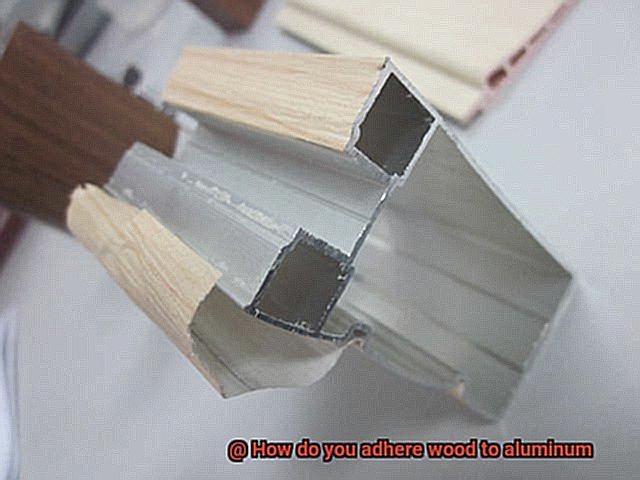

Are you itching to take on a DIY project that combines the rustic charm of wood with the sleekness of aluminum? Whether it’s a custom window frame or an outdoor patio table, joining these two materials can be a daunting task. But don’t fret. With the right tools and techniques, you can achieve a secure bond that will make your finished product both sturdy and visually appealing.

One option for adhering wood to aluminum is epoxy. This two-part adhesive creates a strong and reliable connection between different surfaces, making it ideal for bonding wood to metal. Alternatively, mechanical fastening involves drilling into both materials and using screws or bolts to create a solid joint. This method allows for easy disassembly and repair if needed.

Want to learn more about how to properly adhere wood to aluminum? Keep reading. We’ll explore different approaches and factors to consider so that you can tackle your next DIY project with confidence.

Adhering Wood to Aluminum: An Overview

Contents

- 1 Adhering Wood to Aluminum: An Overview

- 2 Mechanical Fasteners for Attaching Wood to Aluminum

- 3 Welding as an Option for Adhering Wood to Aluminum

- 4 Adhesive Bonding: The Most Common Method for Adhering Wood to Aluminum

- 5 Epoxy Adhesives: A Popular Choice for Bonding Wood and Aluminum

- 6 Polyurethane Adhesives: Flexible and Durable Bonding Solution

- 7 Cyanoacrylate (Super Glue) Adhesives: Fast-Acting and Easy to Use

- 8 Silicone Adhesives: Ideal for Applications Requiring Flexibility and Water Resistance

- 9 Conclusion

If you’re looking to combine the strength and durability of wood with the lightweight and versatile properties of aluminum, you may be wondering how to effectively adhere the two materials together. Fortunately, there are several techniques and adhesives available that can create a strong, long-lasting bond between wood and aluminum.

Adhesive bonding is one of the most popular methods for adhering wood to aluminum. This involves using an adhesive that can bond both materials together effectively. Epoxy resin and polyurethane glue are two of the most widely used adhesives for this application.

Epoxy resin is a two-part adhesive that consists of a resin and a hardener. It provides a strong and durable bond between wood and aluminum, making it ideal for bonding large areas or irregularly shaped surfaces. While it does require mixing before use and may take some time to cure, the bond it creates is exceptionally strong.

Polyurethane glue, on the other hand, is a one-part adhesive that expands as it cures. It can fill gaps between the wood and aluminum surfaces, creating a tight and secure bond. Additionally, polyurethane glue is resistant to water and can be sanded or painted once cured.

Other adhesives that can be used for adhering wood to aluminum include cyanoacrylate (super glue) and acrylic adhesives. However, it’s important to keep in mind that they may not provide as strong of a bond as epoxy resin or polyurethane glue.

Before applying any adhesive, proper surface preparation is crucial. This includes cleaning both surfaces thoroughly and roughening them up with sandpaper or a wire brush to help the adhesive adhere better to both surfaces.

In addition to adhesive bonding, mechanical fasteners and welding are other options for adhering wood to aluminum. However, they may not be as practical or suitable for all applications.

Mechanical Fasteners for Attaching Wood to Aluminum

When it comes to attaching wood to aluminum, mechanical fasteners are a reliable and versatile option. From screws to bolts, nails to rivets, each type of fastener has its own unique set of advantages and disadvantages. With the right choice and installation technique, you can securely attach these two materials together for a variety of applications.

Self-tapping screws are a popular choice for DIY projects as they can be driven directly into the aluminum without the need for a pre-drilled hole. Bolts and nuts are another common option, with their threaded rods providing a strong and secure hold. Nails may not be as strong as screws or bolts, but they can still be effective in certain applications such as attaching trim or molding to an aluminum frame. Rivets, on the other hand, are commonly used in construction and industrial applications where strength and durability are key.

When choosing the right mechanical fastener for your project, consider the strength and durability requirements. Self-tapping screws may be quick and easy to use, but bolts and rivets may provide a stronger hold. Nails may be suitable for lighter applications. It’s important to choose the right tool for the job.

Mechanical fasteners offer a robust solution for attaching wood to aluminum in various applications such as construction, furniture making, and DIY projects. With a wide range of sizes and materials available, there is a fastener suitable for any project.

Welding as an Option for Adhering Wood to Aluminum

Adhering wood to aluminum can be a tricky task, but welding is one option that can provide a strong and durable bond. However, it’s essential to consider the benefits and drawbacks before deciding whether welding is the right technique for your project.

Welding involves melting the aluminum and using a filler material to create a bond between the wood and metal. TIG welding is a common type of welding used for wood and aluminum bonding, offering precise control of the heat and filler material. On the other hand, MIG welding is faster but can result in a messier bond.

The advantages of welding are significant. When done correctly by a skilled welder, welding creates a strong and long-lasting bond between wood and aluminum. This can be particularly crucial for projects where strength and stability are vital. Moreover, TIG welding provides precision control that results in a clean and robust bond.

However, there are disadvantages to consider as well. Welding requires specialized equipment such as a welder and filler material, as well as proper training to use it safely and effectively. This can add to the cost and complexity of a project. Additionally, welding can be time-consuming, especially when compared to other methods of adhering wood to aluminum. Furthermore, it can cause distortion or damage to the surrounding materials, making it necessary to plan and prepare the area carefully before starting the weld.

While welding can be an effective method of adhering wood to aluminum, it may not be suitable for all projects. It requires specialized equipment, training, and safety precautions that may not be practical or cost-effective for certain projects. Therefore, you should weigh the advantages and disadvantages carefully before committing to this technique.

Adhesive Bonding: The Most Common Method for Adhering Wood to Aluminum

If you’re looking for a reliable and sturdy way to join wood and aluminum, look no further than adhesive bonding. This method involves using an adhesive to permanently bond two surfaces together, making it one of the most common techniques used by experts.

When it comes to wood-to-aluminum bonding, there are several types of adhesives to choose from. Among the most popular are epoxy, cyanoacrylate, and polyurethane. Epoxy is a top choice because it creates an incredibly strong bond that can withstand water and chemicals. Cyanoacrylate adhesives, also known as superglues, dry quickly and form a strong bond. Meanwhile, polyurethane adhesives are versatile and can be used in a range of temperatures.

Before applying the adhesive, it’s crucial to properly prepare both surfaces. Make sure both the wood and aluminum are clean, dry, and free from any dust or debris. In some cases, you may need to sand or roughen the surfaces to improve adhesion.

Once you’re ready to apply the adhesive, carefully follow the manufacturer’s instructions. Apply it evenly and thinly to both surfaces for the best results. Then press the wood and aluminum together firmly and hold them in place until the adhesive has fully cured.

Epoxy Adhesives: A Popular Choice for Bonding Wood and Aluminum

Epoxy adhesives are the go-to solution for those looking to bond wood and aluminum with confidence. As an expert in this area, I can attest to the popularity and effectiveness of epoxy adhesives when it comes to bonding these two materials.

One of the main benefits of using epoxy adhesives is their high strength and durability. Epoxy is a two-part adhesive that consists of a resin and a hardener. When these two components are mixed together, a chemical reaction occurs, resulting in a strong, permanent bond that can withstand even the most challenging conditions.

Another benefit of using epoxy adhesives is their versatility. These adhesives can bond different materials together, including wood and aluminum, making them ideal for applications where the two materials need to be joined, such as in furniture or woodworking projects.

To use epoxy adhesives for bonding wood and aluminum, there are a few key steps to follow. Firstly, ensure that the surfaces to be bonded are clean and free from any contaminants such as grease or oil. Next, mix the epoxy adhesive according to the manufacturer’s instructions and apply it evenly to both surfaces. Finally, press the two surfaces together firmly and hold them in place until the adhesive sets.

It’s important to note that curing times for epoxy adhesives can vary depending on the type of adhesive used and environmental conditions. In general, it’s best to allow at least 24 hours for the adhesive to cure fully before subjecting the bond to any stress or load.

Polyurethane Adhesives: Flexible and Durable Bonding Solution

Look no further than polyurethane adhesives. These adhesives are the superheroes of bonding wood to aluminum due to their excellent flexibility, durability, and resistance to water and temperature changes.

One of the biggest advantages of using polyurethane adhesives is their incredible strength. These adhesives are made up of a polymer compound that forms a strong and long-lasting bond between two different materials. They are ideal for applications where the bonded materials are subjected to heavy loads or vibrations. Additionally, they have a high resistance to chemicals which protects against corrosion, making them perfect for bonding aluminum.

In addition to strength, polyurethane adhesives offer another significant benefit: flexibility. These adhesives can accommodate any movement or expansion that occurs between the two materials, ensuring that the bond remains intact even when exposed to stress or strain. This is particularly important when bonding wood to aluminum since these materials have different rates of thermal expansion and contraction.

Polyurethane adhesives are typically applied in a two-part system, which involves mixing the adhesive with a hardener before use. Once mixed, the adhesive is applied to one surface and then pressed onto the other material. The bond sets relatively quickly, typically within an hour, but can take up to 24 hours to fully cure.

Overall, polyurethane adhesives are a reliable and effective solution for adhering wood to aluminum. Their combination of strength, flexibility, and resistance to water and temperature changes make them an excellent choice for a wide range of industrial and commercial applications. Here’s a list of reasons why you should choose polyurethane adhesives:

- Excellent strength

- High resistance to chemicals

- Protects against corrosion

- Great flexibility

- Accommodates movement or expansion

- Quick setting time

Cyanoacrylate (Super Glue) Adhesives: Fast-Acting and Easy to Use

Look no further than cyanoacrylate adhesives, also known as super glue. These fast-acting and easy-to-use adhesives are perfect for bonding wood to aluminum and can easily fill in small gaps between surfaces.

To achieve the best results when using cyanoacrylate adhesives, it’s essential to ensure that the surfaces being bonded are clean, dry, and free of any oils or debris. Any contaminants on the surfaces can hinder the adhesive’s ability to bond properly. Once the surfaces are ready, apply a small amount of adhesive onto one surface, press the two surfaces together firmly, and hold them in place for a few seconds.

The advantage of these adhesives is their ability to bond irregularly shaped or uneven surfaces. However, it’s important to keep in mind that they may not be suitable for larger projects or long-term use. They can break down over time and may not withstand heavy stress or constant movement.

Silicone Adhesives: Ideal for Applications Requiring Flexibility and Water Resistance

When it comes to adhering wood to aluminum, silicone adhesives are the go-to choice for outdoor projects such as decks, patios, and fences. These adhesives offer a range of benefits that make them ideal for applications requiring flexibility and water resistance.

One of the primary advantages of silicone adhesives is their remarkable flexibility. Unlike other types of adhesives, silicone can withstand significant levels of movement without cracking or losing its hold. This is particularly beneficial for projects involving wood and aluminum, as these materials have different rates of expansion and contraction due to changes in temperature and humidity.

In addition to their flexibility, silicone adhesives are highly resistant to water. Wood is particularly vulnerable to rotting and decay when exposed to moisture. However, silicone can create a waterproof seal that prevents water from seeping into the wood. This not only helps to protect the longevity of the project but also ensures that it retains its aesthetic appeal for years to come.

Selecting the right type of silicone adhesive is crucial when bonding wood to aluminum. Some adhesives are specifically designed for use with wood, while others are better suited for bonding aluminum. Additionally, proper surface preparation is necessary to ensure a strong bond between the two materials.

Ys4bcJJ2cAE” >

Conclusion

To sum up, adhering wood to aluminum may seem like a daunting task, but with the right tools and techniques, it can be accomplished successfully. Among the most popular methods for joining these two materials is adhesive bonding. Epoxy resin and polyurethane glue are two of the most widely used adhesives for this application. Alternatively, mechanical fastening involves drilling into both materials and using screws or bolts to create a solid joint. Welding can provide a strong and durable bond, but it requires specialized equipment and training.

Before applying any adhesive or mechanical fastener, proper surface preparation is crucial. Cleaning both surfaces thoroughly and roughening them up with sandpaper or a wire brush will help the adhesive adhere better to both surfaces.

When selecting the right method for your project, consider strength and durability requirements as well as practicality and cost-effectiveness. Adhesive bonding is often the most common method due to its reliability, versatility, and ease of use. Epoxy adhesives are known for their high strength and durability while polyurethane adhesives offer flexibility and resistance to water and temperature changes. For fast-acting projects that require ease-of-use, cyanoacrylate adhesives are ideal but may not be suitable for larger projects or long-term use. Silicone adhesives are perfect for outdoor projects requiring flexibility and water resistance.