Today, we’re diving headfirst into the world of Gorilla Super Glue – the ultimate bonding beast that’s turning heads in the glue game. Sure, we all know it’s strong and versatile, but here’s where things get interesting – this bad boy can handle some serious heat.

Ever wondered just how hot Gorilla Super Glue can go? Buckle up as we take a wild ride through the science behind its mind-blowing heat resistance. We’ll be uncovering its ability to laugh in the face of scorching temperatures, conquering even the toughest bonding challenges with ease.

Get ready to have your mind blown.

Temperature Resistance of Gorilla Super Glue

Contents

- 1 Temperature Resistance of Gorilla Super Glue

- 2 Effects of Extreme Temperatures on Gorilla Super Glue

- 3 Manufacturer Guidelines for Using Gorilla Super Glue

- 4 Proper Ventilation and Avoiding Heat Sources

- 5 Bonding Materials and Their Temperature Tolerance

- 6 Alternative Adhesives for High-Temperature Applications

- 7 Conclusion

Gorilla Super Glue is renowned for its exceptional bonding strength and quick-drying properties. However, understanding its temperature resistance is crucial for ensuring optimal performance in various environments.

In this comprehensive guide, we will delve into the properties and chemical composition of Gorilla Super Glue that make it resistant to temperature changes. Additionally, we will discuss the effects of extreme temperatures on its performance and provide tips on how to best utilize this adhesive in different temperature conditions.

Temperature Resistance and Chemical Composition:

Gorilla Super Glue, once fully cured, can withstand temperatures ranging from -65°F (-54°C) to 220°F (104°C), as stated by the manufacturer’s website. This impressive range can be attributed to the unique chemical composition of the glue, which includes cyanoacrylate as the primary bonding agent. Cyanoacrylate is known for its excellent temperature resistance and ability to form strong bonds.

Effects of Extreme Temperatures:

While Gorilla Super Glue boasts remarkable temperature resistance, it is important to note that extreme temperatures can still impact its performance. Excessive heat can weaken the bond and potentially cause the glue to break down or lose its adhesive properties. Prolonged exposure to temperatures near the upper limit of its heat resistance may compromise its effectiveness.

Similarly, freezing temperatures can have negative effects on Gorilla Super Glue. Cold temperatures can render the glue brittle and less effective in bonding. To ensure optimal temperature resistance, it is crucial to store the glue in a cool and dry place, away from extreme heat or cold.

Tips for Using Gorilla Super Glue in Different Temperature Conditions:

- Follow manufacturer guidelines: Always refer to the manufacturer’s instructions regarding temperature limits for using Gorilla Super Glue. Exceeding these limits can result in poor bonding or adhesive failure.

- Ensure proper ventilation: When using Gorilla Super Glue in high-temperature environments, ensure proper ventilation to prevent the glue from overheating or releasing harmful fumes.

- Avoid direct exposure to heat sources: To maintain the integrity of the bond, it is advisable to avoid direct exposure to heat sources such as open flames or hot objects. This precaution will help prevent any potential weakening of the adhesive.

- Consider material temperature tolerance: Different materials have varying heat resistance, and Gorilla Super Glue may not be suitable for bonding certain high-temperature materials. Always consider the temperature tolerance of the materials being bonded.

Effects of Extreme Temperatures on Gorilla Super Glue

When it comes to adhesive strength, Gorilla Super Glue stands tall as a formidable choice for various DIY projects. However, even the mightiest glue can be influenced by extreme temperatures. In this article, we will explore the effects of scorching heat and freezing cold on Gorilla Super Glue, providing you with valuable insights to ensure maximum bond strength in any temperature condition.

Heat and its Impact:

- Weakening Bonds: Gorilla Super Glue’s impressive bonding strength is not designed to withstand high temperatures. Exposure to heat can soften the glue, weaken its adhesion, or even cause it to fail altogether.

- Liquidity Issues: Extreme heat can transform your trusty adhesive into a runny mess, making it challenging to control and apply accurately.

- Brittle Bonding: Prolonged exposure to heat can render the glue brittle and prone to breakage under stress, compromising its overall strength.

The Cold Truth:

- Viscosity Woes: Freezing temperatures can cause Gorilla Super Glue to become less viscous, transforming it into a thicker substance that is more difficult to work with.

- Fragile Bonds: Similar to extreme heat, freezing temperatures can make the glue brittle and susceptible to breaking under pressure.

Optimal Storage:

- Store Smart: To maintain Gorilla Super Glue’s effectiveness, store it in a cool and dry place away from direct sunlight and extreme temperature fluctuations.

When in Doubt, Discard:

If your Gorilla Super Glue has been compromised by extreme temperatures or has expired, it is best to discard it and use a fresh bottle for optimal results.

Manufacturer Guidelines for Using Gorilla Super Glue

Gorilla Super Glue is a formidable adhesive that bonds quickly and securely. To fully harness its potential, it is crucial to adhere to the manufacturer’s guidelines. In this comprehensive guide, we will explore the key steps and precautions necessary to use Gorilla Super Glue safely and effectively.

Clean and Dry Surfaces:

Before applying Gorilla Super Glue, prepare the surfaces by ensuring they are clean and dry. Dust, dirt, or moisture can hinder the adhesive’s effectiveness. Wipe away impurities with a clean cloth or alcohol wipes, leaving behind pristine bonding surfaces.

Sparingly Apply the Glue:

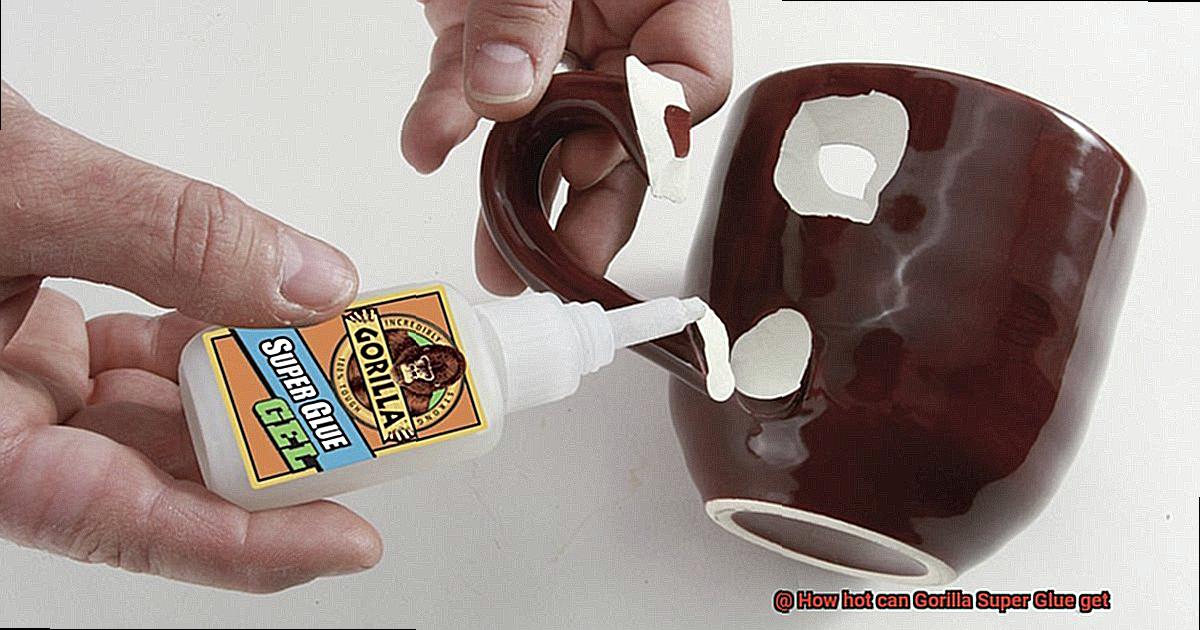

Remember, less is more with Gorilla Super Glue. Apply a thin layer of glue to one surface only. Excessive glue can weaken the bond. Hold the bottle vertically and gently squeeze, avoiding excessive pressure that could cause the glue to flow too quickly.

Firmly Press and Hold:

After applying the glue, firmly press the two surfaces together and hold them for at least 30 seconds. This ensures proper bonding. For larger or heavier objects, consider using clamps or other means of securing the bond until it fully sets.

Cure Time:

Gorilla Super Glue reaches its initial cure within 10-45 seconds, depending on the materials being bonded. However, full cure takes up to 24 hours. During this time, protect the bond from excessive heat or moisture, as they may compromise its strength.

Temperature Resistance:

Under normal conditions, Gorilla Super Glue performs well across temperatures ranging from -40°F (-40°C) up to 200°F (93°C) once fully cured. However, prolonged exposure to extreme temperatures can weaken the bond. Shield bonded objects from extreme heat or cold for long-lasting results.

Material Compatibility:

Gorilla Super Glue excels at bonding various materials, but it is not recommended for polyethylene or polypropylene plastics. Always consult the manufacturer’s recommendations and perform a small compatibility test on a hidden area before applying the glue to ensure optimal bonding.

Proper Storage:

To maintain its effectiveness, store Gorilla Super Glue properly. Keep the bottle tightly sealed when not in use and store it in a cool, dry place. Avoid exposing the glue to extreme temperatures or direct sunlight, as this may compromise its performance over time.

Proper Ventilation and Avoiding Heat Sources

If you’re someone who loves DIY projects or frequently finds yourself in need of a reliable adhesive, then Gorilla Super Glue is likely your go-to choice. This powerful cyanoacrylate adhesive can create bonds so strong they seem indestructible. However, to truly harness its power while staying safe, it’s crucial to understand the importance of proper ventilation and avoiding heat sources when working with this remarkable glue.

The Science Behind Gorilla Super Glue:

Gorilla Super Glue is a cyanoacrylate adhesive that creates a formidable bond by reacting with moisture in the air. This chemical reaction generates heat during the curing process, making ventilation a critical factor to consider.

Ventilation: The Breath of Fresh Air:

Working in a well-ventilated area is crucial when using Gorilla Super Glue. Here’s why:

- Open those windows and doors: Ensure fresh air circulates around your workspace, allowing any heat generated during curing to dissipate effectively.

- Protecting yourself: Proper ventilation prevents the accumulation of potentially harmful fumes that may irritate your eyes, nose, or throat. It’s always better to be safe than sorry.

Heat Sources: Don’t Play with Fire (or Heat.):

Heat can be both a friend and a foe when it comes to Gorilla Super Glue:

- No flame zone: Keep the glue away from open flames like candles or stovetops. The intense heat can accelerate the curing process, leading to overheating.

- Stay cool, glue: Avoid exposing Gorilla Super Glue to heat-emitting appliances such as heaters or ovens. Extreme temperatures can compromise its performance and even damage the container.

Storage: A Cool Refuge for Your Glue:

Storing Gorilla Super Glue properly ensures its longevity and effectiveness:

When it comes to Gorilla Super Glue, proper ventilation and avoiding heat sources are paramount for both safety and optimum performance. By working in a well-ventilated area, keeping the glue away from heat-emitting sources, and storing it properly, you can unleash the true power of this adhesive while ensuring a safe and successful bonding experience.

Bonding Materials and Their Temperature Tolerance

In this article, we will explore the fascinating world of adhesive materials, using Gorilla Super Glue as an example.

Melting Points and Heat Resistance:

- The significance of melting points in determining a material’s temperature tolerance.

- A comparison between metals like steel and aluminum and plastics and organic materials when it comes to heat resistance.

Gorilla Super Glue’s Temperature Tolerance:

- Unveiling the maximum temperature Gorilla Super Glue can withstand.

- Understanding how this temperature tolerance affects the bond strength between different materials.

Compatibility of Materials:

- The importance of choosing materials with compatible temperature tolerances.

- Exploring alternative bonding methods for materials with significantly different tolerances.

Factors Influencing Bond Performance:

- Examining the impact of duration of heat exposure on bonded materials.

- Identifying external stressors that can affect the performance of adhesive bonds under high temperatures.

Understanding the temperature tolerance of bonding materials is crucial for achieving successful bonding applications.

While Gorilla Super Glue can withstand temperatures up to 200 degrees Fahrenheit (93 degrees Celsius), selecting materials with compatible temperature tolerances is key to ensuring a strong and durable bond.

By considering factors such as melting points, exposure duration, and external stressors, you can make informed decisions and achieve optimal results when working with adhesive products like Gorilla Super Glue.

Alternative Adhesives for High-Temperature Applications

Imagine yourself in the midst of a scorching project, where high temperatures threaten to weaken your bonds. Don’t let the heat hold you back. In this captivating exploration, we will delve into the world of alternative adhesives for high-temperature applications. Discover the remarkable types of adhesives available and unravel the key factors to consider when selecting the perfect adhesive for your fiery endeavor.

Epoxy Adhesives: The Mighty Heat Warriors

First on our list are the superheroes of high-temperature bonding – epoxy adhesives. These mighty warriors are renowned for their exceptional heat resistance, withstanding temperatures ranging from 250°F (121°C) to a staggering 600°F (316°C). With their robust bonding strength, epoxy adhesives prove indispensable in automotive, aerospace, and industrial applications.

Silicone Adhesives: Flexibility in the Face of Extreme Heat

Next in line are the versatile and flexible silicone adhesives. These adhesive marvels can handle temperatures up to 500°F (260°C) or even higher depending on the specific product. Not only do they withstand extreme heat, but they also offer excellent flexibility, moisture resistance, and chemical resistance. Silicone adhesives emerge as the go-to choice for demanding environments.

Ceramic Adhesives: Conquering the Hottest Frontiers

For applications that push the boundaries of temperature extremes, ceramic adhesives step in as the saviors. These specialized adhesives are formulated to bond ceramic materials and can endure mind-boggling temperatures exceeding 2000°F (1093°C). Aerospace, defense, and electronics industries rely on ceramic adhesives to conquer their high-temperature challenges.

Factors to Consider: A High-Stakes Selection Process

When selecting an alternative adhesive for high-temperature use, several factors demand careful consideration:

- Maximum Temperature: Ascertain the highest temperature your adhesive will encounter during its lifetime to ensure it can withstand the heat.

- Material Compatibility: Different adhesives flourish with specific materials, so ponder upon the type of materials you’ll be bonding.

- Additional Requirements: Flexibility, chemical resistance, and moisture resistance may prove critical for your application. Take these factors into account when making your selection.

bG60VfP5Z84″ >

Also Read: What Temperature Does Super Glue Melt?

Conclusion

In conclusion, Gorilla Super Glue is an extraordinary adhesive that can handle scorching temperatures with ease. It boasts an impressive temperature resistance range, from a bone-chilling -65°F (-54°C) to a sizzling 220°F (104°C), making it a versatile glue that can withstand extreme heat once it’s fully cured. The secret behind its exceptional heat resistance lies in its unique chemical composition, with cyanoacrylate serving as the primary bonding agent.

However, it’s important to keep in mind that even this super glue has its limits when it comes to extreme temperatures. Excessive heat can put strain on the bond and potentially cause the glue to deteriorate or lose its adhesive properties altogether. Prolonged exposure to near maximum heat levels may compromise its effectiveness, so caution is key.

Similarly, freezing temperatures are no friend of Gorilla Super Glue either. When faced with icy conditions, the glue becomes brittle and less reliable for bonding purposes.

To ensure optimal temperature resistance, it’s crucial to follow the manufacturer’s guidelines diligently. Proper ventilation is essential when using the glue in high-temperature environments. Direct exposure to intense heat sources should be avoided at all costs. Additionally, considering the temperature tolerance of the materials being bonded is vital for successful outcomes.

By understanding and implementing these expert tips, you can unleash the true power of Gorilla Super Glue while ensuring safe and effective bonding in various temperature conditions.