If you’re itching to attach plexiglass to metal for your next project, you’ve come to the right place. Get ready for a step-by-step journey through the ins and outs of creating a rock-solid bond between these two materials.

Imagine the possibilities: a jaw-dropping sign that grabs attention, a sleek barrier that protects with style, or a custom enclosure that showcases your creativity. By combining the transparency and toughness of plexiglass with the strength and versatility of metal, you can bring your visions to life in ways that will leave jaws dropping.

But before we jump into the nitty-gritty, let’s make sure you have everything you need. Grab those plexiglass sheets, find yourself a sturdy metal surface, gather up a measuring tape, pencil, drill machine, metal screws, screwdriver – oh yeah, don’t forget some masking tape too. And hey, make sure you’ve got yourself a ruler or straightedge handy along with a trusty clamp or vise. Oh. And of course, don’t forget about that silicone adhesive specifically designed for bonding metal and plexiglass.

In the upcoming sections, we’ll break down each step in this process and share some insider tips and precautions so you can achieve success without breaking a sweat. So what are we waiting for? Let’s dive right in and unlock the secrets behind securely attaching plexiglass to metal.

Adhesive Bonding

Contents

- 1 Adhesive Bonding

- 2 Epoxy Resin: Preparation and Application

- 3 Mechanical Fasteners: Drill Holes and Insert Screws/Bolts

- 4 Combining Adhesives and Fasteners for Added Strength

- 5 Considerations When Using Mechanical Fasteners

- 6 Benefits of Adhesive Bonding vs Mechanical Fastening

- 7 Different Types of Adhesives to Use for Plexiglass-Metal Bonding

- 8 Tips for Ensuring a Durable Bond Between Plexiglass and Metal

- 9 Conclusion

Adhesive bonding is the go-to method for affixing plexiglass to metal, offering a flawless and visually appealing finish without the need for unsightly screws or joints. This technique evenly distributes stress across the entire surface, significantly reducing the risk of cracking or damage to the plexiglass. Now, let’s delve into the adhesive bonding process, step by step.

- Choose the right adhesive: When it comes to adhesive selection, it’s vital to opt for one specifically designed for bonding plexiglass to metal. Not all adhesives are compatible with these materials, so go for proven options like epoxy, acrylic, or cyanoacrylate adhesives.

- Surface preparation: Properly preparing the surfaces is key to achieving a successful bond. Thoroughly clean both the plexiglass and metal surfaces, banishing any dirt, dust, or grease. Use a mild detergent or rubbing alcohol for cleaning, ensuring they are completely dry before moving on.

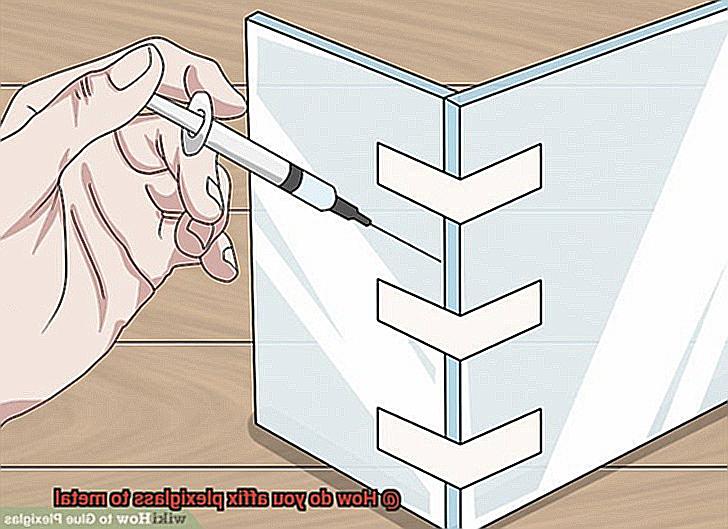

- Apply the adhesive: With precision and finesse, apply a thin layer of adhesive to either the plexiglass or metal surface using a brush or small applicator. Avoid applying too much adhesive to prevent any impact on the final appearance of the bond.

- Align and press: With meticulousness, align the plexiglass with the metal surface and gently press them together. Take a moment to double-check alignment before applying pressure to avoid misalignment or unsightly gaps.

- Clamp or secure: If necessary, use clamps or other securing methods to hold the materials together while the adhesive cures. Follow the manufacturer’s instructions regarding curing time and any additional precautions.

- Allow curing: Patience is key here. Give ample time for the adhesive to cure completely before subjecting the bonded materials to any stress or load. Curing times vary depending on the adhesive type, so refer to the manufacturer’s guidelines for accurate information.

Epoxy Resin: Preparation and Application

Have you ever marveled at how plexiglass seems to effortlessly stick to metal surfaces without any visible screws or joints? The secret lies in the power of epoxy resin, a two-part adhesive that creates a strong and durable bond between these materials. Let’s dive into the fascinating process of preparing and applying epoxy resin to affix plexiglass to metal surfaces.

Proper Surface Preparation:

- Clean both the plexiglass and metal surfaces thoroughly, removing dust, dirt, and grease.

- Use a mild detergent solution for wiping them down, followed by thorough drying.

- To enhance the bond, roughen the metal surface using sandpaper or a sanding block.

Mixing Epoxy Resin:

Applying Epoxy Resin:

- Using a brush or spatula, evenly apply the mixed epoxy resin to both the plexiglass and metal surfaces.

- Take your time and ensure complete coverage for a strong bond.

Placing Plexiglass onto Metal Surface:

- Carefully align the plexiglass before pressing it down firmly onto the metal surface.

- It should fit together like perfectly interlocking puzzle pieces.

- Remove any excess adhesive with solvents or acetone before it cures.

- Follow safety precautions and work in a well-ventilated area.

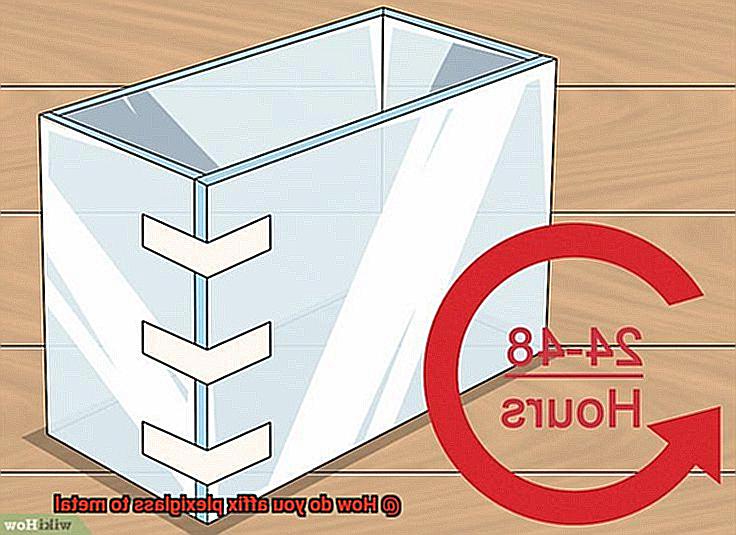

- Allow the epoxy resin to cure fully, which can take several hours.

- For optimal results, let it cure undisturbed for at least 24 hours to strengthen the bond.

- Once cured, the epoxy resin provides excellent adhesion between plexiglass and metal surfaces.

- It creates a secure attachment that can withstand the test of time.

Cleaning Up Excess Adhesive:

Waiting for Magic to Happen:

The Strong and Durable Bond:

Mechanical Fasteners: Drill Holes and Insert Screws/Bolts

Today, we embark on a journey to uncover the secrets behind attaching plexiglass to metal surfaces using screws and bolts. Prepare to be enchanted by the step-by-step process that will leave you with a secure and visually pleasing installation.

Step 1: Measure and Mark

Precision is key, like a skilled wizard. Begin by measuring and marking the positions where the screws or bolts will be inserted. This ensures both a sturdy connection and an aesthetically pleasing outcome.

Step 2: Choose the Right Drill Bit

Accuracy is everything. Select a drill bit that matches the diameter of your screws or bolts. This ensures a perfect fit and prevents any unwanted surprises during installation.

Step 3: Cleanse and Prepare

Before diving into the magical realm of drilling, ensure both the plexiglass and metal surfaces are free from debris. Use a brush or compressed air to banish any remnants that may hinder your attachment.

Step 4: Drill with Care

With your trusty drill press at hand, carefully drill the holes in both the plexiglass and metal surfaces. Take your time, for haste may lead to misalignment, causing frustration in this mystical journey.

Step 5: Banish Debris

Now that you have successfully drilled the holes, it’s time to banish any remaining debris. Use your brush or compressed air once again to ensure a clean and smooth surface for attachment.

Step 6: Insert Fasteners

Align the holes on the plexiglass with those on the metal surface. With finesse, insert the screws or bolts through the holes. To achieve true stability, consider using washers between the fastener head and plexiglass surface. This ensures an even distribution of pressure, reducing the risk of cracks.

Step 7: Secure the Connection

With your screwdriver or wrench, tighten the screws or bolts. But beware. Do not overtighten, lest you awaken the wrath of cracked plexiglass. Find the perfect balance between snug and secure.

Step 8: Optimize Aesthetics

For those who seek a seamless appearance, consider countersinking or using flush-mount hardware. This artistic technique involves drilling larger holes in the plexiglass to recess the screw or bolt heads, creating a smooth and flush surface.

Step 9: Maintain and Check

Like any enchantment, maintenance is key. Periodically check the tightness of the screws or bolts, especially in applications exposed to vibrations or temperature fluctuations. Tightening them regularly ensures a long-lasting and secure attachment.

Combining Adhesives and Fasteners for Added Strength

If you’re tired of struggling to attach plexiglass to metal surfaces and want a reliable method that will ensure the plexiglass stays securely in place, look no further. Combining adhesives and fasteners is the answer you’ve been searching for.

Let’s dive into the world of adhesives first. One popular choice is epoxy adhesive – a two-part system that forms a strong and durable bond between the plexiglass and metal. Simply mix the adhesive and hardener, apply it to the surfaces, and watch the magic happen. Epoxy adhesive is known for its exceptional strength, making it perfect for heavy-duty applications.

But if clarity is your top priority, acrylic adhesive is your best friend. Formulated specifically for bonding plastics like plexiglass to metals, acrylic adhesives offer excellent clarity and good strength. Whether you prefer tape or liquid adhesives, acrylic will provide a reliable bond that can withstand various environmental conditions.

But why stop there? Let’s add some extra reinforcement with fasteners. Screws and bolts are your trusty sidekicks in this process. Pre-drill pilot holes in both the plexiglass and metal surfaces to prevent any cracking or splitting. Then, secure the plexiglass to the metal using these fasteners. By combining adhesives with fasteners, you create a double reinforcement that adds extra stability and prevents any potential detachment.

Remember, every project has its unique requirements. Consider factors like the size and weight of the plexiglass, as well as the intended use and environmental conditions. This will help you choose the best approach for attaching plexiglass to metal surfaces.

So, whether you’re working on a DIY project or a professional installation, combining adhesives and fasteners is a reliable method for attaching plexiglass to metal surfaces. It’s like a magical spell that ensures your plexiglass stays securely in place, even under the most demanding conditions.

Considerations When Using Mechanical Fasteners

When it comes to securely attaching plexiglass to metal, mechanical fasteners are a reliable and durable solution. These hardware devices provide a strong bond that can withstand tough conditions. In this article, we will explore the key considerations for using mechanical fasteners to attach plexiglass to metal surfaces, ensuring a rock-solid connection.

Consideration 1: Material Compatibility

The choice of fastener material is crucial for a successful attachment. Plexiglass and metal can have different properties, so it’s important to select a fastener that is compatible with both materials. Non-corrosive materials like stainless steel are ideal to prevent damage or degradation over time.

Consideration 2: Size and Type of Fastener

The size and type of fastener play a significant role in achieving a secure attachment. Ensure that the length and diameter of the fastener are appropriate for the thickness of the plexiglass and the metal. Using fasteners that are too short may compromise grip strength, while using ones that are too long can damage the plexiglass or interfere with its functionality.

Consideration 3: Placement and Spacing

Proper placement and spacing of the fasteners are essential for even stress distribution. Distribute the fasteners evenly along the edges of the plexiglass to ensure maximum support. Placing them too close together may weaken the material, while placing them too far apart may result in inadequate support. Consider the weight and size of the plexiglass when determining the number and spacing of the fasteners.

Consideration 4: Thermal Expansion

Both plexiglass and metal can expand and contract with temperature changes. To accommodate this movement, leave room for expansion or use fasteners that allow slight movement. Failure to consider thermal expansion can stress the fasteners and compromise the attachment over time.

Consideration 5: Installation Process

The installation process of mechanical fasteners requires care and precision. Pre-drilling pilot holes can prevent cracks or splits in the plexiglass during installation. Use the correct drill bit size and avoid excessive force. When tightening the fasteners, do so evenly and avoid overtightening, which can damage the plexiglass and compromise the attachment.

Benefits of Adhesive Bonding vs Mechanical Fastening

When it comes to attaching plexiglass to metal, there are two popular methods to choose from: adhesive bonding and mechanical fastening. Each method has its own distinct benefits, considerations, and factors to consider.

Adhesive bonding offers a seamless and visually appealing finish. By using a strong adhesive or glue, there are no visible fasteners or screws, creating a clean and professional look. The adhesive spreads evenly across the entire surface area, providing a strong and durable bond that can withstand tough conditions. This method also helps to reduce stress concentrations, as there are no holes or penetrations in the plexiglass that could weaken its structure. Additionally, adhesive bonding can provide improved insulation properties, acting as a barrier against heat or sound transmission.

However, the quality of the adhesive and proper surface preparation are crucial for a successful bond. Thoroughly cleaning and treating the surfaces of both the plexiglass and metal are essential to ensure maximum adhesion.

On the other hand, mechanical fastening offers the advantage of easy disassembly and reassembly. If frequent maintenance or repairs are anticipated, mechanical fastening allows for easy removal and reattachment without damaging the plexiglass or metal. This method also provides a strong and secure connection, as fasteners can be tightened to achieve a desired level of clamping force. Mechanical fastening is quick and convenient since it doesn’t require any special curing time like adhesive bonding does.

However, mechanical fastening may not be suitable for applications where aesthetics are important. The visible fasteners can detract from the overall appearance of the finished product. It’s also important to consider potential stress concentrations around the fasteners since the holes made in the plexiglass can weaken its structure.

Different Types of Adhesives to Use for Plexiglass-Metal Bonding

Prepare to be amazed as we delve into the world of adhesives that can transform this union into a force to be reckoned with. In this guide, we will explore the different types of adhesives available and unveil their unique advantages and disadvantages, equipping you with the knowledge to make the right choice for your bonding adventures.

Mighty Epoxy:

Picture a superhero endowed with unrivaled strength and durability – that’s epoxy for you. Known for its exceptional ability to create robust bonds, epoxy adhesives are ideal for plexiglass-metal bonding. They can withstand extreme conditions, from heat and chemicals to moisture. Beware though, like brewing a complex potion, epoxy requires careful mixing and application. However, its messiness is a small price to pay for its formidable bond.

Swift Super Glue:

Meet cyanoacrylate, the speedy superhero commonly known as super glue. It dries in a flash and forms a strong bond between plexiglass and metal surfaces. Perfect for quick fixes and smaller projects, super glue is easy to use and requires no mixing or special equipment. However, it may not possess the same durability as epoxy and may not excel under extreme conditions.

Enchanting Acrylic Adhesive:

Imagine a magical spell crafted exclusively for plexiglass-metal bonding – that’s acrylic adhesive. Specially formulated for this purpose, acrylic adhesive offers a powerful bond between plexiglass and metal surfaces. With excellent resistance to heat, chemicals, and moisture, it acts as an impenetrable shield against the elements. And the best part? No mixing required – simply apply and let the magic unfold.

Flexible Silicone Sorcery:

Envision a superhero capable of stretching and bending without breaking – that’s silicone adhesive. Silicone creates a flexible bond between plexiglass and metal, capable of withstanding extreme temperatures, harsh environments, and even UV rays. It is the perfect choice for outdoor projects or instances where movement is involved. Embrace its versatility and let your imagination run wild.

Preparation is Key:

Before embarking on your bonding quest, ensure both the plexiglass and metal surfaces are gleaming and free from any impurities. Just as adventurers prepare themselves before a grand quest, cleaning the surfaces ensures optimal adhesive performance. For an even stronger bond, consider lightly sanding the surfaces to enhance adhesion.

Tips for Ensuring a Durable Bond Between Plexiglass and Metal

Whether you’re working on a DIY project or a professional job, creating a durable bond between these two materials is essential. In this article, we will share five tips to help you achieve a strong and long-lasting bond. Let’s get started.

Prepare the Surfaces:

To ensure a durable bond, proper surface preparation is crucial. Begin by cleaning both the plexiglass and metal surfaces using a mild detergent or solvent. This will remove any dirt, dust, or grease that could interfere with the bonding process. After cleaning, make sure the surfaces are completely dry before proceeding. This step is vital as it ensures that the adhesive can adhere effectively to the materials.

Sanding:

To improve adhesion, lightly sand both the plexiglass and metal surfaces. Sanding creates a rough texture that allows the adhesive to grip the surfaces better. However, be cautious when sanding plexiglass as excessive force or using coarse sandpaper can cause scratches or damage. Use fine-grit sandpaper and sand gently to achieve the desired roughness.

Choose the Right Adhesive:

Selecting the right adhesive is crucial for a strong bond between plexiglass and metal. Look for adhesives specifically designed for bonding plastic (plexiglass) and metal surfaces. Epoxy, cyanoacrylate (super glue), silicone, and acrylic-based adhesives are commonly used options. Read product labels and consult experts at hardware stores to make an informed decision. Consider factors such as the required curing time, temperature resistance, and flexibility of the adhesive.

Test Compatibility:

Before applying adhesive to the entire surface, conduct a small test on a small piece of plexiglass and metal to ensure compatibility and effectiveness of the adhesive. Apply the adhesive according to the manufacturer’s instructions and allow it to cure. This testing phase helps identify any issues or challenges that may arise during the bonding process. It is better to make adjustments or try different adhesives during this phase rather than discovering problems after bonding the entire surface.

Apply Adhesive Evenly:

To ensure a strong and uniform bond, apply the adhesive evenly on both the plexiglass and metal surfaces. Use a brush or applicator that allows for precise application, ensuring that the adhesive covers the entire surface evenly. Pay special attention to the edges and corners where stress concentration might occur. Avoid applying too much adhesive, as excess squeeze-out can create messy results and weaken the bond.

zXDb4cBewGo” >

Conclusion

Affixing plexiglass to metal is a task that requires careful attention and precision. There are several methods you can use to securely attach plexiglass to metal surfaces, ensuring a strong and durable bond.

One effective way is by using adhesive bonding agents specifically designed for this purpose. These adhesives, such as epoxy or acrylic-based ones, provide excellent bonding strength between the plexiglass and the metal surface. Make sure to clean both surfaces thoroughly before applying the adhesive, removing any dirt, grease, or debris that could interfere with the bond.

Another method is through mechanical fastening. This involves using screws, bolts, or clips to secure the plexiglass onto the metal surface. Pre-drill holes in both materials to prevent cracking or splitting, then carefully align them before tightening the fasteners. This method provides a reliable and easily reversible attachment.

For a more seamless look, you can also consider using specialized mounting hardware designed specifically for affixing plexiglass to metal. These hardware options include edge grips or standoffs that hold the plexiglass in place while minimizing visible attachments. They offer a sleek and professional appearance while ensuring stability.

Regardless of the method you choose, it’s essential to take safety precautions when working with plexiglass and metal. Wear protective gloves and eyewear to prevent injuries while handling sharp edges or tools.

In conclusion, affixing plexiglass to metal requires careful consideration of the desired outcome and appropriate methods for achieving a secure bond.