Leather, the epitome of timeless style and elegance. It’s the material that has captivated fashion enthusiasts and practicality seekers for ages. But have you ever wondered if leather can join forces with wood? If you’re a DIY enthusiast or simply curious about this unlikely combination, you might be asking yourself if wood glue is up to the task. Can it create a lasting bond on leather?

In this blog post, we dive into the fascinating world of adhesion and explore the burning question: Does wood glue stick to leather? Whether you’re planning an exciting leather-wood hybrid project or just satisfying your curiosity, get ready to uncover the secrets behind this potential union.

We’ll dig deep into the characteristics of wood glue, examine the properties of leather, and provide you with practical tips and recommendations for achieving a successful bond. So buckle up for this adhesive adventure as we discover the untapped harmony between wood and leather like never before.

What is Wood Glue?

Contents

- 1 What is Wood Glue?

- 2 Properties of Leather that Prevent Wood Glue from Sticking

- 3 The Challenge of Penetrating Leather Fibers

- 4 Natural Oils and Waxes on Leather as a Barrier to Bonding

- 5 Pressure Required for Optimal Bonding with Wood Glue

- 6 Damage or Distortion to the Soft and Flexible Surface of Leather

- 7 Alternative Adhesives for Bonding Leather

- 8 Conclusion

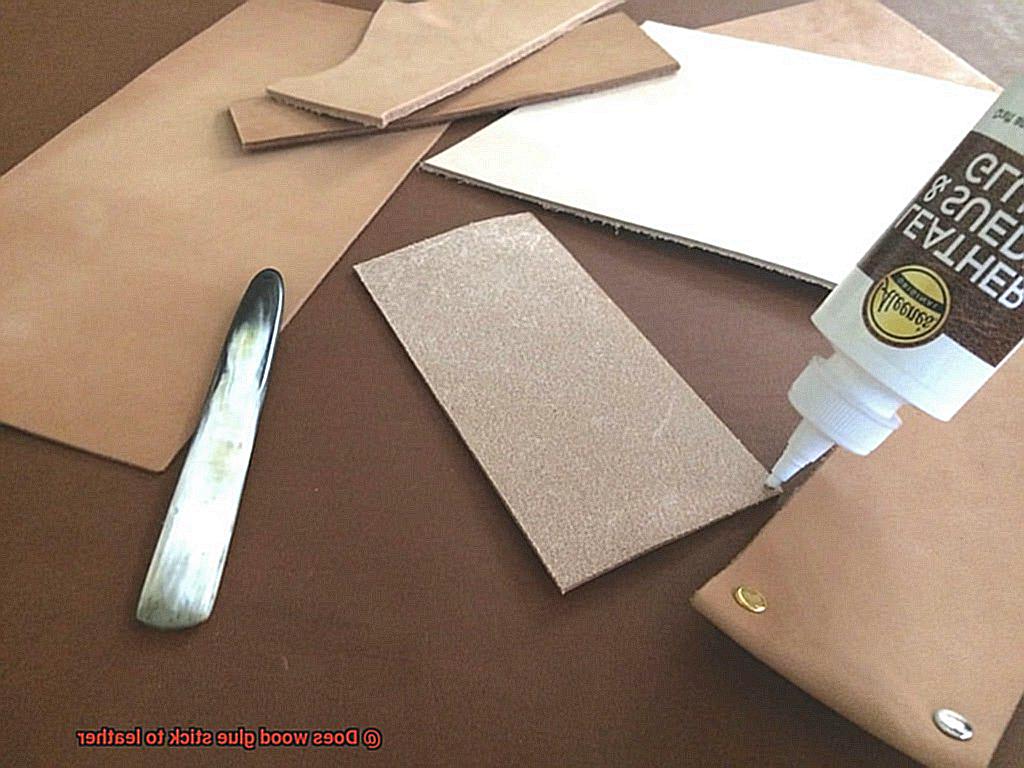

Wood glue, also known as woodworking adhesive, is a remarkable substance that has revolutionized the world of woodworking. It is a type of adhesive specifically designed to bond wood together, creating strong and durable connections that withstand the test of time. Whether you’re working on a small DIY project or constructing a piece of furniture, wood glue is an essential tool in your arsenal.

So, what makes wood glue so special? Let’s delve into its key characteristics and explore some useful tips for its application.

- Types of Wood Glue: Wood glue comes in various forms, such as liquid, gel, and paste. Each type has its own unique properties and uses. Liquid wood glue is the most commonly used, while gel and paste variants are ideal for vertical applications or when a thicker consistency is required.

- Penetration and Bonding: The magic of wood glue lies in its ability to penetrate the porous surface of wood, creating a powerful bond that is resistant to moisture and temperature changes. This makes it perfect for joining pieces of wood together, ensuring a tight and long-lasting connection.

- Preparation: Before applying wood glue, it is crucial to prepare the surfaces being bonded. Cleanliness is key here – make sure to remove any dust or debris by sanding or wiping down the surfaces. This ensures optimal adhesion and strengthens the bond.

- Application: Applying wood glue is a breeze. You can use a brush or an applicator to spread an even layer of glue onto both surfaces being bonded. Be generous but not excessive – too much glue can lead to messy drips and uneven bonding.

- Clamping: To achieve the best results, it’s important to clamp the glued pieces together while the glue dries. Clamping helps maintain pressure and ensures a tight bond, especially for larger or heavier pieces of wood.

- Drying Time: Unlike other adhesives that dry quickly, wood glue requires a bit more patience. It can take anywhere from 30 minutes to several hours for the glue to fully dry and reach its maximum strength. Avoid disturbing or moving the glued pieces during this time to prevent weakening the bond.

- Limitations: While wood glue works wonders on wood, it may not be as effective when bonding other materials, such as leather. The smooth and non-porous surface of leather makes it difficult for wood glue to penetrate and create a strong bond. In such cases, it is advisable to use a specialized adhesive designed for leather.

Properties of Leather that Prevent Wood Glue from Sticking

Leather, with its unique properties, poses challenges for wood glue to adhere effectively. Firstly, the porous surface of leather is a major factor. The small holes and gaps in the material’s structure allow air and moisture to pass through, which prevents wood glue from forming a strong bond. Unlike other materials that provide a solid and non-porous surface for glue to adhere properly, leather’s porosity creates a barrier.

In addition, the presence of natural oils in leather contributes to its resistance to wood glue. These oils keep the material soft, supple, and resistant to water. However, they also act as a barrier between the leather and the wood glue. When the glue comes into contact with these oils, it finds it difficult to penetrate the surface and create a strong bond.

Furthermore, leather’s flexibility makes it challenging for wood glue to adhere effectively. Leather is made up of interwoven fibers that allow it to stretch and bend without breaking. This flexibility creates difficulty for the glue to bond properly, as it needs a rigid surface for optimal adhesion.

Moreover, the smooth finish of leather hinders wood glue from sticking effectively. Leather often undergoes various treatments and finishing processes to achieve a smooth surface. This smoothness creates a slippery surface that lacks texture or roughness, preventing the glue from creating enough friction to form a strong bond.

Additionally, leather is typically treated with tannins during the tanning process. Tannins are naturally occurring compounds found in plants that give leather its characteristic color and durability. However, these tannins can interfere with the bonding process of wood glue as they can compete for adhesion sites on the surface of the leather.

Lastly, over time, leather can age and deteriorate due to environmental factors. This aging process further weakens the adhesive properties of leather, making it even more difficult for wood glue to stick effectively.

The Challenge of Penetrating Leather Fibers

The challenge of penetrating leather fibers when using wood glue is no easy feat. Leather’s dense and tightly packed fibers make it difficult for the glue to seep in and create a strong bond. Unlike porous surfaces like wood or fabric, leather has a smooth surface with closed fibers that resist glue penetration. Additionally, the natural oils and waxes present in leather act as barriers, preventing the glue from adhering properly.

To overcome these challenges, there are several techniques that can be employed. One option is to roughen the surface of the leather using sandpaper or a wire brush, creating micro abrasions for the glue to grip onto. However, caution must be exercised to avoid damaging the delicate leather fibers.

Another approach is to use a leather conditioner or deglazer before applying the wood glue. These products remove oils, waxes, and finishes from the leather’s surface, making it more receptive to adhesion. It is crucial to follow the manufacturer’s instructions and ensure compatibility with both the leather and the wood glue.

Choosing the right type of wood glue can also make a difference. Polyvinyl acetate (PVA) or aliphatic resin glues are known for their better compatibility with leather and may provide stronger bonds. It is important to select a flexible wood glue with good moisture resistance to withstand the natural movements and potential exposure to moisture that leather may experience.

Natural Oils and Waxes on Leather as a Barrier to Bonding

Natural oils and waxes are essential components of leather, providing moisture, flexibility, and a lustrous appearance. However, when it comes to bonding leather with wood glue or other adhesives, these same oils and waxes can pose a significant challenge. Acting as a protective barrier, they prevent the adhesive from penetrating the leather surface and forming a strong bond.

Leather is a non-porous material, meaning it does not readily absorb liquids or adhesives. This characteristic makes it difficult for the glue to effectively adhere to the surface, resulting in a weaker bond. Additionally, the presence of natural oils and waxes on leather can prolong the drying time of the adhesive by slowing down solvent evaporation, further compromising the bonding process.

To overcome this obstacle, it is crucial to ensure that the leather surface is thoroughly cleaned and free from any dirt, oils, or waxes. Using a mild detergent or specialized leather cleaner will help remove these contaminants and optimize the adhesive bonding process.

While wood glues with additives or modifiers may enhance their adhesion to non-porous surfaces like leather, exploring alternative adhesive options specifically designed for bonding different materials is advisable. These specialized glues are formulated to better accommodate the natural oils and waxes present in leather, resulting in a stronger and more durable bond.

In situations where wood glue alone is insufficient, combining mechanical fasteners like staples or screws with adhesive can provide a more secure bond between the wood and leather. However, it is important to remember that removing the natural oils and waxes completely can compromise the integrity of the leather itself, leading to potential damage such as drying or cracking.

Pressure Required for Optimal Bonding with Wood Glue

To achieve optimal bonding between wood and leather using wood glue, it is crucial to apply the right amount of pressure. The porous nature of wood and the smooth, non-porous surface of leather require different levels of pressure for the glue to penetrate and adhere effectively. Here are some key points to consider:

- Characteristics of Wood and Leather: Wood is rough and porous, while leather is smooth and non-porous. These differences affect how the glue interacts with each material.

- Type of Glue: Choose a wood glue specifically formulated for bonding wood and leather. These glues have enhanced adhesion properties on non-porous surfaces like leather.

- Thickness of Materials: Thicker materials may require more pressure to ensure a strong bond. Consider the thickness of the wood and leather being bonded.

- Desired Strength of Bond: Different applications require varying pressure levels to achieve the desired strength of the bond. Determine the level of strength needed for your project.

- Clamping: Use clamps to apply pressure during bonding. Clamps ensure that both materials are firmly pressed together, allowing the glue to create a strong bond. Distribute the pressure evenly across the entire bonded area.

- Alternatives to Clamping: In cases where clamps may not be feasible, weight or a press can be used. Apply weight by placing heavy objects on top of the glued joint, exerting pressure for better adhesion. Presses provide controlled and consistent pressure for bonding larger or intricate wood and leather pieces.

Damage or Distortion to the Soft and Flexible Surface of Leather

Damage or distortion to the soft and flexible surface of leather can occur when wood glue is applied. The strong bonding properties of wood glue, designed for use on wood surfaces, can make it unsuitable for delicate materials like leather. When applied to leather, wood glue can cause the surface to become stiff and inflexible, compromising its natural suppleness.

Chemical reactions between the harsh chemicals in wood glue and the natural oils and proteins in leather can also have adverse effects. These reactions can lead to discoloration or staining, significantly diminishing the overall quality and appearance of the leather.

In addition, applying wood glue to leather can result in a loss of shape and structure. Leather is known for its ability to stretch and mold to different shapes over time. However, when wood glue is used, it may restrict this natural flexibility and alter the original form of the leather. This can lead to a loss of comfort and functionality in items such as shoes or bags.

It is important to note that not all types of wood glue will have the same impact on leather. Variations in chemical composition may make some variants less damaging than others. However, caution should always be exercised when using any type of adhesive on leather surfaces.

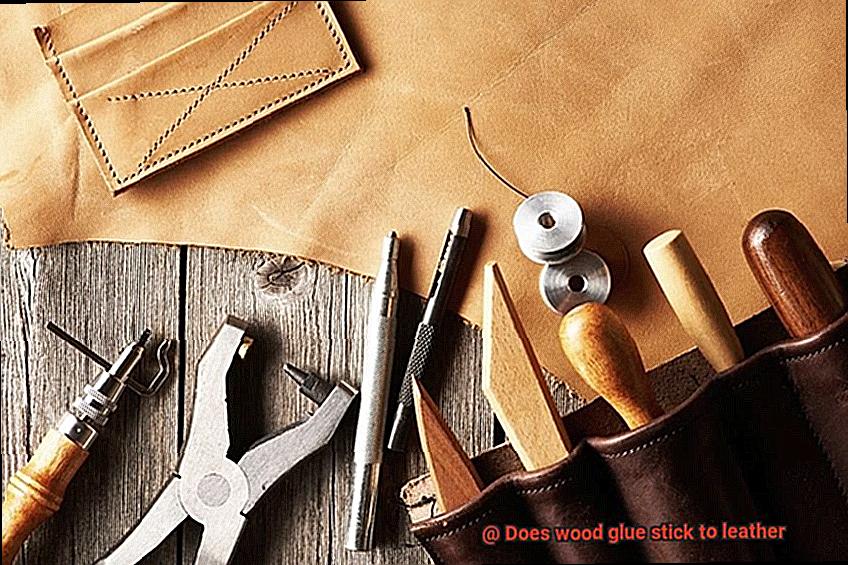

Alternative Adhesives for Bonding Leather

When it comes to bonding leather, wood glue simply won’t cut it. The smooth and flexible surface of leather requires an adhesive specifically designed to adhere to its unique properties. Luckily, there are several alternative adhesives that can provide a strong and durable bond for all your leather crafting needs. Let’s dive into some of these options:

- Contact Cement: This adhesive is a top choice for bonding leather. It creates a permanent bond when applied to both surfaces and allowed to dry before joining them together. Contact cement comes in two formulas: solvent-based and water-based. You can choose the one that suits your preferences and project requirements. However, keep in mind that contact cement sets quickly, so careful application is key to ensuring a successful bond.

- Epoxy: Known for its strength and durability, epoxy is a two-part adhesive consisting of a resin and a hardener. When mixed together, these components create a powerful bond that can withstand heavy use and stress. While epoxy is commonly used for materials like metal or plastic, it can also be used for leather if you desire a robust bond.

- Fabric Glue and Leather Glue: Specifically formulated for bonding fabric or leather materials, these adhesives offer flexibility and durability. Fabric glue is often used for lighter weight applications, while leather glue provides a stronger bond for heavier weight materials. Both options are suitable for various leather projects and can help you achieve professional results.

Remember, in order to achieve the best results when using any adhesive on leather, proper surface preparation is essential. Ensure the surface is clean, dry, and free from any dirt, oils, or coatings that may hinder adhesion. Some experts even recommend lightly sanding the leather surface to create a rougher texture that enhances the bond with the adhesive.

When applying the adhesive, make sure to do so evenly and in the recommended amount, following the manufacturer’s instructions for application and drying times. Applying pressure using clamps or weights will help ensure a tight and secure bond. Allow the adhesive to fully cure or dry according to the manufacturer’s instructions before subjecting the bonded leather to any stress or use.

u_sZe9IRA4k” >

Conclusion

In conclusion, wood glue and leather have a complicated relationship. While wood glue is known for its strong bonding capabilities, it falls short when it comes to sticking effectively to leather. This can be attributed to several factors that make the union between these materials a challenging task.

The porous nature of wood allows the glue to seep into its fibers, creating a powerful bond that withstands the test of time. However, leather’s smooth and non-porous surface poses a significant hurdle for adhesion. It’s like trying to stick two magnets together with one missing its magnetic force – there’s simply no attraction.

Adding insult to injury, natural oils present in leather act as formidable barriers, preventing the glue from penetrating its surface and forming a strong bond. It’s like trying to swim through a pool of oil with weights tied around your ankles – you’re going nowhere fast.

But fear not. There are techniques that can be employed to enhance the bonding between wood and leather. By roughening the surface of the leather, using specialized glues designed for bonding different materials, and applying pressure during bonding, you can give yourself a fighting chance at achieving adhesion. Just remember to tread lightly so as not to damage the delicate fibers of the leather – think ballet dancer tiptoeing on eggshells.

Alternatively, there are alternative adhesives specifically formulated for bonding leather that provide better results. Think of them as superheroes swooping in to save the day. Contact cement, epoxy, fabric glue, and leather glue all possess superpowers capable of creating a strong and durable bond on leather surfaces.

Ultimately, when working with wood and leather together, it is crucial to choose an adhesive that plays nice with both materials and follow proper surface preparation techniques. This will ensure a successful bond that stands tall against the ravages of time while maintaining the integrity of both wood and leather components.

So remember: when it comes to sticking wood and leather together, wood glue may not be the knight in shining armor you were hoping for.