Want to create a rock-solid bond between PVC and plywood? Whether you’re tackling a DIY project or a professional installation, knowing how to bond these materials effectively is key. When done right, this bond can add strength, protection, and even style. In this blog post, we’ll guide you through the process of bonding PVC to plywood, covering the essential materials, steps involved, and potential challenges to keep an eye out for.

Materials You’ll Need:

To get started, gather these materials:

- PVC adhesive or solvent cement: Choose a formula specifically made for bonding PVC to different surfaces.

- Plywood: Opt for high-quality plywood that’s clean, smooth, and free from any coatings or sealants that could obstruct adhesion.

- PVC primer (optional): While not always necessary, using a PVC primer before applying the adhesive can boost the bond’s strength and durability.

- Sandpaper or sanding block: This will help prep the surfaces you plan to bond by ensuring they’re clean and flawless.

- Clean cloth: Have a lint-free cloth handy to wipe away excess adhesive and clean up any spills or smudges.

Steps for Bonding PVC to Plywood:

- Surface Prep: Start by thoroughly cleaning both the PVC and plywood surfaces you want to bond. Use mild detergent with a clean cloth to remove dirt and debris. Lightly sand the plywood surface for better adhesion.

- Apply PVC Primer (optional): If recommended by the adhesive manufacturer or if you prefer added strength, apply a small amount of PVC primer on the PVC surface. Let it dry completely before moving on.

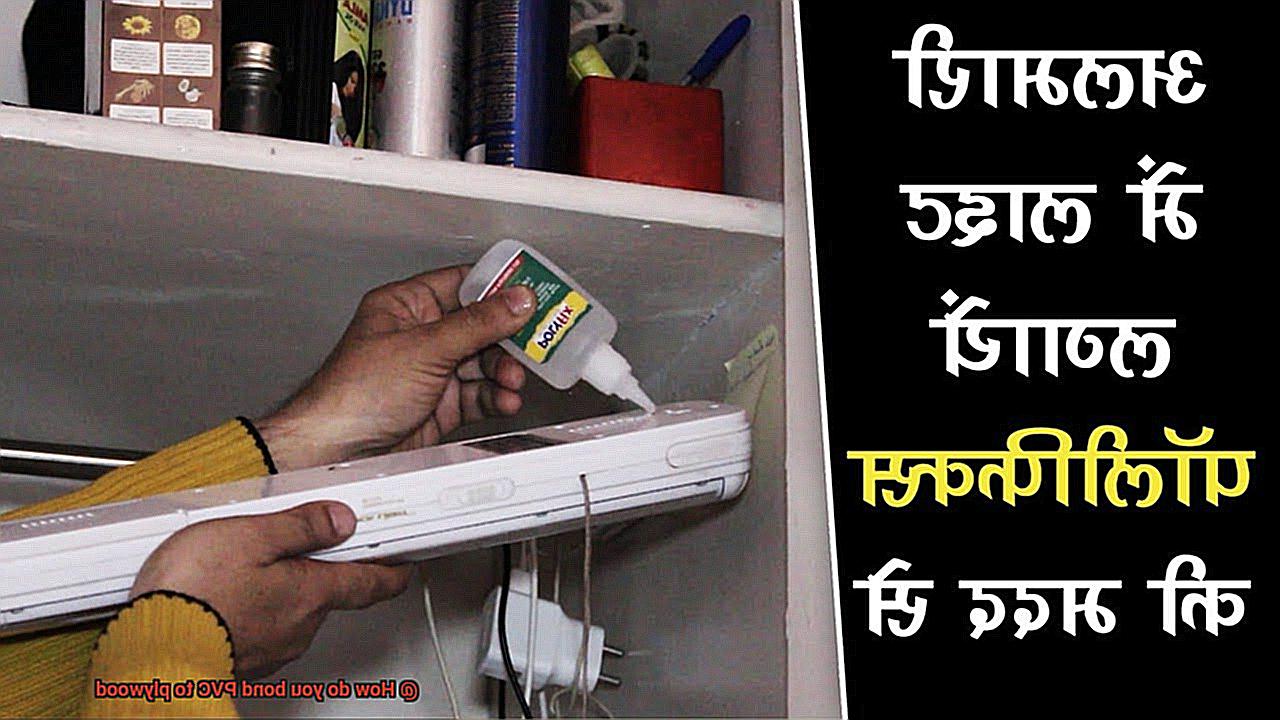

- Apply PVC Adhesive: Use a brush or applicator to apply a thin, even layer of PVC adhesive onto the PVC surface. Work swiftly as most adhesives have limited open time.

- Press and Hold: Place the PVC onto the prepared plywood surface, aligning it as desired. Press down firmly and hold for the recommended duration specified by the adhesive manufacturer. This step ensures a solid bond.

- Clean Up: After the suggested holding time, use a clean cloth to wipe away any excess adhesive, taking care not to disturb the bond.

Challenges to be Aware of:

While bonding PVC to plywood

What is PVC and Plywood?

Contents

Choosing the right material for your project is vital, and understanding the unique qualities of PVC and plywood is key. In this informative article, we will delve into the world of PVC and plywood, exploring their diverse characteristics, applications, and effective bonding techniques.

PVC: Durability, Versatility, and Affordability

PVC, a synthetic plastic polymer, is celebrated for its incredible durability and adaptability.

Resistant to chemicals, sunlight, and weathering, PVC thrives in both indoor and outdoor environments.

Its versatility shines through in its applications across construction, plumbing, electrical insulation, signage, and the automotive industry.

Lightweight and corrosion-resistant PVC pipes revolutionize plumbing systems.

As an exceptional electrical insulator, PVC is ideal for wiring applications.

Window frames, vinyl flooring, and various types of siding all owe their existence to the manufacturing prowess of PVC.

Plywood: Strength, Stability, and Flexibility

Crafted from thin layers or plies of wood veneer fused together, plywood boasts impressive strength and stability.

Unyielding against warping or cracking, plywood is a reliable choice for any project.

Softwood species like pine or fir can create sturdy plywood while hardwood species such as oak or birch offer even greater density.

From building construction to furniture manufacturing to cabinetry, plywood’s strength is an indispensable asset.

Flooring projects benefit greatly from plywood’s dimensional stability compared to solid wood.

The flexibility of plywood allows for customization in size and shape that traditional materials cannot match.

Bonding PVC to Plywood: Techniques for Success

Thoroughly clean surfaces using a mild detergent and water solution to eliminate any dirt or grease.

To enhance bonding surface quality, gently roughen the surfaces with fine-grit sandpaper.

Utilize a solvent-based adhesive such as PVC cement, strictly adhering to the manufacturer’s instructions.

Apply an even layer of adhesive onto both the PVC and plywood surfaces.

Align the materials meticulously and evenly distribute pressure across the entire surface using clamps or weights.

Allow sufficient curing time for the adhesive to create a secure and lasting connection.

Adhesives Suitable for Bonding PVC to Plywood

Well, you’ve come to the right place. Today, we’re going to explore the wonderful world of adhesives and discover the best options for this specific task. So, let’s dive in.

First up, we have polyurethane adhesive. This powerful adhesive is known for its excellent bonding properties and can create a strong and flexible bond between PVC and plywood. Not only can it withstand heat and moisture, but it also has incredible gap-filling abilities, making it perfect for irregular surfaces. Whether you’re working on an outdoor project or need a reliable adhesive for your DIY endeavors, polyurethane adhesive won’t let you down.

Next on our list is epoxy adhesive. This high-strength adhesive is resistant to water, chemicals, and temperature fluctuations, making it ideal for harsh environments. It’s like a superhero for bonding PVC to plywood. Just remember, epoxy adhesives typically come in two components that need to be mixed before application. So be sure to follow the instructions carefully and unleash the power of this adhesive.

If you’re in a hurry or need a quick-drying option, consider solvent-based contact adhesive. This versatile adhesive is applied to both surfaces and dries quickly, creating an instant and permanent bond. It’s perfect if you’re pressed for time or need a strong initial bond. Just remember to firmly press the surfaces together to activate the adhesive and witness its magic.

For those specifically working with PVC materials, vinyl adhesive is a great choice. Specially formulated to bond PVC surfaces, this adhesive provides a strong and durable bond. All you need is a brush or roller to apply it, let it dry properly, and then join the surfaces together. It’s like a match made in heaven for PVC and plywood.

Last but not least, we have cyanoacrylate adhesive, also known as super glue. This adhesive creates an instant bond and is famous for its strength and fast curing time. It’s like having a superhero in your DIY arsenal. However, keep in mind that cyanoacrylate adhesive may not be suitable for all applications, especially if you need your bond to withstand high temperatures or exposure to moisture.

Before applying any adhesive, make sure to properly prepare the surfaces. Clean them thoroughly, removing any dust or grease, and roughen them slightly with sandpaper for better adhesion. It’s like giving the surfaces a fresh start before their amazing bonding journey.

Preparing the Surfaces for Bonding

To create a strong and durable bond when working with PVC and plywood, proper surface preparation is essential. In this article, we will explore the crucial steps involved in preparing surfaces for bonding. Whether you’re a DIY enthusiast or a professional, following these steps will help you achieve a rock-solid bond that stands the test of time.

Step 1: Thoroughly Clean the Surfaces:

Before diving into the bonding process, take the time to meticulously clean both the PVC and plywood surfaces. Rid them of dirt, dust, oil, or grease using a mild detergent or specialized cleaner. This crucial step eliminates any contaminants that could hinder the adhesive’s effectiveness.

Step 2: Enhance Adhesion with Sanding:

To improve adhesion, gently sand both the PVC and plywood surfaces using fine-grit sandpaper. This creates a slightly rough texture, allowing the adhesive to grip the surfaces better. After sanding, be sure to wipe away any dust using a clean cloth or tack cloth.

Step 3: Prime the Plywood for Extra Strength:

For an extra-strong bond, consider priming the plywood surface before applying adhesive. Applying a thin layer of primer designed specifically for wood surfaces helps seal the wood and provides a better surface for adhesion. It also acts as a barrier against moisture penetration, preserving the integrity of the bond.

Step 4: Use Solvent-Based Cleaner:

After priming, it’s recommended to use a solvent-based cleaner on the plywood surface. This powerful cleaner further cleans and prepares the surface by removing any residual contaminants such as oils or wax that may interfere with bonding. A pristine surface ensures optimal adhesion.

Step 5: Perform a Compatibility Test:

Before applying adhesive to the entire surface, perform a compatibility test in a small inconspicuous area. Apply a small amount of adhesive on both PVC and plywood surfaces and allow it to cure according to manufacturer instructions. Check if the bond is strong and if any issues arise, such as discoloration or weakening of materials. This test ensures that the chosen adhesive is suitable for both materials.

Step 6: Select the Right Adhesive:

Choosing the right adhesive is crucial for a successful bond between PVC and plywood. Consider using contact cement or a two-part epoxy adhesive as they are commonly used for bonding these materials together. Ensure that the adhesive you choose is compatible with both PVC and plywood.

Applying the Adhesive

This comprehensive guide will take you through the step-by-step process of applying adhesive to bond PVC to plywood. Whether you’re a seasoned DIY enthusiast or a curious beginner, this article will equip you with the knowledge and techniques needed to create a robust and long-lasting bond between these two materials.

Step 1: Choosing the Perfect Adhesive

Before diving into the application process, it’s essential to select the right adhesive for the job. Look for adhesives specifically designed for bonding PVC to wood. Solvent-based adhesives, epoxy adhesives, and polyurethane adhesives are commonly recommended options. Consult manufacturer instructions and seek expert advice if necessary.

Step 2: Surface Preparation – The Key to Success

Achieving a strong bond starts with proper surface preparation. Begin by meticulously cleaning both the PVC and plywood surfaces. Use a mild detergent and water solution or a solvent-based cleaner to eliminate any dirt, dust, or grease. Next, gently sand both surfaces to create a rough texture that allows for superior adhesive penetration.

Step 3: Mastering the Application Technique

Follow the manufacturer’s instructions for applying the adhesive, as different types of adhesives may require specific application methods. You can use a brush, roller, or spreader to apply an even layer of adhesive on both the PVC and plywood surfaces. Take your time to ensure uniform coverage, leaving no area untouched.

Step 4: Allowing Adequate Curing Time

Once the adhesive is applied, it requires sufficient time to cure properly. The curing time varies depending on the type of adhesive used, ranging from a few minutes to several hours. Refer to the manufacturer’s instructions for precise guidance on curing times. Patience is key in this step.

Step 5: The Power of Pressure

After the adhesive has cured, it’s time to unite the PVC and plywood. Employ clamps or weights to apply consistent pressure across the bonded area. This step is crucial in achieving a solid bond between the materials. Ensure that enough pressure is applied without causing damage to the surfaces.

Step 6: Drying Time and Reinforcement

Allow the bonded PVC and plywood to dry for a minimum of 24 hours before subjecting them to any stress or load. This ensures that the adhesive fully cures, resulting in a strong bond. It’s important to note that the bond between PVC and plywood may not be as strong as between similar materials. To reinforce the bond, consider using mechanical fasteners like screws or nails in conjunction with the adhesive.

Aligning the PVC and Plywood

Look no further. This comprehensive guide will walk you through the step-by-step process of achieving a strong and durable connection between these two materials.

Surface Preparation:

Before bonding PVC and plywood, it’s crucial to clean both surfaces thoroughly. No one wants a dirty bond, right? So grab some mild detergent or solvent and give those surfaces a good scrub. Make sure they’re squeaky clean and completely dry before moving on to the next step.

Adhesive Selection:

Now that your surfaces are sparkling clean, it’s time to choose the perfect adhesive. You have options like epoxy, polyurethane, and contact cement. Consider factors like your specific project, strength requirements, and working conditions to make the right choice. Once you’ve selected your adhesive, follow the manufacturer’s instructions for application.

Alignment Techniques:

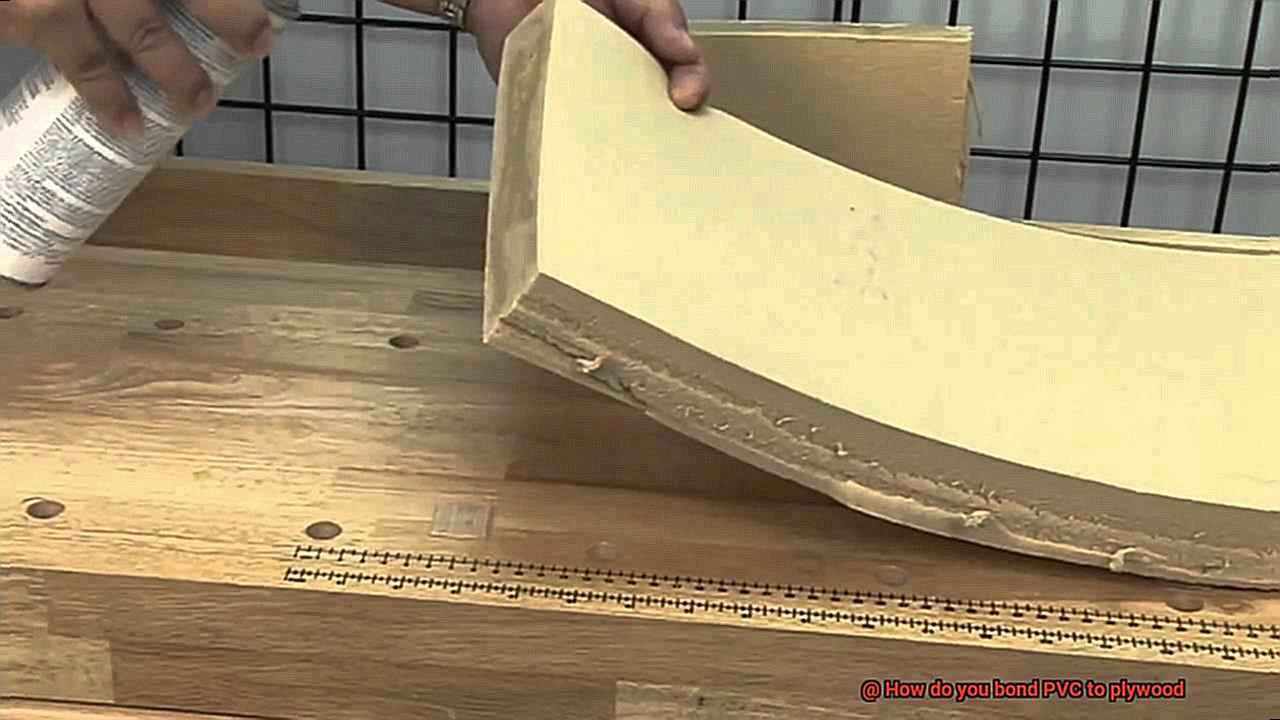

With adhesive in hand (or brush), it’s time to align the PVC and plywood. Start by placing one edge of the PVC against the corresponding edge of the plywood. Press down firmly to ensure good contact between the two surfaces. Pro tip: use your hands or a rubber mallet to gently tap along the length of the PVC, gradually aligning it with the plywood.

Alignment Marks:

To make life easier, consider using alignment marks or guidelines on both materials. These marks can be drawn using a pencil or marker before applying the adhesive. Aligning these marks will help you position the PVC accurately onto the plywood.

Clamping Techniques:

In some cases, clamping may be necessary to hold everything in place while the adhesive cures. Clamp it like it’s hot. Place those clamps along the length of the PVC and plywood, applying enough pressure to hold them together without causing damage. Let it sit for the recommended curing time specified by the adhesive manufacturer. Patience is a virtue.

Excess Adhesive Removal:

Once the adhesive has cured, it’s time to remove any excess that may have squeezed out from the edges. Grab a scraper or a sharp knife and carefully remove the excess adhesive, taking care not to damage those beautiful surfaces.

Securing the Bond

Today, we embark on a journey into the world of adhesives, exploring the intricacies of creating a strong bond between PVC and plywood. Whether you’re working on a home improvement project or crafting a masterpiece, this comprehensive guide will equip you with the knowledge and techniques to achieve a secure and long-lasting connection. So grab your adhesive of choice, put on your thinking cap, and let’s dive into the art of gluing.

Step 1: Cleanliness is Key

Before we dive headfirst into the gluing process, it’s imperative to ensure that both the PVC and plywood surfaces are scrubbed squeaky clean. Picture this as priming your canvas before painting a masterpiece – cleanliness is key. Give them a thorough scrub using a mild detergent and water solution, banishing any pesky dirt, dust, or debris that could hinder the bond.

Step 2: Choosing the Right Adhesive

In our quest for an unbreakable bond between PVC and plywood, we highly recommend using a solvent-based PVC adhesive. This specialized adhesive is formulated to bond PVC materials seamlessly while providing outstanding adhesion to plywood as well. It’s like finding the perfect partner for your project – someone who effortlessly complements both sides.

Step 3: Applying the Adhesive

Now comes the thrilling part – applying the adhesive. Equip yourself with a trusty brush or roller and generously coat the plywood surface with the solvent-based PVC adhesive. Remember, even distribution is paramount for a robust bond, so ensure you cover every nook and cranny. If you’re tackling a larger project, take it on in small sections to prevent the adhesive from drying out prematurely before bonding the PVC.

Step 4: The Perfect Pairing

With precision and finesse, carefully place the PVC material onto the adhesive-drenched plywood surface. Apply gentle pressure while exerting even force across the entire bonded area. You can employ clamps or weights to secure a snug fit. This step is all about creating a connection that’s as tight as a bear hug – firm, secure, and unyielding.

Step 5: Time to Cure

Remember, patience is a virtue in the world of adhesives. Solvent-based PVC adhesives require ample time to dry and cure fully. To give your bond the best chance for success, leave the glued materials undisturbed for a minimum of 24 hours. Think of it as allowing your adhesive to work its magic, slowly but surely creating an unbreakable bond that will withstand the test of time.

Curing Time

Curing time, the period required for adhesive to fully dry and create a strong bond between PVC and plywood, is a critical factor in the process of bonding these materials. Understanding and adhering to curing time ensures a durable connection that can withstand heavy loads and constant movement.

Different types of adhesives are commonly used for bonding PVC to plywood, each with its own unique curing characteristics. Solvent-based adhesives, known for their strong bond strength and moisture resistance, typically have a relatively fast curing time ranging from a few minutes to several hours. However, temperature and humidity can affect the curing process, with higher temperatures accelerating the cure and lower temperatures prolonging it.

Epoxy adhesives, offering excellent bond strength and durability, require mixing before application and have a longer curing time. This can range from a few hours to several days. Following the manufacturer’s instructions regarding mixing ratios and curing time is crucial for optimal results.

Contact adhesives, another popular choice, are applied on both surfaces and allowed to dry before bringing PVC and plywood together. The curing time for contact adhesives varies depending on the specific brand and formulation used, typically taking anywhere from 15 minutes to 24 hours.

To ensure a strong bond between PVC and plywood, it is necessary to adhere to the recommended curing time provided by the adhesive manufacturer. Rushing the process or applying stress prematurely can compromise the bond strength. Patience is key in allowing sufficient time for the adhesive to fully cure before subjecting the bonded materials to any stress or load.

Alternative Adhesives Available in the Market

In this comprehensive guide, we’ll explore the wide range of adhesives available in the market and their unique properties that make them suitable for this specific application. So let’s dive in and discover the perfect glue for your PVC and plywood bonding projects.

Solvent-based contact adhesive:

Solvent-based contact adhesive is a popular choice known for its fast-drying properties and exceptional bonding strength. It requires applying a thin layer of adhesive to both surfaces, allowing it to dry until it becomes tacky. Once both surfaces are tacky, they can be pressed together, creating a robust bond. This adhesive is ideal for large surface areas and can withstand temperature variations.

Epoxy adhesive:

For an incredibly strong bond that can withstand high levels of stress and strain, epoxy adhesive is the way to go. It consists of two components – a resin and a hardener – that need to be mixed together before application. Widely used in construction and marine applications, epoxy adhesive ensures exceptional durability.

Polyurethane adhesive:

Flexibility is essential in certain applications, and that’s where polyurethane adhesive shines. This adhesive reacts with moisture in the air, creating a durable and resilient bond. Its resistance to water, heat, and chemicals makes it suitable for outdoor or high-moisture environments.

Cyanoacrylate adhesive:

Commonly known as super glue, cyanoacrylate adhesive is a fast-setting adhesive that forms an instant bond when applied to surfaces. While not suitable for large surface areas due to its quick-drying nature, it excels in smaller, precise applications.

Specific PVC adhesives:

The market also offers adhesives specifically formulated for bonding PVC to various materials, including wood. These adhesives provide a strong and lasting bond, ensuring a reliable connection between PVC and plywood surfaces.

Conclusion

To successfully bond PVC to plywood, follow these essential steps: Start by thoroughly cleaning both surfaces, ensuring they are free from dirt and debris – this is crucial for creating a solid connection between the two materials.

Next, choose a solvent-based adhesive specifically formulated for bonding PVC and wood; always carefully review and adhere to the manufacturer’s instructions while working in a well-ventilated area. Use a brush or roller to apply an even layer of adhesive on the PVC surface, making sure to cover all areas that will come into contact with the plywood.

Then comes the critical part – firmly press down on the PVC material, applying uniform pressure across its entire surface. Consider using clamps or weights to hold everything together until the adhesive sets completely.

Patience is key here – allow ample drying time according to manufacturer guidelines before removing any clamps or weights. Once dry, inspect the bond for any gaps or irregularities; if necessary, fill them with additional adhesive to ensure a flawless connection.