If you’re like me, you know that having a reliable adhesive in your toolkit can make or break a project. That’s where Gorilla Construction Glue comes in. This stuff is like the superhero of adhesives – it can bond wood, metal, ceramics, and even stone with ease.

But here’s the burning question on everyone’s minds: How long does Gorilla Construction Glue take to dry? Well, my friend, you’ve come to the right place.

In this guide, we’re going to dive deep into the world of Gorilla Construction Glue and give you all the juicy details about its drying time. Whether you’re a newbie or a seasoned DIY pro, understanding how long this glue takes to dry will save you time and frustration on your projects.

So, buckle up and get ready for an adhesive adventure as we uncover the secrets of Gorilla Construction Glue’s drying time.

What is Gorilla Construction Glue?

Contents

- 1 What is Gorilla Construction Glue?

- 2 Factors Affecting Drying Time

- 3 Drying Time for Different Applications

- 4 Tips for Faster Drying

- 5 Curing vs Full Strength

- 6 Temperature and Humidity Effects on Drying Time

- 7 Different Surfaces and Their Impact on Drying Time

- 8 Wood Bonding with Gorilla Construction Glue

- 9 Conclusion

For heavy-duty construction projects, having a reliable adhesive is essential. Enter Gorilla Construction Glue – the go-to choice for professionals and DIY enthusiasts in need of superior strength and versatility. In this article, we will dive into the key features of Gorilla Construction Glue, explore its wide range of applications, and provide tips for achieving optimal results.

Unleashing the Power of Gorilla Construction Glue:

Unmatched Bonding Power:

Gorilla Construction Glue possesses an extraordinary bonding power that can adhere to a variety of surfaces including wood, metal, stone, ceramic, and more. Whether it’s carpentry, masonry, or general repairs, this adhesive is the ideal companion for any construction application.

Defying Extreme Conditions:

One standout feature of Gorilla Construction Glue is its ability to withstand extreme conditions. It is water-resistant, unaffected by temperature fluctuations, and can even resist some chemicals. This means that the bond created remains strong and durable over time, making it an excellent choice for both indoor and outdoor projects.

Effortless and Precise Application:

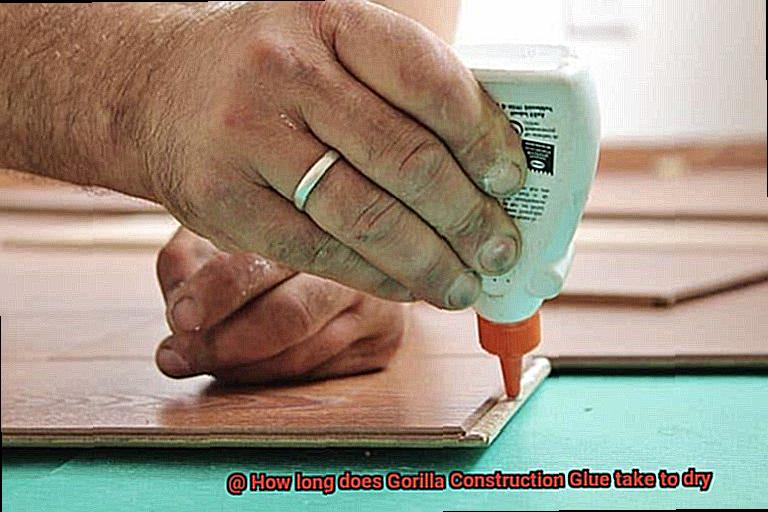

Gorilla Construction Glue comes in a convenient squeeze bottle or cartridge form compatible with a caulking gun. Its thick consistency ensures that the adhesive stays in place without dripping or running during the bonding process. This allows for easy and precise application, minimizing waste and ensuring accurate results.

Drying Time and Achieving Maximum Strength:

While Gorilla Construction Glue boasts a relatively fast drying time compared to other adhesives, it is crucial to allow at least 24 hours for the glue to fully cure and achieve maximum strength. During this initial drying phase, providing support or clamping may be necessary to prevent any movement or shifting of the bonded materials.

Factors Affecting Drying Time

This adhesive superhero has unmatched strength and versatility, but it needs time to dry properly. Let’s dive into the various factors that can influence the drying time and gain some valuable insights.

Firstly, let’s talk about temperature. The surrounding temperature has a significant impact on how quickly the glue dries. Higher temperatures speed up the drying process, while lower temperatures can slow it down. However, extreme temperatures can have adverse effects on the glue, so finding the sweet spot is crucial for optimal drying.

Next up is humidity. The level of humidity in the air also plays a role in drying time. High humidity levels prolong the process as moisture in the air slows down evaporation. Conversely, low humidity speeds up drying as it facilitates faster moisture evaporation from the glue. If you’re working in a humid environment, be prepared for slightly longer drying times.

The thickness or amount of glue applied is another factor to consider. Thicker applications naturally take longer to dry compared to thinner ones. A thicker layer requires more time for the solvents to evaporate fully. So, if you’re aiming for a quicker drying time, apply a thin and even layer of Gorilla Construction Glue.

The porosity of the surfaces being bonded also affects drying time. Porous materials like wood or fabric absorb some of the glue, extending the drying time as it takes longer for solvents to evaporate from within the material. Non-porous surfaces like metal or glass do not absorb the glue, resulting in quicker drying times.

Proper ventilation is crucial for faster drying. Adequate airflow carries away moisture and speeds up evaporation, promoting quicker drying times. If working in an enclosed space with poor ventilation, use fans or open windows to facilitate air circulation and make a noticeable difference in drying time.

Lastly, don’t forget to consider the temperature of the substrate or surface being bonded. Even if the ambient temperature is warm, a cold substrate can potentially slow down the drying process. Ensure both the ambient temperature and substrate temperature are conducive to optimal drying conditions.

Drying Time for Different Applications

Today, we’re going on a journey to uncover the secrets behind the drying time of Gorilla Construction Glue. If you’ve ever wondered why your glue is taking longer to dry than expected or why it’s not as strong as you hoped, you’re in for a treat.

Let’s start by exploring the factors that can affect the drying time of Gorilla Construction Glue. First and foremost, the size of your project and the materials you’re bonding play a significant role. Smaller projects or lighter materials may dry within a few hours or overnight, while larger projects or heavier materials require more patience. Remember, rushing the drying process is a definite no-go if you want a rock-solid bond.

But that’s not all. The environment also has its say in how quickly Gorilla Construction Glue dries. Temperature and humidity levels are key players here. Higher temperatures and lower humidity tend to speed up the drying process, while lower temperatures and higher humidity can slow it down. So, if you find yourself working in a chilly basement or on a humid summer day, be prepared for a slightly longer waiting game.

Now, let’s talk about the thickness of your glue application and the porosity of the surface you’re bonding. Thicker layers take longer to dry because the glue needs time to cure internally. And if you’re working with porous materials like wood or stone, they may absorb some of the glue, extending the drying time. So, keep these factors in mind when planning out your project timeline.

Proper ventilation is another crucial factor for efficient drying. Good airflow helps evaporate moisture from the glue, allowing it to dry faster. So, make sure your workspace is well-ventilated to speed up the process. But be careful not to go overboard and blast fans directly at your project – gentle airflow is all you need.

Lastly, it’s essential to always follow the manufacturer’s instructions for drying time. Gorilla Construction Glue recommends allowing at least 24 hours of drying time before subjecting your project to any stress or load. This ensures that the adhesive has fully cured and provides maximum strength. Trust me, patience pays off when it comes to glue.

Tips for Faster Drying

Gorilla Construction Glue is a powerful adhesive renowned for its strength and durability. However, waiting for it to dry can be a test of patience, especially when you’re eager to complete your project. Fortunately, there are some simple yet effective tips and tricks that can help speed up the drying process and reduce your wait time. In this article, we will explore five key techniques to achieve faster drying times for your Gorilla Construction Glue.

Apply Thin Layers:

When working with Gorilla Construction Glue, remember that less is more. Applying a thin layer of glue instead of a thick one allows for quicker evaporation of excess moisture. This not only helps the glue dry more rapidly but also ensures a stronger bond between the materials being glued. So, be mindful of the amount of glue you apply – a little can go a long way.

Control Temperature and Humidity:

Temperature and humidity play vital roles in the drying time of Gorilla Construction Glue. Higher temperatures and lower humidity levels promote faster curing. Therefore, it is essential to work in a warm environment, preferably above 50°F (10°C), to expedite drying. Avoid cold areas that can prolong drying time. Additionally, ensure good ventilation to facilitate the quick evaporation of moisture.

Use External Aids:

Sometimes, you may need an extra boost to speed up the drying process. In such cases, external aids like fans or blow dryers can come to the rescue. Set them on a low heat setting and direct them towards the glued surfaces. These tools increase airflow around the glue, enhancing evaporation and reducing drying time. However, avoid using high heat as it may affect the bonding strength of the glue.

Apply Pressure or Use Clamps:

To further accelerate drying and ensure a strong bond, apply pressure or use clamps on the glued surfaces. This technique maximizes contact between the adhesive and the materials, allowing them to bond more efficiently. Be cautious when using clamps to avoid damaging the materials – apply pressure evenly and use protective pads if necessary.

Be Patient:

While these tips can expedite the drying time of Gorilla Construction Glue, it’s important to exercise patience. Allow sufficient curing time for the glue to reach its full strength before subjecting it to stress or load. The recommended curing time is 24 hours, so resist the temptation to rush the process for the best results. Remember, good things come to those who wait.

Curing vs Full Strength

Today, we embark on a journey into the realm of Gorilla Construction Glue, delving deeper into the nuances between curing and full strength—the two pivotal stages in the drying process of this mighty adhesive. So grab your safety goggles and brace yourself for an enlightening exploration.

Picture this: you’ve applied Gorilla Construction Glue to your project, and it appears dry on the surface. However, don’t be fooled. This is merely the curing stage, where the glue begins to set and harden. Though it may seem cured, it has yet to reach its full strength.

Factors Influencing Curing Time

Now, let’s discuss timing. The curing process hinges on factors like temperature and humidity. Under standard conditions, Gorilla Construction Glue typically cures within 24 hours. Yet, for optimal results, exercising patience and allowing a full 72 hours before subjecting your glued surfaces to stress or load is highly recommended.

Full Strength: The Pinnacle of Power

Ah, behold the magnificence of full strength. This is where Gorilla Construction Glue truly flexes its muscles. Although the glue may appear cured within 24 hours, it can take much longer to achieve its maximum bonding capabilities. In fact, one must wait a full seven days before subjecting those glued surfaces to any significant stress or load.

The Dance of Chemical Reactions

Why does it require such time to reach full strength? It all comes down to the intricate chemical reactions transpiring within the glue during the curing process. As time elapses, these reactions fortify the adhesive bonds, rendering them stronger and more enduring. Hence, impatience is unwarranted. Allow those bonds to unleash their full potential over time.

Evaluating Full Strength

Curious to ascertain if your Gorilla Construction Glue has attained its full strength? Fear not. A simple test awaits you. Once the recommended curing time has passed, gently apply pressure or force to the bonded surfaces. If any movement or separation occurs between the materials, it serves as a telltale sign that the glue is yet to reach its maximum strength. Be patient, grant it more time, and witness the magic unfold.

Temperature and Humidity Effects on Drying Time

Today, we embark on an exhilarating exploration of the intricate dance between temperature, humidity, and drying time when it comes to Gorilla Construction Glue. Prepare to be amazed.

Let’s start with temperature, the maestro of this adhesive symphony. Imagine a Goldilocks scenario, where the temperature hovers around a delightful 70°F (21°C). In this perfect equilibrium, your Gorilla Construction Glue will cure magnificently within a mere 24 hours. Bravo.

Now, picture the polar opposite. If the temperature plunges below a frosty 40°F (4°C), well, brace yourself for an extended waiting game. In some unfortunate cases, the glue may refuse to dry altogether. Talk about a bummer. So, make sure to keep things cozy for your sticky companion.

On the flip side, let’s crank up the heat. As the temperature soars above a scorching 90°F (32°C), you might be greeted with a rapid-drying glue that lacks the robust bond strength you desire. Nobody wants a feeble bond, right? So, remember to keep things cool and controlled.

Now, onto the sneaky culprit known as humidity. This mischievous factor can throw an unexpected wrench into your drying endeavors. When the air is thick with moisture, drying time can stretch out like an endless horizon. It’s akin to attempting to dry your clothes on a humid summer day – frustratingly slow.

So, what can you do in high humidity situations? Unleash the power of a dehumidifier or air conditioner to accelerate the process. By banishing excess moisture from the air, you’ll be one step closer to witnessing your project dry to perfection.

But what about those arid desert-like environments? Even low humidity can influence drying time. In these parched conditions, consider employing a humble humidifier to infuse some much-needed moisture into the air. Your glue will undoubtedly thank you.

Remember, extreme temperature and humidity conditions can meddle with the performance of your Gorilla Construction Glue. Always consult the instructions and recommendations from the manufacturer – they possess the wisdom to guide you through these tricky circumstances.

Different Surfaces and Their Impact on Drying Time

Today, we embark on a journey to uncover the impact of different surfaces on the drying time of our beloved Gorilla Construction Glue. So, gear up with your safety goggles and let’s dive right in.

Gorilla Construction Glue is a remarkable adhesive that effortlessly adheres to a variety of surfaces like wood, metal, stone, and ceramic. However, the drying time can fluctuate depending on the type of surface you’re working with. Let’s unravel this mystery piece by piece:

- Wood Surfaces: Wood has an innate affinity for glue, eagerly absorbing it like a sponge. Consequently, the drying time on wood surfaces is significantly shorter compared to other materials. So, rejoice, woodworking enthusiasts. Your glue will dry in a jiffy.

- Metal Surfaces: Ah, metal – the cool and unforgiving beauty that demands patience. When bonding with metal, the glue needs ample time to forge a strong bond. Thus, exercise restraint and allow it to dry for a bit longer than you would on other surfaces.

- Stone and Ceramic Surfaces: These porous materials are akin to marathon runners in the realm of drying time. The glue must penetrate their surface to create a robust bond, necessitating a little more patience compared to other surfaces. So sit back, relax, and let the glue work its magic.

Nevertheless, it is crucial to note that drying time isn’t solely influenced by surface type. Temperature and humidity play significant roles in this dance of adhesion. To ensure a timely cure, keep a watchful eye on these environmental factors.

Generally speaking, drying time for Gorilla Construction Glue can range from mere minutes to several hours depending on the surface and conditions at hand. For an unyielding bond, apply pressure or utilize clamps throughout the drying process. Above all else, be patient and allow sufficient drying time before subjecting your newly bonded materials to any stress.

And there you have it, my adhesive aficionados. The impact of different surfaces on drying time is now laid bare before you. Venture forth, armed with your Gorilla Construction Glue, and create something extraordinary. Remember to consult the instructions for specific guidelines – they hold the key to adhesive greatness.

Wood Bonding with Gorilla Construction Glue

Wood bonding with Gorilla Construction Glue is a reliable and effective method for achieving a strong and durable bond in woodworking projects. Whether you’re working on a small DIY project or a large-scale endeavor, this adhesive is here to help you create something extraordinary.

To ensure a successful bond, it is crucial to prepare the surfaces properly. Begin by cleaning the surfaces and removing any dirt, dust, or grease. This step promotes better adhesion and improves the overall bond strength. Once your surfaces are clean, you can proceed to apply the Gorilla Construction Glue.

When applying the glue, it is recommended to spread a thin, even layer on one of the surfaces being bonded. Remember that Gorilla Construction Glue is a high-strength adhesive, so a little goes a long way. Applying too much glue can lead to squeeze-out and make clamping more challenging.

After applying the glue, it is important to clamp the bonded surfaces together for at least 30 minutes. Clamping prevents any movement or shifting during the drying process, ensuring a secure bond. Use clamps that distribute pressure evenly across the entire bond area for optimal results.

Once the initial 30 minutes have passed, it is best to leave the glued surfaces undisturbed for the next 24 hours. This allows the glue to fully cure and reach its maximum strength and durability. However, keep in mind that drying time can be influenced by factors such as temperature and humidity. Colder temperatures and higher humidity levels can extend the drying time, so consider these conditions when planning your project.

In some cases, if the bonded area will be subjected to excessive stress or load-bearing activities, it may be advisable to wait for 72 hours before putting significant weight or pressure on the joint. This extended curing time ensures optimal bond strength.

Gorilla Construction Glue is suitable for bonding a wide range of wood materials, including plywood, MDF, hardwoods, softwoods, and even treated lumber. Its versatility makes it an excellent choice for both indoor and outdoor applications.

To achieve the best results when using Gorilla Construction Glue for wood bonding, always follow the manufacturer’s instructions and guidelines. This will ensure that you get the most out of this powerful adhesive.

eTv4dL_CJeA” >

Also Read: How Long Does Super Glue Take to Dry?

Conclusion

Gorilla Construction Glue, a popular choice among DIY enthusiasts and professionals alike, is known for its exceptional strength and durability. But when it comes to drying time, how long can you expect to wait before your project is ready? Well, the answer depends on a few factors.

Firstly, the type of materials you’re bonding together plays a role in the drying time. Gorilla Construction Glue is designed to work on a variety of surfaces including wood, metal, stone, ceramic, and more. However, different materials have different properties that can affect how quickly the glue sets.

Secondly, the temperature and humidity conditions in your environment can impact drying time. In general, warmer temperatures and lower humidity levels tend to promote faster drying. So if you’re working in a chilly basement or during a humid summer day, be prepared for potentially longer drying times.

Now let’s get down to specifics. On average, Gorilla Construction Glue takes about 24 hours to fully cure. However, keep in mind that this is just an estimate and actual drying times may vary based on the factors mentioned earlier.

For best results, it’s recommended to clamp or apply pressure to your bonded materials while the glue dries. This helps ensure a strong bond and prevents any shifting or movement during the curing process.

So whether you’re tackling a small craft project or embarking on a major construction endeavor, patience is key when using Gorilla Construction Glue. Give it ample time to dry and cure properly for optimal results that will stand the test of time.

In conclusion, Gorilla Construction Glue offers impressive strength and versatility but requires some patience when it comes to drying. With an average curing time of around 24 hours and factors such as material type and environmental conditions affecting drying speed, it’s important to plan accordingly for your projects.

By following proper application techniques and allowing adequate drying time, you’ll be rewarded with durable bonds that can withstand the toughest challenges.