensures optimal performance and longevity. Pay attention to the details and make an informed decision for the best results.

Considerations When Using Loctite Super Glue in High-Heat Applications

Look no further than Loctite Super Glue, the ultimate savior. This powerful adhesive is renowned for its strong bond and quick-drying properties. However, before diving into your high-heat project, there are a few crucial considerations to keep in mind.

Firstly, selecting the right formulation of Loctite Super Glue is paramount. Loctite offers specialized super glues, such as their High-Temperature Resistant Super Glue, capable of withstanding temperatures up to 250°F (121°C). By utilizing the correct product designed for high-heat applications, you guarantee superior performance and durability, ensuring your bonds hold up even under extreme heat conditions.

Surface preparation cannot be overlooked. Prior to bonding, ensure the surfaces are clean, dry, and free from any contaminants like oil or dust. A simple cleaning with isopropyl alcohol or a mild detergent will do the trick. Remember, a clean surface equals a stronger bond.

To prevent bond failure caused by thermal expansion, guarantee a tight fit between the parts being bonded. High heat leads to material expansion and contraction, so using clamps or other suitable methods to hold the parts firmly together until the glue cures is absolutely crucial.

Now, here’s an important consideration: the duration of heat exposure. While Loctite Super Glue can tolerate high temperatures for a short period, prolonged exposure may weaken the bond strength. Therefore, remain mindful of how long your project will be exposed to heat and plan accordingly.

One last thing to bear in mind is that Loctite Super Glue is not flame-resistant. It is not designed to withstand direct flame or continuous contact with open flames. Exposing the glue to flames can result in melting, burning, or the emission of harmful fumes. Keep your glued parts away from any direct heat sources or flames.

Testing the Adhesive for Heat Resistance

When it comes to adhesive strength, Loctite Super Glue is a force to be reckoned with. But what about its ability to withstand high temperatures? If you’re embarking on a project that involves scorching heat, it’s important to understand how this mighty glue performs under such conditions. In this article, we will delve into the various testing methods used to determine the heat resistance of Loctite Super Glue and provide key considerations for your next blisteringly hot endeavor.

Testing Methods:

To assess the heat resistance of Loctite Super Glue, two common testing methods are employed:

Heat Aging Test:

Samples of the adhesive are mercilessly exposed to high temperatures for a specified period. These samples are then meticulously evaluated, scrutinizing any alterations in their physical and chemical properties. From color changes to consistency transformations and even strength fluctuations, this test reveals how the adhesive behaves when faced with scorching heat.

Hot Strength Test:

In this method, the adhesive is applied to a substrate and subjected to unrelenting high temperatures. The bond’s strength is put to the ultimate test under these blistering conditions, determining how well the adhesive holds up when faced with intense heat. This test provides a direct measure of the adhesive’s performance under fiery circumstances.

Factors Affecting Heat Resistance:

It is important to note that different formulations of Loctite Super Glue may possess varying heat resistance capabilities. Some variants can endure temperatures up to a scorching 250°F (121°C), while others have been known to handle even higher temperatures. To ascertain the specific heat resistance limits of a particular product, it is essential to consult the manufacturer’s specifications.

Moreover, factors such as the duration and intensity of heat exposure can significantly impact the adhesive’s performance. To ensure the suitability of the adhesive for your specific application, it is advisable to conduct tests under simulated or actual operating conditions.

Conclusion:

While Loctite Super Glue boasts exceptional adhesive properties, its heat resistance capability may differ depending on the formulation and conditions of use. By employing heat aging tests and hot strength tests, manufacturers can determine the adhesive’s performance under scorching temperatures. It is crucial to select the appropriate Loctite formulation for your project and consider factors like duration and intensity of heat exposure. With proper testing and evaluation, you can ensure that Loctite Super Glue meets the requirements of your blisteringly hot application, providing you with a bond that is strong and reliable.

The Manufacturer’s Instructions and Guidelines for Temperature Limits

Think of these instructions as the key that unlocks the heat resistance of your glue – a secret code that ensures its adhesive powers remain intact.

So why is it so critical to adhere to these temperature limits? Well, going beyond these boundaries is like playing with fire – not literally, of course, but you get the idea. Exceeding the specified temperature range can weaken or even cause the bonds created by the glue to fail completely. Imagine spending hours on a project, only to have it fall apart because you neglected to pay attention to temperature limits. That’s a sticky situation you definitely want to avoid.

The manufacturer’s instructions are here to save the day. Not only do they provide specific details about the maximum and minimum temperatures your glue can handle, but they also offer valuable information on how long it can withstand high temperatures before its performance begins to degrade.

Remember, it’s not just about the overall temperature – ambient temperature, surface temperature, and operating temperature all play a role in determining your glue’s performance under heat. So, it’s essential to consider these factors and consult the manufacturer’s instructions accordingly.

And here’s a little bonus tip: sometimes, the manufacturer may recommend using primers or accelerators to enhance your glue’s heat resistance. These sidekicks can make your glue supercharged and ready to tackle even the hottest challenges.

In conclusion, before embarking on any high-temperature projects, take a moment to consult the manufacturer’s instructions and guidelines for temperature limits. Your bonds will thank you for it. Knowledge is power – or in this case, adhesive power.

Compatible Surfaces and Heat Resistance

Loctite super glue is a superhero in the world of adhesives, capable of bonding a multitude of materials together with ease. From metal to plastic, wood to ceramic, rubber to leather, Loctite can create a strong and lasting bond between compatible surfaces. However, before diving into your glue-filled adventure, it’s crucial to ensure that the surfaces are clean and dry. Just like relationships, a strong bond requires a clean slate.

But what about heat resistance? Loctite super glue is no ordinary adhesive when it comes to handling heat. It can withstand temperatures ranging from -49°F to 180°F (-45°C to 82°C), making it suitable for most everyday applications. Whether you’re fixing broken ceramics or patching up a plastic toy, Loctite can handle the heat.

However, it’s important to exercise caution when dealing with excessive heat. While Loctite super glue is heat-resistant within its specified temperature range, prolonged exposure to high temperatures can weaken the bond strength over time. So if you’re planning on gluing something near a stovetop or open flames, it’s wise to think twice.

But fear not. Loctite has your back with specialized adhesives designed for high-temperature environments. These tailor-made glues are formulated to handle extreme heat and provide a stronger bond in situations where standard super glues might crumble under pressure. So whether you’re fixing up your car engine or working on an electronics project that’s hotter than the sun, these specialized adhesives will have your back.

Also Read: How To Glue Silicone To Silicone?

Conclusion

In summary, Loctite super glue is a remarkable adhesive with exceptional strength, rapid drying time, and the ability to withstand impact and vibrations. Its versatility makes it suitable for a wide range of materials and applications. When it comes to heat resistance, Loctite super glue can handle temperatures ranging from -50°C to 120°C (-58°F to 248°F), although actual heat tolerance may vary depending on factors such as glue layer thickness, bonded materials, and duration of exposure.

Loctite offers various types of super glues with different heat resistance ratings. Everyday tasks can be tackled with low heat resistance glues that can endure temperatures up to 150°F (65°C). For automotive applications, medium heat resistance glues are ideal, capable of withstanding temperatures from 150°F (65°C) to 250°F (121°C). Industrial settings require high heat resistance glues that can tolerate temperatures above 250°F (121°C).

It’s worth noting that prolonged exposure to high temperatures may weaken the bond strength of Loctite super glue. Therefore, it’s advisable to minimize subjecting bonded items to extreme heat whenever possible. Furthermore, selecting the appropriate formulation of Loctite super glue for your specific application and adhering to the manufacturer’s instructions regarding temperature limits is crucial.